Patents

Literature

73results about How to "Achieve antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant antistatic wood powder/polypropylene wood-plastic composite material with silane modified conductive carbon black, and preparation method of composite material

ActiveCN103554950AReduce dosageImprove flame retardant performancePolypropylene compositesAntistatic agent

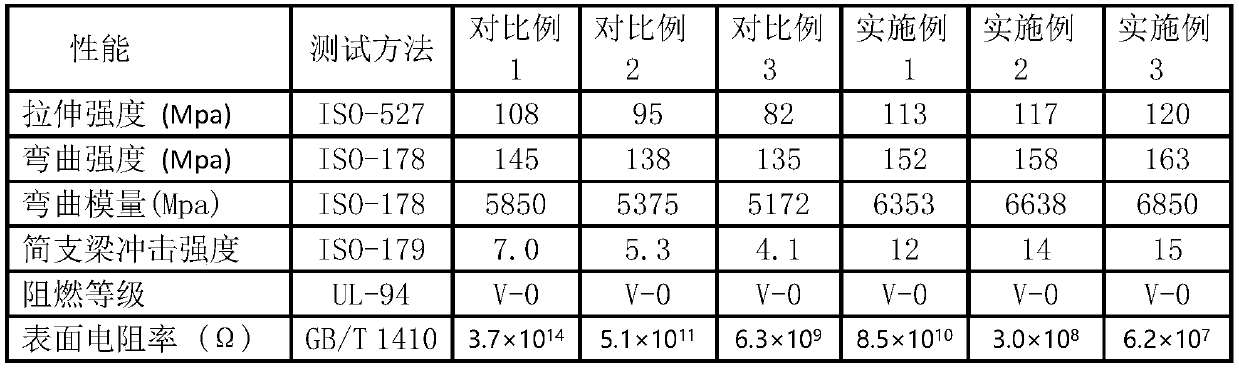

The invention discloses a flame-retardant antistatic wood powder / polypropylene wood-plastic composite material with silane modified conductive carbon black and a preparation method of the composite material, and relates to a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material with silane modified conductive carbon black as an antistatic agent and expansible graphite as a flame retardant is prepared from the following components in parts by weight: 50-70 parts of wood powder, 30-50 parts of polypropylene, 5-30 parts of silane modified conductive carbon black, 5-30 parts of expansible graphite, 3-10 parts of an m-isopropenyl-alpha, alpha-dimethyl benzyl isocyanate grafted polypropylene coupling reagent, and 0.1-1 part of antioxidant. The use amount of the conductive carbon black is lowered greatly; besides, the flame-retardant property, the physical and mechanical properties and the heat-resisting property of the wood powder / polypropylene composite material are improved, so that the wood powder / polypropylene composite material disclosed by the invention is superior to the existing flame-retardant anti-static wood powder / polypropylene composite material in each property.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of composite antistatic agent for fiber fabric

The invention discloses a preparation method of a composite antistatic agent for a fiber fabric. The composite antistatic agent for the fiber fabric in the preparation method comprises the following components: a butanol phosphate ester antistatic agent, a terminal hydroxyl hyperbranched antistatic agent, a terminal carboxyl hyperbranched antistatic agent and a terminal quaternary ammonium salt hyperbranched antistatic agent; and the preparation method comprises the following steps: firstly, respectively preparing the butanol phosphate ester antistatic agent, the terminal hydroxyl hyperbranched antistatic agent, the terminal carboxyl hyperbranched antistatic agent and the terminal quaternary ammonium salt hyperbranched antistatic agent; and mixing the four antistatic agents to prepare the composite antistatic agent for the fiber fabric. The preparation method is simple and feasible; and the prepared antistatic agent has a good antistatic effect, good heat resistance and good acid and alkali resistance.

Owner:SUZHOU CHENHENG WEAVING

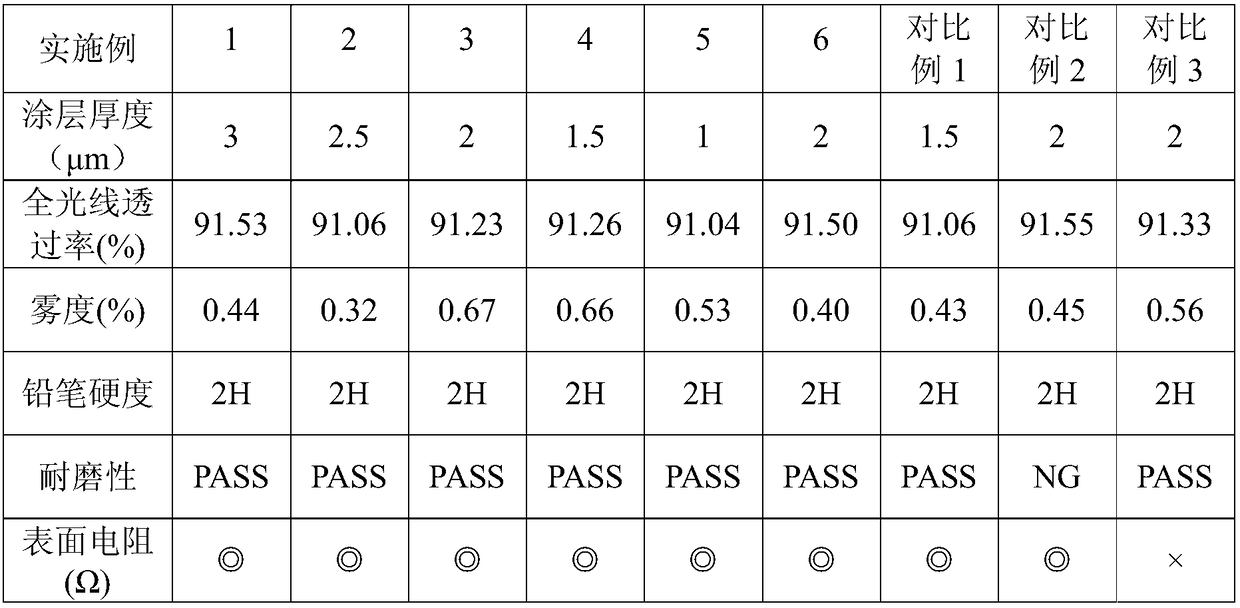

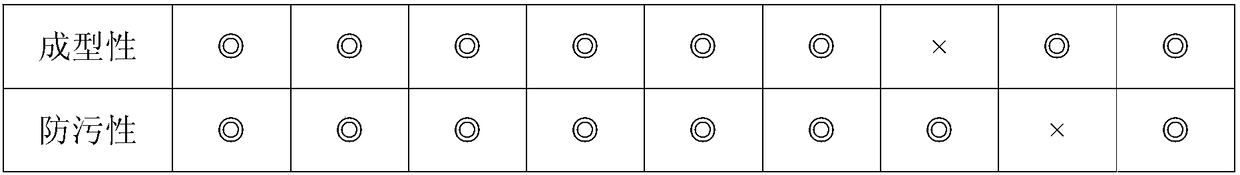

Photocuring composition and hard coating film

ActiveCN108753146AReduce surface tensionExcellent anti-fingerprint functionAntifouling/underwater paintsPaints with biocidesOligomerMicroparticle

Owner:宁波安特弗新材料科技有限公司

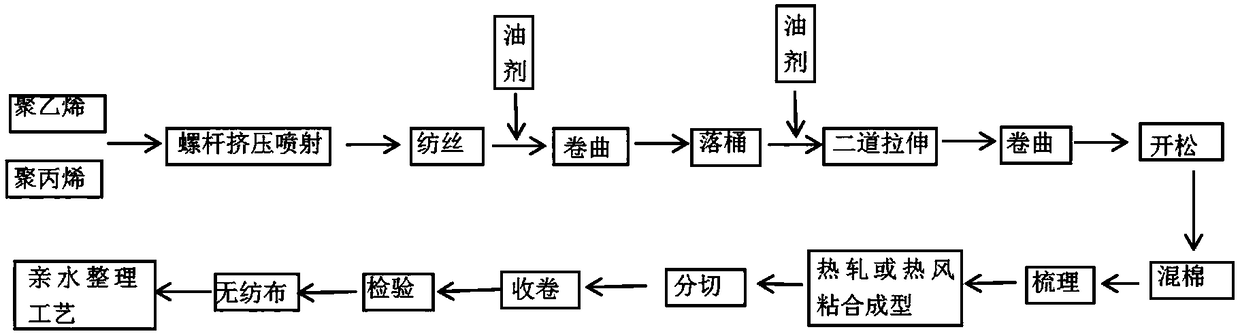

Manufacturing process of ES hydrophilic fiber non-woven fabric

InactiveCN108998889AEasy to wetImprove smoothnessFibre typesNon-woven fabricsNonwoven fabricMaterials science

The invention discloses a manufacturing process of ES hydrophilic fiber non-woven fabric. The non-woven fabric adopts PE and PP as raw materials, the manufacturing process is characterized by comprising following steps of screw extrusion spraying, spinning, pre-spinning oiling, curling, in-barrel treatment, post-spinning oiling, two-way stretching, curling, opening, cotton blending, carding, hot rolling or hot air bonding forming, slitting, winding, inspection, non-woven fabric and hydrophilic finishing process, and lastly, the ES hydrophilic fiber nonwoven fabric is obtained, and the hydrophilic nonwoven fabric produced by the process has high hydrophilicity and good hygroscopicity and can be applied to high-level products.

