Preparation method and application for biomass fibre-aliphatic polyester composite material macromolecular coupling agent

A technology of macromolecular coupling agent and biomass fiber is applied in the field of preparing aliphatic polyester composite materials to achieve the effect of improving comprehensive performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method and application of a biomass fiber-aliphatic polyester composite material macromolecular coupling agent, comprising the following steps:

[0037] Step 1, preparation of biomass-based macromolecular coupling agent product:

[0038] Dissolve the biomass-based component in a suitable aprotic solvent to obtain a solution with a mass concentration of 0.1%~10%, stir for 1~20min under the protection of an inert gas, and use a 1:1~1:3 reactive group The molar ratio is added dropwise to the esterification reaction reagent, and the reaction is stirred at 30-70°C for 8-48 hours; the product after the above-mentioned stirring reaction is precipitated in 2-20 times the volume of deionized water, separated and precipitated, and the biomass-based macromolecular coupling is obtained. agent product;

[0039] Step 2, surface treatment of biomass fibers:

[0040] Continue to dissolve the biomass-based macromolecular coupling agent obtained in step 1 in an aprotic s...

Embodiment 1

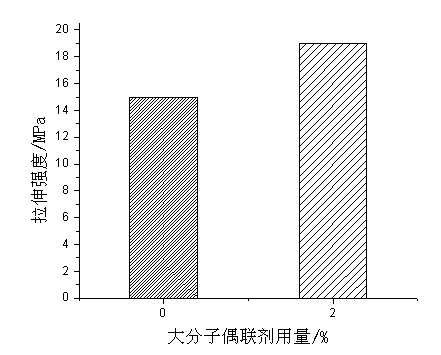

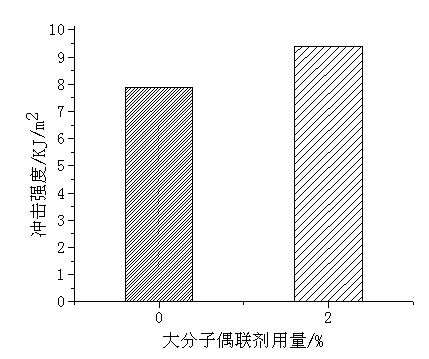

[0048] (1) Synthesis of lignin-based macromolecular coupling agent: Dissolve 5g sulfate lignin in 100ml DMF, pass N 2 Stir for 10 min under protected conditions, add lauroyl chloride dropwise at a molar ratio of reactive groups of 1:1.2, stir and react at 50°C for 24 h, the obtained product is precipitated in 6 times the volume of deionized water to obtain a lignin-based macromolecular coupling agent product.

[0049] (2) Surface treatment of wood flour: Dissolve the obtained lignin-based macromolecular coupling agent in DMF to prepare a solution with a concentration of 5%. Surface treatment of 80-mesh poplar wood powder with the prepared solution, in which the amount of macromolecular coupling agent relative to the wood powder is 2% by mass ratio, stirred in a high-speed mixer at a speed of 2000rpm for 15min, and drummed at 100°C Air-dried for 12 hours to obtain surface-treated wood powder.

[0050] (3) Preparation of composite materials: Proportion materials according to t...

Embodiment 2

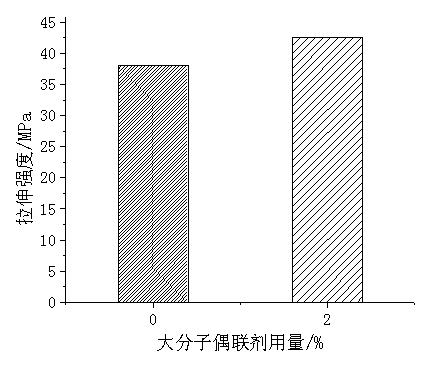

[0053] (1) Synthesis of cellulose-based macromolecular coupling agent: Dissolve 5g of hydroxyethylcellulose (HEC) in 100ml of DMF, pass through N 2 Stir under protected conditions for 10 min, drop octanoyl chloride at a molar ratio of reactive groups of 1:1.3, stir and react at 50°C for 24 h, the obtained product is precipitated in 8 times the volume of deionized water to obtain a cellulose-based macromolecular coupling agent product.

[0054] (2) Surface treatment of bamboo fiber: dissolve the obtained macromolecular coupling agent in DMF to prepare a solution with a concentration of 3%. The prepared solution is used for surface treatment of 80-mesh bamboo powder, wherein the amount of macromolecular coupling agent relative to the bamboo powder is 2% by mass ratio, stirred in a high-speed mixer at a speed of 2000rpm for 15min, and blasted at 100°C Dry for 12h.

[0055] (3) Preparation of composite materials: Proportion materials according to the following mass percentages: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com