A kind of preparation method of superhydrophobic coating and film with hydrophobic migration

A super-hydrophobic coating and hydrophobic migration technology, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of not having hydrophobic migration and achieve excellent hydrophobic migration , Ease of large-scale production and coating, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

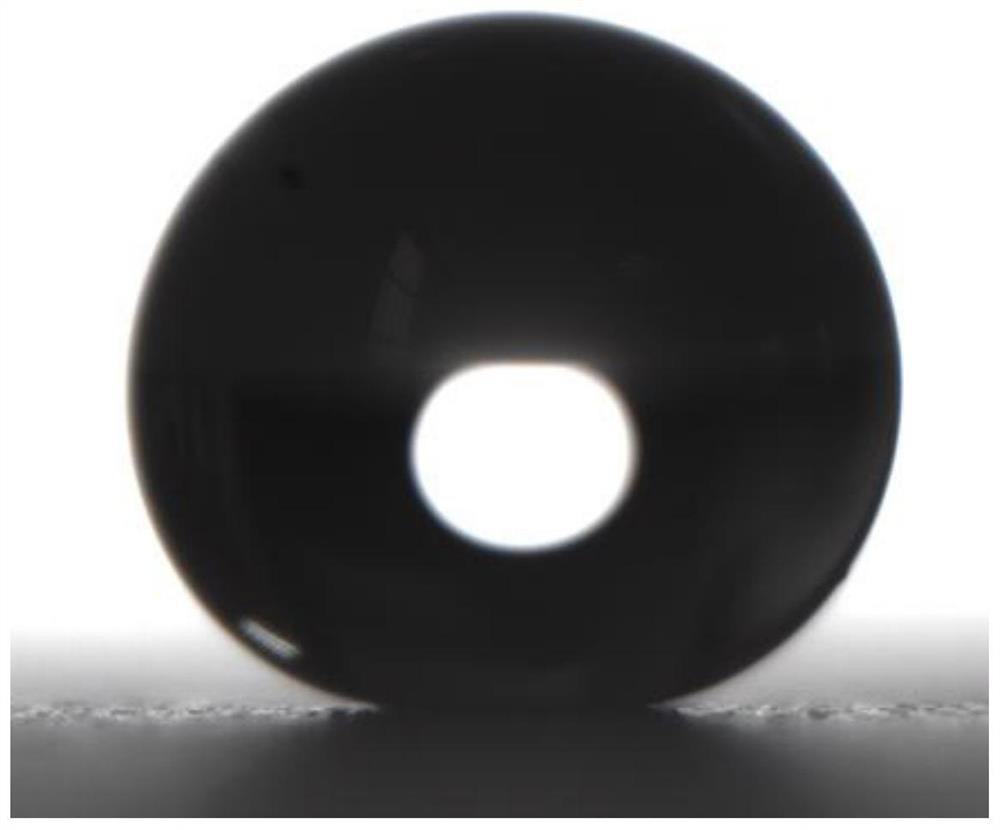

Image

Examples

Embodiment 1

[0032] The embodiment of the present invention provides a method for preparing a superhydrophobic coating with hydrophobic mobility, comprising the following steps:

[0033] (1) adding concentrated ammonia water and tetraethyl orthosilicate to the ethanol solvent, stirring and aging, and then adding hexamethyldisilazane to prepare a superhydrophobic coating;

[0034] (2) In the super-hydrophobic coating prepared above, add silicone oil and a silane coupling agent with hydrophobic mobility to prepare a super-hydrophobic coating with hydrophobic migration.

[0035] Silicone oils include methyl silicone oil, ethyl silicone oil, methyl phenyl silicone oil, methyl chlorophenyl silicone oil, methyl ethoxy silicone oil, hydroxyl hydrogen silicone oil, methyl trifluoropropyl silicone oil, phenyl silicone oil, methyl One or more of hydrogen silicone oil, methyl vinyl silicone oil, ethyl hydrogen silicone oil, and methyl hydroxy silicone oil. The mass ratio of the silicone oil to the s...

Embodiment 2

[0038] The embodiment of the present invention provides a method for preparing a superhydrophobic coating with hydrophobic mobility, comprising the following steps:

[0039] In the super-hydrophobic coating, silicone oil with hydrophobic migration and silane coupling agent are added to prepare super-hydrophobic coating with hydrophobic migration. Superhydrophobic coatings without silicone oil can be purchased through online shopping and other channels, such as SM-supercoat-SHFC3150 produced by Shangmeng Technology (Zhangjiagang) Co., Ltd., which is made of nano-materials such as silicon oxide and montmorillonite and modified high-performance fluorocarbons Resin composition; "CCP002&CCP003- Super-hydrophobic and super-oleophobic nano-coating "normal temperature self-drying super-hydrophobic coating; NC317 super-hydrophobic coating produced by Changzhou Naroco Coatings Co., Ltd.

[0040] Silicone oils include methyl silicone oil, ethyl silicone oil, methyl phenyl silicone oil, m...

Embodiment 3

[0043] An embodiment of the present invention provides a method for preparing a superhydrophobic insulating film with hydrophobic mobility, comprising the following steps:

[0044] (1) Hydrophobic SiO 2 Preparation of nanoparticles: add 8mL concentrated ammonia water to 100mL ethanol and heat up to 40°C, then add 18mL tetraethylorthosilicate, stir for 1.5h, cool down, age for 24h, then add 20mL hexamethyldisilazane, Stir for 4 hours to obtain the superhydrophobic coating.

[0045] (2) In the state of stirring, add 0.3 g of polydimethylsilicone oil and 0.1 g of silane coupling agent (KH560) to the superhydrophobic coating prepared in step (1) to obtain a superhydrophobic coating with hydrophobic mobility .

[0046] (3) Spraying and curing the superhydrophobic coating prepared in step (2) on a glass substrate and drying naturally to obtain a superhydrophobic insulating film with hydrophobic mobility.

[0047] The embodiment of the present invention also provides a super-hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com