Owner:JIXI YUANDAO AGRI IND TECH

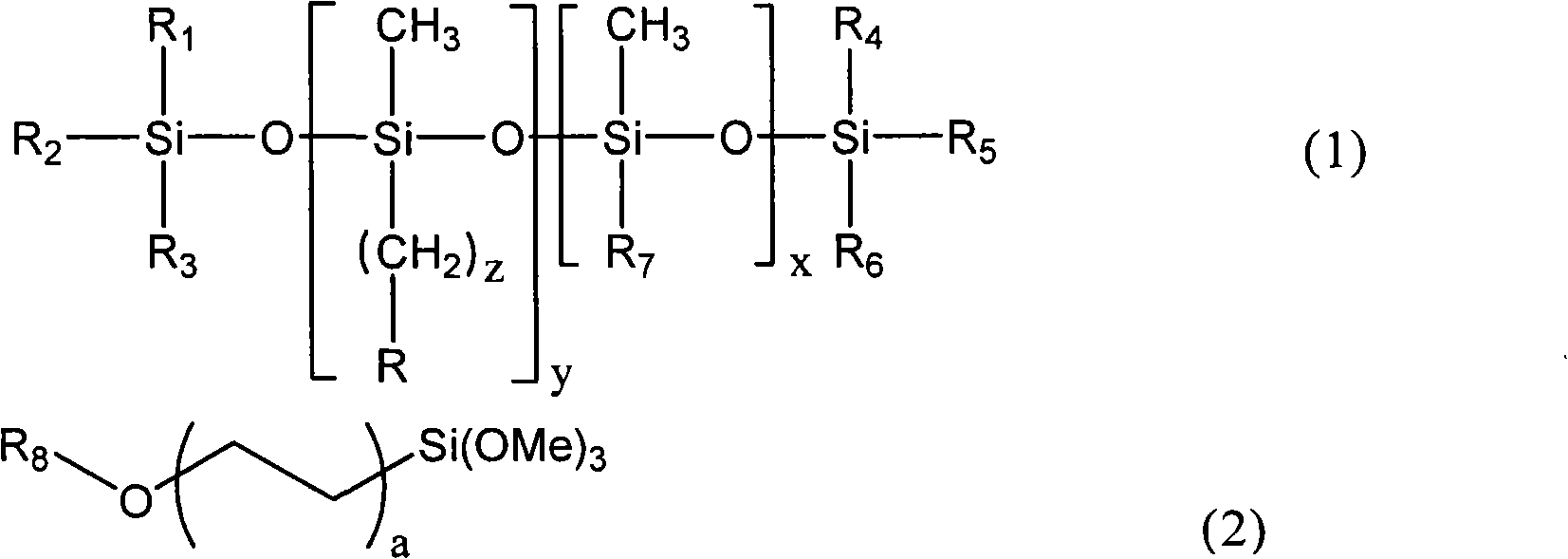

Coating composite and usage thereof

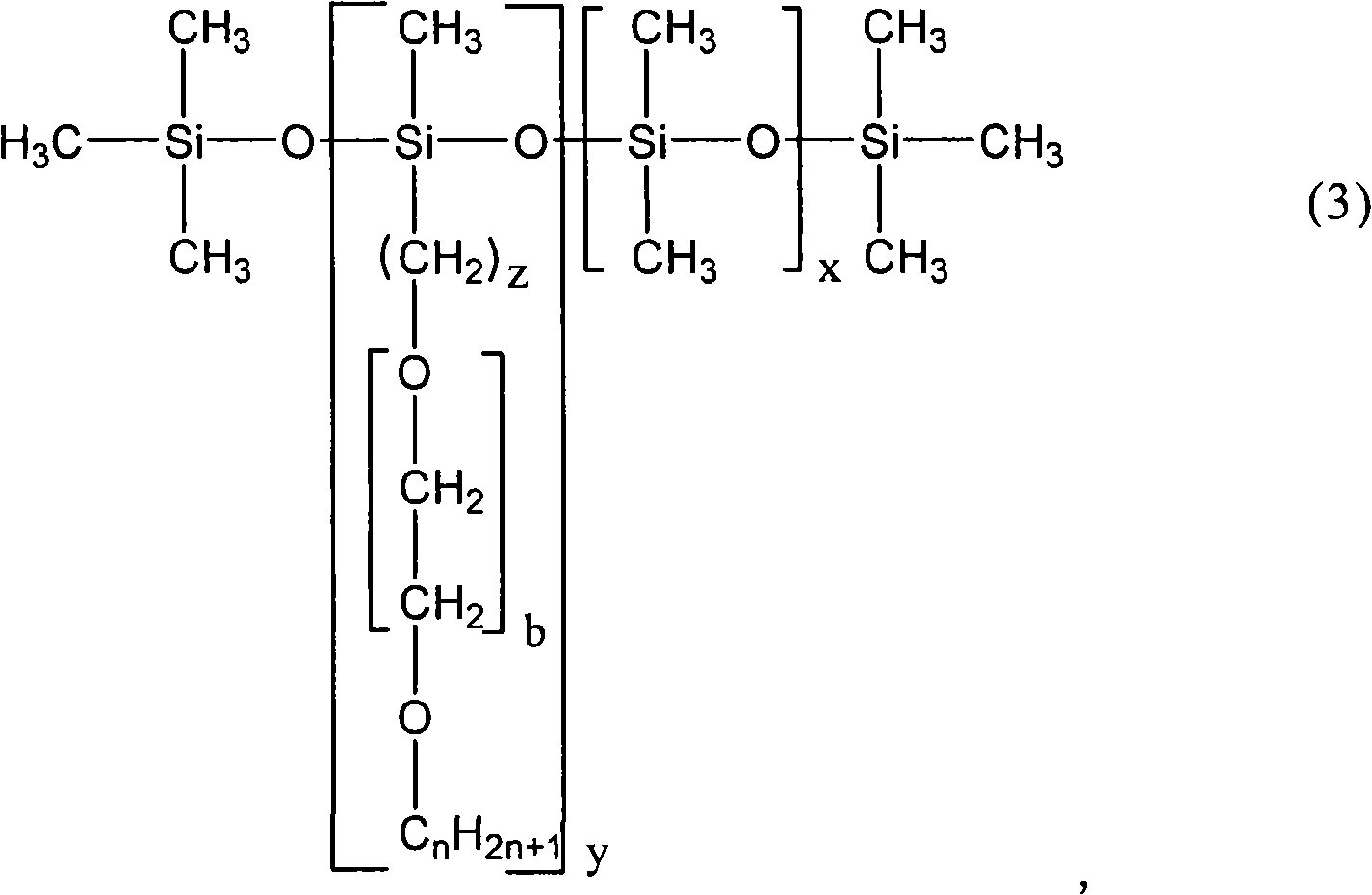

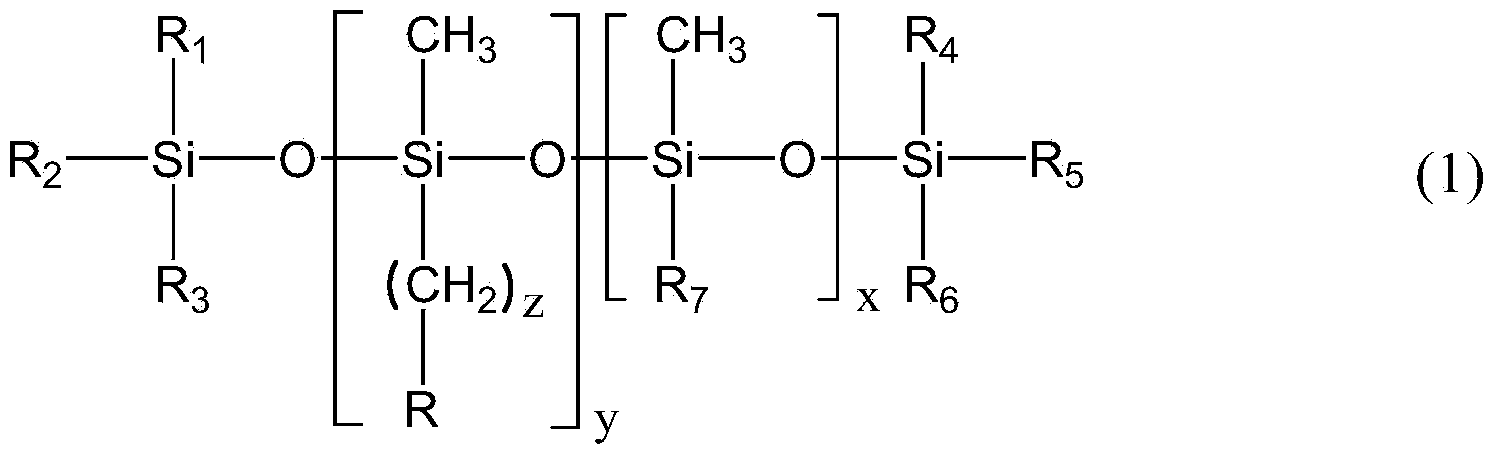

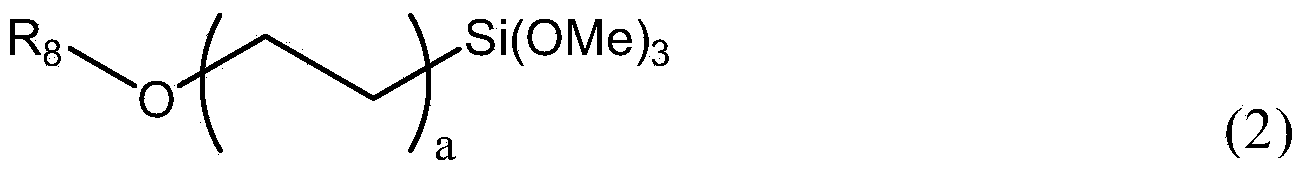

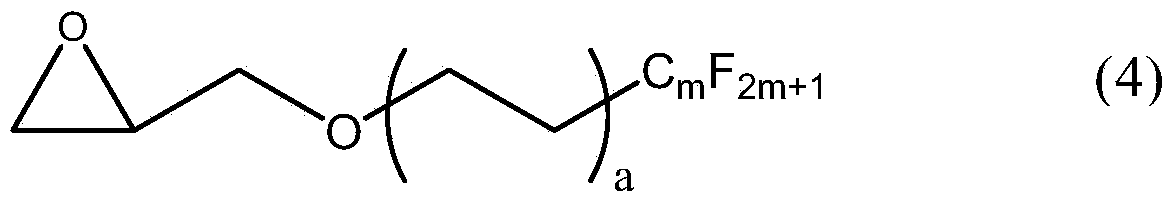

InactiveCN101565573AReduce dosageAchieve antistatic effectPolyurea/polyurethane coatingsPolyether coatingsPolymer sciencePolymer chemistry

The invention relates to a coating composite comprising resin, antistatic agent and antistatic auxiliary agent. The antistatic auxiliary agent can be siloxane compound, fluorine compound or the composite of the siloxane compound and the fluorine compound and can produce synergistic effect with the antistatic agent; after the antistatic agent and a small amount of antistatic auxiliary agent are coated on the surface of a coating, the usage amount of the antistatic agent can be markedly reduced and the antistatic effect needed can be achieved. The coating composite can be applied to various products needing antistatic ability.

