Self-repairing super-hydrophobic anti-drag elastomer thin film and preparation method thereof

An elastomer, super-hydrophobic technology, applied in the field of preparation of self-healing super-hydrophobic membranes, can solve problems such as performance degradation and disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

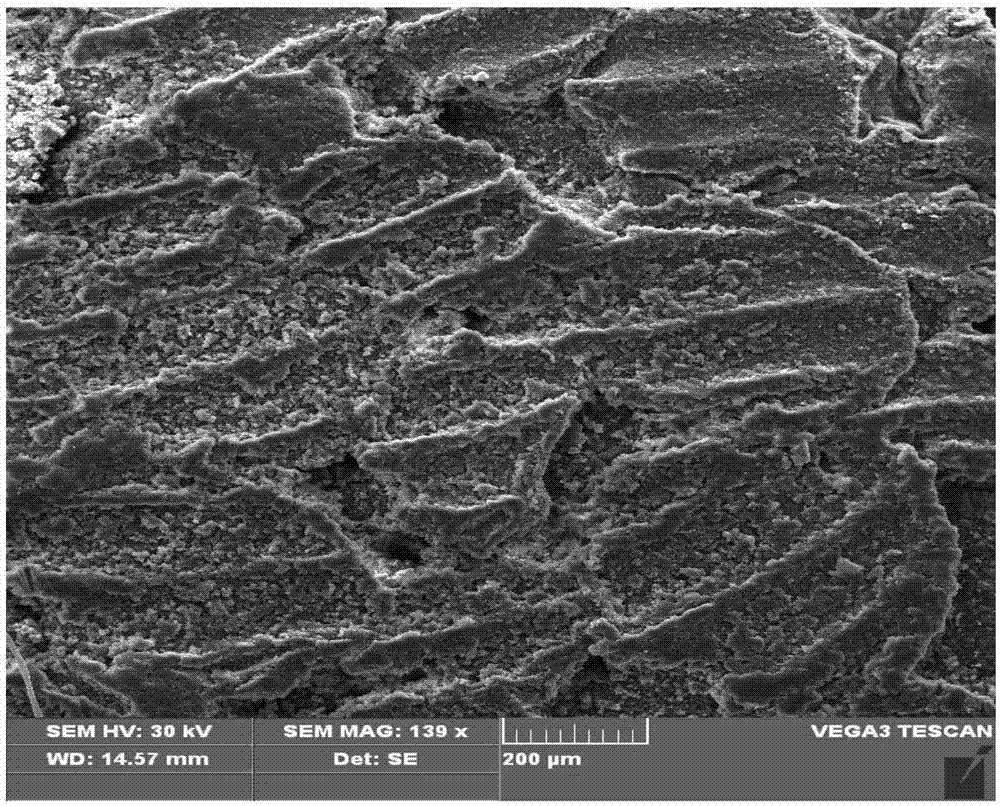

[0037] After the subcutaneous fat is completely removed from the fresh shark skin, it is soaked in formalin for 12 hours, then taken out and sandwiched between two glass plates for heating and drying. Then attach the surface with microstructure to the acrylic plate and put it into the flat vulcanizing machine, load 5MPa pressure at 100°C, turn on the condensed water cooling after 15 minutes, unload the pressure after the temperature drops to 60°C, and take out the acrylic Plate, remove the shark skin attached to the mold according to the natural arrangement of the scales and pull the mold in the opposite direction along the scales, and finally get a template with a groove structure on the surface of the shark skin.

