Antistatic explosion-proof polyurea material as well as preparation method and application thereof

An antistatic and polyurea technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of polyurea material strength decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

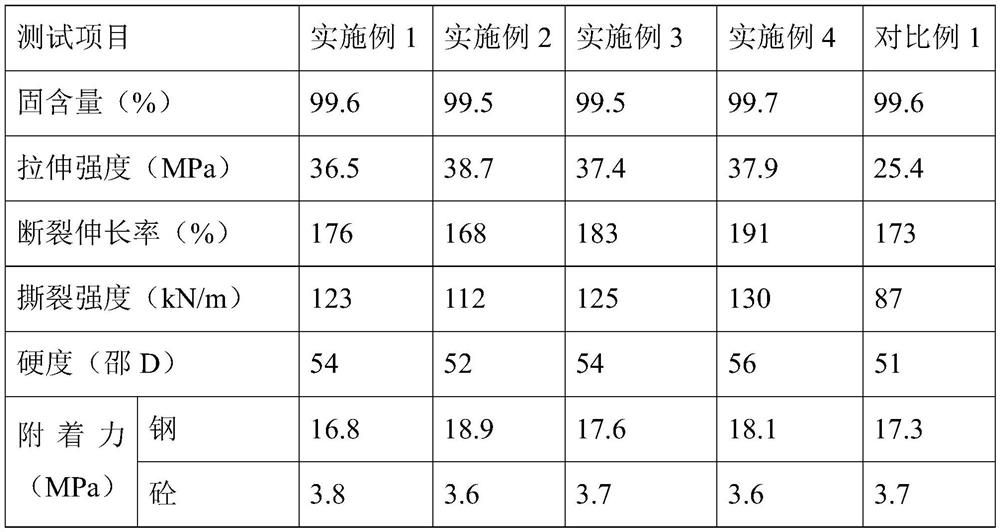

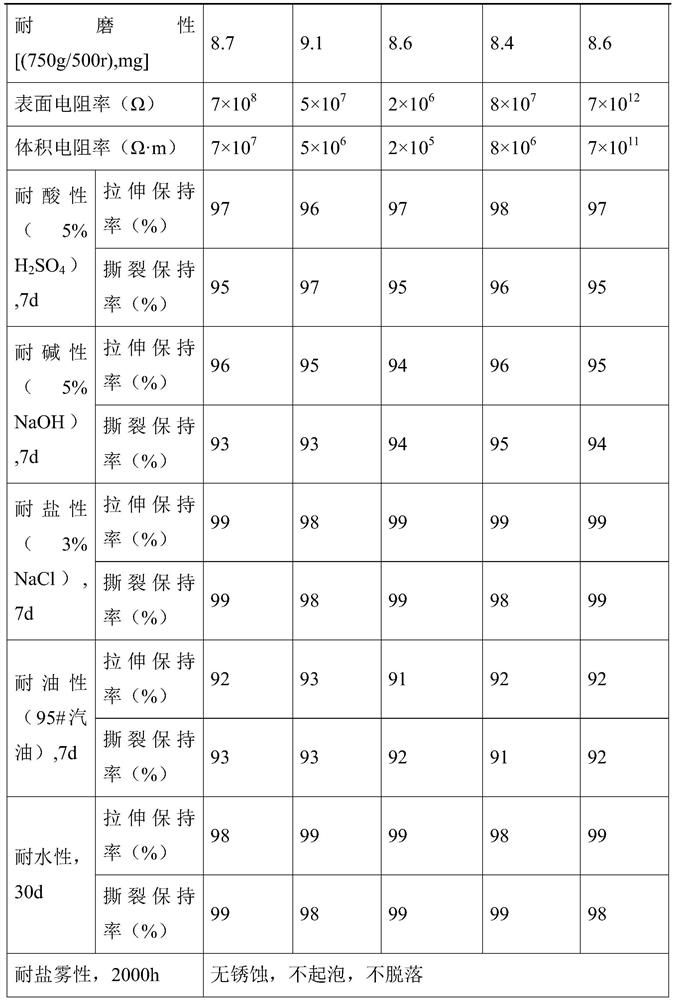

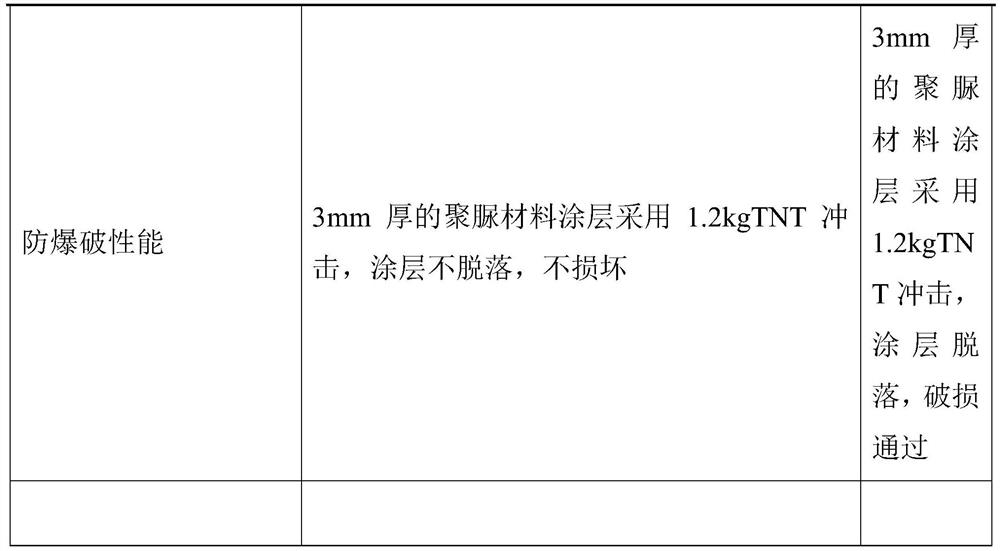

Examples

Embodiment 1

[0032] A kind of antistatic explosion-proof polyurea material, comprises A component and B component, and described A component comprises following parts by weight

[0033] Raw materials: 474 parts of toluene diisocyanate, 521 parts of polyhexamethylene adipate diol (PHA-1000) and 5 parts of single-walled amino carbon nanotubes. The average diameter of the single-wall amino carbon nanotubes is 6nm, and the average length is 20μm. The aminated carbon nanotubes are based on carboxylated carbon nanotubes. obtained by decarboxylation.

[0034] The B component includes polyester polyols, amino-terminated chain extenders and auxiliary agents; wherein, the relative molecular weight of polyester polyols is 2000, and the average functionality is 2.0; specifically, polyester polyols include 305 parts by weight Parts of polyhexamethylene adipate diol (PHA-2000) and 280 parts of polyethylene adipate diol (PEA-2000); The terminal amino chain extender includes 320 parts by weight of 3 ,5 ...

Embodiment 2

[0042] A kind of antistatic explosion-proof polyurea material, comprises A component and B component, and described A component comprises following parts by weight

[0043] Raw materials: 483 parts of isophorone diisocyanate, 505 parts of polycaprolactone polyol (PCL-2000) and 12 parts of multi-wall amino carbon nanotubes; the average diameter of multi-wall amino carbon nanotubes is 8nm , with an average length of 30 μm;

