Graphene antistatic lithium-based sealing curing agent for concrete and preparation method of sealing curing agent

A sealing and curing agent and graphene technology, applied in the field of anti-static functional decorative coatings for concrete floors, can solve problems such as the inability of concrete sealing and curing agents to meet the requirements, and achieve the effects of reducing maintenance costs, improving strength and hardness, and increasing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A graphene antistatic concrete sealing and curing agent is composed of the following component mass ratios:

[0031] raw material Mass ratio / % water 55.5 Sodium dodecyl sulfonate 1 Condensate of Fatty Alcohol and Ethylene Oxide 1 5% graphene aqueous slurry (graphene: graphene oxide = 1:4) 0.5 Nano conductive mica powder 12 Lithium silicate 25 Water-based color paste 5 total 100

[0032] Its preparation method comprises the following steps:

[0033] (1) Add 55.5Kg of water into the dispersion tank, add 1Kg of sodium dodecylsulfonate and 1Kg of fatty alcohol and ethylene oxide condensate successively at low speed, and disperse 10mim at 1000RPM;

[0034] (2) Add 0.5Kg graphene water-based slurry (5%) and 12Kg nano conductive mica powder, after uniform dispersion, grind in a sand mill for 30min;

[0035] (3) Stir the ground components, 25Kg lithium silicate and 5Kg water-based color paste evenly.

Embodiment 2

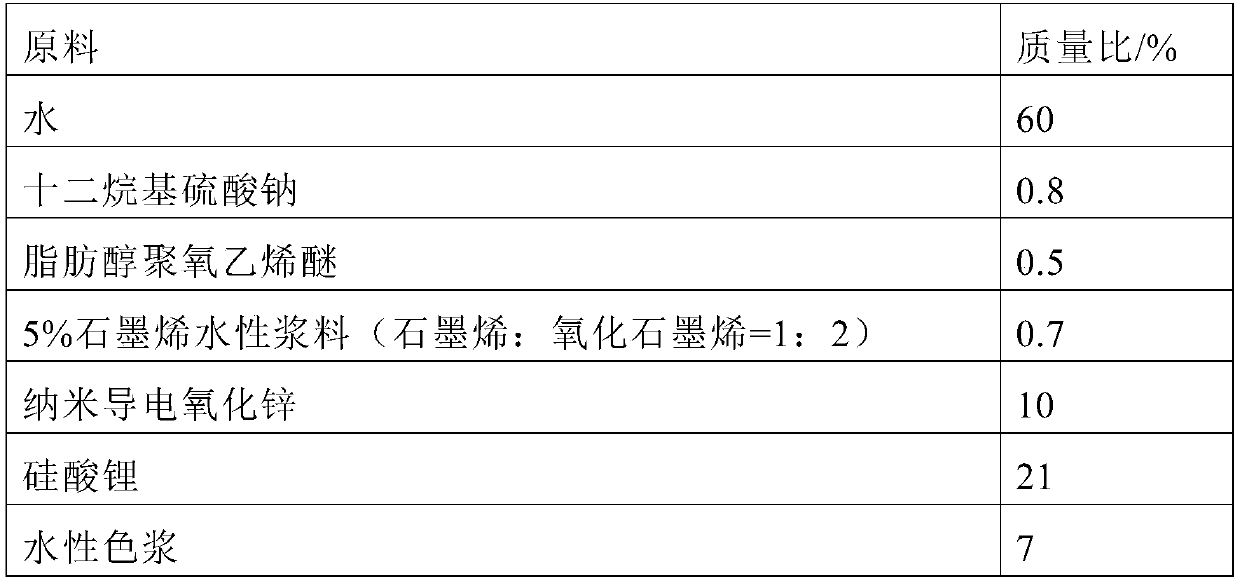

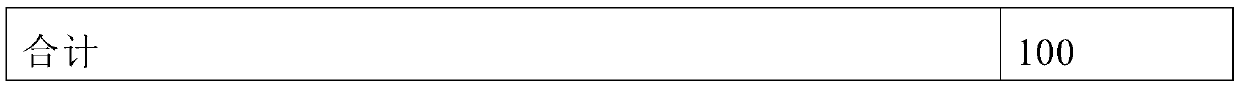

[0037] A graphene antistatic concrete sealing and curing agent is composed of the following component mass ratios:

[0038]

[0039]

[0040] Its preparation method comprises the following steps:

[0041] (1) Add 59Kg of water into the dispersion tank, add 0.8Kg of sodium lauryl sulfate and 0.5Kg of fatty alcohol polyoxyethylene ether in sequence at a low speed, and disperse for 10 minutes at 1000RPM;

[0042] (2) Add 0.7Kg graphene water-based slurry (5%) and 10Kg nano-conductive zinc oxide, after uniform dispersion, grind in a sand mill for 30 minutes;

[0043] (3) Stir the ground components, 21Kg lithium silicate and 7Kg water-based color paste evenly.

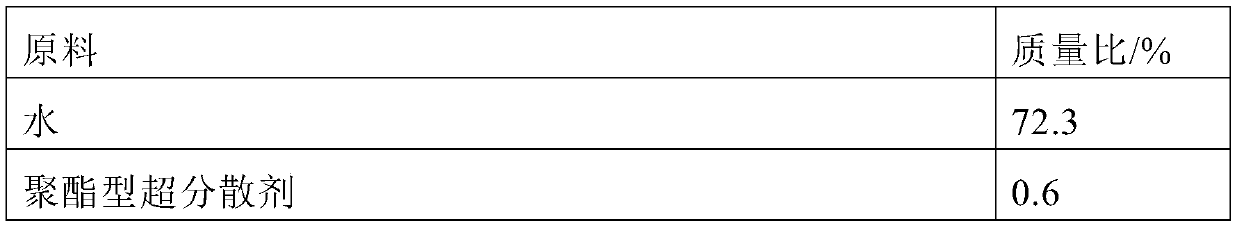

Embodiment 3

[0045] A graphene antistatic concrete sealing and curing agent is composed of the following component mass ratios:

[0046] raw material Mass ratio / % water 68.8 Sodium dodecyl sulfonate 0.6 Fatty alcohol polyoxyethylene ether 0.6 5% graphene aqueous slurry (graphene: graphene oxide = 1:1) 2 Nano conductive carbon black 4 conductive fiber 5 Lithium silicate 19 total 100

[0047] Its preparation method comprises the following steps:

[0048] (1) Add 68.8Kg of water into the dispersion tank, add 0.6Kg of sodium dodecylsulfonate and 0.6Kg of fatty alcohol polyoxyethylene ether in sequence at a low speed, and disperse at 1000RPM for 10min;

[0049] (2) Add 2Kg graphene aqueous slurry (5%) and 4Kg nanometer conductive carbon black and 5Kg conductive fiber, after dispersing evenly, grind in sand mill, grind 30min;

[0050] (3) Stir the ground components and 19Kg of lithium silicate evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com