Surface treating agent for glass fiber filter cloth and preparation method of surface treating agent

A surface treatment agent and glass fiber technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of poor corrosion resistance to strong acids, short service life, etc., and achieve the effect of improving bonding ability and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A surface treatment agent for glass fiber filter cloth, comprising the following components by mass percentage:

[0024] Water and oil repellent 1%

[0025] Softener 2%

[0026] Inorganic pigment 0.1%

[0027] Fluorocarbon Surfactant 0.01%

[0028] Acid proof binder 2%

[0029] PTFE dispersion 10%

[0030] Demineralized water balance.

[0031] In this example, the water-repellent and oil-repellent agent is a commercially available brand of ionic fluorine-containing water-repellent and oil-repellent agent, the binder is a polyurethane binder, and the softener is a high-temperature-resistant silicone softener. agent, the inorganic pigment is a commercially available conventional inorganic pigment, the fluorocarbon surfactant is a commercially available conventional fluorocarbon surfactant, and the PTFE dispersion is a polytetrafluoroethylene dispersion.

[0032] A preparation method of a surface treatment agent, after preparing materials according to the above ratio...

Embodiment 2

[0036] A surface treatment agent for glass fiber filter cloth, comprising the following components by mass percentage:

[0037] Water and oil repellent 2%

[0038] Softener 1%

[0039] Inorganic pigment 0.4%

[0040] Fluorocarbon Surfactant 0.1%

[0041] Acid proof binder 3%

[0042] PTFE dispersion 2%

[0043] Demineralized water balance.

[0044] A preparation method of a surface treatment agent, after preparing the materials according to the above ratio, first disperse the inorganic pigment into demineralized water under the stirring state of 2900 rpm to obtain the mixed solution, and then sequentially add the mixed liquid under the stirring state of 300 rpm to Add fluorocarbon surfactant, high-temperature softener, water and oil repellent, acid-proof binder and PTFE dispersion into the mixed liquid, and keep stirring until it turns white to obtain the surface treatment agent.

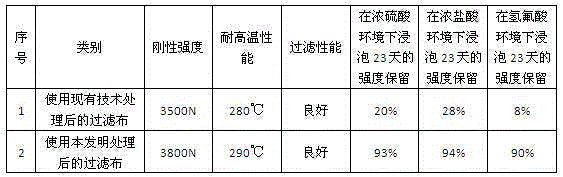

[0045] Adopt the glass fiber filter cloth after the treatment of the present invention, it...

Embodiment 3

[0048] A surface treatment agent for glass fiber filter cloth, comprising the following components by mass percentage:

[0049] Water and oil repellent 5%

[0050] Softener 1.5%

[0051] Inorganic pigment 0.3%

[0052] Fluorocarbon Surfactant 0.07%

[0053] Acid proof binder 5%

[0054] PTFE dispersion 7%

[0055] Demineralized water balance.

[0056] A preparation method of a surface treatment agent, after preparing materials according to the above ratio, first disperse the inorganic pigment into demineralized water under the stirring state of 3000 rpm to obtain the mixed solution, and then sequentially add the mixed liquid under the stirring state of 300 rpm Add fluorocarbon surfactant, high-temperature softener, water and oil repellent, acid-proof binder and PTFE dispersion into the mixed liquid, and keep stirring until white, and then the surface treatment agent is obtained.

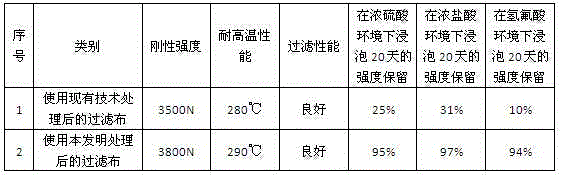

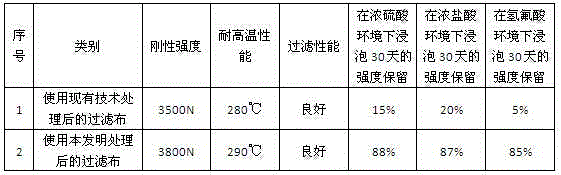

[0057] Adopt the glass fiber filter cloth after the treatment of the present invention, its o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com