Pole seal material for lithium ion batteries and preparation method of pole seal material for lithium ion batteries

A sealing material and lithium battery technology, applied in the field of modified rubber, can solve the problems of poor high-temperature pressure change performance, low tensile strength, low resistivity, etc., and achieve excellent high-temperature pressure change, improved processing performance, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

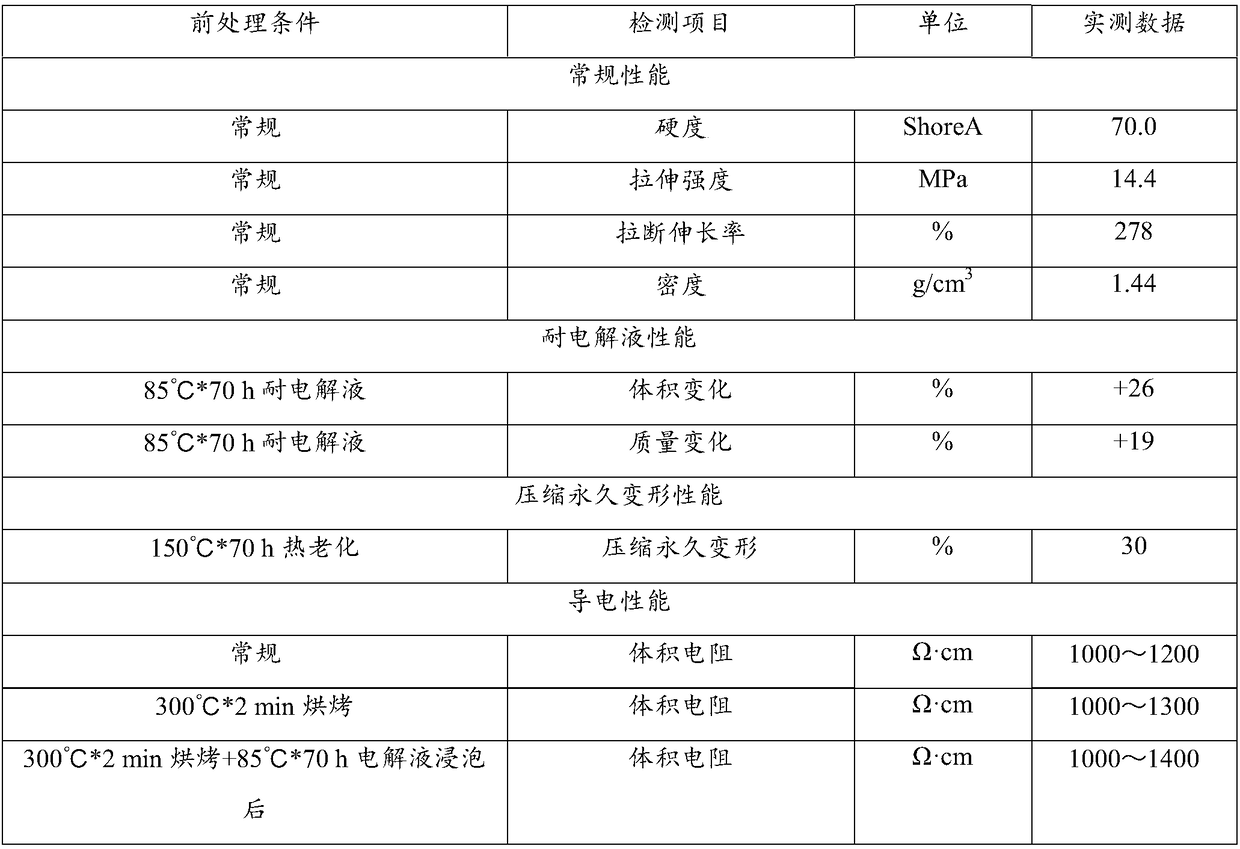

Embodiment 1

[0038] As an embodiment of the pole sealing material of the lithium battery described in the present invention, the pole sealing material of the lithium battery described in this embodiment includes the following components in parts by mass: 70 parts of fluorine rubber, 30 parts of ethylene propylene rubber, super 7 parts of conductive carbon black, 6 parts of weak conductive carbon black, 3 parts of mixture of natural fatty acid calcium salt and amide fat wax, 1 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane 0.5 parts, 0.5 parts of dicumyl peroxide and 2.5 parts of triallyl isocyanurate.

[0039] The BET specific surface area of superconducting carbon black described in the present embodiment is 1000m 2 / g, the BET specific surface area of the weakly conductive carbon black is 800m 2 / g.

[0040] The preparation method of the pole sealing material of the lithium battery described in this embodiment comprises the following steps:

[0041] 1. Make the roller distan...

