a kind of sio 2 Synthetic method of hybrid comb-like organofluorosilicon copolymer

An organic fluorine and copolymer technology is applied in the synthesis field of nano-SiO2 hybrid comb-shaped organic fluorosilicon copolymer, which can solve the problems of low washing resistance of waterproof fabrics and achieve the effect of good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the content provided by the present invention, the inventor makes nano-SiO according to the following method 2 Hybrid comb-like organofluorosilicon copolymer 1:

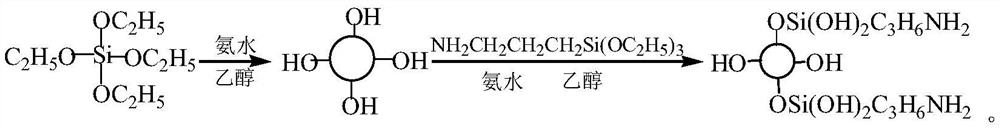

[0024] Step 1: Add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, raise the temperature to 60°C, add 70ml of ammonia water dropwise, keep the temperature for 4 hours, hydrolyze and polycondense to obtain nano-scale translucency , Alkaline SiO 2 sol; then, add 20g of γ-aminopropyltriethoxysilane to the above sol for reflux reaction for 2h, then repeatedly wash, centrifuge, and vacuum dry to obtain a white powdery aminopropyl-modified SiO 2 ;

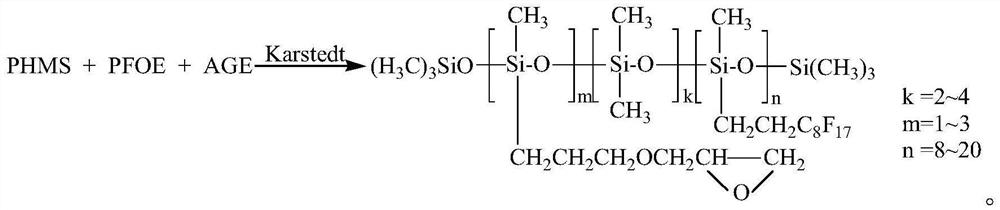

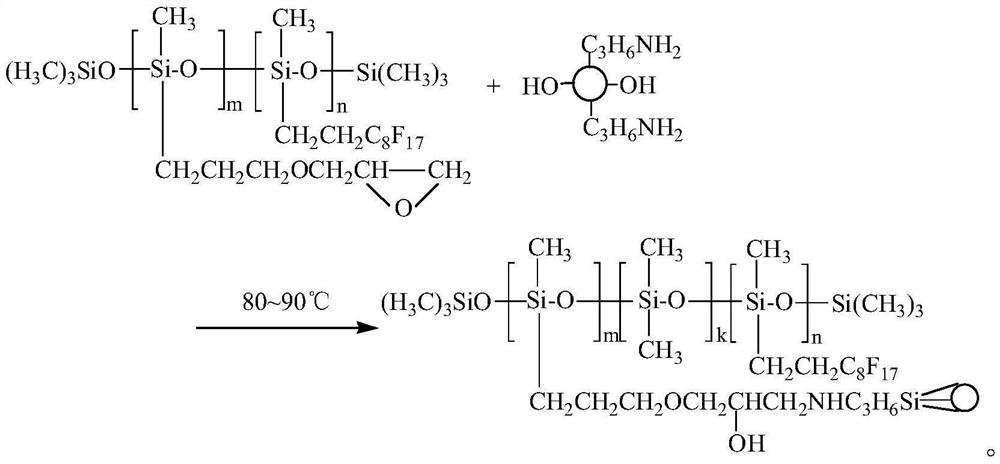

[0025] In a 250ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, successively add metered hydrogen-containing silicone oil, perfluorooctylethylene and allyl glycidyl ether, the Si-H bond of the hydrogen-containing silicone oil and The molar ratio of t...

Embodiment 2

[0029] According to the content provided by the present invention, the inventor makes nano-SiO according to the following method 2 Hybrid comb-like organofluorosilicon copolymer 2:

[0030] Step 1: Add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, heat up to 60°C, add 70ml of ammonia water dropwise, keep the temperature for 6 hours, hydrolyze and polycondense to obtain nano-scale translucency , Alkaline SiO 2 sol; then, add 20g of γ-aminopropyltriethoxysilane to the above sol for reflux reaction for 3h, then wash repeatedly, centrifuge, and dry in vacuum to obtain white powdery aminopropyl-modified SiO 2 ;

[0031] In a 250ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, successively add metered hydrogen-containing silicone oil, perfluorooctylethylene and allyl glycidyl ether, the Si-H bond of the hydrogen-containing silicone oil and The molar ratio of the sum of the...

Embodiment 3

[0035] According to the content provided by the present invention, the inventor makes nano-SiO according to the following method 2 Hybrid comb-like organofluorosilicon copolymer 3:

[0036] Step 1: Add 100g of tetraethyl orthosilicate, 80g of absolute ethanol, and 25g of deionized water into a three-necked flask, stir, raise the temperature to 60°C, add 70ml of ammonia water dropwise, keep the temperature for 5 hours, hydrolyze and polycondense to obtain nano-scale translucency , Alkaline SiO 2 sol; then, add 20g of γ-aminopropyltriethoxysilane to the above sol for reflux reaction for 2.5h, then wash repeatedly, centrifuge, and vacuum dry to obtain a white powdery aminopropyl-modified SiO 2 ;

[0037] In a 250ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, successively add metered hydrogen-containing silicone oil, perfluorooctylethylene and allyl glycidyl ether, the Si-H bond of the hydrogen-containing silicone oil and The molar ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com