Method for preparing nano composite material of hydroxyl-functional polyester/montmorillonite

A nano-composite material and hydroxyl-functional technology are applied in the preparation of hydroxyl-functional polyester/montmorillonite nano-composite materials, and in the field of in-situ polymerization to prepare hydroxyl-functional polyester/montmorillonite nano-composite materials, which can solve the problem of difficult to achieve Industrialization, insufficient intercalation, difficult molecular chain movement, etc., to achieve the effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

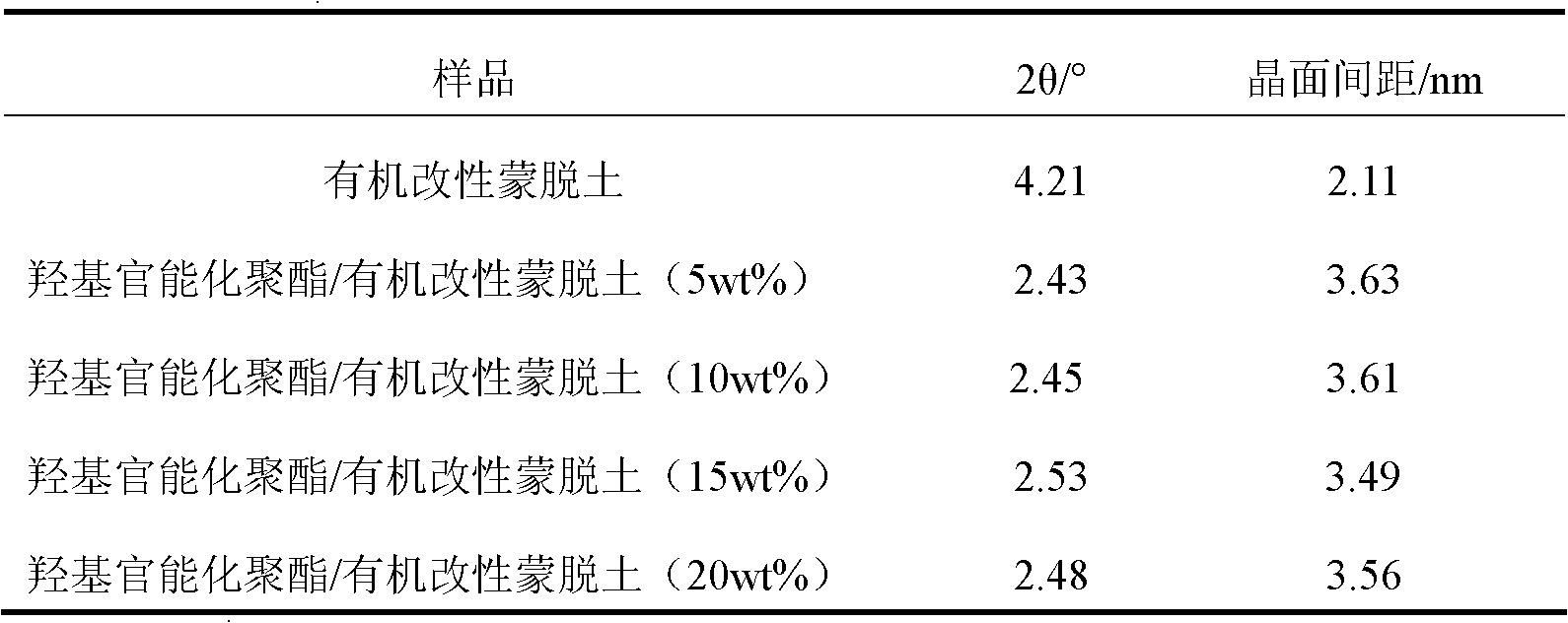

[0032] (1) Weigh 4g of sodium-based montmorillonite and 200ml of deionized water, mix them in a three-necked flask and heat them in a constant temperature water bath at 80°C, and prepare a montmorillonite suspension under stirring; weigh cetyl tri Dissolve 3 g of methyl ammonium bromide (greater than the ion exchange capacity of sodium montmorillonite) in 100 ml of deionized water to prepare a catalyst solution; add the catalyst solution dropwise to a three-neck flask in a constant temperature water bath at 80°C under stirring, and react for 2 hours ; stop heating at constant temperature; stand still, the obtained white precipitate is suction filtered, and washed 3 times with deionized water, the unexchanged catalyst is removed, and dried to obtain organically modified montmorillonite, which is analyzed by XRD. The interlayer spacing of soil increased from 1.24nm before organic modification to 2.11nm after organic modification.