Owner:ETERNAL MATERIALS CO LTD

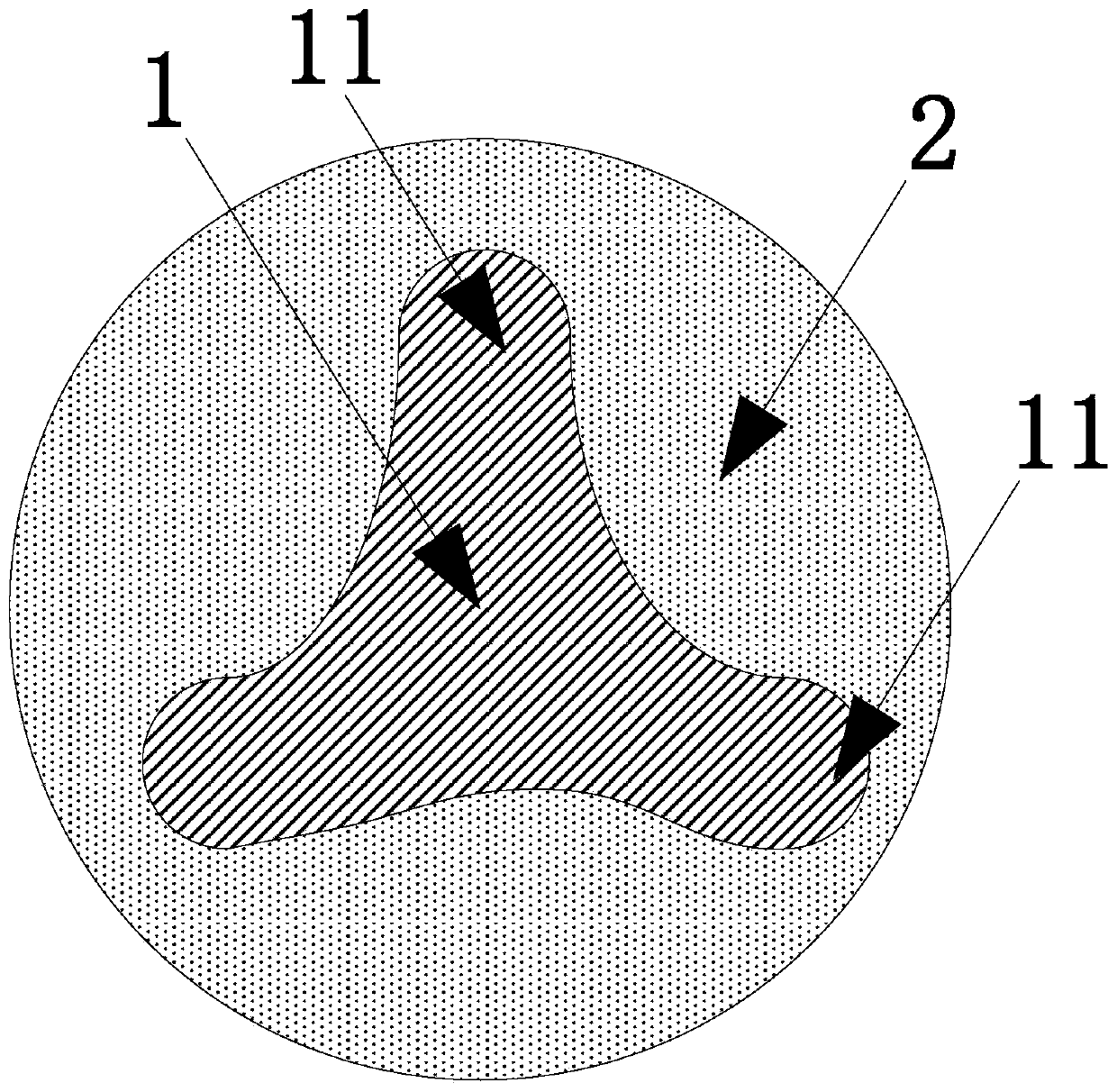

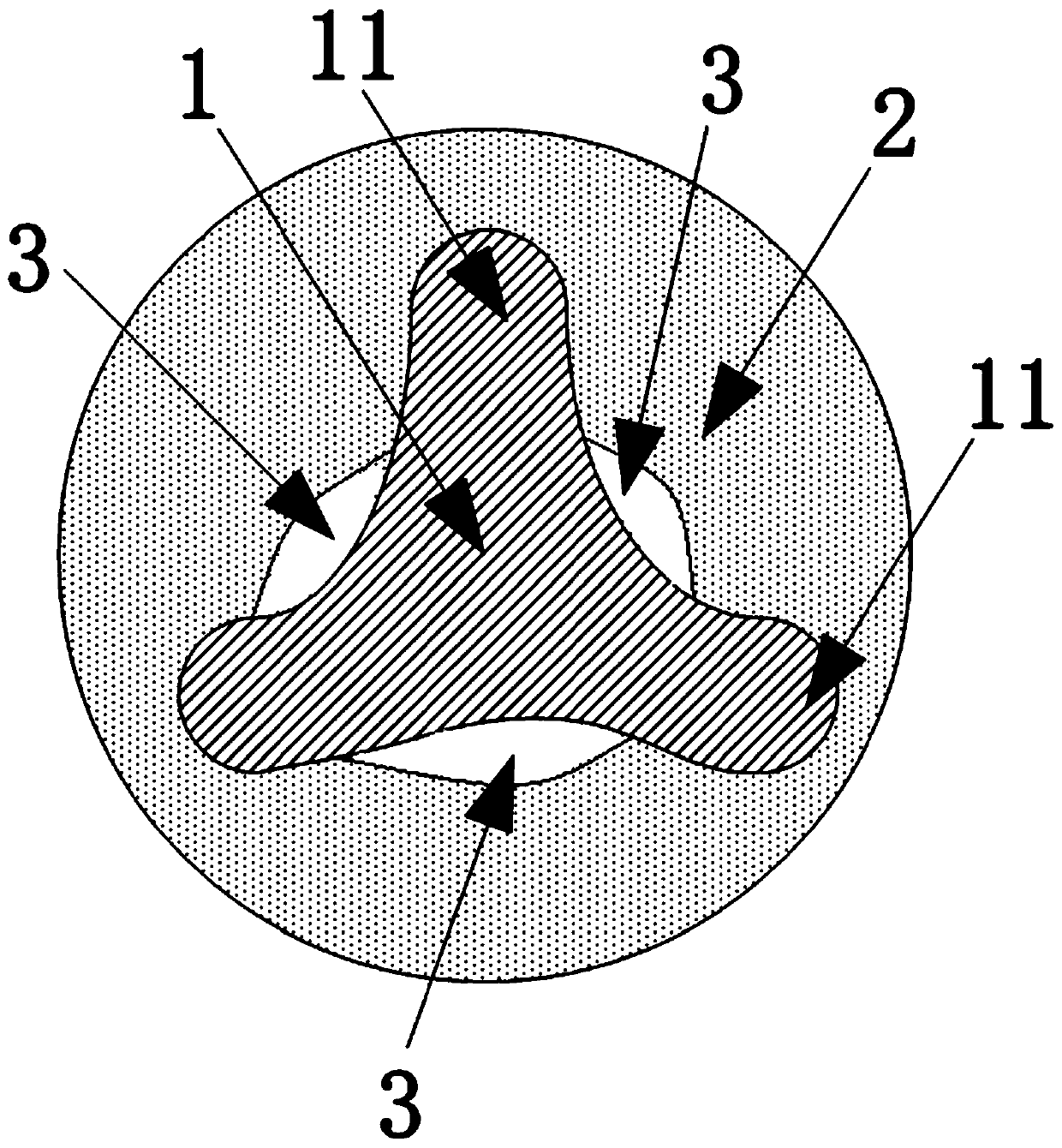

Antibacterial conductive fiber and preparation method thereof

ActiveCN111364121AAchieve antistatic effectImprove antimicrobial durabilityElectroconductive/antistatic filament manufactureFilament/thread formingFiberResin matrix

The invention discloses an antibacterial conductive fiber and a preparation method thereof. The antibacterial conductive fiber comprises a skin layer containing an antibacterial agent and a resin matrix, and a core layer containing an antibacterial agent, a conductive component and a resin matrix, wherein the content of the antibacterial agent is gradually reduced from the skin layer to the core layer, the area of the radial section of the core layer is gradually reduced by extending from the geometric center of the radial section of the fiber to the skin layer, at least three extending ends are formed, and the ends of the extending ends on the radial section are all curves with certain curvatures. The core layer of the provided antibacterial conductive fiber adopts the special-shaped section, so that electrostatic charges generated by the composite fiber in friction are concentrated at the extending ends of the core layer, the charges are dissipated by utilizing a point discharge phenomenon, and an antibacterial agent gradient formed from the core layer to the skin layer provides a lasting antibacterial effect for the fiber.

