SiO2/PAA-b-PS amphiphilic Janus microsphere, preparation method and application thereof

A paa-b-ps, amphiphilic technology, applied in the field of leather coating, can solve the problems of harsh reaction conditions, poor coating superhydrophobicity, and difficult structure control, and achieve the effect of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

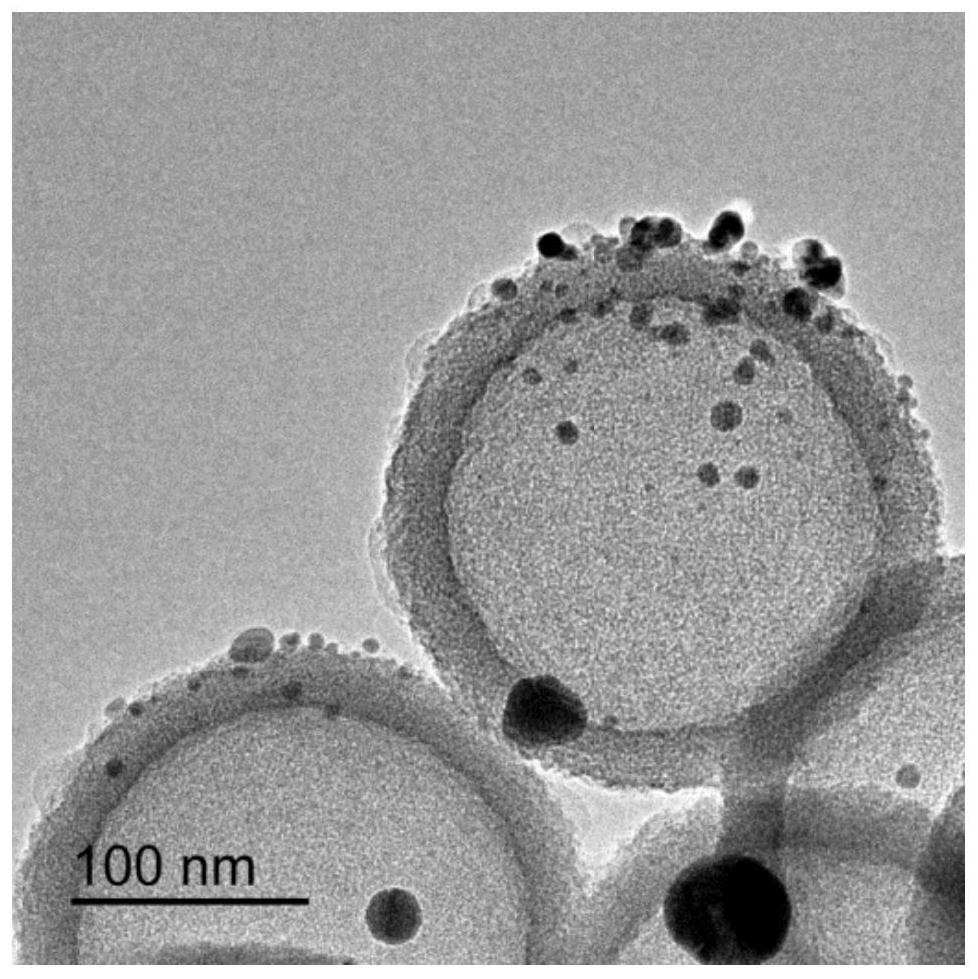

[0044] A SiO 2 The preparation method of / PAA-b-PS amphiphilic Janus microspheres comprises the steps:

[0045] Step 1, 0.05g of hollow SiO with a particle size of 30nm made in the laboratory 2 Microspheres were added to 10mL absolute ethanol for ultrasonic dispersion, and then SiO 2 γ-aminopropyltriethoxysilane with 30% mass of microspheres, then heated to 50°C, reacted for 2h, centrifuged, washed, and dried to obtain γ-aminopropyltriethoxysilane modified hollow SiO 2 Microspheres.

[0046] Step 2: Add 7.206g of acrylic acid and 0.093g of 1,1-stilbene into 30g of deionized water, raise the temperature to 60°C, stir mechanically for 5min, add 0.062g of potassium persulfate, keep it warm for 4h, then drop into the system at the same time Add 2.6038g of styrene and 8.02g of 0.25% potassium persulfate aqueous solution, add dropwise for 30 minutes, and finally keep warm for 4 hours to obtain the amphiphilic block copolymer PAA-b-PS emulsion, and use sodium chloride to demulsify...

Embodiment 2

[0051] A SiO 2 The preparation method of / PAA-b-PS amphiphilic Janus microspheres comprises the steps:

[0052] Step 1, 0.30g of hollow SiO with a particle size of 500nm made in the laboratory 2 Microspheres were added to 60mL absolute ethanol for ultrasonic dispersion, and then SiO 2 γ-aminopropyltriethoxysilane with 80% mass of microspheres, then heated to 80°C, reacted for 12h, centrifuged, washed, and dried to obtain γ-aminopropyltriethoxysilane modified hollow SiO 2 Microspheres.