Embodiment 2

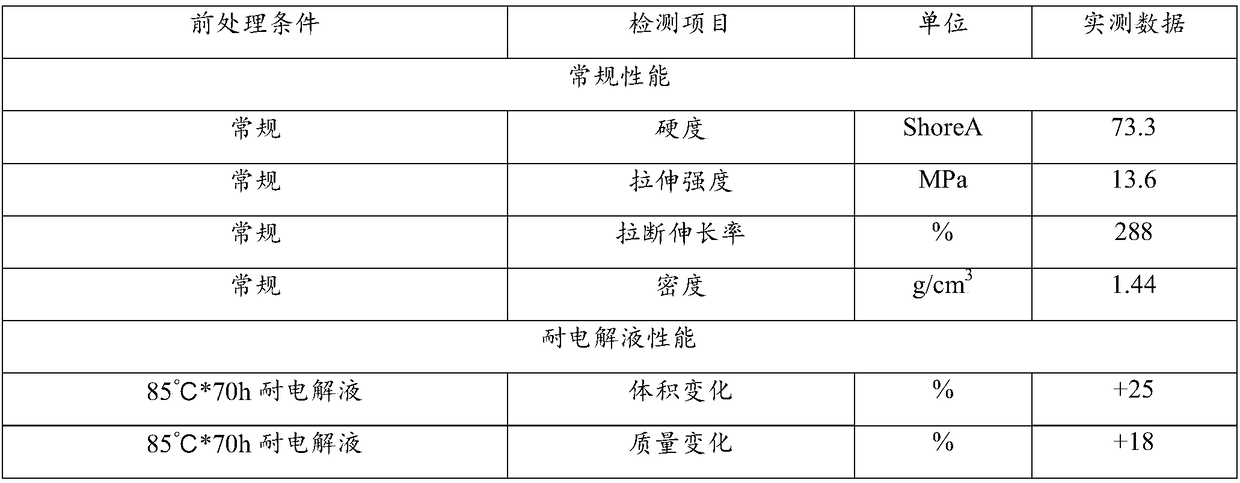

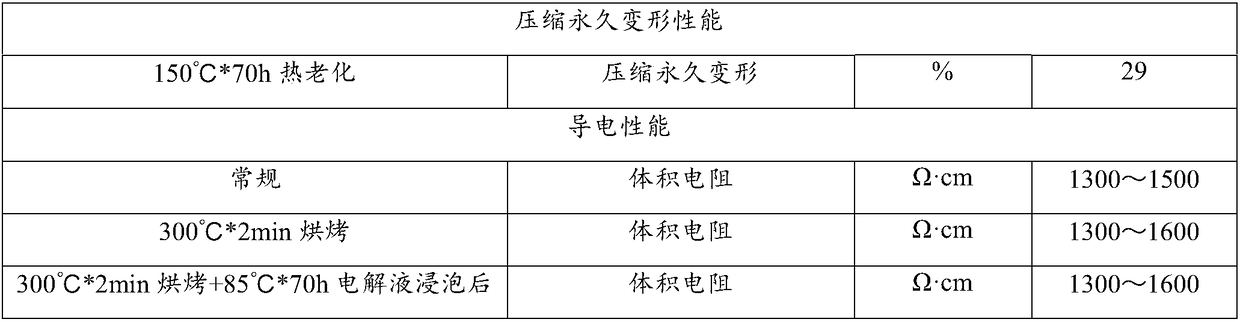

[0049] As an embodiment of the pole sealing material of the lithium battery described in the present invention, the pole sealing material of the lithium battery described in this embodiment includes the following components in parts by mass: 75 parts of peroxide vulcanized fluororubber, ethylene-propylene rubber 25 parts, 11 parts of superconducting carbon black, 1 part of aliphatic hydrocarbon processing aid, 1 part of wax processing aid, 1 part of organosilicon compound, 0.5 part of magnesium aluminum hydrotalcite, 2,5-dimethyl-2, 1 part of 5-bis(tert-butylperoxy)hexane, 0.5 part of dicumyl peroxide, 1 part of triallyl isocyanurate and N, N'-m-phenylene bismaleimide 1 part of amine.

[0050] The Mooney viscosity [ML (1+10) 121 ℃] of peroxide vulcanized fluororubber in the present embodiment is 17~33, and fluorine content is 69wt%~71wt%; The Mooney viscosity [ML( 1+4) 100°C] is 8 to 55, and the ethylene content is 45wt% to 54wt%; the BET specific surface area of the superc...

Embodiment 3

[0061] As an embodiment of the pole sealing material of the lithium battery described in the present invention, the pole sealing material of the lithium battery described in this embodiment includes the following components in parts by mass: 72 parts of peroxide vulcanized fluororubber, ethylene-propylene rubber 28 parts, 15 parts of superconducting carbon black, 1 part of aliphatic hydrocarbon derivatives, 0.5 parts of organosilicon compound, 2 parts of magnesium aluminum hydrotalcite, 2,5-dimethyl-2,5-bis(tert-butyl peroxy base) 1.5 parts of hexane, 1.5 parts of dicumyl peroxide, 1 part of triallyl isocyanurate and 1.5 parts of N, N'-m-phenylene bismaleimide.

[0062] The Mooney viscosity [ML (1+10) 121 ℃] of peroxide vulcanized fluororubber in the present embodiment is 17~33, and fluorine content is 69wt%~71wt%; The Mooney viscosity [ML( 1+4) 100°C] is 8 to 55, and the ethylene content is 45wt% to 54wt%; the BET specific surface area of the superconducting carbon black is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com