Owner:CTA HIGH TECH FIBER

Conductive fibre

InactiveCN101158058AAddressing Permanent ConductivityStretchability is not affectedElectroconductive/antistatic filament manufactureMasterbatchHot melt

A conductive fiber is characterized in that the fiber is composed of conductive masterbatch and fiber grade resin sections, wherein, the weight percentage of conductive masterbatch in the fiber is from 20% to 30%. The production method includes (1) coupling agent, carrier resin and dispersant are added to dried conductive powder for mixing and then the mixture is melted and extruded, cooled and granulated through a twinscrew so as to prepare conductive masterbatch; (2) fiber grade PP resin sections are added in the conductive masterbatch and spun by adopting a hot-melt extrusion spinning method. The invention has the advantages that (1) under the precondition of no change of the physical and chemical properties of the polypropylene fiber, the invention solves the problem of the permanent conductivity of polypropylene fiber basically and effectively to achieve an antistatic effect without impacting other fine properties of polypropylene fiber; (2) the tensility, strength and color fastness of the fiber can not be affected and the fiber is suitable for making various clothing and costume; (3) the invention has mature technique and low production cost, thus being able to be applied and popularized.

Owner:TIANJIN SAIYUAN HEALTH PROD +1

Novel antistatic ABS composite material and preparation method thereof

The invention relates to the field of high polymer materials, and discloses an antistatic ABS composite material and a preparation method thereof. The antistatic ABS composite material is prepared from the following components in parts by weight: 22 to 25 parts of ABS powder, 65 to 75 parts of SAN resin, 5 to 10 parts of compatilizer, 2 to 5 parts of antistatic agent and 0.1 to 0.3 part of antioxidant. According to the invention, ABS is used as matrix resin, and carbon nanotubes are used as an anti-static agent; meanwhile, the ionic liquid is introduced as a compatilizer of the ABS resin and the carbon nanotubes, so that the carbon nanotubes can be well dispersed in the ABS resin and form a conductive path, the ABS composite material has excellent antistatic property, impact resistance andflowability, and the resistivity of the ABS composite material is reduced from 10<16> ohms to 10<5> ohms. The composite material can be widely applied to the fields of instrument equipment, medical equipment and the like with higher requirements on the antistatic property of the material.

Owner:CHANGCHUN UNIV OF TECH

Military oil storage bag TPU composite material and preparation method thereof

The invention discloses a preparation method of a military oil storage bag TPU composite material. The military oil storage bag TPU composite material is prepared through the steps that a thermoplastic polyurethane elastomer (TPU) and polyamide 6 (PA6) are taken as a matrix, a self-prepared compatibilizer (EVA-g-MAH) is adopted to reduce interfacial tension between the TPU and the PA6, the system compatibility is improved, ATO powder is taken as an antistatic agent, modified MH is taken as a flame retardant, a combined anti-aging and anti-yellowing agent is processed through melt blending and then processed through extrusion pelletizing, and calendaring molding is performed to prepare the military oil storage bag TPU composite material with the excellent property. According to the preparation method, by adding the compatibilizer, the TPU and the PA6 are blended to prepare alloy with the excellent comprehensive property to achieve the purpose of reducing the cost of only using the TPU material; meanwhile, the prepared military oil storage bag TPU composite material has the good antistatic property and flame-retardant property, and through the synergistic effect of the combined anti-aging and anti-yellowing agent, the defect that the TPU is prone to be aged and yellowed is overcome.

Owner:FUZHOU UNIV

Antistatic release paper and making method thereof

InactiveCN102587205AAchieve antistatic effectAchieve the purpose of release type and antistaticNon-fibrous pulp additionCoated paper substrateAntistatic agentBiochemical engineering

The invention discloses antistatic release paper and a making method thereof. According to the making method of the antistatic release paper, an antistatic agent is coated on the surface of body paper through a surface coating method to form an antistatic layer to achieve an antistatic effect; and then a release agent is coated under control according to the requirement of a user to form a release agent layer to achieving a release effect, and thus the antistatic release paper which is provided with both the release agent layer and the antistatic layer is obtained and the release and antistatic purposes are reached.

Owner:江苏福泰涂布科技股份有限公司

Preparation method of antistatic flame-retardant non-woven fabric for textiles

ActiveCN109972221AImprove flame retardant performanceImprove antistatic performanceFlame-proof filament manufactureGroup 5/15 element organic compoundsAntistatic agentPolymer science

The invention discloses a preparation method of an antistatic flame-retardant non-woven fabric for textiles. Polyethylene glycol terephthalate particles and an antistatic flame retardant are taken asraw materials for melting extrusion and enter a spinning assembly through a metering pump, then thin flow is extruded from a spinning nozzle, drafting and cooling are carried out to form fibers, the fibers form a net through a net forming device, the net forming fibers are conveyed to a hot rolling mill for hot rolling to form the antistatic flame-retardant non-woven fabric. A mode of melting theantistatic flame-retardant non-woven fabric and the polyethylene glycol terephthalate particles replaces an existing impregnating method, the prepared antistatic flame-retardant non-woven fabric has good flame-retardant and antistatic properties, can continuously maintain the antistatic and flame-retardant properties and has stronger washability, and the service life of the antistatic flame-retardant non-woven fabric is prolonged.

Owner:东营红星劳保用品有限责任公司

Flame-retardant antistatic reinforced nylon composite material and preparation method thereof

The invention discloses a flame-retardant antistatic reinforced nylon composite material. The composite material is characterized by comprising the following raw materials in parts by weight: 60-90 parts of nylon, 5-15 parts of glass fibers, 3-10 parts of carbon fibers, 0.5-10 parts of carbon nano tubes, 10-15 parts of red phosphorus, 0.3-2 parts of borate alkyl amine, 0-1.5 parts of a lubricant and 0.3-3 parts of a composite additive. The invention also discloses a preparation method of the flame-retardant antistatic reinforced nylon composite material. The composite material not only has excellent flame retardance and high mechanical strength, but also has an excellent antistatic performance, and can be used for manufacturing conveying rollers, which are applied to the fields of coal mines and the like.

Owner:苏州禾润昌新材料有限公司

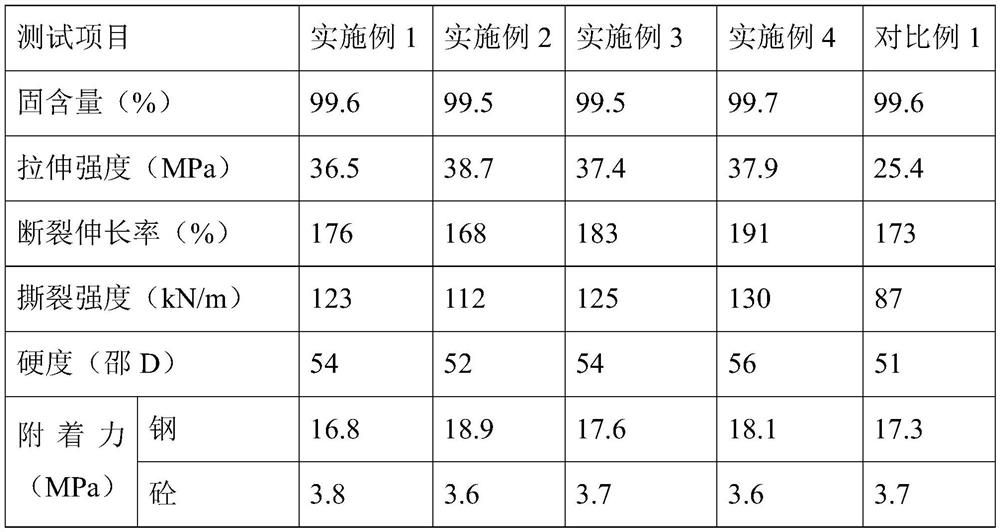

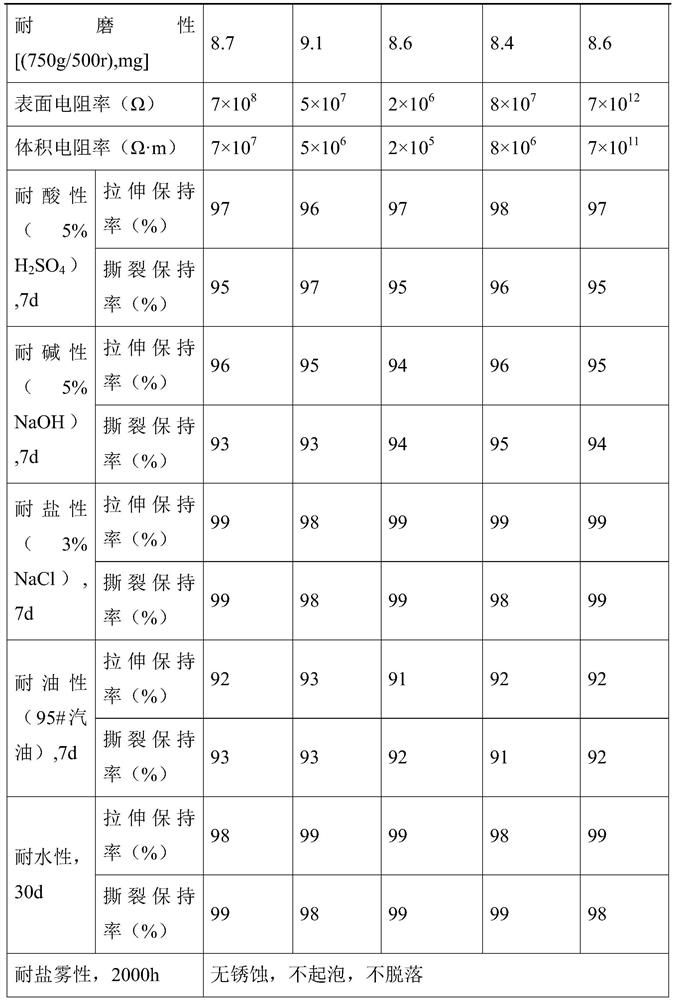

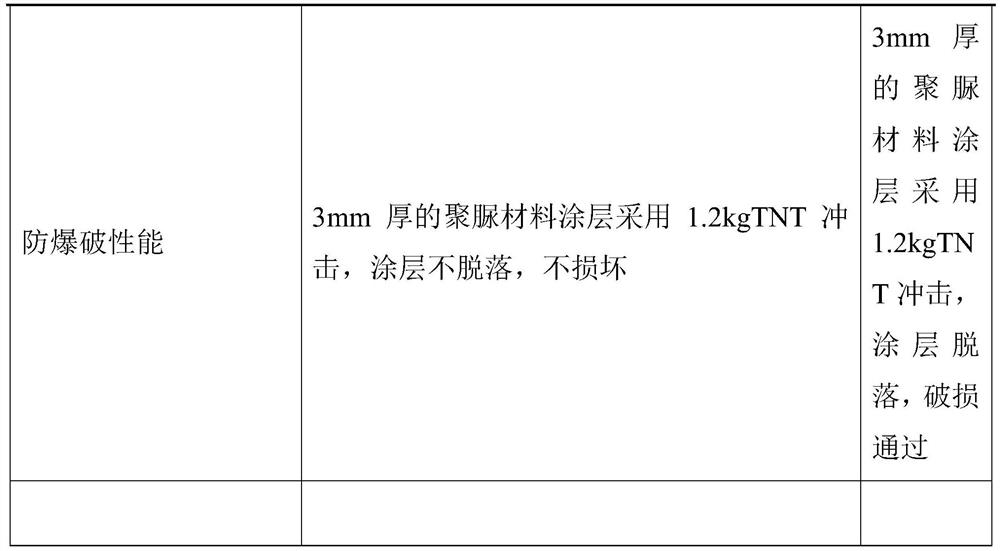

Antistatic explosion-proof polyurea material as well as preparation method and application thereof

