Static-electricity proof tile

An anti-static, ceramic tile technology, applied in the direction of coatings, building components, layered products, etc., can solve the problems of difficult surface resistance reduction, static electricity, and volume resistance cannot be reduced, so as to prevent bleeding and peeling The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 (surface resistance of ceramic tile of the present invention)

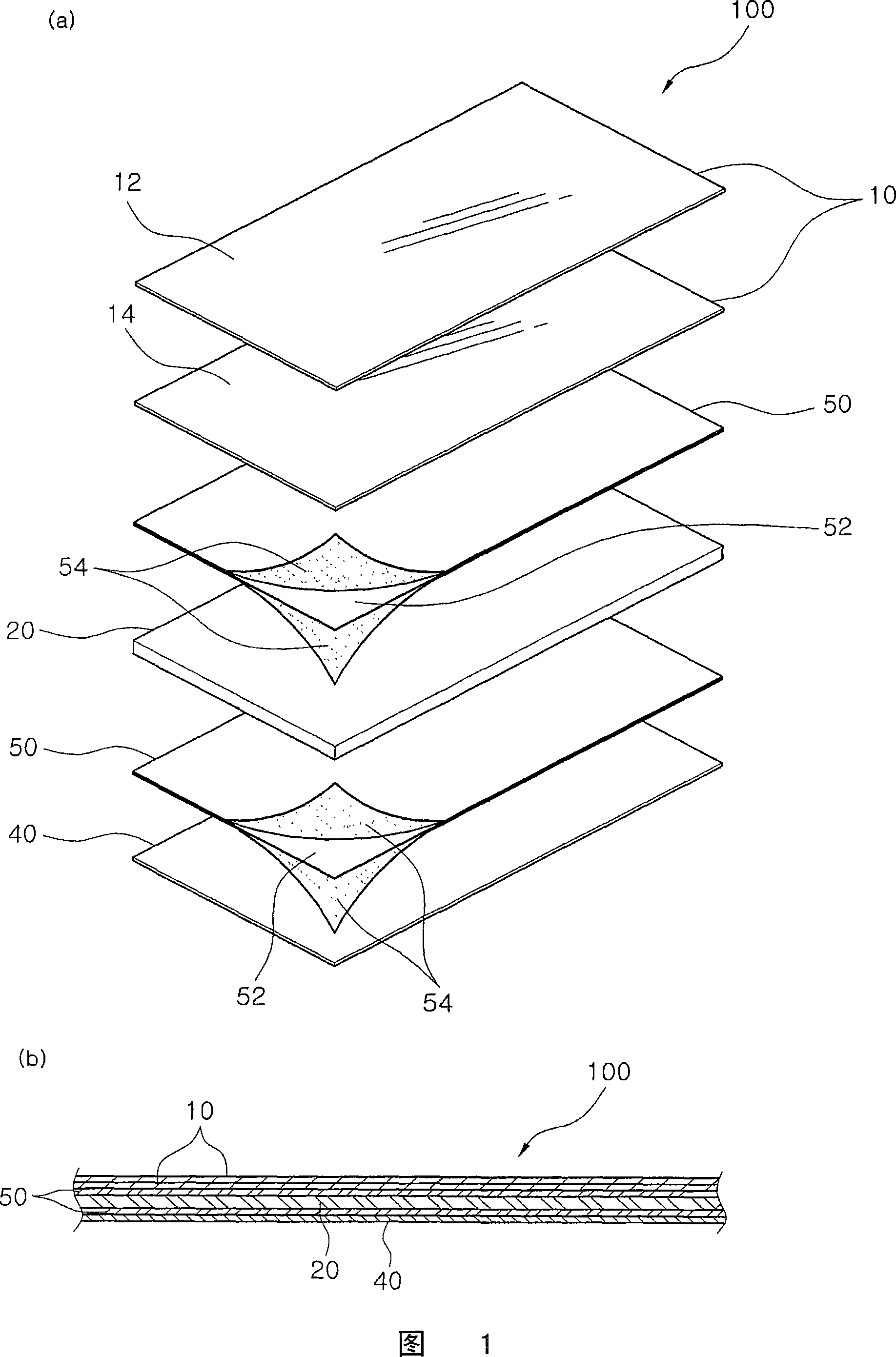

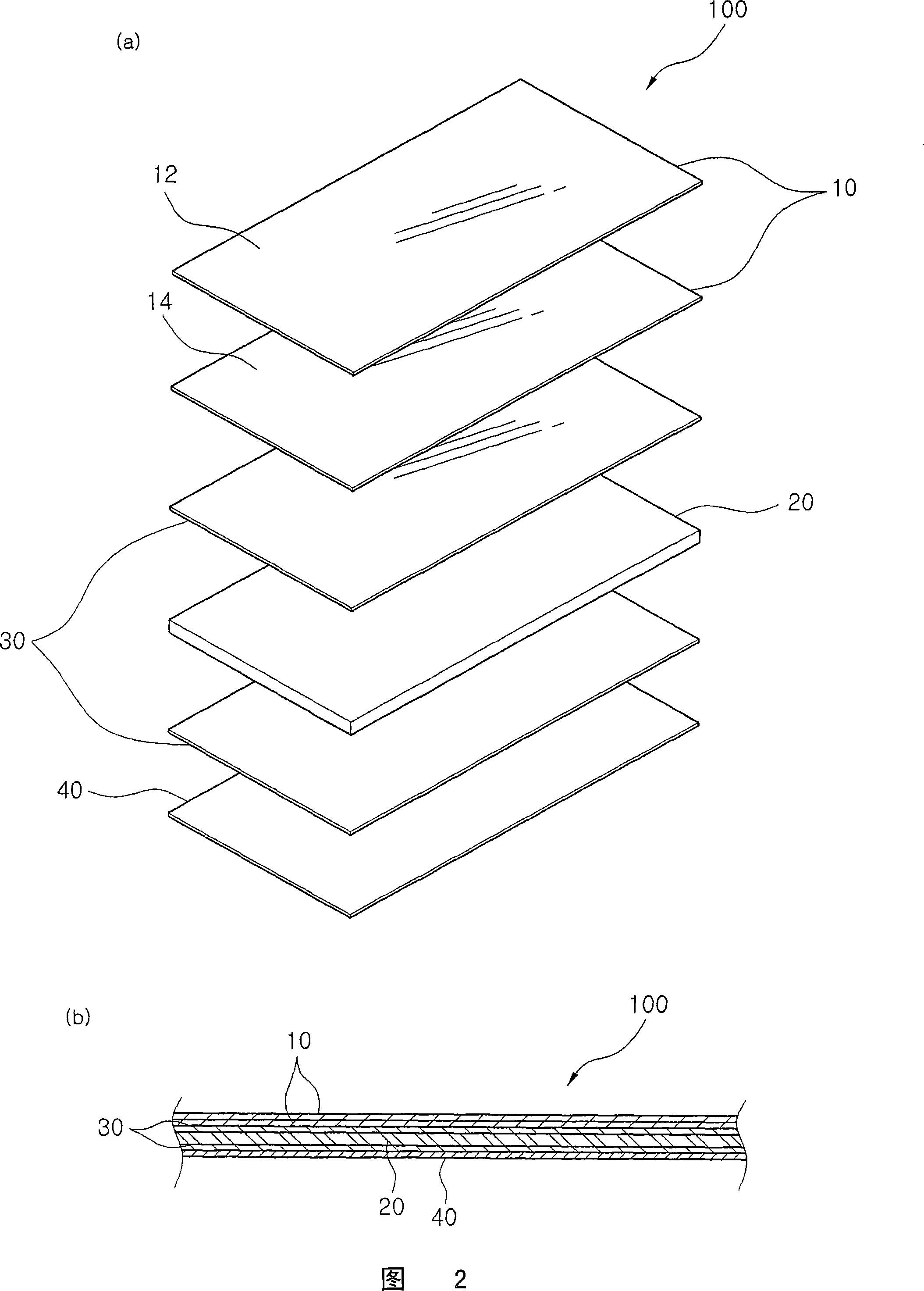

[0050] Coat carbon on the conductive unit (40) positioned at the lower surface of the above-mentioned lower layer, add 5% (volume ratio) surfactant in the lower layer, insert its upper and lower sides between the upper layer (10) and the lower layer (20) and coat Aluminum sheet (52) made of polyethylene, and the results of evaluating the resistance between electrodes on the same plane showed that its surface resistance was 10 8 Ω / cm 2 And it is lower than the existing antistatic ceramic tile (100), which not only contributes to the antistatic effect, but also can exert the electromagnetic wave shielding effect as shown below.

Embodiment 2

[0051] Embodiment 2 (volume resistance of ceramic tile of the present invention)

[0052] In the invention of the above-mentioned embodiment 1, the resistance value is measured after the electrodes are arranged along the thickness direction, and it can be known that when the volume resistance is arranged along the thickness direction, the volume resistance value is 10 8 Ω / cm 2 .

[0053] Therefore, the volume resistance on the embodiment of the present invention is changed from 10 14 Ω / cm 2 down to 10 8 Ω / cm 2 When the overall conductivity of the tile is highlighted, it can effectively reduce static electricity.

Embodiment 3

[0054] Embodiment 3 (electromagnetic wave shielding experiment of ceramic tile of the present invention)

[0055] When testing the electromagnetic wave shielding ability of the antistatic ceramic tile of the present invention, use the "ASTM D4935-89" test method to measure, and its decibel value (A) is 8 ± 05dB.

[0056] Therefore, the above-mentioned test method (A) is substituted into the calculation formula of the electromagnetic wave shielding effect (shielding effect (%)=(1-10 -A / 10 )×100%), it is known that it can shield 82.21%~~85.87% of electromagnetic waves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com