Knitted fabric with one-way moisture guide function

A knitted fabric, unidirectional moisture guide technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of weak fiber surface contact strength, low processing efficiency, complex fabric processing technology, etc., to achieve good perspiration performance. Beneficial, strong hygroscopic breathability, good hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

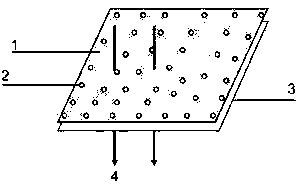

Image

Examples

Embodiment 1

[0023] A knitted fabric with unidirectional moisture-wicking function using new raw materials and a specific printing process; preparation of highly hydrophilic bio-based polyester fiber (raw material)→weaving of knitted fabric→dyeing process→printing process→unidirectional moisture-wicking knitted fabric.

[0024] The printing process is as follows: (1) Preparation of hydrophobic functional additives. The flat screen printing machine applies the hydrophobic functional additives to the reverse side of the fabric and forms a coating of hydrophobic functional additives on the surface of the fabric. The hydrophobic area of the agent and the hydrophilic area not coated with the hydrophobic additive, and then dried;

[0025] (2) Drying the dried fabric;

[0026] As a preferred technical solution:

[0027] In the step (1), the drying temperature of the hydrophobic functional additive after grouting is 130°C, and the vehicle speed is 40m / min;

[0028] The dryin...

Embodiment 2

[0031] A knitted fabric with unidirectional moisture-wicking function using new raw materials and a specific printing process; preparation of highly hydrophilic bio-based polyester fiber (raw material)→weaving of knitted fabric→dyeing process→special printing process→unidirectional moisture-wicking knitted fabric.

[0032] The printing process is as follows: (1) Preparation of hydrophobic functional additives. The flat screen printing machine applies the hydrophobic functional additives to the reverse side of the fabric and forms a coating of hydrophobic functional additives on the surface of the fabric. The hydrophobic area of the agent and the hydrophilic area not coated with the hydrophobic additive, and then dried;

[0033] (2) Drying the dried fabric;

[0034] (3) Low-temperature setting of the fabric after dry setting treatment;

[0035] As a preferred technical solution:

[0036] In the step (1), the drying temperature of the hydrophobic functional additive after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com