[0053] Step 2: Add 7.206g of acrylic acid and 0.620g of 1,1-stilbene into 80g of deionized water, raise the temperature to 90°C, stir mechanically for 30min, add 0.496g of potassium persulfate, keep warm for 24h, and then add Add dropwise 31.245g of styrene and 8.22g of 2.75% potassium persulfate aqueous solution for 80 minutes, and finally keep the temperature for 24 hours to obtain the amphiphilic block copolymer PAA-b-PS emulsion, which is broken by sodium chloride. The milk was centrifu...

Embodiment 3

[0058] A SiO 2 The preparation method of / PAA-b-PS amphiphilic Janus microspheres comprises the steps:

[0059] Step 1, 0.10g particle size is 150nm laboratory-made solid SiO 2 Microspheres were added to 20mL absolute ethanol for ultrasonic dispersion, and then SiO 2 γ-aminopropyltriethoxysilane with 40% mass of microspheres, then heated to 55°C, reacted for 4h, centrifuged, washed, and dried to obtain γ-aminopropyltriethoxysilane modified solid SiO 2 Microspheres.

[0060] Step 2: Add 7.206g of acrylic acid and 0.124g of 1,1-stilbene into 40g of deionized water, raise the temperature to 65°C, stir mechanically for 10 minutes, add 0.093g of potassium persulfate, keep the reaction for 8 hours, and then drop into the system at the same time Add 3.4707g of styrene and 8.06g of 0.75% potassium persulfate aqueous solution, add dropwise for 40 minutes, and finally keep warm for 8 hours to obtain the amphiphilic block copolymer PAA-b-PS emulsion, and use sodium chloride to demulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

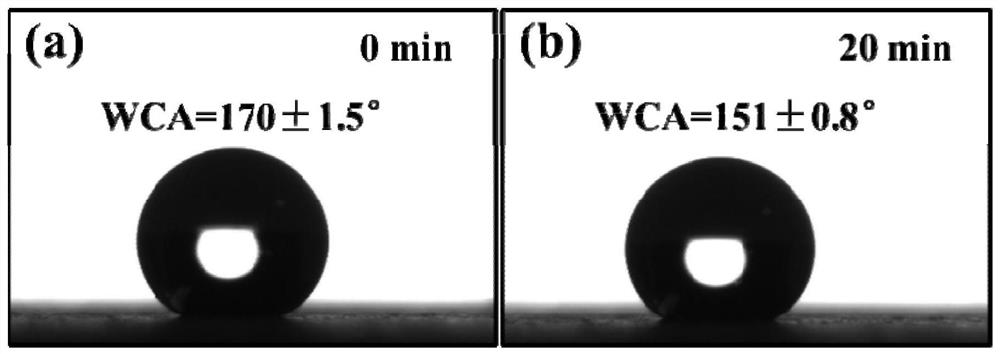

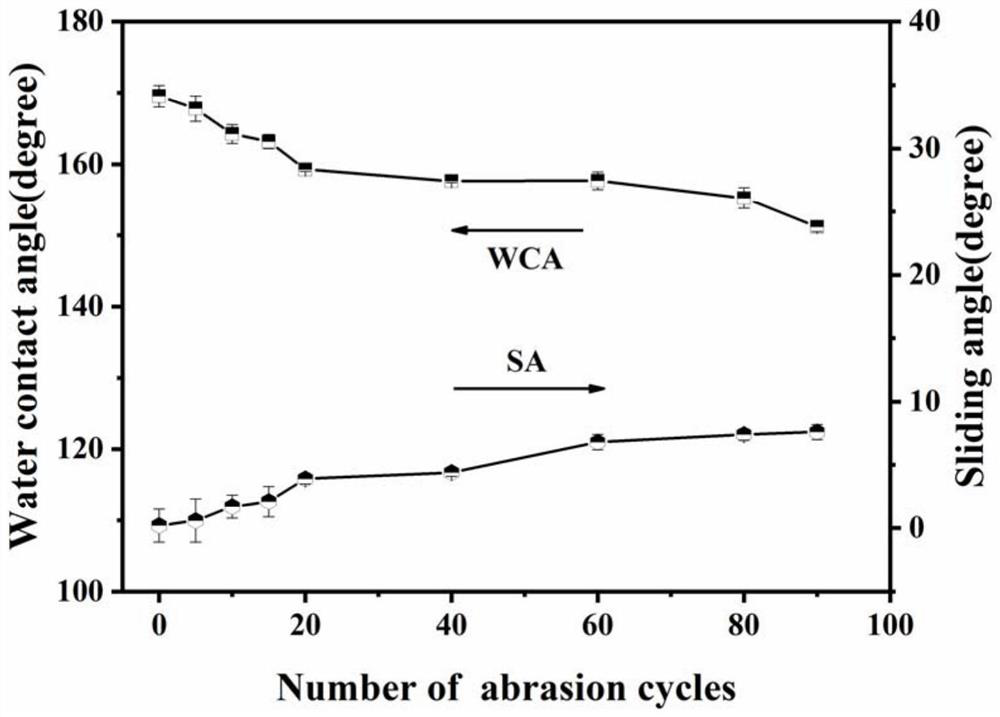

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com