Low-surface-energy water-based self-polishing emulsion and preparation method thereof, and low-surface-energy water-based self-polishing anti-drag antifouling coating

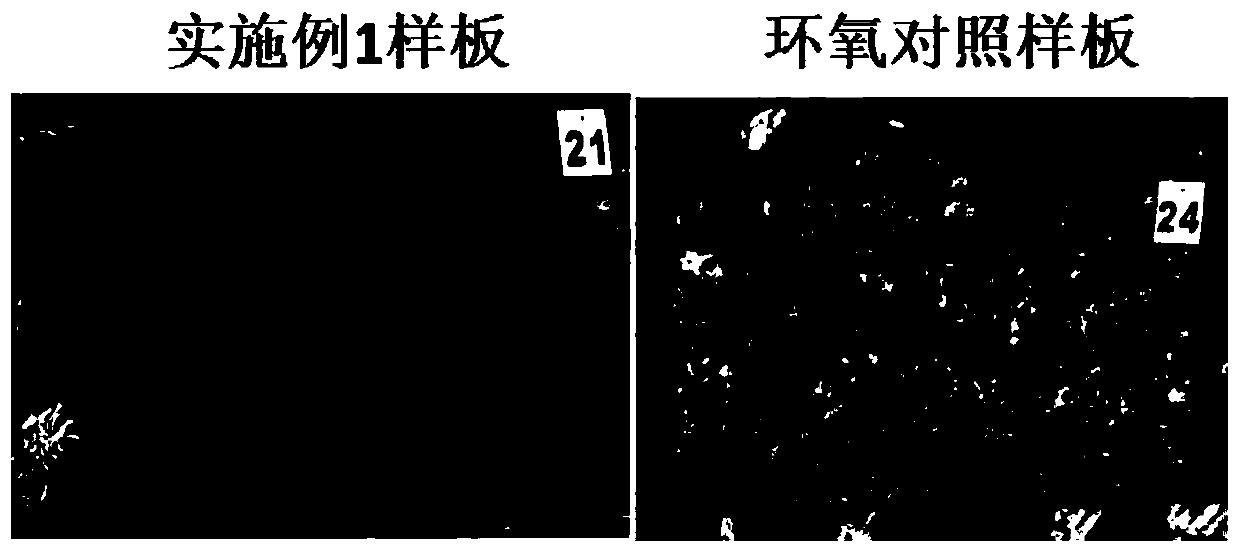

A low surface energy, antifouling coating technology, applied in antifouling/underwater coatings, rosin coatings, coatings, etc., can solve the problems of short antifouling period, poor static antifouling performance, etc., and achieve excellent antifouling performance , Good water resistance, obvious drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides the preparation method of low surface energy water-based self-polishing emulsion described in the above technical scheme, comprising the following steps:

[0048] Mixing fluorine-containing acrylate monomers, silicon acrylate monomers, acrylate monomers, acrylic acid, an emulsifier and the first part of water, and then emulsifying to obtain a monomer emulsion;

[0049] The initiator is dissolved in the second part of water to obtain an aqueous initiator solution;

[0050] Stir and mix sodium bicarbonate, remaining water, part of the monomer emulsion and part of the initiator aqueous solution, then raise the temperature to 80-81 °C, keep warm and continue stirring for 50-100 minutes to obtain the seed emulsion;

[0051] At 80-81°C, add the remaining monomer emulsion and the remaining initiator aqueous solution dropwise into the seed emulsion, keep it warm for 50-70 minutes after the addition, raise the temperature to 87-89°C and keep it for...

Embodiment 1

[0087] Preparation of low surface energy aqueous self-polishing emulsion:

[0088] Weigh 30g dodecafluoroheptyl methacrylate, 45g triisopropyl silicon methacrylate, 10g butyl acrylate, 50g methyl methacrylate, 11g isobornyl methacrylate and 2.5g acrylic acid, at room temperature Mix well, then add 3g of nonionic surfactant OP-10, 1.5g of anionic surfactant sodium dodecylsulfonate and 110g of deionized water, stir and emulsify at a speed of 600r / min for 30min to obtain a monomer emulsion;

[0089] Weighing 1.4g ammonium persulfate was dissolved in 20g deionized water to obtain an aqueous initiator solution;

[0090] Weigh 0.2g of sodium bicarbonate, 20g of deionized water, 75g of monomer emulsion and 3.2g of initiator aqueous solution, stir at a speed of 600r / min for 0.5h at room temperature, and then stir at 5°C / min under stirring conditions The heating rate was increased to 81°C, and the stirring was continued for 40 minutes. A faint blue light appeared in the system, and th...

Embodiment 2

[0098] Prepare low surface energy water-based self-polishing emulsion, rosin emulsion and aqueous slurry according to the method of Example 1;

[0099] Preparation of low surface energy waterborne self-polishing drag-reducing and antifouling coatings:

[0100] Weigh 25g low surface energy water-based self-polishing emulsion, 10g rosin emulsion, 48g water-based slurry, 0.6g propylene glycol, 0.2g water-based leveling agent DC57, 0.4g water-based defoamer DAPROAP7010 and 15.8g deionized water, at 300r / min Fully stirred and dispersed for 30 minutes under the same conditions, and filtered to obtain a low surface energy water-based self-polishing drag-reducing antifouling coating with a solid content of 46.7wt% and a pigment-to-base ratio of 1.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com