Antistatic rubber core-filling rubber shoe rubber material prepared from phosphorus gypsum whiskers and preparation method

A phosphogypsum whisker and anti-static technology, which is applied in the field of rubber processing, can solve the problems of poor dispersion effect affecting the anti-static effect and reinforcing effect of rubber core rubber, and achieve stable resistance value, wide range of material sources, and good use effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of the antistatic rubber core-filled rubber shoes compound made of phosphogypsum whiskers, comprising:

[0028] (1) Weighing: get each component by weight parts;

[0029] (2) Rubber mixing: masticate 2# standard rubber on an open rubber mixing machine at a temperature of 20°C-50°C until the Vickers plasticity is 0.55-0.60, add sulfur, vulcanization accelerator, nano-zinc oxide, hard Fatty acid, phosphogypsum whiskers, salicylic acid, high wear-resistant carbon black, conductive carbon black, engine oil and dibutyl phthalate; then the rubber is kneaded evenly and the air bubbles are removed to make a thickness of 1.2 to 1.4 mm film, naturally cooled to room temperature;

[0030] (3) Vulcanization: cut the smelted film according to the shape of the shoe sole, put it in a vulcanization steam tank for 30 minutes to vulcanize, and then get the antistatic rubber core-filled rubber shoe compound made of phosphogypsum whiskers.

[0031] Paste the antistat...

Embodiment 1

[0042] Calculated in parts by weight, including 100 parts of standard glue, 2.5 parts of sulfur, 1.9 parts of vulcanization accelerator, 8 parts of nano zinc oxide, 13.5 parts of stearic acid, 80 parts of phosphogypsum whiskers, 0.5 parts of salicylic acid, 20 parts of high Wear-resistant carbon black, 25 parts of conductive carbon black, 15 parts of engine oil and 10 parts of dibutyl phthalate.

[0043] The phosphogypsum whiskers are mixed with a silane coupling agent at a ratio of 95:5, added to a high-speed blender for modification, and blended at a temperature of 120° C. for 20 minutes to be taken out.

[0044] The standard glue is 2# standard glue.

[0045] Described engine oil is 46# engine oil.

[0046] The vulcanization accelerator is that every 1.9 parts of the vulcanization accelerator is composed of 0.7 parts of accelerator M and 1.2 parts of accelerator DM.

[0047] The invention relates to a method for preparing antistatic rubber core-filling rubber shoes made o...

