One-way moisture-transferring fabric and processing method thereof

A processing method and fabric technology, applied in textiles and papermaking, weft knitting, knitting and other directions, can solve the problems of poor hygroscopicity and quick-drying properties of polypropylene fibers, stuffy wearing, and lack of easy washing and quick-drying of natural fiber fabrics. Increase surface area, keep dry and comfortable, good hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Process and produce unidirectional moisture-wicking fabrics as follows:

[0031] 1. Selection of raw materials:

[0032] Inner layer material: 75D / 72F (non-dyed polypropylene yarn);

[0033] Middle connecting part material: 100D / 144F (cross section polyester long fiber);

[0034] Outer layer material: COOLMAX 100D / 36F (moisture-absorbing and sweat-wicking polyester long fiber with special-shaped cross-section)

[0035] 2. Weaving process:

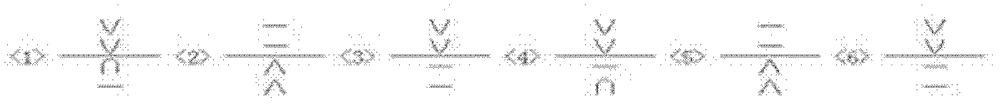

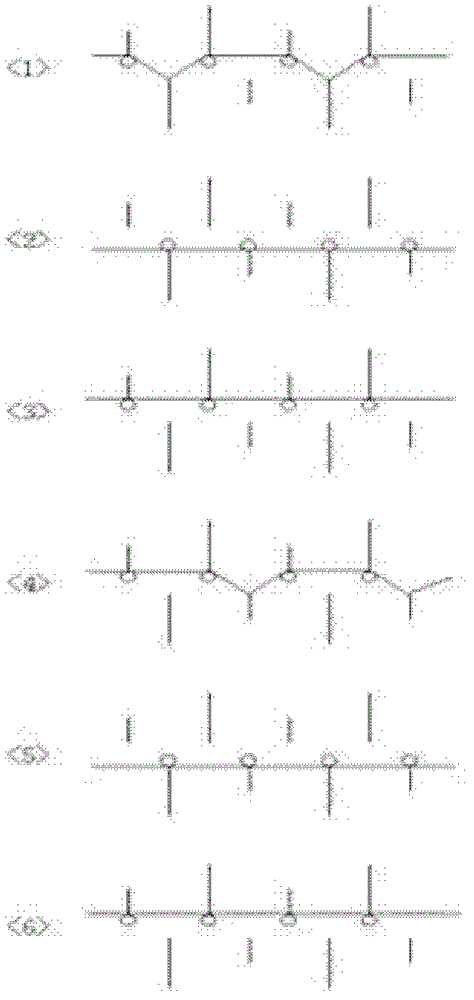

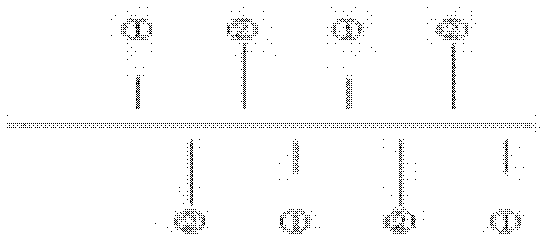

[0036] Choose Meyer-4-1 1.6QC type double-sided machine, machine number 26#, 18G needle cylinder, cylinder diameter 30", ribbed needle arrangement, needle cylinder needle press image 3 Arrange in order, the upper needle cylinder and the lower needle cylinder each have two knitting needles, the triangular arrangement method is as follows figure 1 shown, press figure 2 The knitting diagram shown is for weaving, and the weaving process is a cycle of six routes, among which, the 2nd and 5th routes wear 75D / 72F non-dyeable polyprop...

Embodiment 2

[0047] Process and produce unidirectional moisture-wicking fabrics as follows:

[0048] 1. Selection of raw materials:

[0049] Inner layer material: 150D / 98F (non-dyed polypropylene yarn);

[0050] The material of the intermediate connection part: 75D / 78F (polyester long fiber with leaf-shaped cross-section);

[0051] Outer material: 100D / 72F (moisture wicking polyester long fiber)

[0052] 2. Weaving process:

[0053] Choose Meyer-4-1 1.6QC type double-sided machine, machine number 26#, 18G needle cylinder, cylinder diameter 30", ribbed needle arrangement, needle cylinder needle press image 3 Arrange in order, the upper needle cylinder and the lower needle cylinder each have two knitting needles, the triangular arrangement method is as follows figure 1 shown, press figure 2The knitting diagram shown is for weaving, and the weaving process is a cycle of six routes, among which, the 2nd and 5th routes wear 150D / 98F non-dyeable polypropylene yarn to weave the inner mesh ...

Embodiment 3

[0063] Process and produce unidirectional moisture-wicking fabrics as follows:

[0064] 1. Selection of raw materials:

[0065] Inner layer material: 75D / 72F (non-dyed polypropylene yarn);

[0066] The material of the intermediate connection part: 100D / 72F (polyester long fiber with T-shaped section);

[0067] Outer layer material: COOLMAX 100D / 36F (moisture-absorbing and quick-drying special-shaped section polyester long fiber)

[0068] 2. Weaving process:

[0069] Choose Meyer-4-1 1.6QC type double-sided machine, machine number 26#, 18G needle cylinder, cylinder diameter 30", ribbed needle arrangement, needle cylinder needle press image 3 Arrange in order, the upper needle cylinder and the lower needle cylinder each have two knitting needles, the triangular arrangement method is as follows figure 1 shown, press figure 2 The knitting diagram shown is for weaving, and the weaving process is a cycle of six routes, among which, the 2nd and 5th routes wear 75D / 72F non-dyea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com