[0044] The B component includes a polyester polyol, an amino-terminated chain extender and an auxiliary agent; specifically, the polyester polyol includes 577 parts by weight of polycaprolactone polyol (PCL-1000) and 10 parts of Polycaprolactone polyol (PCL-3031); amino-terminated chain extenders include 107 parts by weight of 3,5 diethyltoluenediamine, 197 parts of 4,4'-bis-sec-butylaminodiphenylmethane ; Auxiliaries include 4 parts of N,N-dimethylcyclohexylamine catalyst, 1 part of stannous octoate, 12 parts of 2-hydroxyl-4-n-octyloxybenzophenone UV absor...

Embodiment 3

[0053] A kind of antistatic explosion-proof polyurea material, comprises A component and B component, and described A component comprises following parts by weight

[0054] Raw materials: 599 parts of diphenylmethane diisocyanate, 381 parts of polyhexamethylene adipate diol (PHA-3000) and 20 parts of single-walled aminocarbon nanotubes; single-walled aminocarbon nanotubes The average diameter is 10nm, and the average length is 40μm;

[0055] The B component includes polyester polyols, amino-terminated chain extenders and auxiliary agents; specifically, the polyester polyols include 316 parts by weight of polyhexamethylene adipate diol (PHA-2000), 227 parts of polycaprolactone polyol (PCDL-2000); the amino-terminated chain extender includes 213 parts by weight of 3,5-dimethylthiotoluenediamine, 161 parts of 4,4'-bis-sec-butyl Aminodiphenylmethane; additives include 3 parts by weight of triethanolamine, 3 parts of lead catalyst of isooctanoate, 8 parts of 2-(2-hydroxyl-3,5 bis(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com