Carbon nanotube modified permanent antistatic ABS material and preparation method thereof

A carbon nanotube modification, ABS material technology, applied in the field of polymer materials, can solve the problems of high overall addition, large addition, poor material toughness, etc., to achieve good mechanical properties and processing properties, and the retention rate of physical properties. High effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

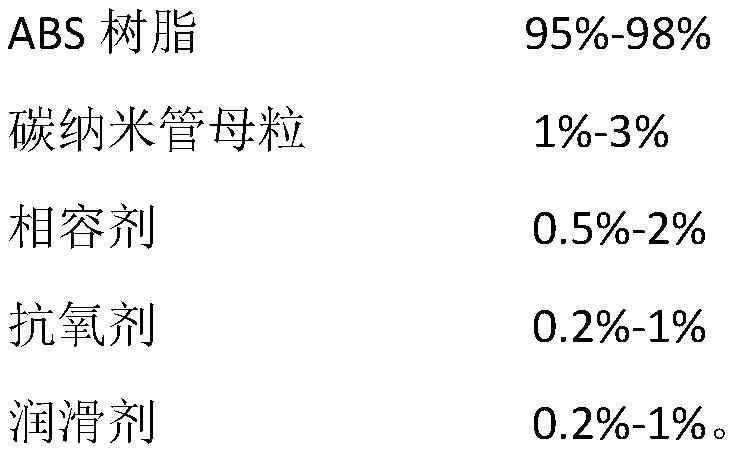

Image

Examples

preparation example Construction

[0040] The preparation method of carbon nanotube master batch in following embodiment 1-3 is as follows:

[0041] Preparation of carbon nanotube masterbatch: Add 79% low-polarity LDPE resin, 20% carbon nanotubes, 0.5% dispersant DP310, 0.25% antioxidant 1010 and 0.25% antioxidant 168 into a high-speed mixer, mix well , fed into the screw through the feeding system of the twin-screw extruder, extruded and granulated for later use. Wherein the process parameters of the extruder are as follows: the screw speed is 400r / min, and the temperature in each zone is:

[0042] Zone 1 100°C, Zone 2 170°C, Zone 3 180°C, Zone 4 190°C, Zone 5 190°C, Zone 6 180°C, Zone 7 180°C, Zone 8 180°C, Zone 9 180°C, Zone 10 180°C, The eleventh zone is 185°C, the twelve zone is 185°C, and the head temperature is 190°C;

Embodiment 1

[0044] Add 97.7% ABS resin PA-757, 1% carbon nanotube masterbatch, 0.5% compatibilizer POE-g-MAH, 0.2% antioxidant 1076, 0.2% antioxidant 168, 0.4% lubricant EBS in proportion In the high-speed mixer, after mixing evenly, it is sent to the screw through the feeding system of the twin-screw extruder, and extruded to granulate. The process parameters of the extruder are as follows: the screw speed is 400-600r / min, and the temperature of each zone is: 100°C in the first zone, 200°C in the second zone, 210°C in the third zone, 220°C in the fourth zone, 220°C in the fifth zone, and 210°C in the sixth zone , Seventh zone 210°C, eighth zone 210°C, ninth zone 200°C, tenth zone 210°C, head temperature 220°C.

Embodiment 2

[0046]Add 96.7% ABS resin PA-757, 2% carbon nanotube masterbatch, 0.5% compatibilizer POE-g-MAH, 0.2% antioxidant 1076, 0.2% antioxidant 168, 0.4% lubricant EBS in proportion In the high-speed mixer, after mixing evenly, it is sent to the screw through the feeding system of the twin-screw extruder, and extruded to granulate. The process parameters of the extruder are as follows: the screw speed is 400-600r / min, and the temperature of each zone is: 100°C in the first zone, 200°C in the second zone, 210°C in the third zone, 220°C in the fourth zone, 220°C in the fifth zone, and 210°C in the sixth zone , Seventh zone 210°C, eighth zone 210°C, ninth zone 200°C, tenth zone 210°C, head temperature 220°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com