Antistatic curtain fabric and preparation method thereof

An antistatic and antistatic agent technology, applied in the field of textile fabrics, can solve problems such as fire hazards, lack of antistatic properties, and unsatisfactory antistatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

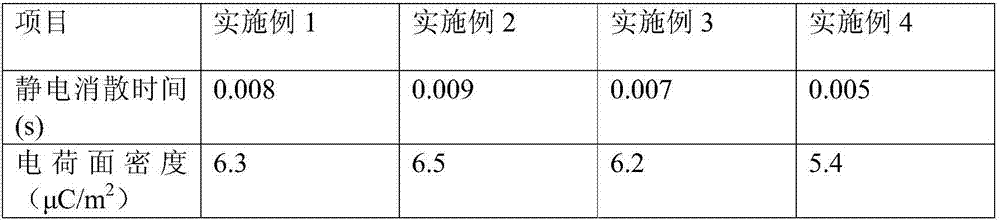

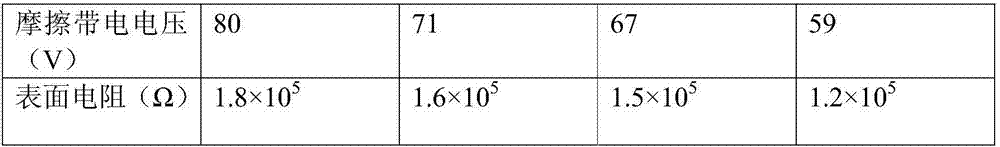

Examples

Embodiment 1

[0018] 1. Prepare polyester fabric as the basic fabric;

[0019] 2. By weight percentage, 1% alkyl dicarboxymethyl ammonium betaine, 1% acrylic resin, 1% tristearin glyceryl (HTG), 5% ethanol and 92% water, total Put 100% in a high-speed mixer and stir for 30 minutes at 1000r / min to fully mix the raw materials to make an antistatic finishing solution;

[0020] 3. Immerse the prepared polyester fabric in the above finishing solution, take it out after 2 hours, pad the finishing solution at room temperature, then put the fabric in a pre-baking dryer, pre-baking at 80°C, baking at 150°C, and then washing with water 1. After drying, the antistatic curtain fabric is obtained.

Embodiment 2

[0022] 1. Prepare spandex fabric as the basic fabric;

[0023] 2. By weight percentage, 3% ethoxyl lauramide, 3% epoxy resin, 5% tristearin (HTG), 10% ethanol and 79% water add up to 100% In a high-speed mixer, stir at 1000r / min for 50 minutes to fully mix the raw materials to make an antistatic finishing solution;

[0024] 3. Immerse the prepared spandex fabric in the above finishing solution, take it out after 4 hours, pad the finishing solution at room temperature, then put the fabric in a pre-baking dryer, pre-baking at 80°C, baking at 150°C, and then washing with water 1. After drying, the antistatic curtain fabric is obtained.

Embodiment 3

[0026] 1. Prepare polyester fabric as the basic fabric;

[0027] 2, 2% alkyl dicarboxymethyl ammonium betaine, 2% epoxy resin, 3% glyceryl tristearate (HTG), 8% ethanol and 85% water by weight percentage, A total of 100% is placed in a high-speed mixer, and stirred at 1000r / min for 40 minutes to fully mix the raw materials to make an antistatic finishing solution;

[0028] 3. Immerse the prepared polyester fabric in the above finishing solution, take it out after 3 hours, pad the finishing solution at room temperature, then put the fabric in a pre-baking dryer, pre-baking at 80°C, baking at 150°C, and then washing with water 1. After drying, the antistatic curtain fabric is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com