Flame-retardant ABS wood-plastic profile and preparation method thereof

A technology of wood-plastic profiles and ABS resin, which is applied in the field of wood-plastic materials, can solve the problems that the flame retardancy cannot meet the actual needs, and achieve the effect of improving the interface, increasing the mechanical properties, and improving the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

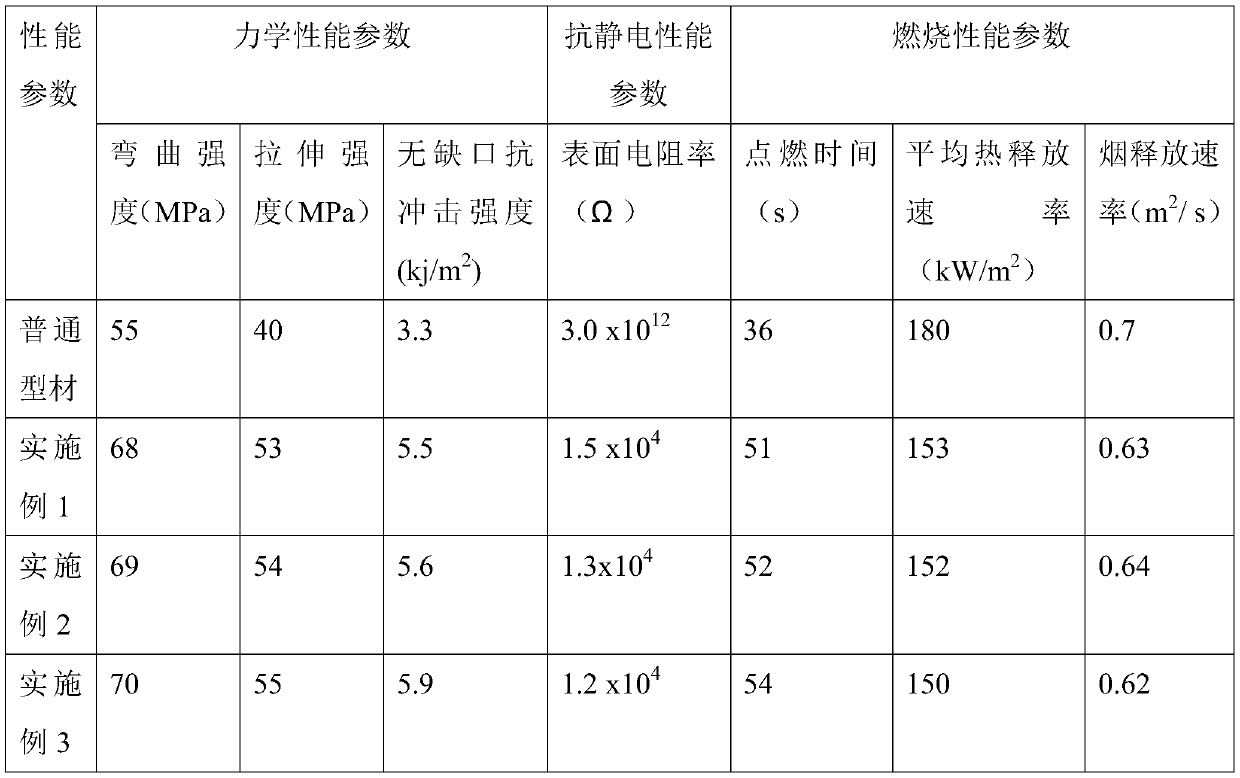

Examples

Embodiment 1

[0032] The flame-retardant ABS wood-plastic profile of this embodiment includes the following raw materials by weight: 80 parts of ABS resin, 40 parts of wood powder or bamboo powder, 3 parts of ABS graft, 3 parts of expanded graphite, silane-modified conductive 2 parts of carbon black, 0.1 part of silica gel, 0.2 part of polyethylene wax, 0.5 part of flame retardant, 0.5 part of smoke suppressant.

[0033] Wherein, the flame retardant is in parts by weight, including the following raw materials: 0.5 part of diatomaceous earth, 0.4 part of antimony trioxide, 0.3 part of hexachlorocyclododecane, 2-chloroethyl-2-bromoethyl carboxylic acid 0.3 part of ester, 0.5 part of molybdenum oxide, 0.3 part of urea-formaldehyde resin, and 0.1 part of polypropylene alcohol.

[0034] The smoke suppressant, in parts by weight, includes the following raw materials: 0.8 part of dibutyltin dilaurate, 0.8 part of zirconium hydroxide, 0.2 part of talc, and 0.5 part of iron oxide.

[0035] Further,...

Embodiment 2

[0041] A flame-retardant ABS wood-plastic profile in this embodiment includes the following raw materials in parts by weight: 100 parts of ABS resin, 60 parts of rice bran or straw powder, 6 parts of ABS grafts, 12 parts of expanded graphite, and silane-modified conductive carbon 8 parts of black, 0.4 parts of silica gel, 0.8 parts of liquid paraffin or silicone oil, 1.5 parts of flame retardant, 1.5 parts of smoke suppressant.

[0042] Wherein, the flame retardant is in parts by weight, including the following raw materials: 0.6 part of diatomaceous earth, 0.8 part of antimony trioxide, 0.4 part of hexachlorocyclododecane, 2-chloroethyl-2-bromoethyl carboxylic acid 0.4 part of ester, 0.6 part of molybdenum oxide, 0.4 part of urea-formaldehyde resin, and 0.2 part of polypropylene alcohol.

[0043] The smoke suppressant is in parts by weight and includes the following raw materials: 1.0 part of dibutyltin dilaurate, 1.0 part of zirconium hydroxide, 0.6 part of talc, and 0.7 par...

Embodiment 3

[0050] The flame-retardant ABS wood-plastic profile of this embodiment includes the following raw materials by weight: 90 parts of ABS resin, 50 parts of sisal powder, 4.5 parts of ABS graft, 6 parts of expanded graphite, and silane-modified conductive carbon black 4 parts, 0.25 part of silica gel, 0.5 part of stearic acid, 1.0 part of flame retardant, 1.0 part of smoke suppressant.

[0051] Wherein, the flame retardant is in parts by weight, including the following raw materials: 0.55 part of diatomaceous earth, 0.6 part of antimony trioxide, 0.35 part of hexachlorocyclododecane, 2-chloroethyl-2-bromoethyl carboxylic acid 0.35 part of ester, 0.55 part of molybdenum oxide, 0.35 part of urea-formaldehyde resin, and 0.15 part of polypropylene alcohol.

[0052] The smoke suppressant is in parts by weight and includes the following raw materials: 0.9 part of dibutyltin dilaurate, 0.9 part of zirconium hydroxide, 0.4 part of talc, and 0.6 part of iron oxide.

[0053] Further, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com