Coating composite and usage thereof

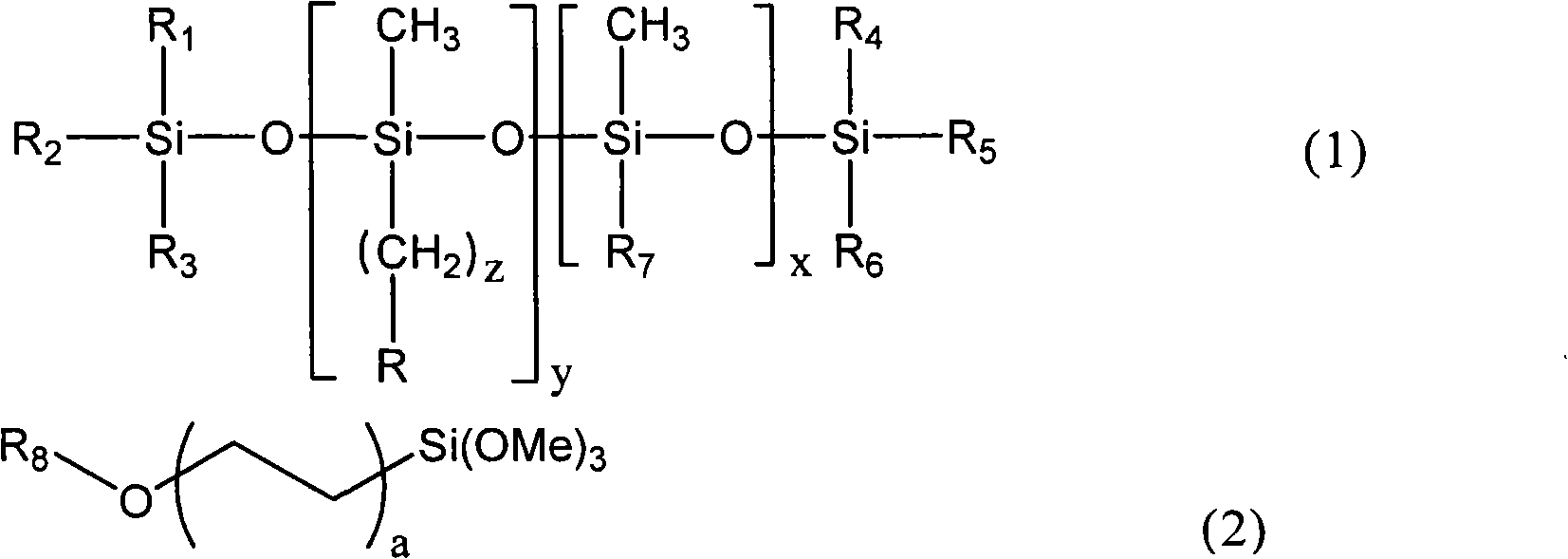

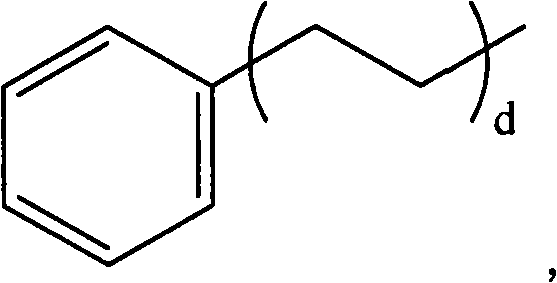

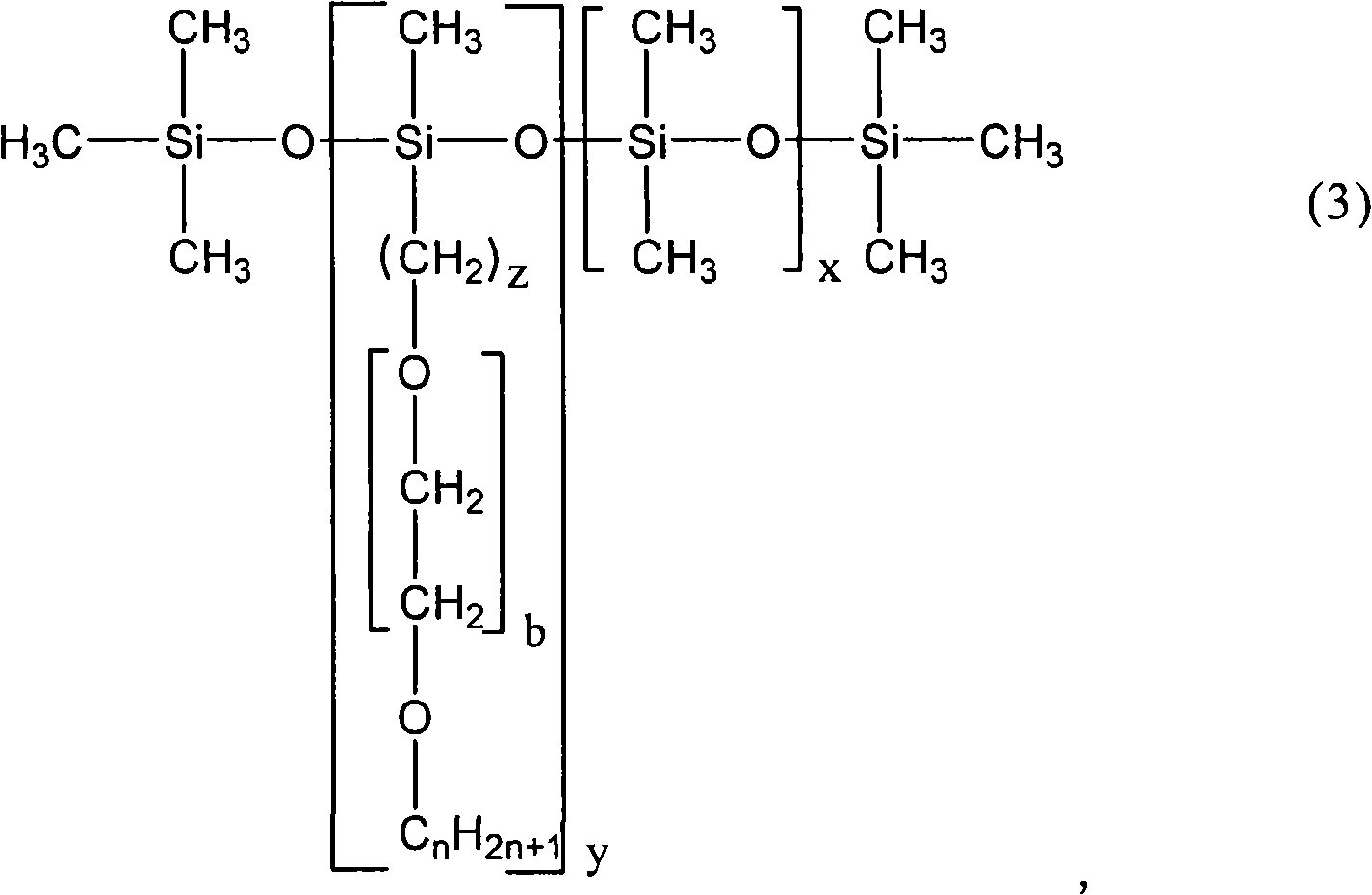

A composition and coating technology, applied in polyester coatings, polyether coatings, polyamide coatings, etc., can solve the problems of insufficient coating resistance and adhesion, and poor antistatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Get the acrylate resin solution E-7713 of 100 parts by weight (Changxing Company, solid content about 25%), then add the nonionic antistatic agent (Ref.No.9398-0155-R2, Marubishi Oil Chemical company, about 30% of solid content), 0.3 parts by weight of antistatic auxiliary agent Dow Corning 57 Additive (Dow Corning Company, polyether modified polydimethylsiloxane), and 1 part by weight of crosslinking agent Desmodur N75 (Bayer company, isocyanate, solid content about 75%), after being uniformly stirred, a coating composition was obtained. After standing for defoaming, apply the composition on one side of a polyethylene terephthalate (PET) film (T100G-38, 38 microns in thickness, produced by Mitsubishi Chem.) with a wire rod coating rod superior. Then, it was dried at 120° C. for 2 minutes to evaporate the solvent to obtain a coating with a solid coating weight of about 20 g / m 2 .

[0052] The samples prepared above were evaluated for the surface resistance value. Usi...

Embodiment 2

[0058] Repeat the preparation steps and test method described in Example 1, but add 0.3 parts by weight of antistatic additive BYK-333 (Byk Chemicals, polyether modified alkylsiloxane), the test results are shown in Table 1 listed in.

Embodiment 3

[0060] The preparation steps and test method described in Example 1 were repeated, but 1 part by weight of antistatic additive BYK-340 (Byk Chemicals, fluorine compound) was added. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com