Embodiment 2

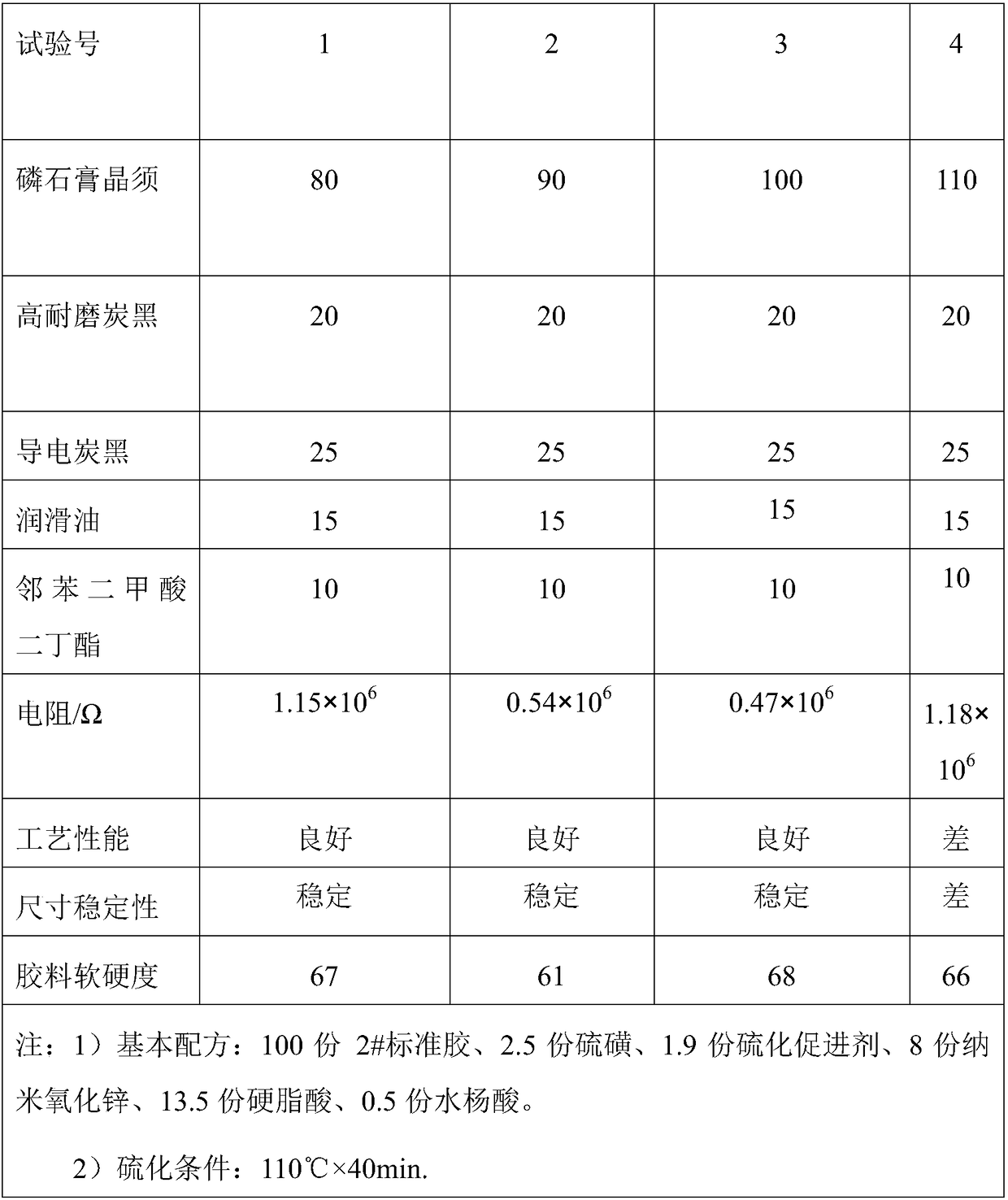

[0056] Calculated in parts by weight, the selection includes 100 parts of standard glue, 2.5 parts of sulfur, 1.9 parts of vulcanization accelerator, 8 parts of nano-zinc oxide, 13.5 parts of stearic acid, 90 parts of phosphogypsum whiskers, 0.5 parts of salicylic acid, 20 parts of High wear-resistant carbon black, 25 parts of conductive carbon black, 15 parts of engine oil and 10 parts of dibutyl phthalate.

[0057] Repeat steps (1)-(4) in Example 1 to obtain the finished product.

