Antibacterial color master batch for polystyrene hard plastic toys

A polystyrene and polystyrene technology, applied in the field of plastics, can solve the problems of non-washability, discoloration, and peculiar smell, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

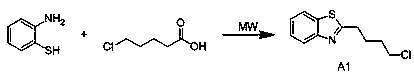

[0032] see figure 1 and figure 2 As shown, the preparation of the modifier

[0033] Q1. Add 0.1mol o-aminothiophenol, 0.12mol 5-chlorovaleric acid, 10mmol cesium carbonate and 300ml solvent dioxane in the reaction flask, stir and mix evenly, then transfer to the microwave reactor, microwave heating reaction The power is 560W, the temperature is 115°C, and the reaction time is 3h. After the reaction is completed, cool to room temperature and recrystallize from absolute ethanol to obtain the thiazole intermediate A1;

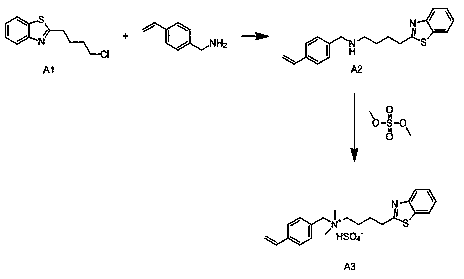

[0034] Q2. Weigh 10mmol of thiazole intermediate A and 12mmol of 4-vinylbenzylamine into the reaction flask, add 100ml of ethanol aqueous solution with a mass fraction of 90%, stir and dissolve, then add 15ml of a 20% mass fraction of hydroxide Sodium aqueous solution, after adding, heat up to 105°C while stirring, and stir for 6 hours. After the reaction, separate the liquid, separate the organic phase and the water phase, add 10ml of 20% sodium hydroxide aque...

Embodiment 2

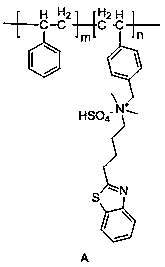

[0038] Preparation of modified polystyrene

[0039] Add 10g of styrene monomer, 0.2g of cuprous chloride and 200ml of solvent xylene in the reaction kettle, stir and mix evenly, add 0.15g of initiator dibenzoyl peroxide, feed nitrogen, replace the Air, heat up to 95°C while stirring, carry out pre-polymerization for 30min, then cool down to 50°C, add 1.8g modifier A3 and 0.15g initiator dibenzoyl peroxide, continue to heat up to 95°C, and stir for 3h Polycondensation reaction, add 200ml methanol to precipitate the product, after washing with water and drying, you can get the following image 3 The modified polystyrene of formula A structure.

[0040] The infrared characterization of modified polystyrene is as follows: IR(KBr): (benzene ring), 2898(-CH 2 -), 1624-1598 (thiazole ring), 1401 (C-N + )cm- 1 .

Embodiment 3

[0042] An antibacterial color masterbatch for polystyrene hard plastic toys, comprising the following raw materials in parts by weight: 100g modified polystyrene, 20g epoxy resin, 6g polyamide resin, 3g toner, 1g lubricant;

[0043] Described lubricant is zinc stearate;

[0044] The preparation method of this antibacterial color masterbatch comprises the following steps:

[0045] S1, first put the modified polystyrene, epoxy resin, polyamide resin, toner, and lubricant into a drying oven, and dry at 105°C for 10 hours;

[0046] S2, adding the dried raw materials in step S1 into a ball mill, and grinding and mixing for 60 minutes;

[0047] S3. Put the mixed raw materials into a screw extruder, melt and extrude at a temperature of 190-245° C., and after cooling, add to a granulator for granulation to obtain antibacterial color masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com