Flame-retardant antistatic wood powder/polypropylene wood-plastic composite material with silane modified conductive carbon black, and preparation method of composite material

A wood-plastic composite material, flame-retardant and anti-static technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of poor anti-static performance, poor heat resistance, poor flame retardant effect, etc., and achieve improved flame retardant performance. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

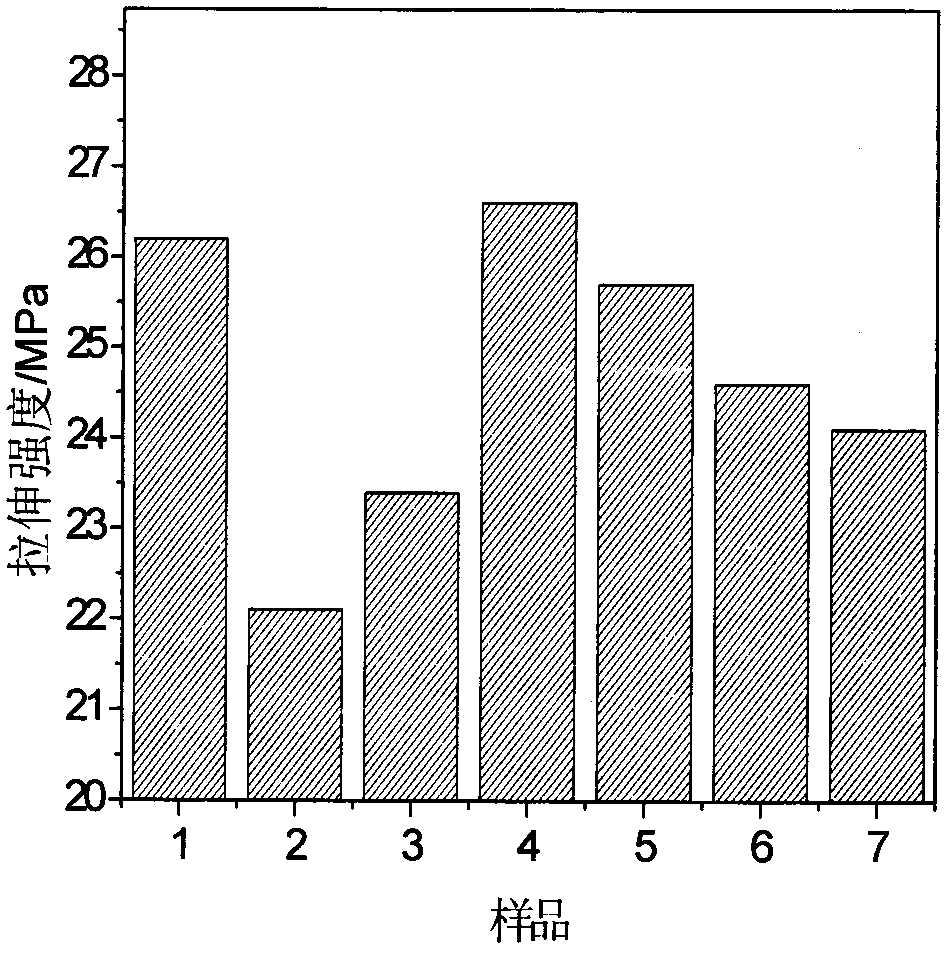

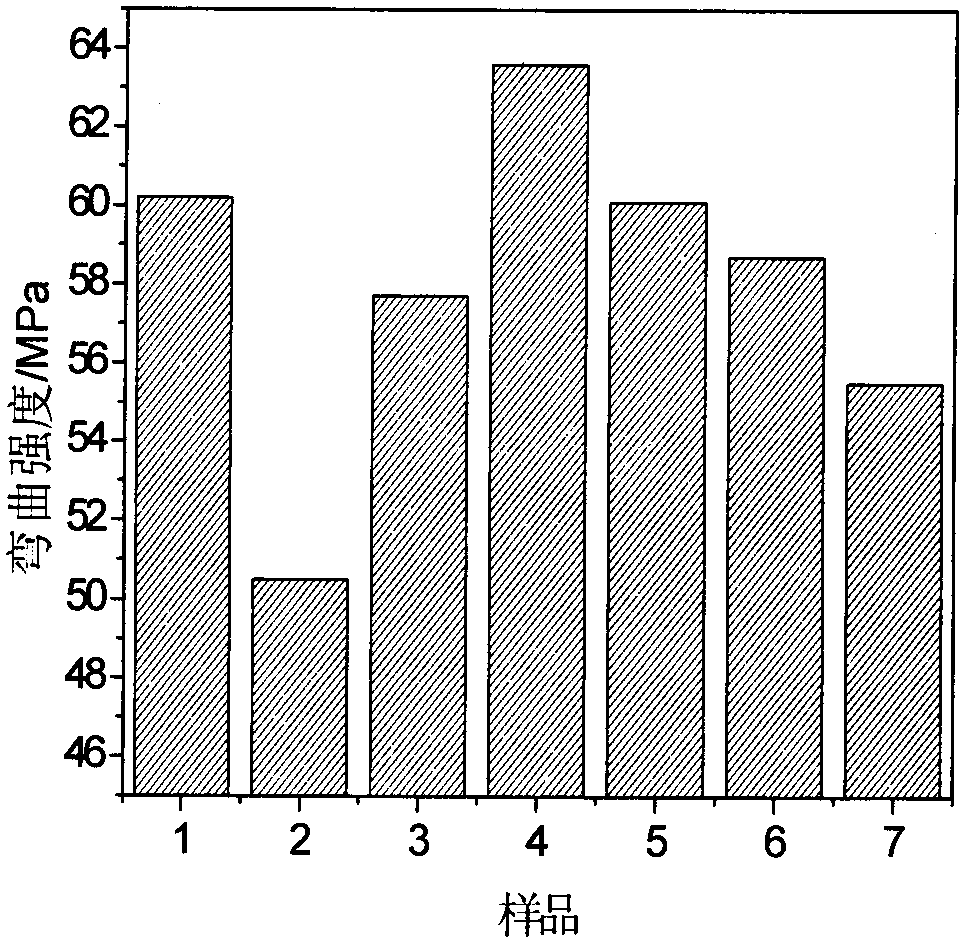

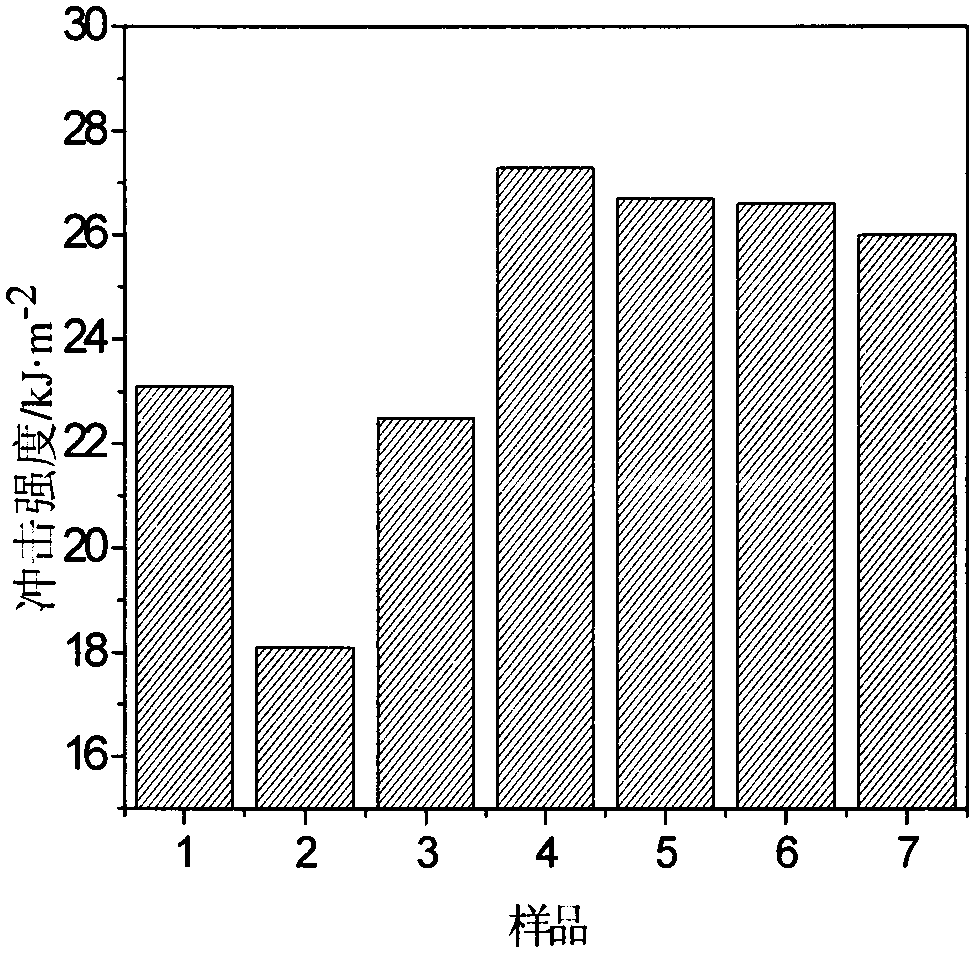

[0023] Embodiment 1: In this embodiment, the wood flour / polypropylene wood-plastic composite material is modified by weight by 50-70 parts of wood flour (WF), 30-50 parts of polypropylene (PP), and 5-30 parts of silane Conductive carbon black (M-CB), 5-30 parts of expandable graphite (EG), 3-10 parts of m-isopropenyl-α, α-dimethylbenzyl isocyanate grafted polypropylene (m-TMI-g -PP) coupling agent and 0.1 to 1 part of antioxidant.

[0024] In this embodiment, the wood powder is poplar wood powder.

[0025] In this embodiment, the antioxidant can use antioxidant 1010, antioxidant 164 or antioxidant CA.

[0026] In this embodiment, the silane-modified conductive carbon black is made of 80-150 parts by weight of conductive carbon black and 1-5 parts of silane coupling agent.

[0027] In this embodiment, the silane coupling agent may be γ-methacryloxypropyltrimethoxysilane (KH-570) or γ-aminopropyltriethoxysilane (KH-550).

[0028] In this embodiment, the raw materials can be o...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the wood powder / polypropylene wood-plastic composite material consists of 50 parts of wood powder, 50 parts of polypropylene, and 10 parts of silane-modified conductive carbon black in parts by weight. , 20 parts of expandable graphite, 4 parts of m-isopropenyl-α, α-dimethylbenzyl isocyanate grafted polypropylene coupling agent and 0.2 parts of antioxidant 1010.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the wood powder / polypropylene wood-plastic composite material consists of 60 parts of wood powder, 30 parts of polypropylene, and 15 parts of silane-modified conductive carbon black in parts by weight. , 10 parts of expandable graphite, 8 parts of m-isopropenyl-α, α-dimethylbenzyl isocyanate grafted polypropylene coupling agent and 0.8 parts of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com