Novel antistatic ABS composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of antistatic ABS composite materials and its preparation, can solve the problems of difficult formation of conductive paths, easy generation of stress concentration areas, and decline in mechanical properties, and achieve good mechanical strength, good conductivity, The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

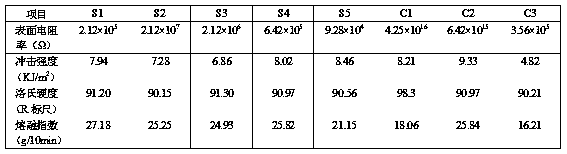

Examples

Embodiment 1

[0028] In parts by weight, weigh 23 parts of ABS powder, 70 parts of SAN resin, 5 parts of compatibilizer 1, 2 parts of antistatic agent, and 0.1 part of antioxidant.

[0029] The manufacturing method of the above-mentioned embodiment: weigh the above raw materials according to the proportion by weight, put them into an oven to dehumidify and dry, then add the raw materials to a mixer and stir them evenly, and extrude them in a twin-screw extruder. Each temperature zone of the extruder The range is 200-220°C and the screw speed is 150-450rpm. The extruded strands are cooled and hardened in a circulating water tank, and then cut and granulated by a pelletizer to obtain finished products of small particles. The ABS composite material is injected through an injection molding machine to obtain a sample for performance testing.

Embodiment 2

[0031] In parts by weight, 23 parts of ABS powder, 70 parts of SAN resin, 5 parts of compatibilizer 2, 2 parts of antistatic agent and 0.2 part of antioxidant were weighed respectively.

[0032] The manufacturing method of the above-mentioned embodiment: weigh the above raw materials according to the proportion by weight, put them into an oven to dehumidify and dry, then add the raw materials to the mixer and stir them evenly, and extrude them in a twin-screw extruder. The range is 200-220°C and the screw speed is 150-450rpm. The extruded strands are cooled and hardened in a circulating water tank, and then cut and granulated by a pelletizer to obtain finished products of small particles. The ABS composite material is injected through an injection molding machine to obtain a sample for performance testing.

Embodiment 3

[0034] In parts by weight, weigh 23 parts of ABS powder, 70 parts of SAN resin, 5 parts of compatibilizer 3, 2 parts of antistatic agent, and 0.3 parts of antioxidant.

[0035] The manufacturing method of the above-mentioned embodiment: weigh the above raw materials according to the proportion by weight, put them into an oven to dehumidify and dry, then add the raw materials to the mixer and stir them evenly, and extrude them in a twin-screw extruder. The range is 200-220°C and the screw speed is 150-450rpm. The extruded strands are cooled and hardened in a circulating water tank, and then cut and granulated by a pelletizer to obtain finished products of small particles. The ABS composite material is injected through an injection molding machine to obtain a sample for performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com