Oil-proof, stain-resistant and flame-retardant composite fiber fabric

A flame-retardant composite and fabric technology, applied in the direction of flame-retardant fiber, fiber type, fiber treatment, etc., can solve the problems of increasing the number of washing by users, adsorption of fabric surface, a large amount of dirt and dust, etc., to reduce the number of washing, The effect of excellent oily dirt repellency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

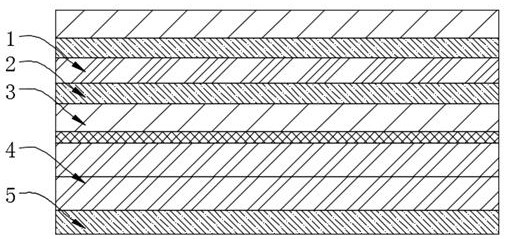

[0026] see figure 1 , the present invention provides a technical solution: an oil-resistant, anti-fouling, and flame-retardant composite fiber fabric, including a basic fabric 1, the upper surface and the lower surface of the basic fabric 1 are provided with a flame-retardant layer 2, and the two flame-retardant layers 2 are connected to each other. Waterproof and antifouling layers 3 are respectively arranged on one side of the repellent, and a non-woven fabric 4 is arranged under the base fabric 1, and the upper surface of the nonwoven fabric 4 is bonded to the lower surface of the waterproof and antifouling layer 3 at the bottom of the flame-retardant layer 2, The bottom of the non-woven fabric 4 is bonded with a backing material 5;

[0027] The oil-proof, anti-fouling and flame-retardant composite fiber fabric is prepared from the following materials: the ratio of materials in parts by weight is: 10 parts of basic fabric 1, 10 parts of flame-retardant layer 2, 10 parts of ...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution: an oil-resistant, anti-fouling, and flame-retardant composite fiber fabric, including a basic fabric 1, the upper surface and the lower surface of the basic fabric 1 are provided with a flame-retardant layer 2, and the two flame-retardant layers 2 are connected to each other. Waterproof and antifouling layers 3 are respectively arranged on one side of the repellent, and a non-woven fabric 4 is arranged under the base fabric 1, and the upper surface of the nonwoven fabric 4 is bonded to the lower surface of the waterproof and antifouling layer 3 at the bottom of the flame-retardant layer 2, The bottom of the non-woven fabric 4 is bonded with a backing material 5;

[0044]The oil-repellent, anti-fouling and flame-retardant composite fiber fabric is prepared from the following materials: the ratio of materials in parts by weight is: 15 parts for the basic fabric 1, 15 parts for the flame-retardant layer 2,...

Embodiment 3

[0060] see figure 1 , the present invention provides a technical solution: an oil-resistant, anti-fouling, and flame-retardant composite fiber fabric, including a basic fabric 1, the upper surface and the lower surface of the basic fabric 1 are provided with a flame-retardant layer 2, and the two flame-retardant layers 2 are connected to each other. Waterproof and antifouling layers 3 are respectively arranged on one side of the repellent, and a non-woven fabric 4 is arranged under the base fabric 1, and the upper surface of the nonwoven fabric 4 is bonded to the lower surface of the waterproof and antifouling layer 3 at the bottom of the flame-retardant layer 2, The bottom of the non-woven fabric 4 is bonded with a backing material 5;

[0061] The oil-proof, anti-fouling and flame-retardant composite fiber fabric is prepared from the following materials: the ratio of materials in parts by weight is: 20 parts of the basic fabric 1, 20 parts of the flame-retardant layer 2, 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com