ActiveCN111808261AHigh tensile strengthHigh tear strengthAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention provides an antistatic explosion-proof polyurea material and a preparation method and application thereof. The antistatic explosion-proof polyurea material is prepared from a component Aand a component B. The component A is prepared from diisocyanate, polyester polyol and carbon nanotubes; the component B comprises the following raw materials: polyester polyol, an amino-terminated chain extender and an auxiliary agent. The antistatic explosion-proof polyurea material comprises carbon nanotubes, the carbon nanotubes have excellent mechanical properties, electrical properties, optical properties, adsorption properties and the like; a small amount of carbon nanotubes are added into the polyurea material, so that the tensile strength and tearing strength of the polyurea materialcan be improved, the mechanical properties of the material can be further improved to achieve explosion-proof and impact-resistant effects, and the surface resistivity of the polyurea material can beobviously reduced to achieve an antistatic effect.

Owner:QINGDAO AIR NEW MATERIALS

Coating composition and application thereof

InactiveCN103613974AReduce dosageAchieve antistatic effectElectrically-conductive paintsAntistatic agentChemistry

The invention relates to a coating composition and an application thereof. The coating composition provided by the invention comprises resin, an antistatic agent and an antistatic auxiliary agent, wherein the antistatic auxiliary agent is selected from a siloxane compound, a fluorine compound and a composition thereof. The antistatic auxiliary agent can generate a synergistic effect with the antistatic agent, and can take the antistatic agent out of a coating surface, so that the dosage of the antistatic agent can be significantly reduced by using a small amount of the antistatic auxiliary agent so as to achieve a desired antistatic effect. The coating composition can be applied to various products desiring antistatic requirements.

Owner:ETERNAL MATERIALS CO LTD

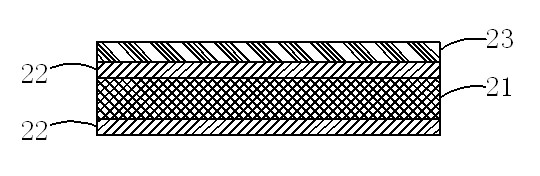

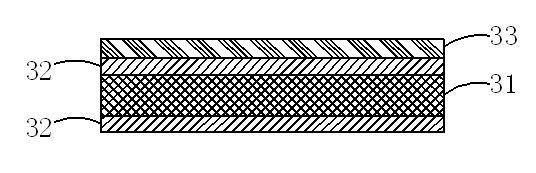

Anti-static anti-ultraviolet modified PET/PC (Polyethylene Terephthalate/Polycarbonate) release film

InactiveCN106183279AHigh melting pointImprove thermal conductivitySynthetic resin layered productsPolyesterCompound a

The invention relates to the technical field of release films, and provides an anti-static anti-ultraviolet modified PET / PC (Polyethylene Terephthalate / Polycarbonate) release film. The release film comprises a base film, an anti-static layer, a release layer and an anti-ultraviolet layer, wherein the base film is a polyester-polycarbonate composite modified film; the anti-static layer is arranged between the base film and the release layer; an anti-static coating is made of ethyl orthosilicate paint; the release layer is arranged on one side of the base film; the anti-ultraviolet layer is arranged on the outer surface of one side free from the release layer of the base film; an ultraviolet absorbent in the anti-ultraviolet layer is a composite ultraviolet absorbent. The base film is prepared by modification and compounding a PET / PC film; the anti-static coating made of the ethyl orthosilicate paint has high conductivity, so that static electricity on the surface of the release film can be carried away, and an anti-static effect is achieved; through synergistic action of the composite ultraviolet absorbent, the anti-ultraviolet property of the PET / PC release film is enhanced greatly.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

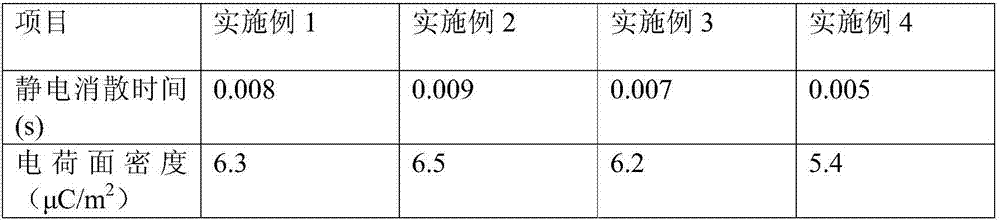

Antistatic curtain fabric and preparation method thereof

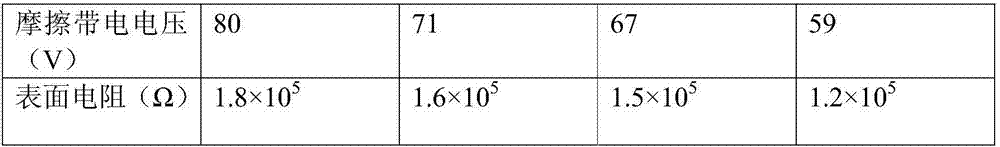

InactiveCN107201651AReduce manufacturing costImprove antistatic performanceFibre typesAntistatic agentCharge voltage

The invention discloses antistatic curtain fabric and a preparation method thereof. The antistatic curtain fabric comprises antistatic coating and fabric, wherein the antistatic coating comprises 1-3% of an antistatic agent, 1-3% of a bonding agent and 1-5% of a dispersing agent and the balance of ethanol and water in percent by weight. The antistatic curtain fabric has excellent antistatic performance; through tests, the fabric has the lowest charge surface density of 5.4[mu]C / m<2> and the lowest frictional charged voltage of 59V, which are much lower than those of the conventional fabric; the adopted preparation method is simple and easy to implement; the production cost of the fabric is effectively reduced.

Owner:句容市恒鑫遮阳科技有限公司

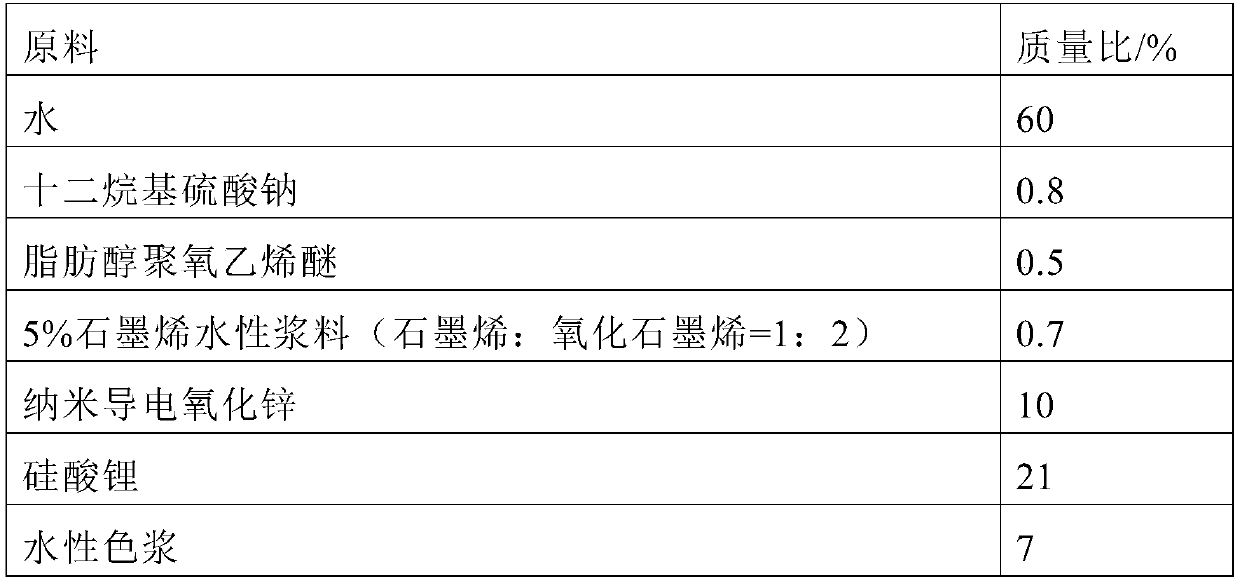

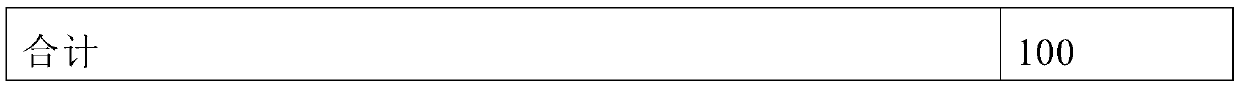

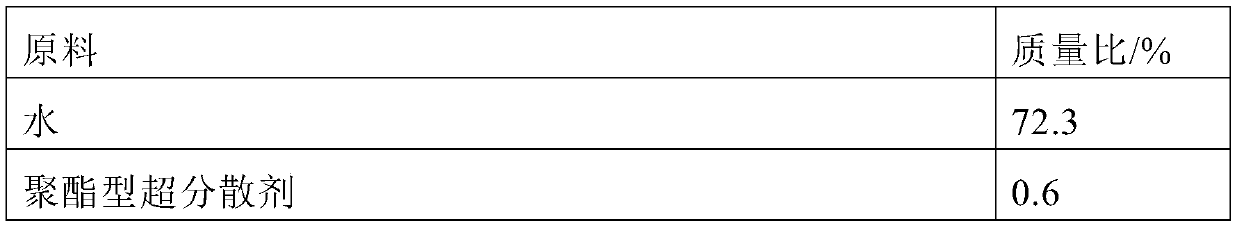

Graphene antistatic lithium-based sealing curing agent for concrete and preparation method of sealing curing agent

