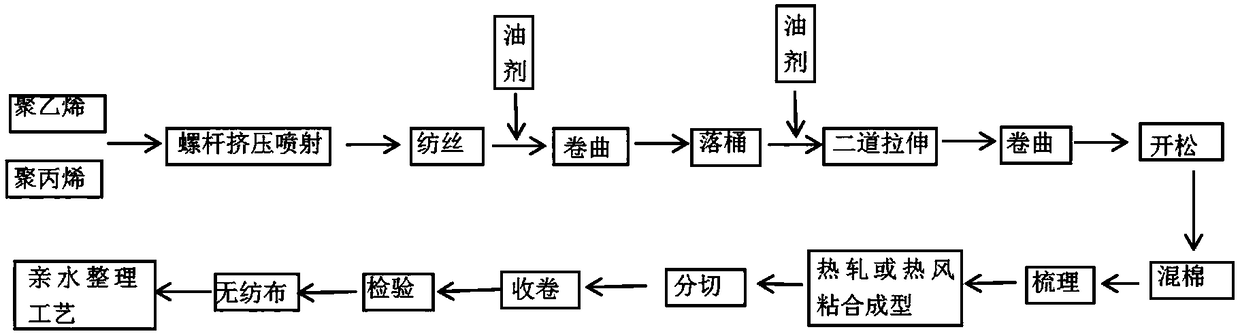

Manufacturing process of ES hydrophilic fiber non-woven fabric

A preparation process and hydrophilic fiber technology, applied in fiber type, fiber treatment, non-woven fabrics, etc., can solve the problems of poor hydrophilicity of fiber non-woven fabrics, achieve ideal bundling and smoothness, simple and efficient production process, easy wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of hydrophilic oil agent: Take fatty alcohol polyoxyethylene ether and sorbitan monostearate polyoxyethylene ether in a 500ml beaker at a mass ratio of 30:10:2 at 80-90°C Mix well with polyether silicone oil, add distilled water and 10% KOH, adjust the pH to neutral, keep the temperature constant, stir for 3 hours, prepare a transparent and uniform oil with a solid content of 30%, cool to 25°C, and measure the hydrophilicity The concentration of the oil agent is 8g / L.

[0023] 2. Take polyethylene and polypropylene according to the mass ratio of 30:70, extrude and spray the raw materials through a screw, spin on a spinning machine, add 0.5% hydrophilic oil agent, wind up through a winding machine, and then fall into a barrel. Add 0.5% hydrophilic oil agent, and then go through secondary stretching, curling, opening, cotton blending, carding, hot rolling or hot air bonding molding, cutting, winding, inspection, to obtain non-woven fabrics, and finally thro...

Embodiment 2

[0026] 1. Preparation of hydrophilic oil agent: Take fatty alcohol polyoxyethylene ether, sorbitan monostearate polyoxyethylene in a 500ml beaker at a mass ratio of 30:10:20:3 at 80-90°C Mix vinyl ether, potassium salt of fatty alcohol ether phosphate and polyether silicone oil evenly, add distilled water and 10% KOH, adjust the pH to neutral, keep the temperature constant, and stir for 4 hours to prepare a transparent and uniform oil with a solid content of 30%. , cooled to 25°C, the measured concentration of the hydrophilic oil agent was 10g / L.

[0027] 2. Take polyethylene and polypropylene according to the mass ratio of 50:50, extrude and spray the raw materials through a screw, spin on a spinning machine, add 0.25% hydrophilic oil agent, wind up through a winding machine, and then fall into a barrel. Add 0.25% hydrophilic oil agent, and then go through secondary stretching, curling, opening, blending, carding, hot rolling or hot air bonding, cutting, winding, and inspecti...

Embodiment 3

[0030] 1. Preparation of hydrophilic oil agent: at 80-90°C, take LX-1, LX-2, sorbitan monostearate polystyrene in a 500ml beaker at a mass ratio of 20:30:10:2 Mix oxyethylene ether and polyether silicone oil evenly, add distilled water and 10% KOH, adjust the pH to neutral, keep the temperature constant, stir for 3-4 hours, prepare a transparent and uniform oil with a solid content of 30%, and cool to 25°C , The recorded concentration of the hydrophilic oil agent is 9g / L.

[0031]2. Take polyethylene and polypropylene according to the mass ratio of 40:60, extrude and spray the raw materials through a screw, spin on a spinning machine, add 0.45% hydrophilic oil agent, wind up through a winding machine, and then fall into a barrel. Add 0.45% hydrophilic oil agent, and then go through secondary stretching, curling, opening, cotton blending, carding, hot rolling or hot air bonding molding, cutting, winding, inspection, to obtain non-woven fabrics, and finally through pro- The wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com