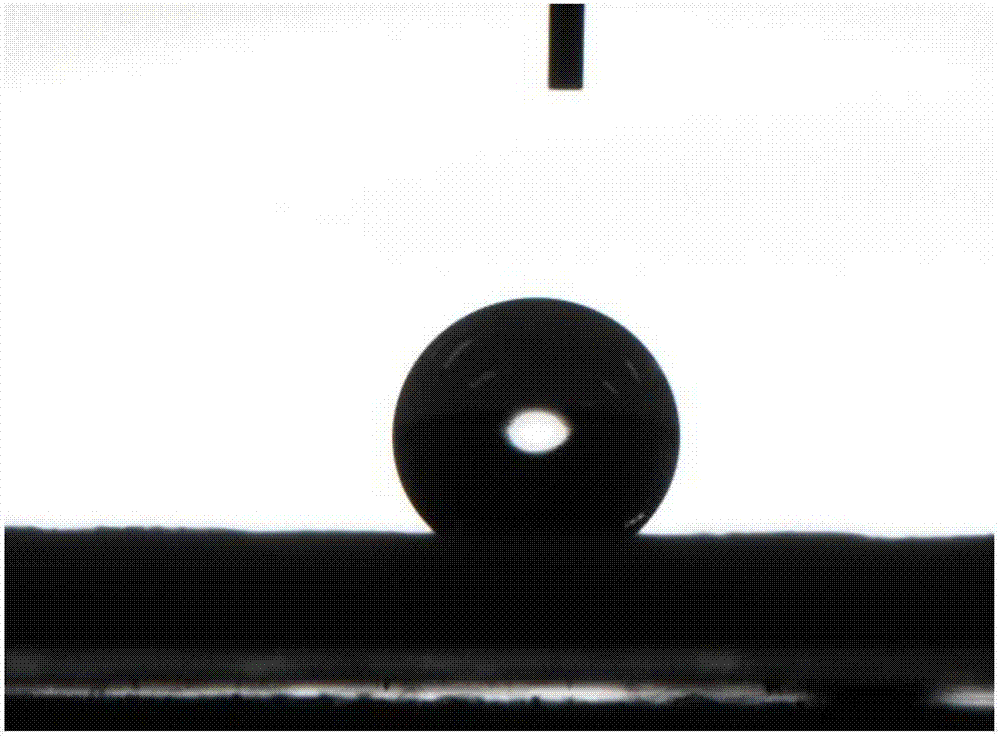

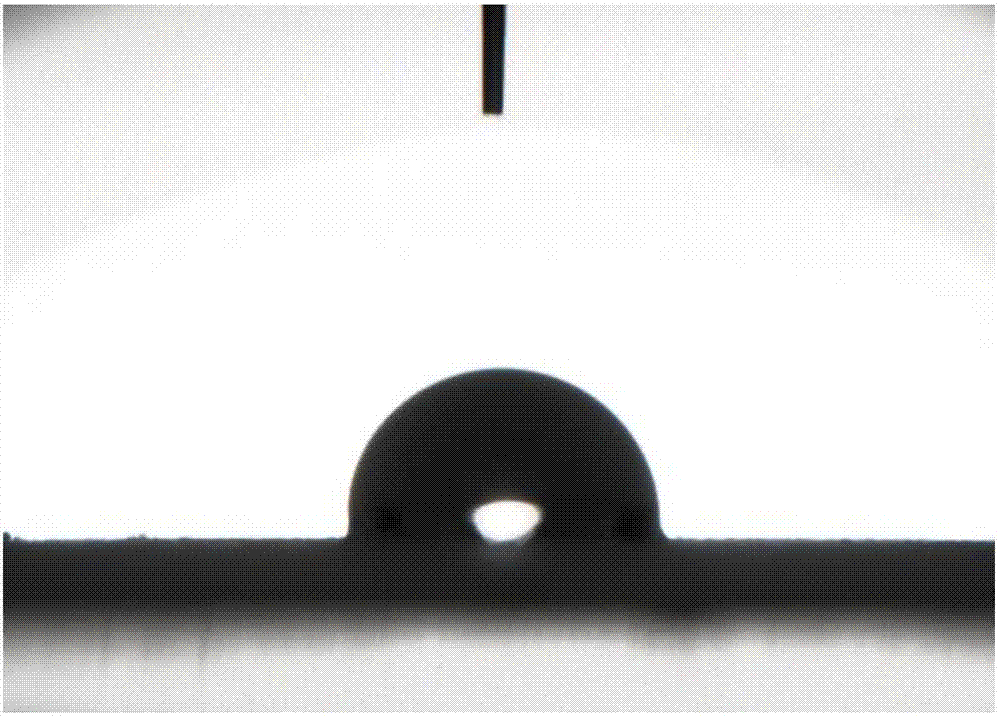

[0038]The polyurethane elastomer is mixed with silica particles with a mass fraction of 50%, and rolled onto a template with a groove structure on the surface of shark skin, and cured by heating. After curing is complete, the elastomeric film is peeled off from th...

Embodiment 2

[0046] After the subcutaneous fat is completely removed from the fresh shark skin, it is soaked in formalin for 12 hours, then taken out and sandwiched between two glass plates for heating and drying. Then attach the surface with microstructure to the acrylic plate and put it into the flat vulcanizing machine, load 4MPa pressure at 110°C, turn on the condensed water cooling after 10 minutes, unload the pressure after the temperature drops to 70°C, and take out the acrylic Plate, remove the shark skin attached to the mold according to the natural arrangement of the scales and pull the mold in the opposite direction along the scales, and finally get a template with a groove structure on the surface of the shark skin.

[0047] The polyurethane elastomer is mixed with titanium dioxide particles with a mass fraction of 75%, and rolled onto a template with a groove structure on the surface of shark skin, and cured by heating. After curing is complete, the elastomeric film is peeled ...

Embodiment 3

[0055] After the subcutaneous fat is completely removed from the fresh shark skin, it is soaked in formalin for 12 hours, then taken out and sandwiched between two glass plates for heating and drying. Then attach the surface with microstructure to the acrylic plate and put it into the flat vulcanizing machine, load 3MPa pressure at 120°C, turn on the condensed water cooling after 5min, unload the pressure after the temperature drops to 80°C, and take out the acrylic Plate, remove the shark skin attached to the mold according to the natural arrangement of the scales and pull the mold in the opposite direction along the scales, and finally get a template with a groove structure on the surface of the shark skin.

[0056] The polyurethane elastomer and the mass fraction of 100% Fe 3 o 4 / SiO 2 Composite particles are mixed, roller coated on a template with grooved structure on the surface of sharkskin, and cured by heating. After curing is complete, the elastomeric film is peel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com