Photocuring composition and hard coating film

A composition, light-curing technology, used in coatings, conductive coatings, antifouling/underwater coatings, etc., can solve the problems of poor comprehensive performance of hard coating films, and achieve the effect of improving flatness and reducing craters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

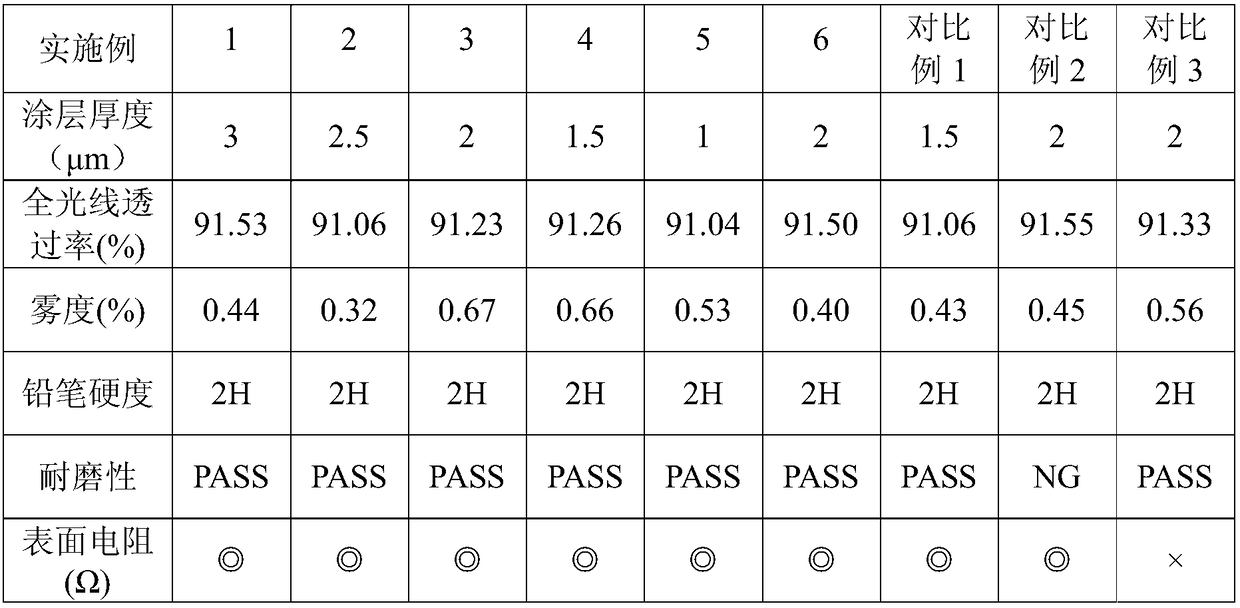

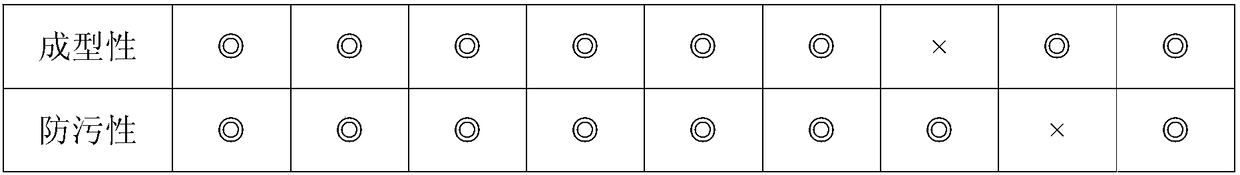

Examples

preparation example Construction

[0085] The preparation method of the hard coating film provided by the present invention is as follows: configuring a photocurable composition, coating the photocurable composition on a substrate, drying the formed coating at 80-90° C. for 2 minutes, and then activating the energy by ionizing radiation. Radiation cures the dried coating to obtain a hard coating.

[0086] The performance of the hard coating provided by the invention is tested according to the following methods:

[0087] (1) Haze, total light transmittance

[0088] Nippon Denshoku NDH 2000N haze meter was used to measure by transmitted light method.

[0089] (2) Pencil hardness

[0090] Product pencil hardness was measured using an Elcometer 3086 Pencil Hardness Tester. Measurement method: use a Mitsubishi pencil with a hardness of H~3H, draw 5 lines under a load of 500g, then observe whether the hard coating is scratched, and judge according to the following standards.

[0091] judgement standard

[0092] ...

Embodiment 1

[0115] The invention provides a photocurable composition and a hard coating film, the hard coating film includes a base material and a hardened layer, the hardened layer contains conductive particles; the hardened layer is formed by curing the photocurable composition.

[0116] 20 parts by weight of hexafunctional aliphatic urethane acrylate oligomer, 10 parts by weight of trifunctional fluorine-containing methyl acrylate, 30 parts by weight of multifunctional reactive monomer trimethylolpropane triacrylate, 0.5 parts by weight Photoinitiator 184, the leveling agent MEGAFACE F440 of 0.1 weight part, the antifouling agent RS-90 of 0.5 weight part, the conductive particle lipophilic ATO (antimony-doped tin dioxide) of 0.5 weight part, the solvent D of 15 weight parts Ketone and 10 parts by weight of solvent propylene glycol monomethyl ether are mixed to obtain a photocurable composition.

[0117] The above-mentioned photocurable composition was coated on one side of an optical-g...

Embodiment 2

[0119] Photocurable composition and hard coat film as provided in Example 1.

[0120] 30 parts by weight of eight-functional aliphatic urethane acrylate oligomer, 15 parts by weight of trifunctional fluorine-containing butyl acrylate, 10 parts by weight of multifunctional active monomer pentaerythritol triacrylate, and 1.5 parts by weight of photoinitiator 1173, 0.3 parts by weight of leveling agent BYK-333, 2.0 parts by weight of antifouling agent RS-75, 1.5 parts by weight of conductive particle oily ATO, 20 parts by weight of solvent 4-methyl-2-pentanone, 5 parts by weight Parts of solvent ethyl acetate were mixed to obtain a photocurable composition.

[0121] The above photocurable composition was coated on one side of an optical-grade polyethylene terephthalate film (manufactured by Toray Corporation, Japan, trade name; U48) with a thickness of 50 μm. After drying the formed coating at 80-90°C for 2 minutes, at 400mJ / cm 2 The amount of light, the dried coating is cured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com