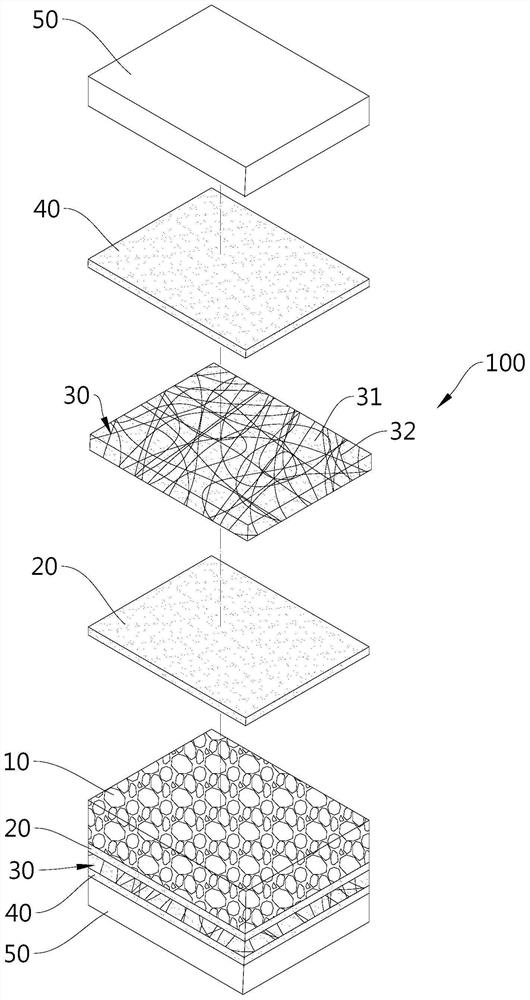

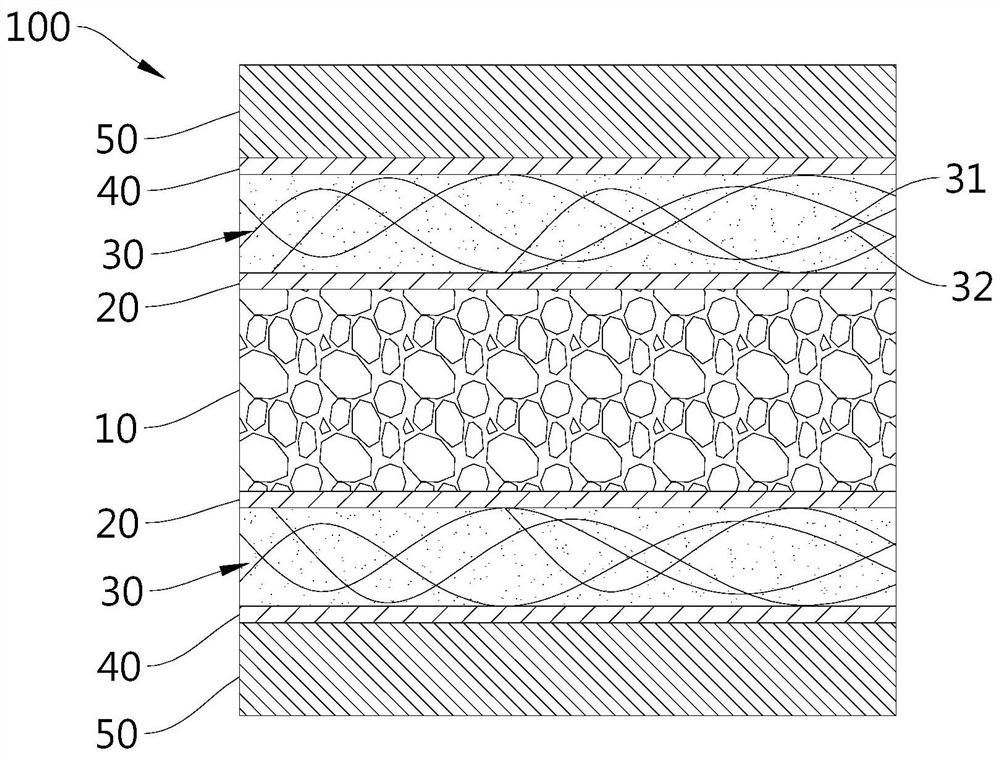

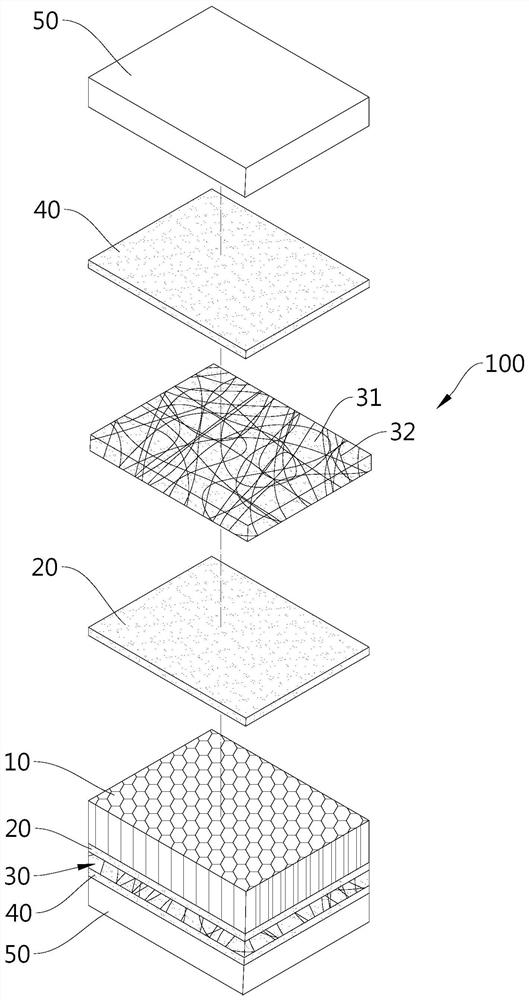

Composite material multilayer structure and manufacturing method thereof

A multi-layer structure and composite material technology, applied in the field of composite materials, can solve the problems of increasing the weight of the bumper, affecting the fuel consumption and acceleration performance of the car, and achieving the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0091] The difference between embodiment 2 and comparative example 1 is that the total fiber content of embodiment 2 is reduced to 10wt% and the average length of the plurality of fiber filaments is 35mm, but the flexural strength of embodiment 2 is 188MPa and flexural modulus 9GPa Higher than the flexural strength 150MPa and flexural modulus 8GPa of Comparative Example 1. Therefore, it is sufficient to prove that the fiber network structure 32 uses a plurality of fiber filaments with an average length greater than or equal to 35 mm, which can reduce the total fiber content to 10% wt and save costs.

[0092] Next, based on Example 2, under the condition that the total fiber content is maintained at 10wt%, Example 2 adopts a plurality of fibers with an average length of 35 mm, and Example 3 adopts a plurality of fibers with an average length of 100 mm. Silk, embodiment 4 adopts a plurality of the fiber filaments with an average length of 250 mm, and embodiment 5 adopts a plural...

Embodiment 6

