Preparation method of double-layer one-way moisture-conducting micro-nano fiber membrane based on near-field direct writing and solution electrospinning technology

A technology of micro-nano fiber and unidirectional moisture transfer, which is applied in fiber processing, electrospinning, processing and manufacturing, etc., can solve the problems of large diameter and specific surface area of micro-nano fiber membrane, restriction of unidirectional moisture transfer performance, and small pore size of fiber membrane. Achieve the effect of excellent one-way water guide, high yield and strong capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

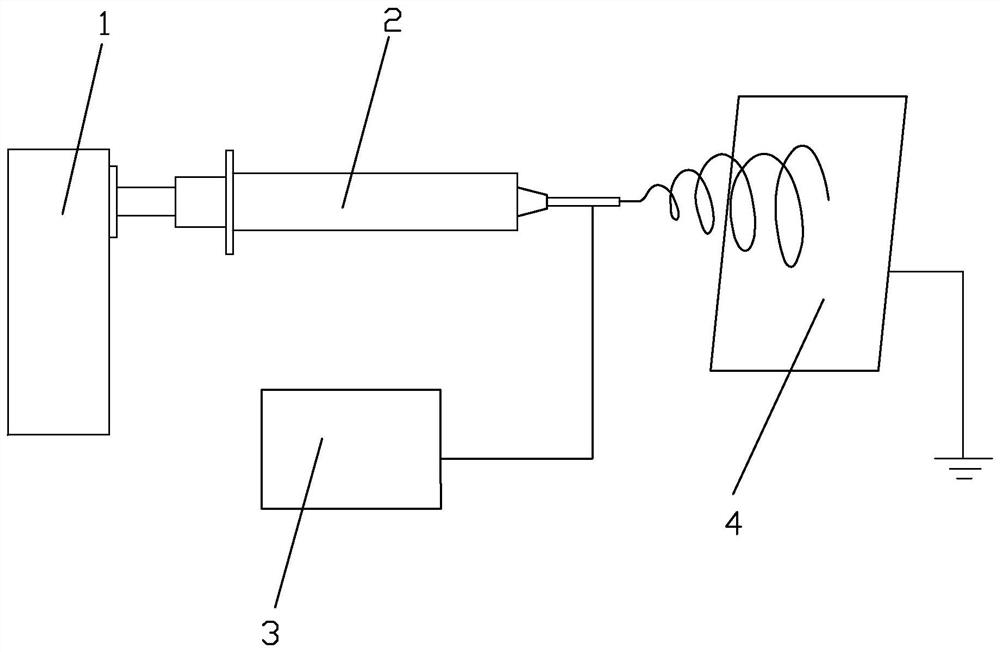

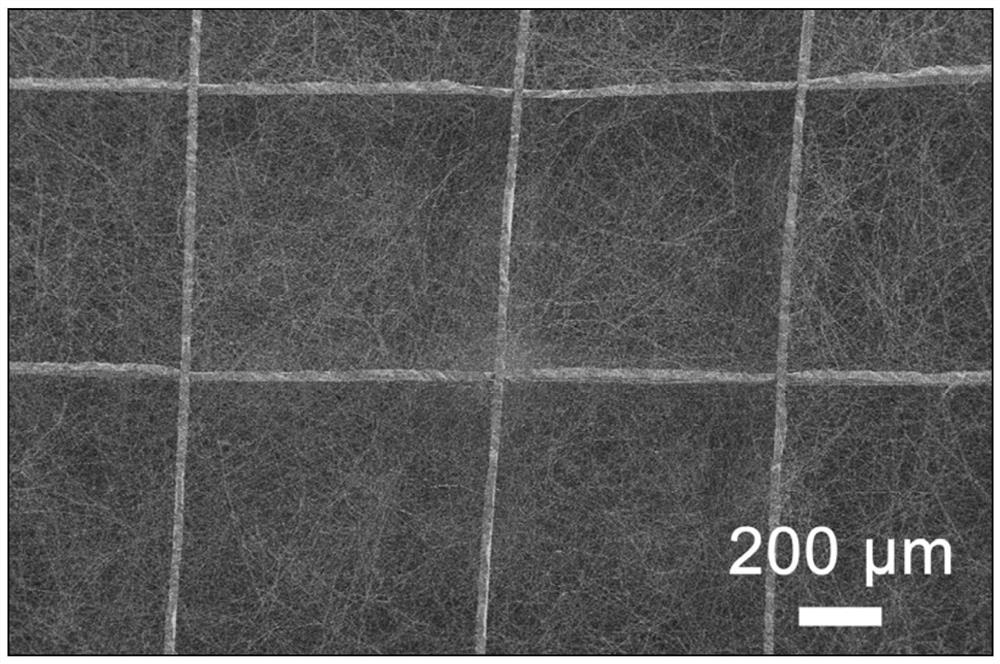

[0039] The first step: disperse the hydrophilic polyacrylonitrile particles in N,N-dimethylformamide, and use a magnetic stirrer to dissolve them fully and uniformly to obtain a polyacrylonitrile electrospinning solution with a mass fraction of 14 wt%. Put it into the spinning syringe A2, clamp the spinning syringe A2 on the sliding table that can move left and right, wrap and fix the silicone oil paper on the receiving plate A4 as the receiving substrate, connect the high-voltage power supply A3 to the needle of the spinning syringe A2, Turn on the syringe pump A1, use the electrospinning device to deposit a layer of disordered hydrophilic micro-nano fiber film A on the