A kind of preparation method of superhydrophobic superoleophilic nickel-plated carbon fiber

A nickel-plated carbon fiber, super lipophilic technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve problems such as inability to use for a long time, and achieve high-efficiency separation ability, good coating bonding strength, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment

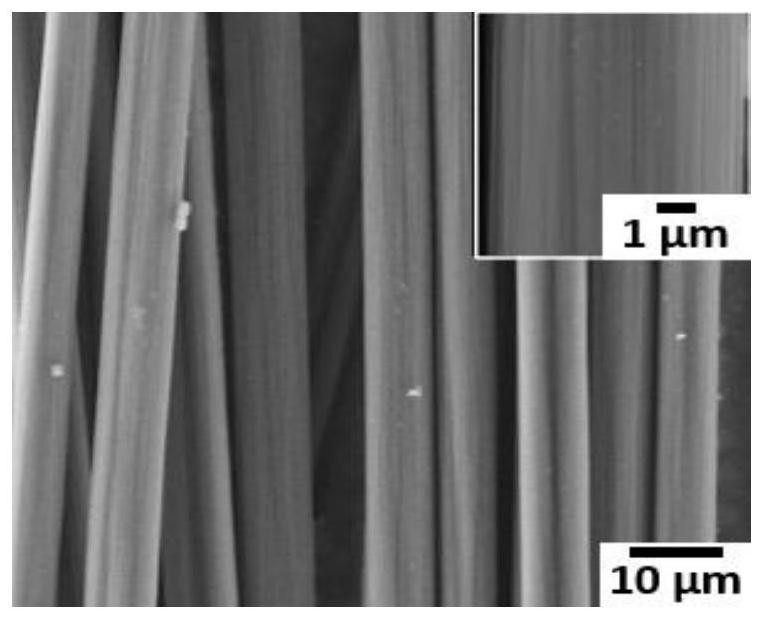

[0028] Use the acetone method to remove the glue, soak the carbon fiber in 500mL of acetone and deionized water and ultrasonically clean it for 60min, and reciprocate twice; / L of HCl solution ultrasonically cleaned for 20min, and cleaned with deionized water; then soak the carbon fiber after removing the surface oil in the mixed aqueous solution of ammonium peroxodisulfate and sulfuric acid, wherein the concentration of ammonium peroxodisulfate is 200g / L, and the concentration of sulfuric acid Concentration is 100ml / L, ultrasonic cleaning is performed for 20 minutes at the same time, and then cleaned with deionized water; finally, it is neutralized with 10% NaOH for 20 minutes, and then cleaned with deionized water. After pretreatment of carbon fibers such as figure 1 shown.

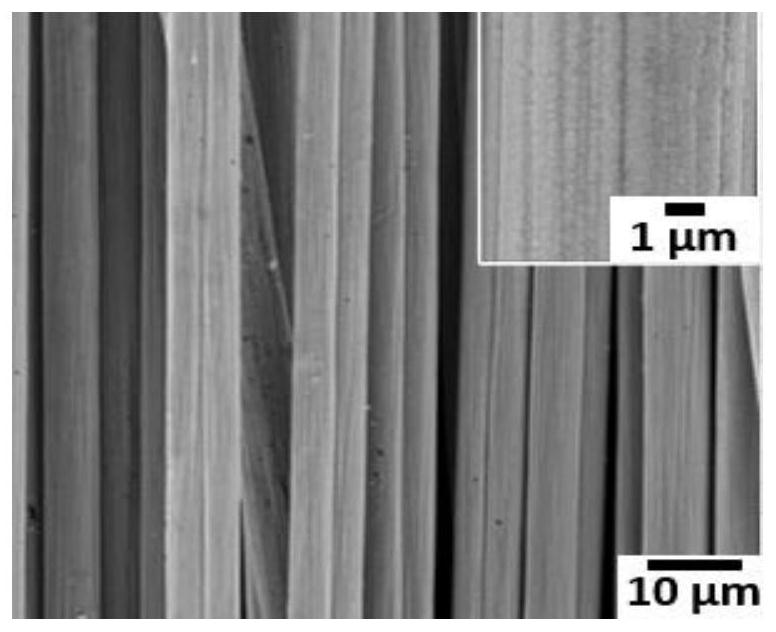

[0029] (2) Nickel plating

[0030] The components and concentrations of the substances in the electroplating solution are as follows: 200g / L nickel sulfate, 50g / L nickel chl...

Embodiment 2

[0036] (1) Pretreatment

[0037]Use the acetone method to remove the glue, soak the carbon fiber in 500mL of acetone and deionized water for 30min and ultrasonically clean it for 30min, reciprocate twice; 0.5mol / L HCl solution was ultrasonically cleaned for 20 minutes, and then cleaned with deionized water; then the carbon fiber after removing the surface oil was soaked in the mixed aqueous solution of ammonium peroxodisulfate and sulfuric acid, wherein the concentration of ammonium peroxodisulfate was 50g / L, The concentration of sulfuric acid is 50ml / L, ultrasonic cleaning for 20min at the same time, and then cleaning with deionized water; finally, use 5% NaOH for neutralization for 10min, and then wash with deionized water.

[0038] (2) Nickel plating

[0039] The components and concentrations of the substances in the electroplating solution are as follows: 50g / L nickel sulfate, 10g / L nickel chloride, 5g / L boric acid, 0.01g / L sodium lauryl sulfate, mixed and prepared aqueou...

Embodiment 3

[0043] (1) Pretreatment

[0044] The acetone method is used to remove the glue, and the carbon fiber is soaked in 500mL of acetone and deionized water for 60min and ultrasonically cleaned for 60min, reciprocating twice; the surface oil is removed by acid and alkali solution, and the degummed carbon fiber is successively washed with 2mol / L NaOH solution and 2mol / L of HCl solution ultrasonically cleaned for 20 minutes, and cleaned with deionized water; then soak the carbon fiber after removing the surface oil in the mixed aqueous solution of ammonium peroxodisulfate and sulfuric acid, wherein the concentration of ammonium peroxodisulfate is 300g / L, and the concentration of sulfuric acid Concentration is 200ml / L, ultrasonic cleaning is performed for 20 minutes at the same time, and then cleaned with deionized water; finally, it is neutralized with 20% NaOH for 20 minutes, and then cleaned with deionized water.

[0045] (2) Nickel plating

[0046] The components and concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com