[0094] The difference between Example 6 and Comparative Example 1 is that the total fiber content of Example 6 is reduced to 10wt%, the average length of the plurality of fiber filaments is 35mm, and the weight of the fiber network structure 32 is reduced to 1150g / m 2 And the thickness is reduced from 2.0 mm of Comparative Example 1 to 0.9 mm, but the bending strength of Example 6 is 171 MPa higher than that of Comparative Example 1 of 150 MPa. Therefore, it is enough to prove that the fiber network structure 32 uses a plurality of fiber filaments with an average length greater than or equal to 35mm, which can reduce the total fiber content to 10%, and can reduce the weight of the fiber network structure 32 and reduce the fiber network structure. The thickness of 32, in addition to saving costs, can be widely used in thin and light products.

Embodiment 7

[0095] The difference between Example 7 and Comparative Example 1 is that the total fiber content of Example 7 is reduced to 5wt%, the average length of the plurality of fiber filaments is 35mm, and the weight of the fiber network structure 32 is reduced to 1150g / m 2 And the thickness is reduced from 2.0mm of Comparative Example 1 to 0.9mm, but the flexural strength of 160MPa of Example 7 is higher than that of Comparative Example 1 of 150MPa. Therefore, it is sufficient to prove that the fiber network structure 32 uses a plurality of fiber filaments with an average length greater than or equal to 35mm, which can reduce the total fiber content to 5%, and can reduce the weight of the fiber network structure 32 and reduce the fiber network structure. The thickness of 32, in addition to saving costs, can be widely used in thin and light products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com