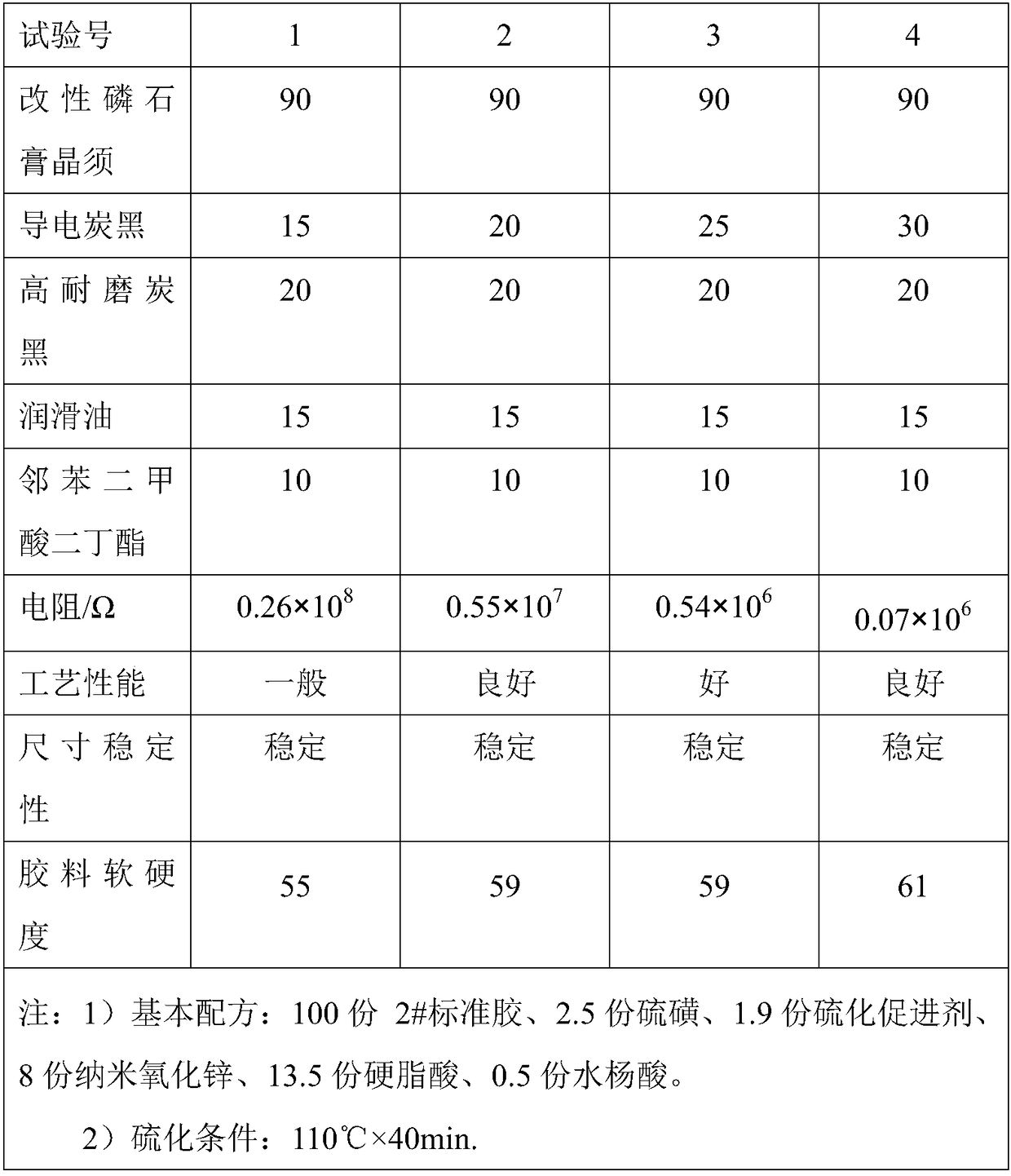

[0058] Table 2

[0059]

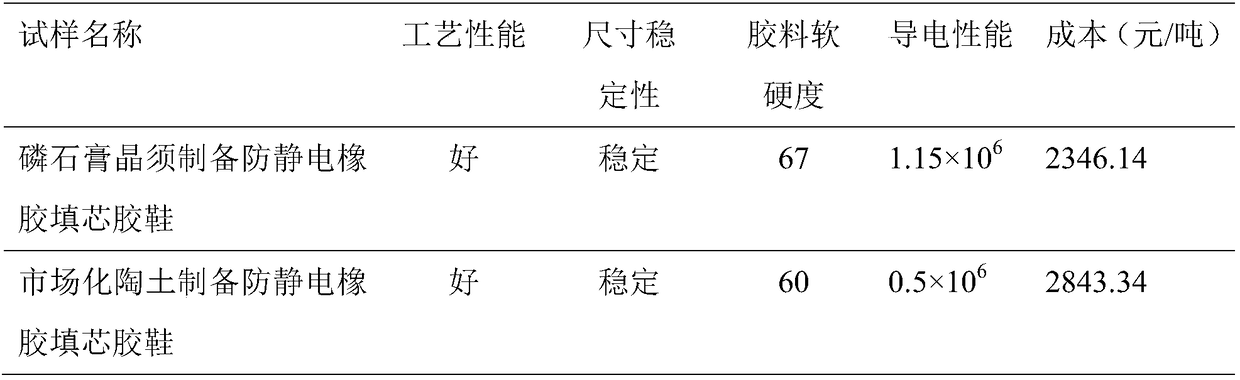

[0060] It can be seen from Table 2 that the semi-finished film of the antistatic rubber core-filled rubber shoe compound prepared according to the above formula is pasted in the groove formed by the sponge rubber surface of the second bottom and the upper foot of the shoe, and then bonded with the antistatic rubber sole Bonding to obtain finished rubber shoes. Test its related properties, and prepare anti-static rubber core-filled rubber shoes with market-oriented cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com