Silver conductive adhesive and preparation method thereof

A technology of conductive silver glue and conductive material, used in conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of high volume resistance, limited application range, low viscosity and strength of conductive silver glue, and achieve low expansion. efficiency, low volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

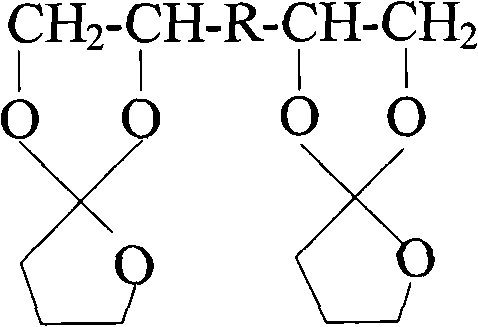

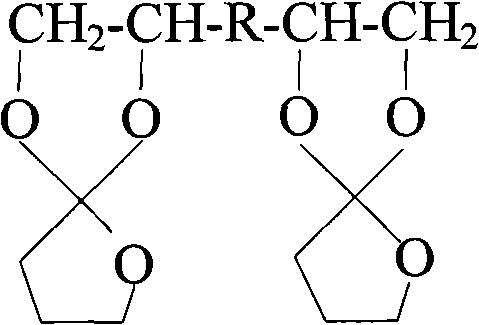

[0012] According to the preparation method of the conductive silver paste provided by the present invention, the γ-butyrolactone modified epoxy resin is obtained by transesterifying γ-butyrolactone and epoxy resin. The epoxy resin is a liquid at normal temperature, preferably a low viscosity liquid, such as E51, E54, E56. The structural formula of described γ-butyrolactone modified epoxy resin is as follows:

[0013]

[0014] Wherein, R is not limited and can be determined according to the selected epoxy resin.

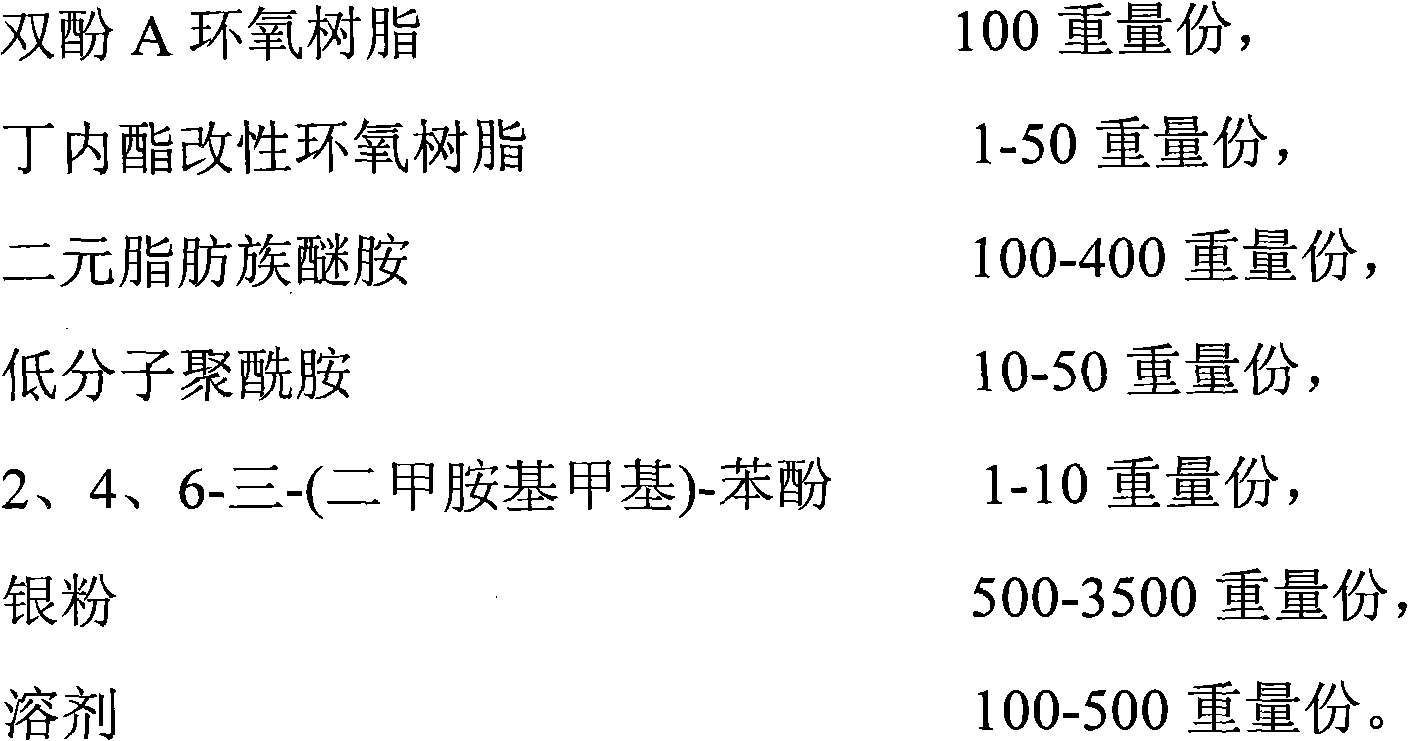

[0015] Conductive silver glue provided by the invention, preferably, the content of each component is:

[0016]

[0017] According to the conductive silver glue provided by the present invention, in order to make the conductive silver glue have better adhesion, preferably, the epoxy equivalent of the bisphenol A epoxy resin is 150-300, more preferably 200-250.

[0018] According to the conductive silver paste provided by the present invention, preferably, the ...

Embodiment 1

[0031] Add 100 parts of γ-butyrolactone and 2.5 parts of BF3OEt2 (boron trifluoride ether) to 600 parts of toluene to prepare solution 1; add 100 parts of epoxy resin E54 to 150 parts of toluene to prepare solution 2; Keep the temperature of solution 1 at -5°C in a salt bath, add solution 2 dropwise to solution 1 within 12 hours, add 6.5 parts of triethylamine to obtain solution 3; wash solution 3 with 8% sodium hydroxide solution 3 times, and then washed to neutral with deionized water to obtain solution 4; solution 4 was distilled under reduced pressure and then vacuum-dried to obtain modified epoxy resin A1.

Embodiment 2

[0033] Add 100 parts of γ-butyrolactone and 2.5 parts of BF3OEt2 (boron trifluoride ether) to 600 parts of toluene to prepare solution 1; add 100 parts of epoxy resin E51 to 150 parts of toluene to prepare solution 2; Keep the temperature of solution 1 in a salt bath at -1°C, add the solution dropwise to solution 1 within 12 hours, add 6.5 parts of triethylamine to obtain solution 3; wash solution 3 with 8% sodium hydroxide solution 3 and then washed with deionized water until neutral to obtain solution 4; after decompression distillation solution 4 was vacuum-dried to obtain modified epoxy resin A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com