Black polyurethane-urea elastic fiber added with carbon nanotube and preparation method thereof

A technology of carbon nanotubes and polyurethane urea, which is applied to the chemical characteristics of fibers, the addition of pigments in spinning liquid, the manufacture of conductive/antistatic filaments, etc. It can solve the problems of weak two-phase interface bonding and difficult dispersion of carbon nanotubes. Problems, achieve good black effect, excellent antistatic effect, excellent heat resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

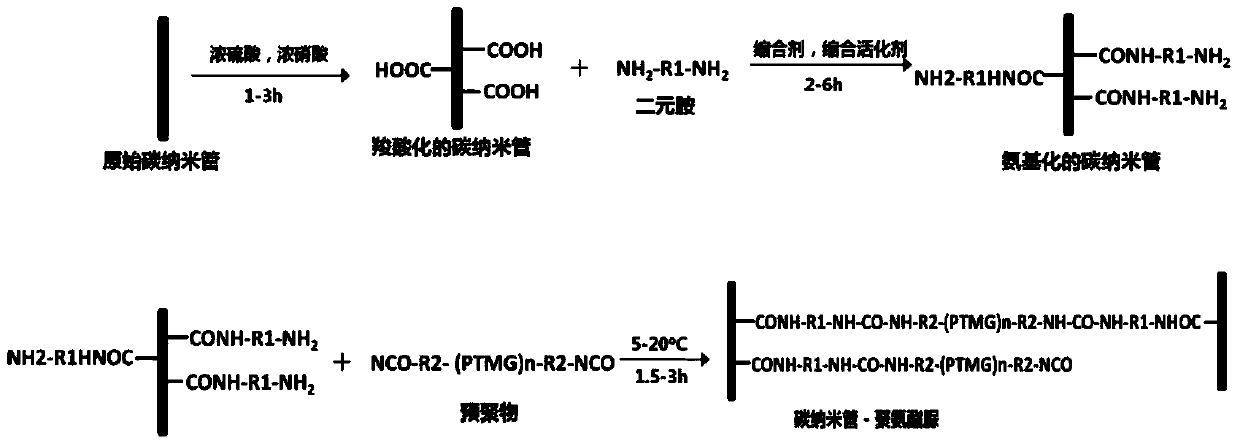

Method used

Image

Examples

Embodiment 1

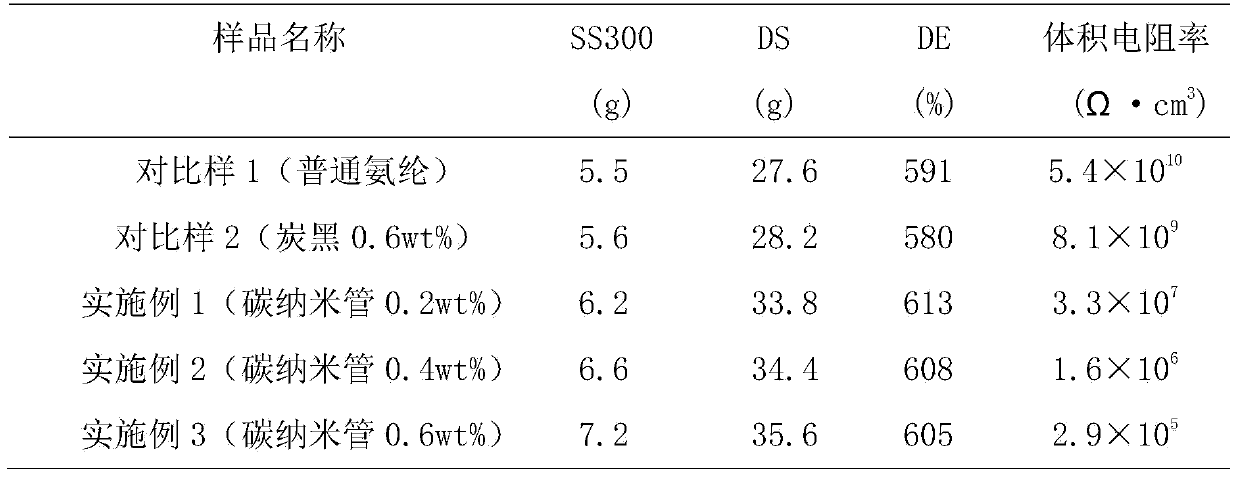

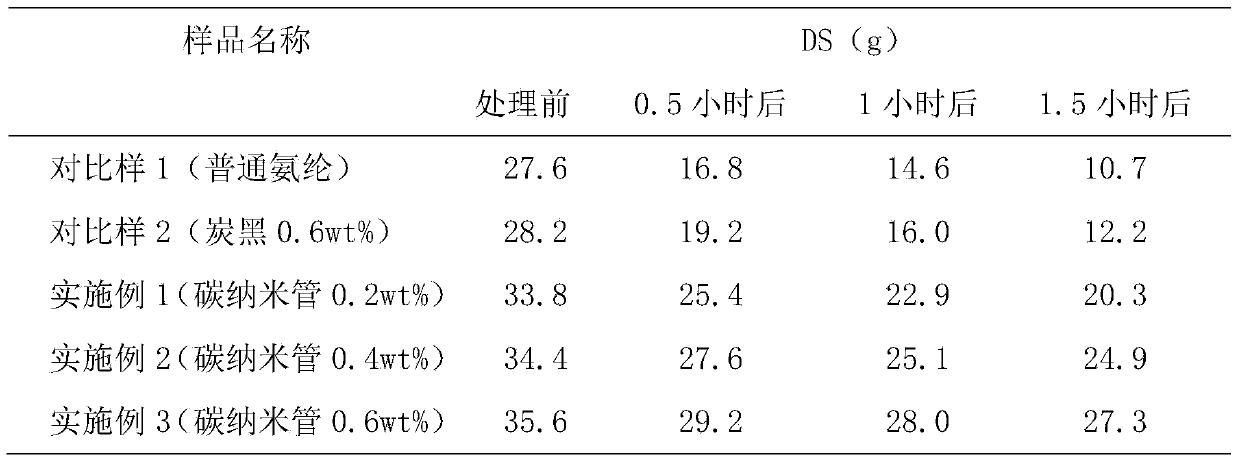

[0038] 12g of original carbon nanotubes were dispersed in 500ml of a mixed liquid of concentrated sulfuric acid and concentrated nitric acid and boiled under reflux for 2 hours. Then the acidified carbon nanotubes were repeatedly washed with deionized water, and filtered through a polytetrafluoroethylene microporous membrane until the filtrate was neutral. The carbon nanotubes obtained after washing and filtering are then placed in a vacuum drying oven, and fully dried to obtain surface carboxylated carbon nanotubes. The carboxylated carbon nanotubes were added into 500ml of DMF solvent and treated with ultrasonic for 1 hour. Add 2g of condensation agent DCC and 0.5g of condensation activator HOBT, and stir mechanically for 0.5 hours. Slowly add 40 g of ethylenediamine dropwise, and react at room temperature for 2 hours. Wash and filter the reactant with DMAC, and obtain surface aminated carbon nanotubes after drying; add the aminated carbon nanotubes and 5ml of DMAC to a ba...

Embodiment 2