The invention relates to a graphene antistatic lithium-based sealing curing agent for concrete and a preparation method of the sealing curing agent. The sealing curing agent is composed of the following components in percentages by mass: 55.5-72.3% of water, 0.6-1% of a dispersing agent, 0.3-1% of a penetrating agent, 0.5-5%of graphene water-based slurry, 3-12% of an electroconductive material, 15-25% of lithium silicate, and 0-10% of water-based color paste. The preparation method comprises the following preparation steps: (1) adding the water into a dispersion cylinder, adding the dispersingagent and the penetrating agent at a low speed, and performing dispersion; (2) adding the graphene water-based slurry and the electroconductive material, and performing grinding in a sand mill; and 3) uniformly stirring the ground components, the lithium silicate and the water-based color paste. According to the method provided by the invention, the product prepared by the method can reduce the use amount of other electroconductive materials correspondingly while ensuring the antistatic effect, and has a durable antistatic effect, high hardness and good water and chemical resistance.

Owner:SHANGHAI INST OF TECH

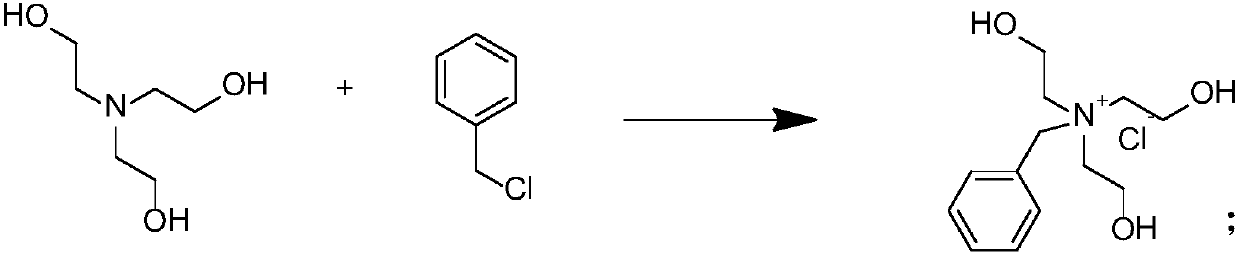

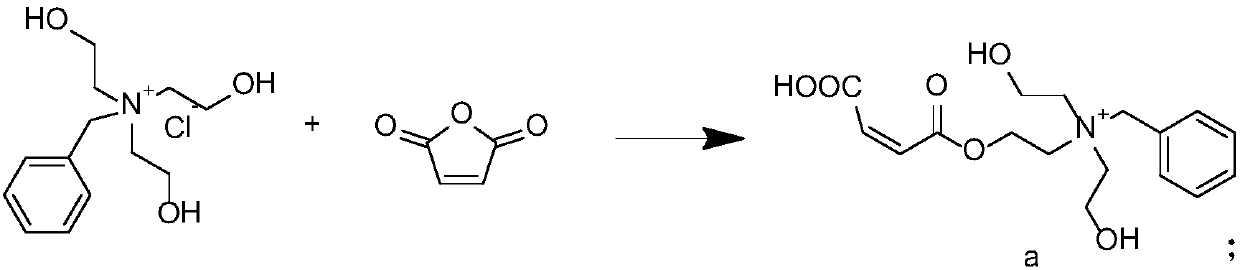

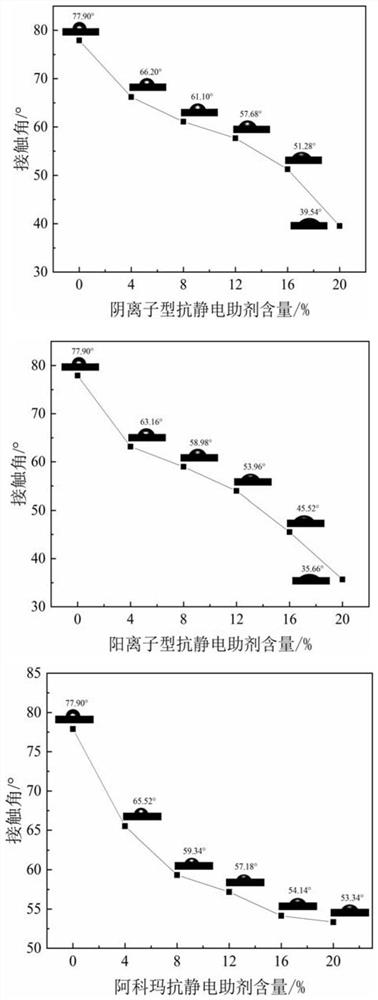

Preparation method of dacron fabric compound antistatic agent

The invention discloses a preparation method of a dacron fabric compound antistatic agent and belongs to the technical field of textile. The preparation method comprises the following steps: firstly, dropwise adding absolute ethyl alcohol and phosphorus pentoxide into a flask; mixing and stirring the mixture and heating and sealing the mixture for stirring reaction; after reaction, dropwise adding deionized water and stirring the mixture to obtain a reaction liquid 1; then adding dimethyl diallyl ammonium chloride and the like into the flask; dropwise adding normal butanol; adjusting the pH value by using sodium hydroxide to obtain a reaction liquid 2; then adding dimethyl diallyl ammonium chloride and the like into a three-mouth flask; stirring the mixture and adding ammonium persulfate to induce a reaction; then supplementing glycidyl acrylate and the like; after reaction, obtaining a reaction liquid 3; and mixing the reaction liquid 2 with the reaction liquid 3 to obtain the dacron fabric compound antistatic agent. The compound antistatic agent prepared by the method does not change color if being used at a high temperature, is stable in performance, and not only can remarkably improve the antistatic performance of the dacron fabric, is lasting in antistatic property, but also is non-irritant and healthy and safe.

Owner:揭阳市庆兴化纤实业有限公司

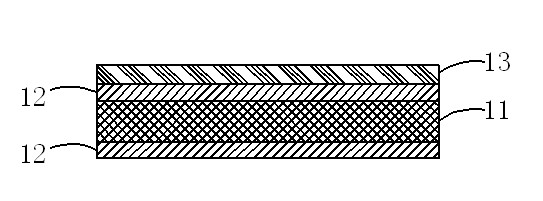

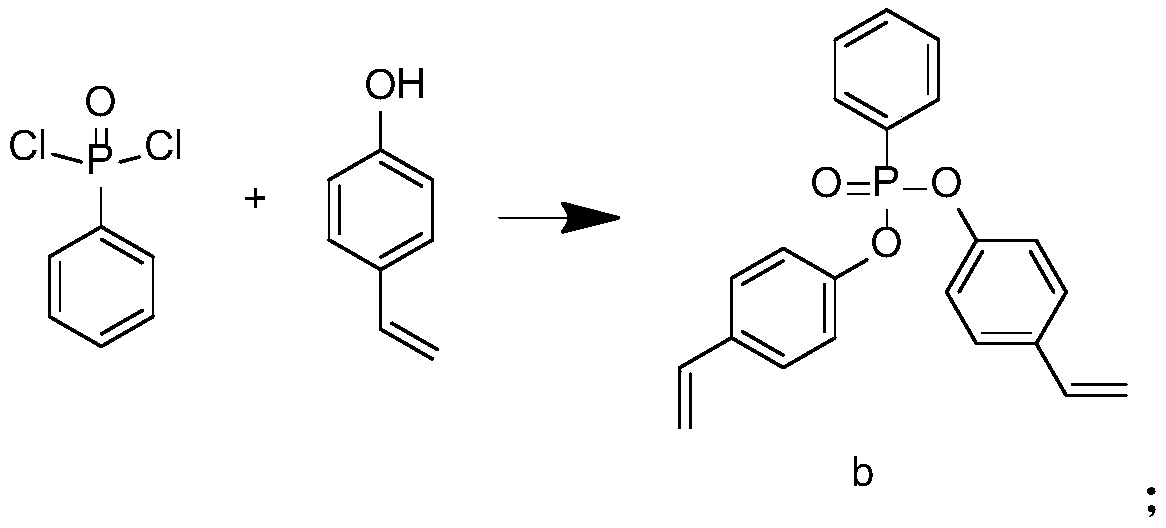

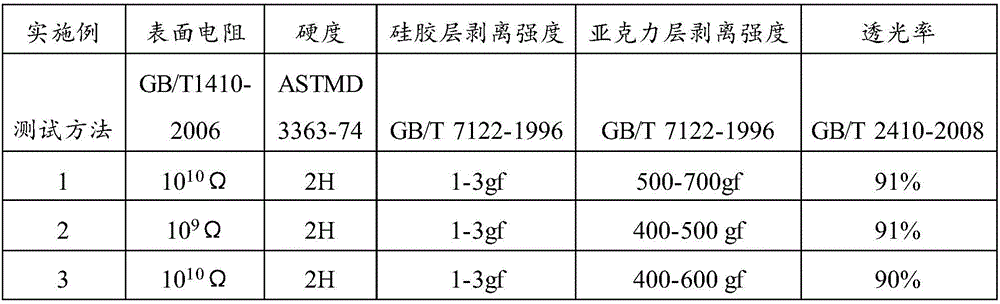

Antistatic protective film and preparation method thereof

InactiveCN106047207ALittle impact on performanceImprove antistatic performanceFilm/foil adhesivesAntistatic agentUltraviolet

The invention provides an antistatic protective film which comprises a stripping layer, a silica gel layer compounded on the stripping layer, a UV (Ultraviolet) layer compounded on the silica gel layer, a substrate layer compounded on the UV layer, an acrylic adhesive layer compounded on the substrate layer and a release layer compounded on the acrylic adhesive layer; the UV layer is made of a material comprising an acrylic monomer, a prepolymer, a photoinitiator and an antistatic agent. The UV layer is formed after the antistatic agent is mixed with a UV adhesive, can achieve an antistatic effect through reducing the volume resistance of the material, is less affected by environmental humidity and also has less influences on the performance of the protective film self. In addition, even if an outermost layer is not coated with the UV layer in the antistatic protective film, a better antistatic effect can also be achieved. Experimental results show that the surface resistance of the protective film provided by the invention can reach 109 ohms. The invention further provides a preparation meted of the antistatic protective film.

