Antistatic release paper and making method thereof

A release paper and antistatic technology, which is applied in papermaking, paper coating, coated paper base paper, etc., can solve the problems of antistatic and antistatic, and cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

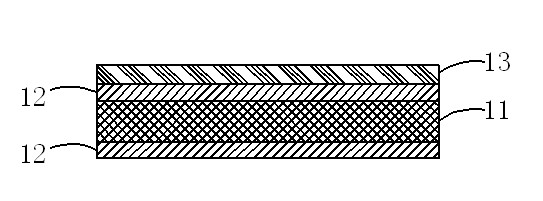

[0020] Example 1: At a mass of 50 to 120 g / m 2 Both sides of Glassine 11 are coated with polyol ester, and the formation mass is 0.2 to 2g / m 2 Polyol ester antistatic layer 12, then a silicone release agent is coated on the surface of a polyol ester antistatic layer to form a mass of 0.2 to 2 g / m 2 The silicone release agent layer 13 in this example is a double-sided antistatic single-sided release paper.

Embodiment 2

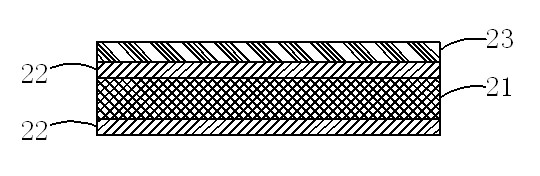

[0021] Example 2: At a mass of 50 to 120 g / m 2 Both sides of the kaolin coated paper (CCK) 21 are coated with quaternary ammonium salts, and the formation quality is 0.2 to 2g / m 2 A quaternary ammonium salt antistatic layer 22, and then a silicone release agent is coated on the surface of a quaternary ammonium salt antistatic layer to form a mass of 0.2 to 2 g / m 2 The silicone release agent layer 23 in this example is a double-sided antistatic single-sided release paper.

Embodiment 3

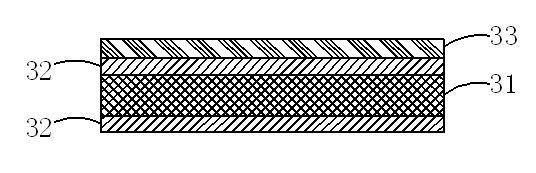

[0022] Example 3: At a mass of 80 to 140 g / m 2 Both sides of the polyethylene coated paper (PEK) 31 are coated with quaternary amine inner salt, and the formation quality is 0.2 to 2g / m 2 A quaternary amine inner salt antistatic layer 32, and then a silicone release agent is coated on the surface of a quaternary amine inner salt antistatic layer to form a mass of 0.2 to 2 g / m 2 The silicone release agent layer 33 in this example is a double-sided antistatic single-sided release paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com