Preparation method of antistatic flame-retardant non-woven fabric for textiles

A flame-retardant non-woven fabric and antistatic technology, which is applied in the manufacture of fire-resistant flame-retardant filaments, non-woven fabrics, textiles, and papermaking, can solve the problems of easy loss, high hydrophobicity, and difficulty in charge dissipation, and achieve good Effects of flame retardancy and antistatic properties, prolonging service life, and strong washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

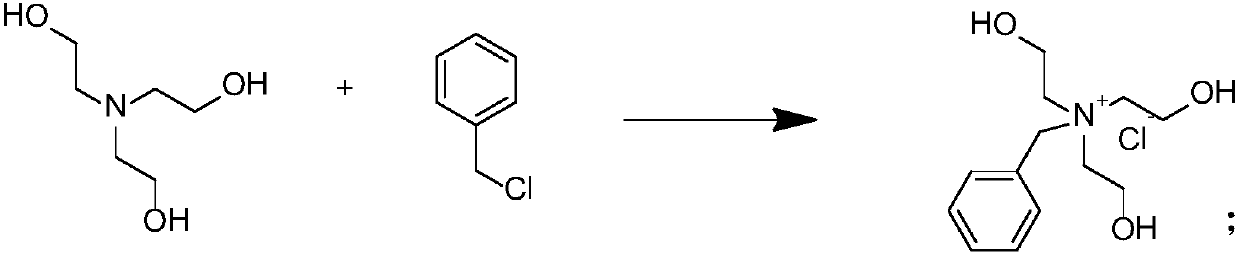

[0045] The first step, the preparation of triethanolamine benzyl chloride quaternary ammonium salt: add 1.0-1.1 mol of triethanolamine and 1 mol of benzyl chloride into the reaction flask, add 200 ml of solvent acetonitrile, stir and react at 60 ° C for 24 h, and cool down to At room temperature, after the reaction is completed, add anhydrous ether to the reactant and stir until crystallization occurs, continue to stir for 5min, stand for 10min and then suction filtration, the obtained solid continues to be washed with 50ml of anhydrous ether while suction filtration, put into an oven, Dry at 45°C for 24h to obtain triethanolamine benzyl chloride quaternary ammonium salt. The reaction formula is as follows:

[0046]

[0047] Infrared Characterization of Triethanolamine Benzyl Chloride Quaternary Ammonium Salt: IR(KBr): 3045(benzene ring), 2944(-CH 2 -),1425(C-N + ).

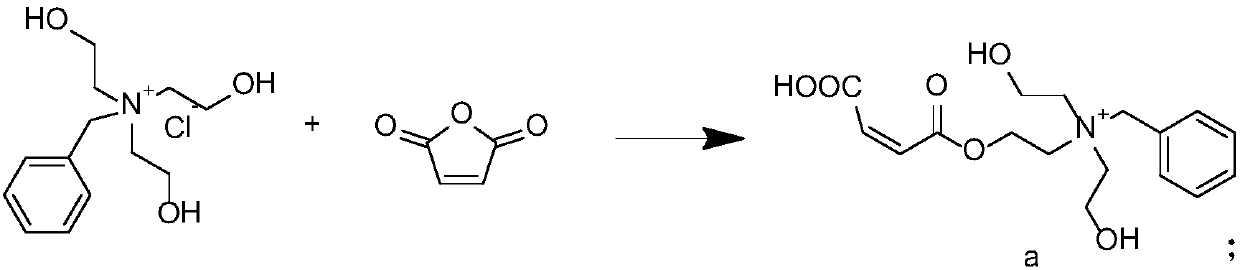

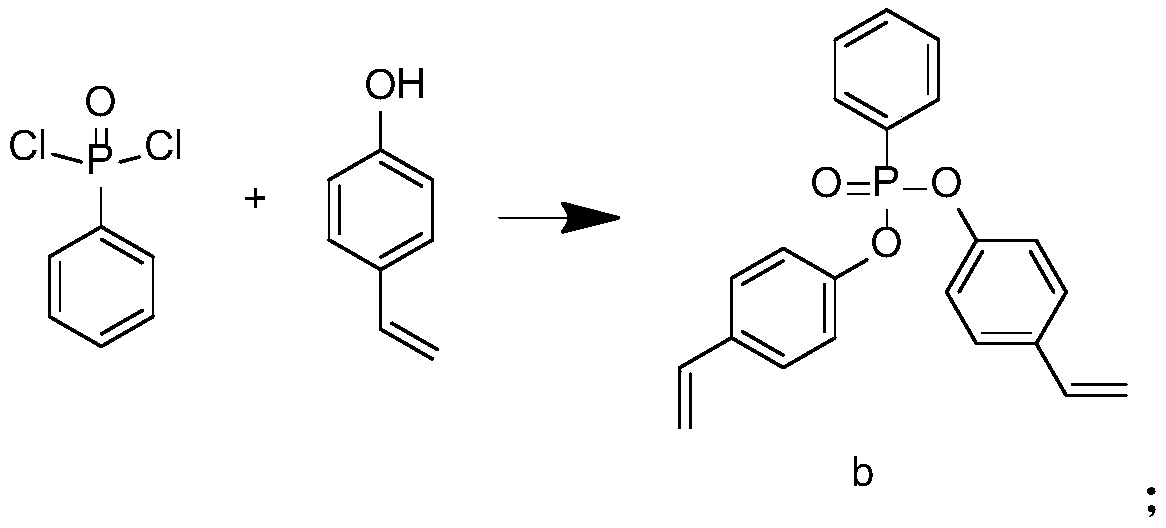

[0048] The second step, the preparation of maleic acid ester quaternary ammonium salt

[0049] Add 1...

Embodiment 1

[0061] The preparation method of antistatic flame retardant non-woven fabric for textile specifically comprises the following steps:

[0062] Step 1. Melt preparation: Specifically:

[0063] S1. Preparation of antistatic flame retardant;

[0064] S2. Premixing of non-woven raw materials: 100g polyethylene terephthalate particles and 1.5g antistatic flame retardant are added to the mixer for premixing for 5 minutes;

[0065] Step 2. Melt extrusion:

[0066] The premixed mixture was added to a screw extruder, heated and melted and extruded. The screw diameter of the screw extruder was 90 mm, the temperature of the screw feeding section was 210 °C, and the temperature of the screw compression section was 250 °C. °C;

[0067] Step 3. After the melt is extruded by the screw extruder, it enters the spinning assembly through the metering pump and extrudes a thin stream from the spinneret. The temperature of the spinneret is 270 ° C. The spinneret The jet aperture is 310nm;

[00...

Embodiment 2

[0072] The preparation method of antistatic flame retardant non-woven fabric for textile specifically comprises the following steps:

[0073] Step 1. Melt preparation: Specifically:

[0074] S1. Preparation of antistatic flame retardant;

[0075] S2. Premixing of non-woven raw materials: 100g polyethylene terephthalate particles and 3g antistatic flame retardant are added to the mixer for premixing for 5min;

[0076] Step 2. Melt extrusion:

[0077] The premixed mixture was added to a screw extruder, heated and melted and extruded. The screw diameter of the screw extruder was 90 mm, the temperature of the screw feeding section was 230 °C, and the temperature of the screw compression section was 270 °C. °C;

[0078] Step 3. After the melt is extruded by the screw extruder, it enters the spinning assembly through the metering pump and extrudes a thin stream from the spinneret. The temperature of the spinneret is 280 ° C. The spinneret The jet aperture is 400nm;

[0079] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com