Modified carbon nanotube flame retardant reinforced polyester composite material and preparation method thereof

A technology of polyester composite materials and carbon nanotubes, which is applied in the field of nanomaterials and plastic processing, can solve the problems of difficult uniform dispersion of carbon nanotubes, achieve broad market application prospects, improve flame retardancy and mechanical properties, and improve dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Place 0.2 g of aminated multi-walled carbon nanotubes, 1.4 g of triethylamine and 50 ml of N,N-dimethylformamide in a three-necked flask, and add 3.0 g of diphenyl Phosphinoyl chloride, after the dropwise addition, continue to react for 2 hours under ice bath and nitrogen conditions, then raise the temperature to 80°C, and react under nitrogen conditions for 24 hours, and finally filter, wash and dry the obtained product to obtain a black solid that is organic Phosphine modified carbon nanotubes.

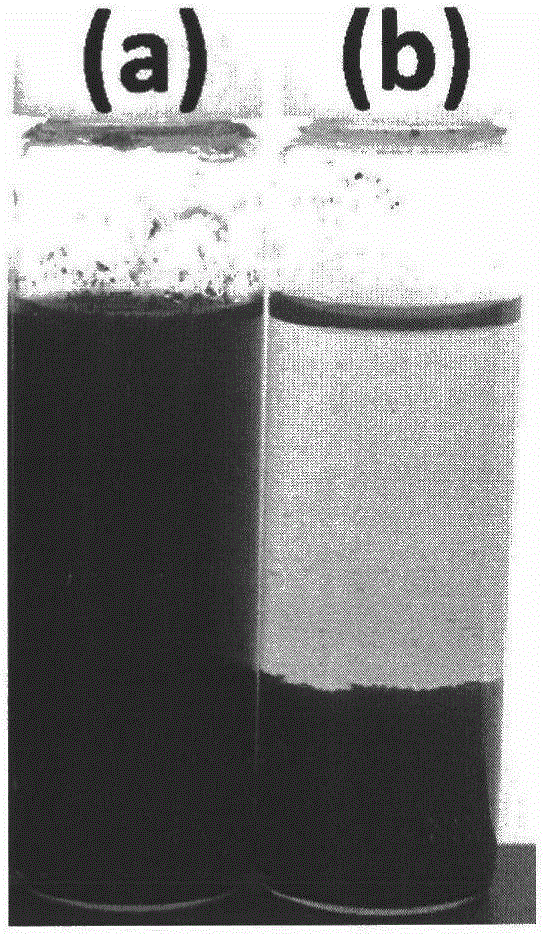

[0030] From figure 1 It can be clearly seen that the organophosphine-modified carbon nanotubes prepared by the present invention have better dispersibility in organic solvents.