Embodiment 2~5

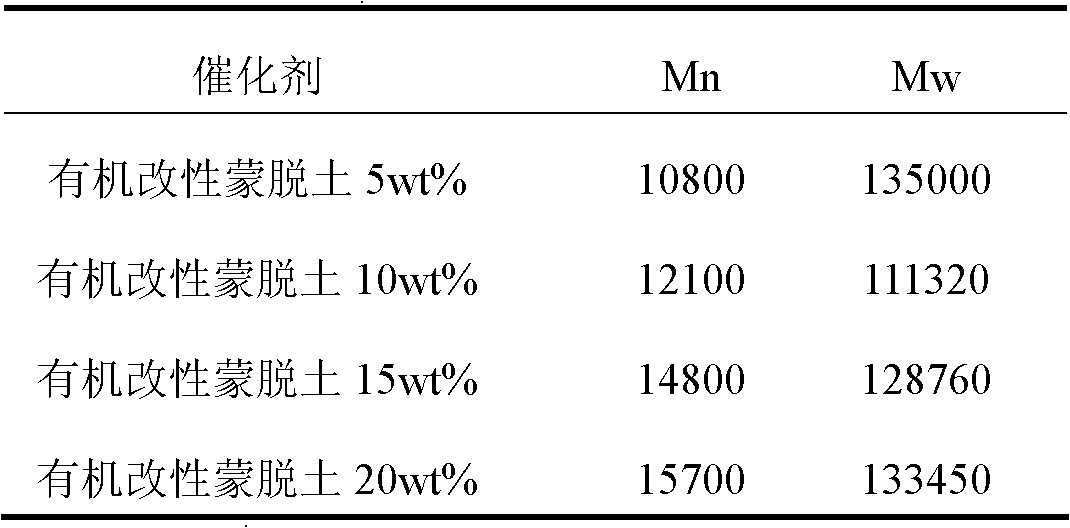

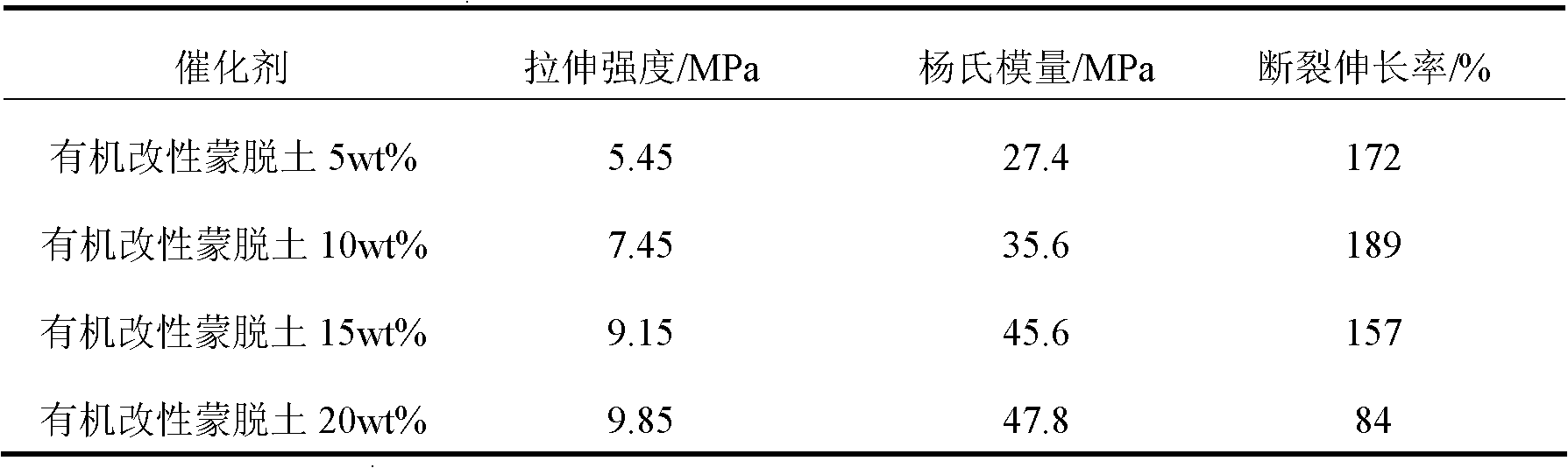

[0034]Get 18.6g (0.05mol) of bisphenol A epoxy resin, 6.74g (0.033mol) of sebacic acid, 2.44g (0.017mol) of adipic acid and 0.244g (4mol) of benzoic acid are placed in a three-necked flask, prepare the same 5 of the three-necked flasks were added the organically modified montmorillonite prepared in Example 1, and the additions were 1.41g (5wt%), 2.8g (10wt%), 4.2g (15wt%) and 5.6g respectively. g (20 wt%). Put the three-necked flask into silicone oil, at 140°C, N 2 The reaction was stirred mechanically under protection. Sampling every 20 minutes during the reaction, until the hydroxyl functionalized polyester in the sample is insoluble in N, N-dimethylformamide (DMF), stop the reaction; the last DMF-soluble sample is described in the present invention An in situ polymerization of hydroxyl-functionalized polyester / montmorillonite nanocomposites for detection and analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com