Method for preparing polystyrol thick sheet material

A polystyrene and plate technology, applied in the field of plastic molding processing, can solve the problems that it is difficult to meet the technical requirements of large-scale dielectric lens materials, and achieve the effects of high thermal deformation temperature, small melt index, and reduced product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

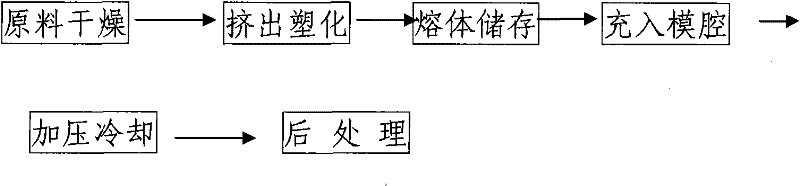

[0040] Such as figure 1 As shown, the preparation process of the thick polystyrene plate of the present embodiment is as follows:

[0041] Use heat-resistant polystyrene resin as raw material (MFR is 2.2g / 10min, its heat distortion temperature reaches 86°C, softening point reaches 104°C, and tensile strength reaches 54MPa), first dry it for use at 80°C, time more than 6 hours.

[0042] Then put the resin into the gradient single-screw extruder. The temperature of each section of the extruder is controlled at 140, 165, and 155°C respectively, the extrusion pressure is 7±1MPa, and the material is supplied to the mold at a screw speed of 60 rpm. The mold system The temperature is 100±10°C. When the material in the mold is full, the extruder stops, the extruder and the mold system are disconnected, and the mold inlet is closed.

[0043] The press applies pressure to the plate, and under the pressure of 10MPa, the segmental isotherm descends for cooling and shaping. Incubate at ...

Embodiment 2

[0046] Such as figure 1 As shown, the preparation process of the thick polystyrene plate of the present embodiment is as follows:

[0047] Use heat-resistant polystyrene resin as raw material (model: GP-303, MFR is 2.1g / 10min, its heat distortion temperature reaches 88°C, softening point reaches 105°C, and tensile strength reaches 53MPa), first dry it for use , the temperature is 80°C, and the time is more than 6 hours.

[0048] Then put the resin into the gradient single-screw extruder. The temperature of each section of the extruder is controlled at 145, 160, and 150°C respectively, the extrusion pressure is 10±1MPa, and the material is fed into the mold at a screw speed of 80 rpm. The mold system The temperature is 95±10°C. When the material in the mold is full, the extruder stops, the extruder and the mold system are disconnected, and the mold inlet is closed.

[0049] The press applies pressure to the plate, and under the pressure of 8MPa, the segmental isotherm descend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com