Cotton, model and nano silver-series antibacterial fine-denier poly propylene fiber scribbled and processing method thereof

A fine-denier polypropylene fiber and processing method technology, which is applied in the fields of yarn, textiles and papermaking, etc., can solve the problems such as the information on the production method of blended yarn that has not been consulted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is production 32 s Example of JC / MR antibacterial PP blended yarn.

[0013] Raw material ratio

[0014] Combed cotton JC35% average grade 2.12

[0015] Modal MR25% Orange Company

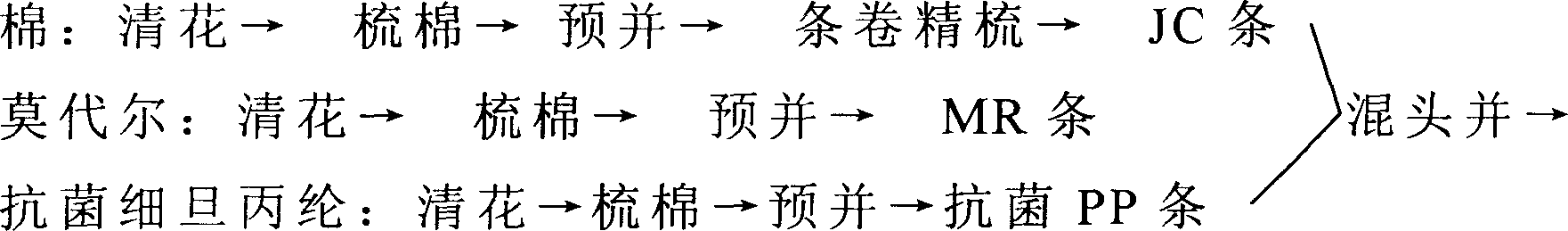

[0016] Nano-silver antibacterial fine denier polypropylene blended yarn staple fiber PP40% Saiteri Company. Processing technology flow:

[0017] Cotton: cleaning machine → carding machine → drawing frame → coiling machine → combing machine

[0018] Modal: cleaning machine → carding machine → pre-draw frame

[0019] Nano-silver antibacterial fine denier polypropylene staple fiber: cleaning machine → carding machine → pre-draw frame

[0020] The above three kinds of fiber strips are merged→mixed first→mixed two→mixed three→roving frame→spinning frame→finished yarn, and the twist coefficient is 310-330.

[0021] Since the moisture regain of polypropylene fiber is almost zero, it is easy to generate static electricity during processing, which will lead to the phenomenon of wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com