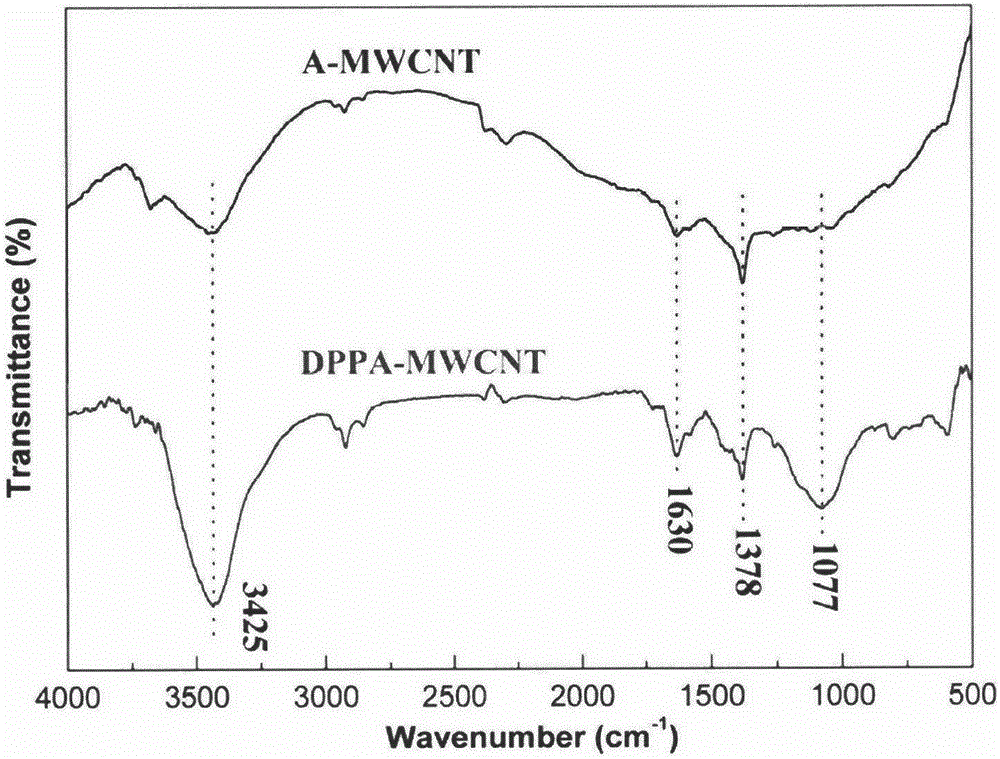

[0031] From figure 2 It can be seen from the spectrum that the most significant difference between the two is that the organic phosphine modified carbon nanotube (DPPA-MWCNT) is at 1077cm -1 A strong and broad absorption peak appeared at , which corresponds to the stretching vibration absorption ...

Embodiment 2

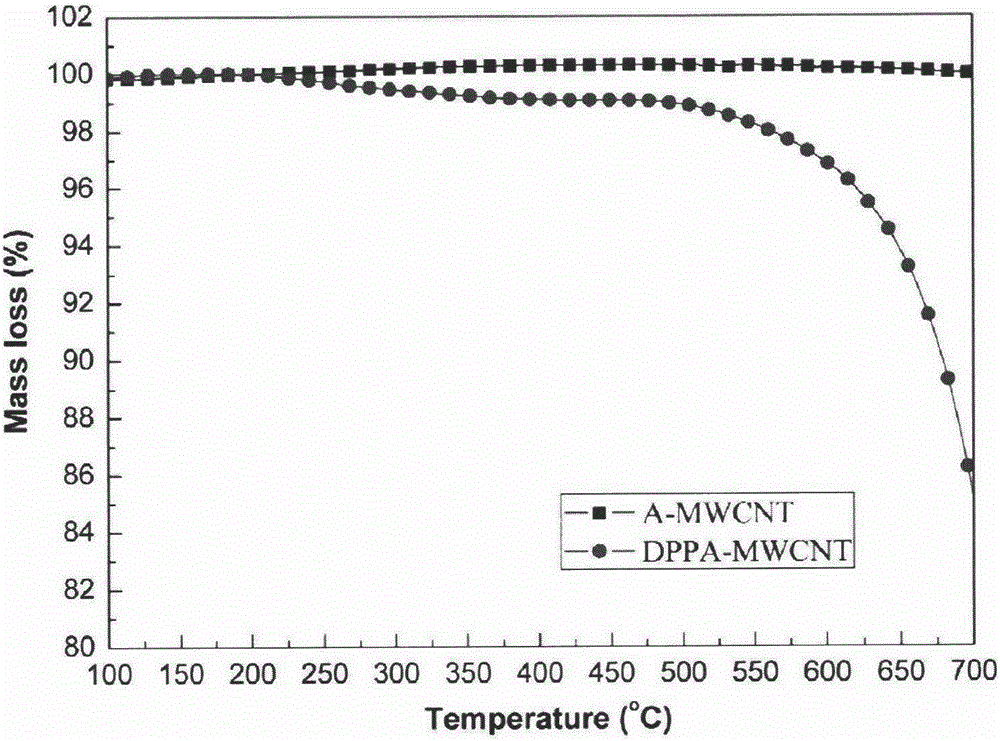

[0034] 0.2 g of aminated single-walled carbon nanotubes, 0.7 g of pyridine and 50 ml of tetrahydrofuran were placed in a three-necked flask, and 2.0 g of diphenylphosphinic chloride was added dropwise under ice bath and nitrogen conditions. Bath and nitrogen conditions continue to react for 1 hour, then heat up to 70 ° C, react under nitrogen conditions for 12 hours, and finally filter, wash, and dry the resulting product to obtain a black solid that is approximately figure 1 photo, figure 2 and 3 Organophosphine-modified carbon nanotubes shown in the curve.

Embodiment 3

[0036] Place 0.2 g of aminated single-walled carbon nanotubes, 1.4 g of pyridine, and 50 ml of N,N-dimethylformamide into a three-necked flask, and add 4.0 g of diphenylphosphine dropwise under ice bath and nitrogen conditions Acyl chloride, after the dropwise addition, continue to react in ice bath and nitrogen for 3 hours, then raise the temperature to 90°C, react in nitrogen for 36 hours, and finally filter, wash and dry the resulting product to obtain a black solid that is approximately figure 1 photo, figure 2 and 3 Organophosphine-modified carbon nanotubes shown in the curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com