Owner:NALI OPTICAL MATERIAL DONGGUAN

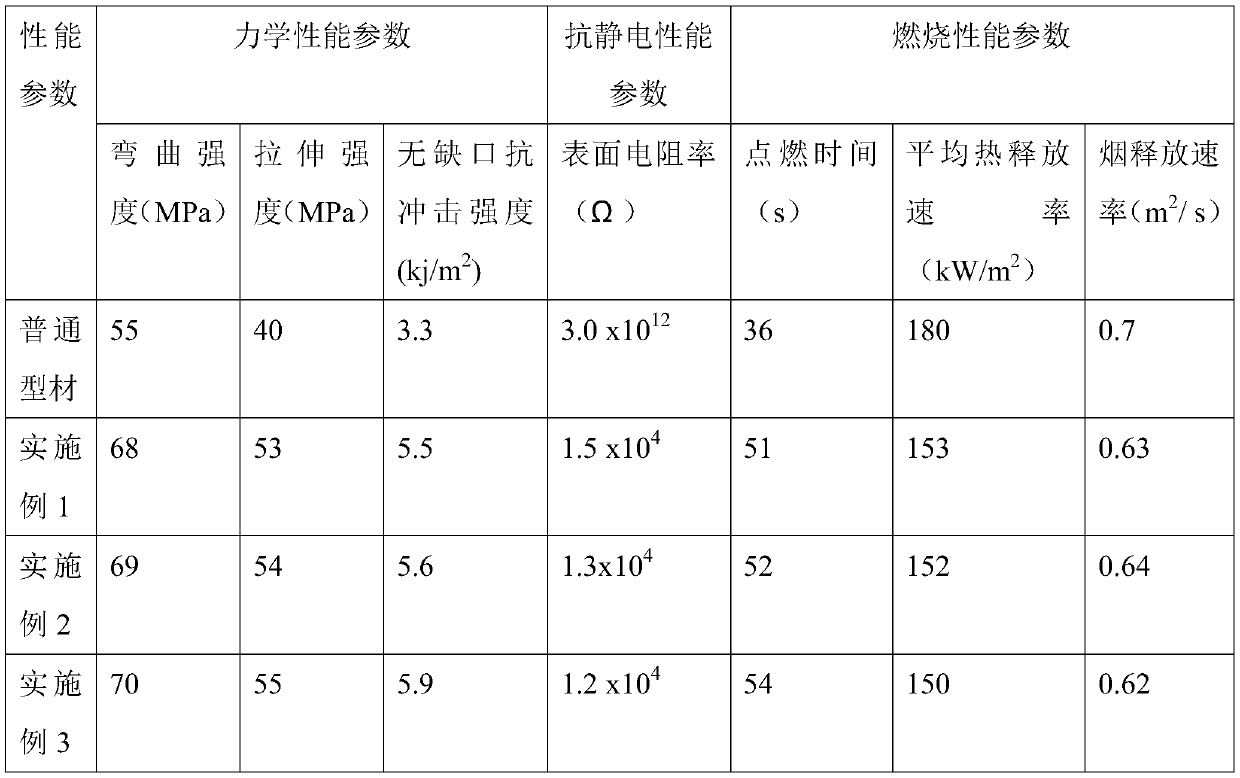

Flame-retardant ABS wood-plastic profile and preparation method thereof

The invention provides a flame-retardant ABS wood-plastic profile. The wood-plastic profile comprises the following raw materials in parts by weight: 80 to 100 parts of ABS resin, 40 to 60 parts of plant fiber powder, 3 to 6 parts of ABS grafted material, 3 to 12 parts of expanded graphite, 2 to 8 parts of silane modified conductive carbon black, 0.1 to 0.4 part of silica gel, 0.2 to 0.8 part of lubricant, 0.5 to 1.5 parts of a flame retardant and 0.5 to 1.5 parts of a smoke suppressant. The invention further provides a preparation method of the flame-retardant ABS wood-plastic profile. The flame retardant, the smoke suppressant, the expanded graphite and the silane modified conductive carbon black are added into the raw materials; wherein the flame retardant and the smoke suppressant enable the wood-plastic profile to have good flame-retardant and smoke-suppressing effects, and toxic and harmful substances cannot be released at high temperature; in addition, the expanded graphite andthe silane modified conductive carbon black enable the wood-plastic profile to maintain good flame-retardant and smoke-suppressing effects, and at the same time, the mechanical properties of the wood-plastic profile can be further improved.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

Method for preparing antistatic anti-UV modified PET / PC release film

InactiveCN106220879AHigh melting pointImprove thermal conductivityRadiation-absorbing paintsElectrically-conductive paintsAntistatic agentUltraviolet

The present invention relates to the field of release film preparation, and provides a method for preparing antistatic anti-UV modified PET / PC release film. The method includes a modified preparation of a composite base membrane, preparation of a coating liquid for a release layer, compound machine coating of an ultraviolet-resistant composite UV absorbent, and the heat curing and light curing of coated base membrane. The modified PET / PC composite release film prepared by the method has effectively improved stiffness and strength; heat curing and light curing make the outer ultraviolet-resistant layer more stable. The release film has excellent mechanical properties, good processability, and good anti-static and anti ultraviolet performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

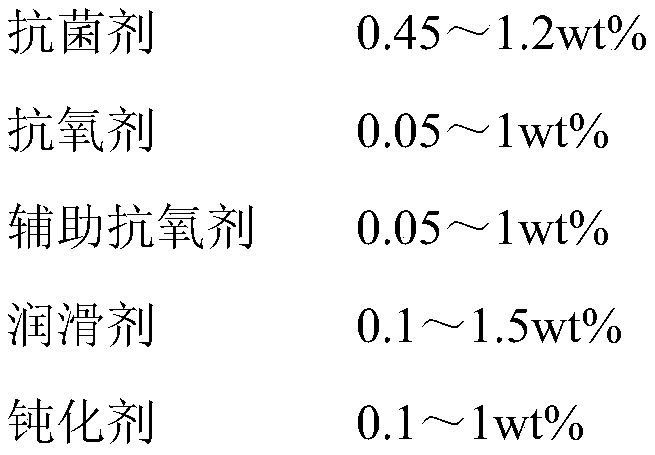

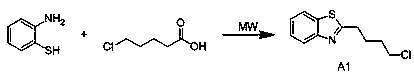

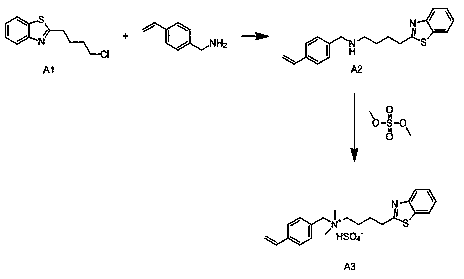

Antibacterial color master batch for polystyrene hard plastic toys

The invention discloses an antibacterial color master batch for polystyrene hard plastic toys. The antibacterial color master batch comprises the following raw materials in parts by weight: 100-150 parts of modified polystyrene, 15-20 parts of epoxy resin, 5-10 parts of polyamide resin, 2-6 parts of toner and 1-3 parts of a lubricant. The preparation method of the antibacterial color master batchcomprises the following steps: S1, firstly, putting the modified polystyrene, the epoxy resin, the polyamide resin, the toner and the lubricant into a drying box and carrying out drying, S2, adding the raw materials dried in the step S1 into a ball mill and carrying out grinding, and S3, putting the mixed raw materials into a screw extruder, carrying out melt extrusion at the temperature of 190-245 DEG C, cooling, then adding into a granulator and carrying out granulation, so as to obtain antibacterial color master batch. The prepared modified polystyrene contains antibacterial double-active-group quaternary ammonium salt and thiazole ring which are firmly connected into polystyrene in a chemical bond manner, so that the modified polystyrene has good washability, the surface is not easy toseparate out, and the antibacterial property of the toy can be maintained for a long time.

