Antistatic powder coating and preparation method thereof

A powder coating and anti-static technology, applied in powder coatings, conductive coatings, anti-corrosion coatings, etc., can solve the problems of anti-static powder without specific solutions, high material cost, affecting powder coating rate and decoration, etc. , to avoid oxidation and structural damage, reduce low utilization rate, and ensure the effects of electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Among the present invention, for the preparation method of described antistatic powder coating, comprise following operation steps:

[0058] a. Put the raw materials in the A component into the high-speed mixer according to the mass percentage to mix to obtain the premix; the speed of the high-speed mixer is 1500-2500r / min, and the high-speed mixing time is 2 -15min;

[0059] b. Add the premixed material in step a into a high-temperature extruder, melt and knead, cool and tablet to make a tablet material, and then finely pulverize the tablet material, and sieve the particle size to D50 It is 15-50μm powder particles, which is made into the powder of component A;

[0060] c. After mixing the component A powder and the component B material prepared in step b according to the weight ratio of 200-20:1, put them into the micropowder agglomeration equipment; obtain agglomerates; micronize the agglomerates, Sieve until the D50 is 20-50μm powder particles, which is made into ...

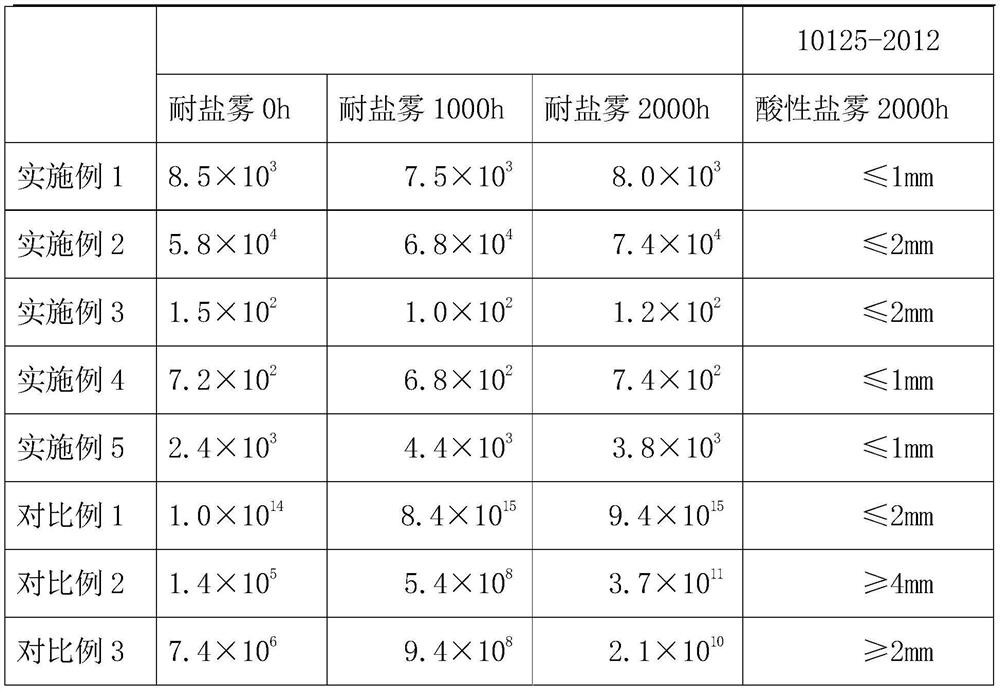

Embodiment 1

[0063] The antistatic powder coating of the present embodiment is made by following A, B component by weight percentage 100:1:

[0064] Described A component comprises the raw material composition of following weight percent:

[0065] Resin: 60.0%

[0066] Curing agent: 3.0%

[0067] Leveling agent: 1.0%

[0068] Defoamer: 0.5%

[0069] Coupling agent: 2.0%

[0070] Booster: 0.3%

[0071] Other additives: 2.0%

[0072] Pigments and fillers: 31.2%

[0073] Described B component comprises the raw material composition of following weight percent:

[0074] Composite conductive additive: 85.0%

[0075] Organic acid modified stabilizer: 12.5%

[0076] Coupling agent: 2.0%

[0077] Dispersant: 0.5%

[0078] Wherein, the resin is an epoxy resin; the curing agent includes substituted dicyandiamide; the coupling agent includes a modified siloxy-modified polymer; the composite conductive additive is a graphene modified conductive additive The mass ratio of the alignment agent...

Embodiment 2

[0084] The antistatic powder coating of the present embodiment is made by following A, B component by weight percentage 200:1:

[0085] Described A component comprises the raw material composition of following weight percent:

[0086] Resin: 80.0%

[0087] Curing agent: 6.0%

[0088] Leveling agent: 1.2%

[0089] Defoamer: 0.3%

[0090] Coupling agent: 1.0%

[0091] Booster: 0.5%

[0092] Other additives: 2.5%

[0093] Pigments and fillers: 8.5%

[0094] Described B component comprises the raw material composition of following weight percent:

[0095] Composite conductive additive: 40.0%

[0096] Organic acid modified stabilizer: 55.0%

[0097] Coupling agent: 3.0%

[0098] Dispersant: 2.0%

[0099] Wherein, the resin is a carboxyl-terminated polyester resin; the curing agent is triglycidyl isocyanurate; the coupling agent is a modified organosiloxane polymer; the composite conductive additive is graphene The mass ratio of the modified conduction aid to the alignme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com