silicone oil paper by the solution electrospinning method, the spinning voltage is 15kV, the receiving distance is 20cm, the spinning solution The propulsion speed is 2mL / h, the obtained fiber diameter is 980nm, and the thickness of the hydrophilic micro-nano fiber membrane A is 15 μm;

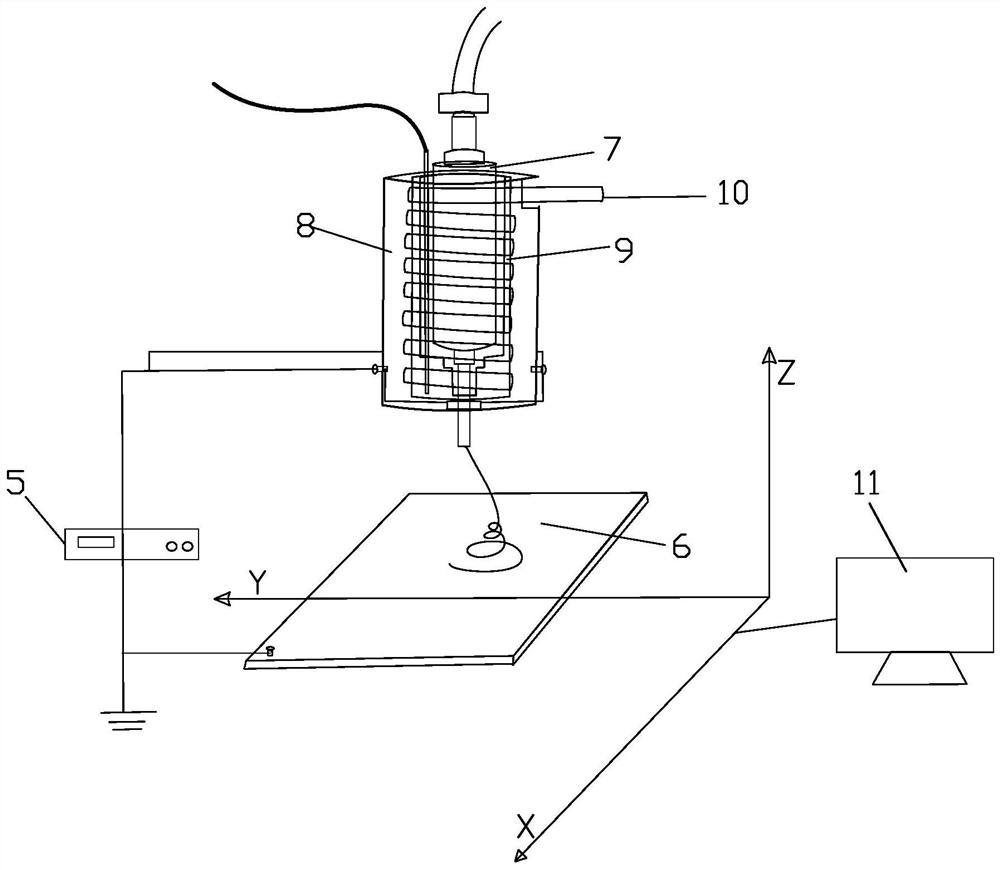

[0040]Step 2: Put the ...

Embodiment 2

[0043] The first step: disperse the hydrophilic polyacrylonitrile powder in N,N-dimethylformamide, and use a magnetic stirrer to dissolve it fully and uniformly to obtain a polyacrylonitrile electrospinning solution with a mass fraction of 14 wt%. Put it into the spinning syringe A2, clamp the spinning syringe A2 on the sliding table that can move left and right, wrap and fix the silicone oil paper on the receiving plate A4 as the receiving substrate, connect the high-voltage power supply A3 to the needle of the spinning syringe A2, Turn on the syringe pump A1, use the electrospinning device to deposit a layer of disordered hydrophilic micro-nano fiber film A on the silicone oil paper by the solution electrospinning method, the spinning voltage is 30kV, the receiving distance is 20cm, and the spinning solution The propulsion speed is 2mL / h, the obtained fiber diameter is 980nm, and the thickness of fiber membrane A is 15 μm;

[0044] Step 2: Put the hydrophobic polycaprolacton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com