Antistatic protective film and preparation method thereof

A protective film, anti-static technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of reduced peel strength, fogging, affecting the adhesion of silicone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a kind of preparation method of antistatic protective film, comprises the following steps:

[0048] A) one side of the substrate is coated with UV glue, and is cured by ultraviolet light to obtain a substrate coated with a UV layer; made of material;

[0049] B) coating silica gel glue on the UV layer, after curing, to obtain a silica gel layer;

[0050] C) coating acrylic glue on the other side of the substrate, and obtaining an acrylic glue layer after curing;

[0051] D) Compounding a release layer on the silica gel layer, and compounding a release layer on the acrylic adhesive layer to obtain an antistatic protective film.

[0052] In the present invention, one side of the substrate is preferably coated with UV glue, and after drying and curing, UV curing is carried out to obtain a substrate coated with a UV layer. In the present invention, the combination of the substrate and the UV glue The composition, dosage and source are ...

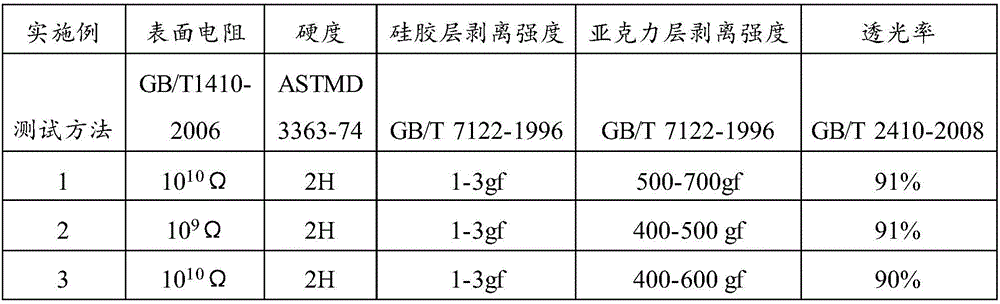

Embodiment 1

[0060] Preparation of UV glue: UV glue adopts 60 parts of BTF-220 UV glue provided by Dongguan Betley Company. Mix 1 part of antistatic agent (ATS-A5 provided by Shanghai Zecheng Chemical Co., Ltd.) and 15 parts of solvent to obtain UV glue;

[0061] Preparation of silicone glue: use 7651 type silicone glue provided by Dow Corning.

[0062] Choose a 20μm PET (JMC-900 provided by Suzhou Dawan Plastic Electronics Co., Ltd.) substrate, and apply UV glue on one side of the substrate. / cm UV lamp energy curing, get 2μm thick UV adhesive layer.

[0063] Use a scraper to coat a layer of silicone glue on the UV glue layer, and cure it in an oven at 150°C for 60 seconds to obtain a 22 μm thick silicone layer, and then cover the silicone layer with a 20 μm PET film.

[0064] Use a scraper to apply acrylic glue (S-804A type acrylic glue provided by Hesheng International Co., Ltd.) on the other side of the substrate, and cure it in an oven at 80°C for 60s to obtain a 30μm thick acrylic ...

Embodiment 2

[0066] Preparation of UV glue: UV glue adopts 60 parts of BTF-220 UV glue provided by Dongguan Betley Company. Mix 3 parts of antistatic agent (ATS-A5 provided by Shanghai Zecheng Chemical Co., Ltd.) and 15 parts of solvent to obtain UV glue;

[0067] Preparation of silicone glue: use 7651 type silicone glue provided by Dow Corning.

[0068] Choose 80μm PET base material (JMC-900 provided by Suzhou Dawan Plastic Electronics Co., Ltd.), and apply UV glue on one side of the base material. / cm UV lamp energy curing, get 3μm thick UV adhesive layer.

[0069] Use a scraper to coat a layer of silicone glue on the UV glue layer, and cure it in an oven at 180°C for 90s to obtain a 35 μm thick silicone layer, and then cover the silicone layer with an 80 μm PET film.

[0070] Use a scraper to apply acrylic glue on the other side of the substrate, and cure it in an oven at 120°C for 90s to obtain a 45 μm thick acrylic adhesive layer, and then cover the acrylic adhesive layer with a 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com