Owner:嵊州市仲明新材料科技有限公司

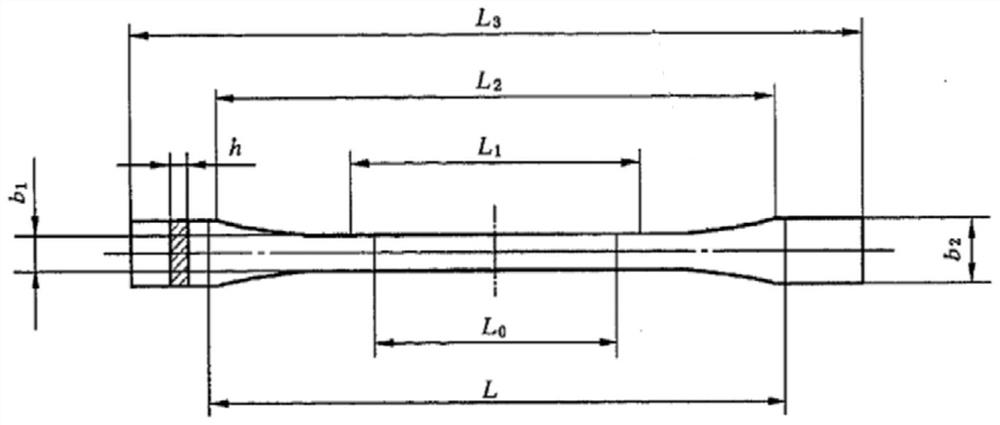

Polymer permanent antistatic agent as well as preparation method and application thereof

PendingCN114634601ASolve the problem of water loss that is not easy to washSolve Wipe LossElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterPolymer chemistry

Owner:SHAOXING RUIKANG BIOTECHNOLOGES CO INC

Vehicle brightening special-effect windscreen wiper essence and preparation process thereof

InactiveCN110760393AStrong cleaningGuaranteed clarityInorganic/elemental detergent compounding agentsCationic surface-active compoundsActive agentLinear alkylbenzene

The invention provides a vehicle brightening special-effect windscreen wiper essence and a preparation process thereof. The windscreen wiper essence is prepared from the following raw materials in parts by mass: 0.1-0.5 part of a pigment, 3-5 parts of coconut oil diethanolamide, 1.0-4.5 parts of a non-ionic fluorine surfactant, 5-8 parts of an alkyl glycoside with high polymerization degree, 0.1-3parts of polyether silicone oil, 5-8 parts of a sodium linear alkyl benzene sulfonate, 0.01-0.1 part of polyoxyethylene lauryl ether, 2-7 parts of ethylene glycol, 0.01-0.1 part of nonylphenol ethoxylate, and 2-6 parts of isopropanol. The windscreen wiper essence has strong cleaning performance, the dust, stains and the like on a windshield can be effectively removed, so that the windshield is kept in an optimal transparent state, the frost can be quickly dissolved, at the same time a layer of protective film is forms on the surface of the windshield, the forming of fog drops is prevented, and the windshield is ensured to be clear and transparent. In addition, the windscreen wiper essence has good antistatic performance, the charges on the surface of the windshield can be effectively eliminated, and the antistatic effect is achieved.

Owner:佛山市南海区巨人化学品制造有限公司

Graphene modification based antistatic rubber composite material and preparation method thereof

The invention discloses a graphene modification based antistatic rubber composite material and a preparation method thereof. The rubber composite material is prepared from, by weight, 80-100 parts of butadiene-acrylonitrile rubber, 5-8 parts of zinc oxide, 1-5 parts of stearic acid, 1-3 parts of an anti-aging agent, 1-2 parts of an accelerant NOBS, 1-3 parts of sulfur, 30-50 parts of reinforcing filler and 0.1-20 parts of functional auxiliaries. Mechanical strength, elasticity and abrasion resistance of the rubber composite material prepared according to the method are improved, the service life of the rubber composite material is prolonged, electric conductivity of the rubber composite material is improved, electric charges generated by friction in a utilization process can be well eliminated, and accordingly an antistatic effect is achieved.

Owner:QINGDAO UNIV

Method for preparing corrosion-resistant antistatic coating

InactiveCN108559387AHigh UV absorptionImprove antioxidant capacityAnti-corrosive paintsPolyurea/polyurethane coatingsOxygenElectron

The invention discloses a method for preparing a corrosion-resistant antistatic coating and belongs to the technical field of coating preparation. When a high polymer material and other non-conductivebase materials is coated with the corrosion-resistant antistatic coating disclosed by the invention, tin powder is first deposited on the surface layer of the base material so as to form a tin metallayer. Therefore, when the tin metal layer is complexed, oxygen and other substances are effectively prevented from entering the metal surface, and a single-molecule hole-electron conductive layer isformed on the covering metal base surface. According to the method disclosed by the invention, mixed coumarin powder, fresh lemon peel and ammonium hydroxide are mixed and fermented to perform acidification precipitation, 2,3-epoxypropyltrimethylammonium chloride is added, the coumarin powder is fermented to produce coumarin, and an effect of promoting cured cross-linking can be achieved. Due to increase of the degree of crosslinking, the ageing degradation ability of resins is decreased, anti-aging and corrosion-resistant effects are achieved, and graphite, carbon black and other highly antioxidant substances can prevent the coating from being corroded. Moreover, the wear resistance and conductivity of the coating are improved, and the application prospects are wide.

Owner:郦璋

Antistatic bamboo charcoal masterbatch for carpet weaving

InactiveCN105623201AMeet individual needsLower surface resistivityElectroconductive/antistatic filament manufactureMasterbatchPolyester

The invention relates to an antistatic bamboo charcoal masterbatch for carpet weaving. The masterbatch is prepared from 63-69% of Dupont polyester carrier, 16-18% of nanoscale white charcoal powder, 14-16% of Lanxess antistatic agent and 1-3% of zinc stearate through the steps of smashing, weighing, stirring, granulating, screening and the like. After Lanxess antistatic agent is added, through migration of active factors and nanometer substances, the surface resistance rate of the masterbatch can be decreased, the surface charge density is dispersed, and therefore the antistatic effect is achieved, and the carpet produced from the masterbatch has dual advantages of charcoal carpet fiber and static prevention; nanoscale white charcoal powder is selected for the masterbatch, and therefore the problem that colors are limited is solved, the requirement of people for carpet color individualization is met, and breakthrough innovativeness and practicability are achieved on the market.

Owner:TIANJIN HONGDA COLOR MASTERBATCH CO LTD

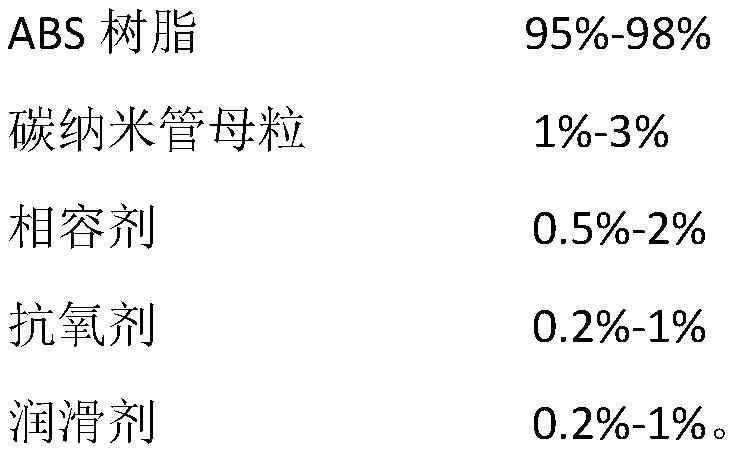

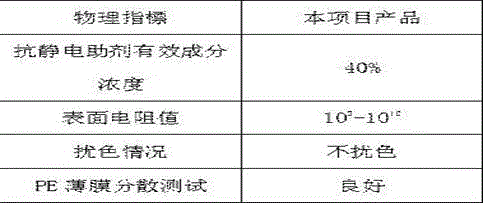

Carbon nanotube modified permanent antistatic ABS material and preparation method thereof

The invention discloses a carbon nanotube modified permanent antistatic ABS material and a preparation method thereof, and belongs to the field of high polymer materials. The carbon nanotube modifiedpermanent antistatic ABS material comprises the following components in percentage by mass: 95%-98% of ABS resin, 1%-3% of carbon nanotube masterbatch, 0.5%-2% of a compatilizer, 0.2%-1% of an antioxidant and 0.2%-1% of a lubricant. The invention also discloses a preparation method. According to the method, the carbon nanotube masterbatch is prepared from the low-polarity resin, then the ABS resinand the carbon nanotube masterbatch are blended and extruded, the carbon nano tube exists in a low-polarity component, the structure of the carbon nano tube is kept complete, and the antistatic effect can be achieved when the actual adding amount of the carbon nano tube is reduced to be within 1%; meanwhile, the mechanical property and the processability of the material are good.

Owner:NANJING JULONG SCI&TECH CO LTD +1

External wall elastic emulsion with antistatic effect and method for preparing external wall elastic emulsion

InactiveCN108148478AThe number of hydroxyl groups increasedImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateFunctional monomer

The invention discloses external wall elastic emulsion with an antistatic effect and a method for preparing the external wall elastic emulsion. The external wall elastic emulsion comprises, by weight,90-120 parts of deionized water, 10-30 parts of iso-octyl acrylate, 60-80 parts of butyl acrylate, 20-35 parts of styrene, 5-15 parts of methyl methacrylate, 0.1-2 parts of acrylic acid, 0.1-1.5 parts of methacrylic acid, 0.1-1 part of acrylamide, 0-0.5 part of methacrylamide, 0-0.5 part of hydroxyethyl acrylate, 3-10 parts of acrylonitrile, 0.5-3 parts of acid anhydride functional monomers, 0.5-4 parts of diethanolamine, 0.1-3 parts of modified organophosphate high polymers, 1-8 parts of emulsifiers, 0.1-5 parts of initiators and 0.3-4.5 parts of ammonia water. The external wall elastic emulsion and the method have the advantages that the antistatic effect can be realized by the external wall elastic emulsion, the external wall elastic emulsion is excellent in stain resistance, and the excellent normal-temperature and low-temperature elasticity of the external wall elastic emulsion can be kept.

Owner:上海巴德富实业有限公司

Antistatic master batch and preparation method thereof

The invention provides an antistatic master batch. The antistatic master batch comprises, by mass, 42% of polyethylene, 15% of calcium carbonate, 40% of an antistatic auxiliary agent, 2% of an anti-oxidant and 1% of a slipping agent. The invention also provides a preparation method for the antistatic master batch. The preparation method can prevent a produced polyethylene film product from the problem of static residues, enables the antistatic master batch to maintain a good dispersion and mixing degree, and allows the surface of the product to be stable, durable, antifrictional and solvent-resistant.

Owner:苏州清丰兴业塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com