[0041] 25g of original carbon nanotubes were dispersed in 500ml of a mixed liquid of concentrated sulfuric acid and concentrated nitric acid and boiled under reflux for 2 hours. Then the acidified carbon nanotubes were repeatedly washed with deionized water, and filtered through a polytetrafluoroethylene microporous membrane until the filtrate was neutral. Then, the carbon nanotubes obtained by washing and filtering are placed in a vacuum drying oven, and fully dried to obtain surface carboxylated carbon nanotubes. The carboxylated carbon nanotubes were added to 600ml DMF and sonicated for 1 hour. Add 6g of condensation agent DIC and 0.75g of condensation activator HOBT, and stir mechanically for 0.5 hours. Slowly add 50g of 1,3-propanediamine and N,N'-diethyl-1,3-propanediamine mixture (the mass ratio of the two is 25 / 25), react at room temperature for 3 hours, and use DMAC to react The material was washed, filtered, and dried to obtain surface aminated carbon nanotubes. T...

Embodiment 3

[0044] 36g of original carbon nanotubes were dispersed in 500ml of a mixed liquid of concentrated sulfuric acid and concentrated nitric acid and boiled under reflux for 3 hours. Then the acidified carbon nanotubes were repeatedly washed with deionized water, and filtered through a polytetrafluoroethylene microporous membrane until the filtrate was neutral. The washed and filtered carbon nanotubes were then placed in a vacuum drying oven, and fully dried to obtain surface carboxylated carbon nanotubes; the carboxylated carbon nanotubes were added to 1000ml of DMF, and ultrasonically treated for 2 hours. Add 8 g of condensation agent EDIC and 1.5 g of condensation activator HOBT, and stir mechanically for 0.5 hours. Slowly add 75g of a mixture of 1,5-pentanediamine and N,N'-dimethyl-1,3-propanediamine (the mass ratio of the two is 50 / 25), react at room temperature for 3 hours, and use DMAC to The reactants are washed, filtered, and dried to obtain surface aminated carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com