Environment-friendly high-strength elastic coating for interior walls and preparation method thereof

An elastic coating, high-strength technology, applied in the direction of coating, etc., can solve the problems of affecting the integrity of the interior wall coating film, the adhesion cannot meet the demand, and the coating elasticity is reduced, so as to improve the ability of self-cleaning and hydrophobicity, excellent adhesion Concentration, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

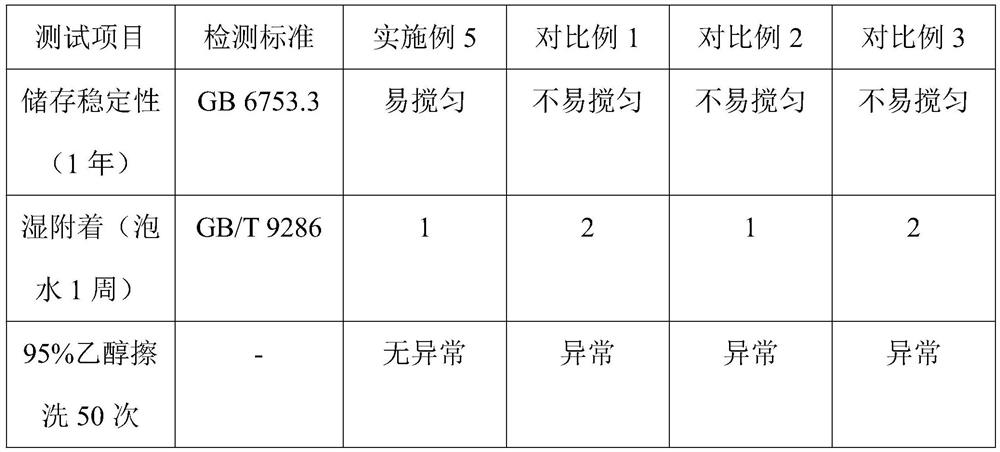

Examples

Embodiment 1

[0025] An environment-friendly high-strength elastic paint for interior walls, its raw materials include: 50kg of high-elastic acrylic emulsion, 5kg of pure acrylic emulsion, 2kg of sodium hexametaphosphate, 2kg of lauryl alcohol ester, 1kg of heavy calcium carbonate, 1kg of cellulose ether, Multifunctional auxiliary agent 1kg, 2,2'-dithiobis(N-methylbenzamide) 1kg, polydimethylsiloxane 1kg, TT-935 thickener 1kg, fatty acid polyoxyethylene ester 1kg, poly Siloxane 1kg, ethylene glycol 1kg, water 50kg.

[0026] In the multifunctional auxiliary agent, mix 2kg ethyl orthosilicate, 1kg methyl orthosilicate, and 30kg ethanol evenly, add 1kg of ammonia water with a concentration of 15wt% and stir for 2 hours to obtain SiO 2 Sol;

[0027] Add 30kg of formamide to the reactor, add 15kg of ethyl crotonate, 1kg of lauryl methacrylate, and 1kg of diethylenetriamine under stirring, stir at 60°C for 1 hour, remove excess methanol by rotary evaporation, and continue stirring 1h, add 1kg d...

Embodiment 2

[0033] An environment-friendly high-strength elastic paint for interior walls, its raw materials include: 100kg of high-elastic acrylic emulsion, 20kg of pure acrylic emulsion, 5kg of sodium hexametaphosphate, 8kg of lauryl alcohol ester, 5kg of heavy calcium carbonate, 4kg of cellulose ether, Multifunctional additive 2kg, 2,2'-dithiobis(N-methylbenzamide) 2kg, polydimethylsiloxane 2kg, TT-935 thickener 2kg, polyoxyethylene alkylamide 2kg, Polysiloxane 2kg, ethylene glycol 2kg, water 100kg.

[0034] In the multifunctional auxiliary agent, mix 8kg ethyl orthosilicate, 5kg methyl orthosilicate, and 60kg ethanol evenly, add 3kg of ammonia water with a concentration of 25wt% and stir for 4 hours to obtain SiO 2 Sol;

[0035] Add 60kg of formamide to the reactor, add 30kg of ethyl crotonate, 5kg of lauryl methacrylate, and 2kg of diethylenetriamine under stirring, stir for 2 hours at a temperature of 80°C, remove excess methanol by rotary evaporation, and continue stirring 2h, ad...

Embodiment 3

[0041] An environment-friendly high-strength elastic paint for interior walls, its raw materials include: 60kg of high-elastic acrylic emulsion, 10kg of pure acrylic emulsion, 3kg of sodium hexametaphosphate, 3kg of propylene glycol ether, 2kg of heavy calcium carbonate, 2kg of cellulose ether, multi-functional Additives 1.2kg, tetramethylthiuram disulfide 1.2kg, polymethylalkylsiloxane 1.2kg, hydroxyethyl cellulose 1.2kg, polyoxyethylene alkylamide 1.2kg, polydimethylsiloxane Alkanes 1.2kg, ethylene glycol 1.2kg, water 60kg.

[0042] In the multifunctional auxiliary agent, mix 3kg ethyl orthosilicate, 2kg methyl orthosilicate, and 40kg ethanol evenly, add 1.5kg of ammonia water with a concentration of 18wt% and stir for 2.5h to obtain SiO 2 Sol;

[0043] Add 35kg of formamide to the reactor, add 18kg of ethyl crotonate, 2kg of lauryl methacrylate, and 1.2kg of diethylenetriamine under stirring, stir at 65°C for 1.5h, and remove excess methanol by rotary evaporation. Continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com