Honeycomb core material, manufacturing method of honeycomb core material, composite honeycomb structure and manufacturing method of composite honeycomb structure

A honeycomb core and composite honeycomb technology, applied in building components, building structures, household components, etc., can solve problems such as weak structural strength, and achieve the effect of improving sound insulation and structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The honeycomb core material and composite honeycomb structure of the present invention can be used as decoration materials for buildings, such as compartment surface materials, or as decoration materials for vehicles, high-speed trains, aircrafts, ships, etc. In addition to the functions of fire prevention and heat insulation, the inner or outer shell can also achieve the purpose of reducing weight and improving structural strength.

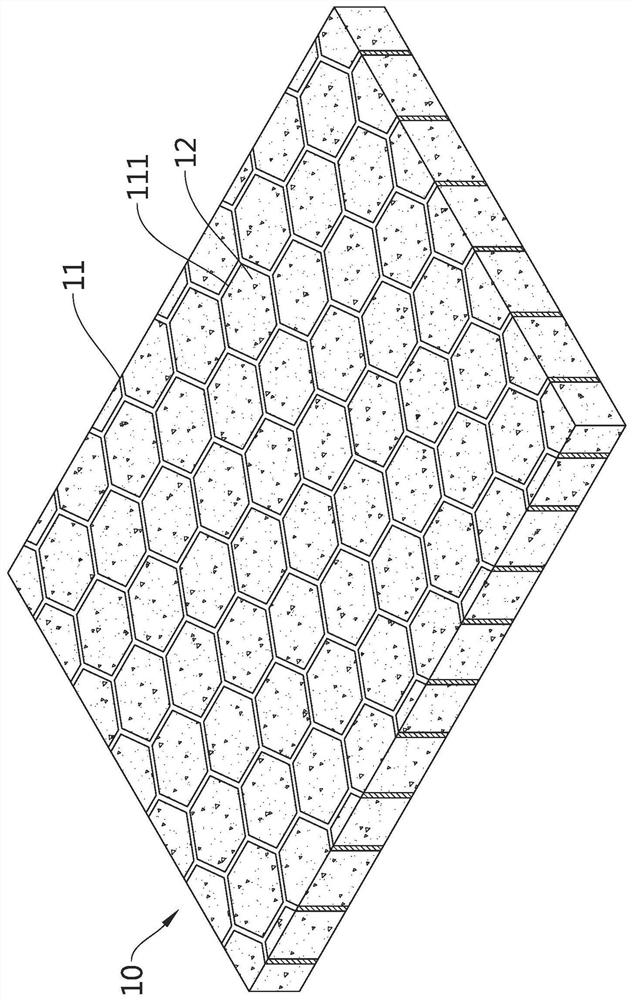

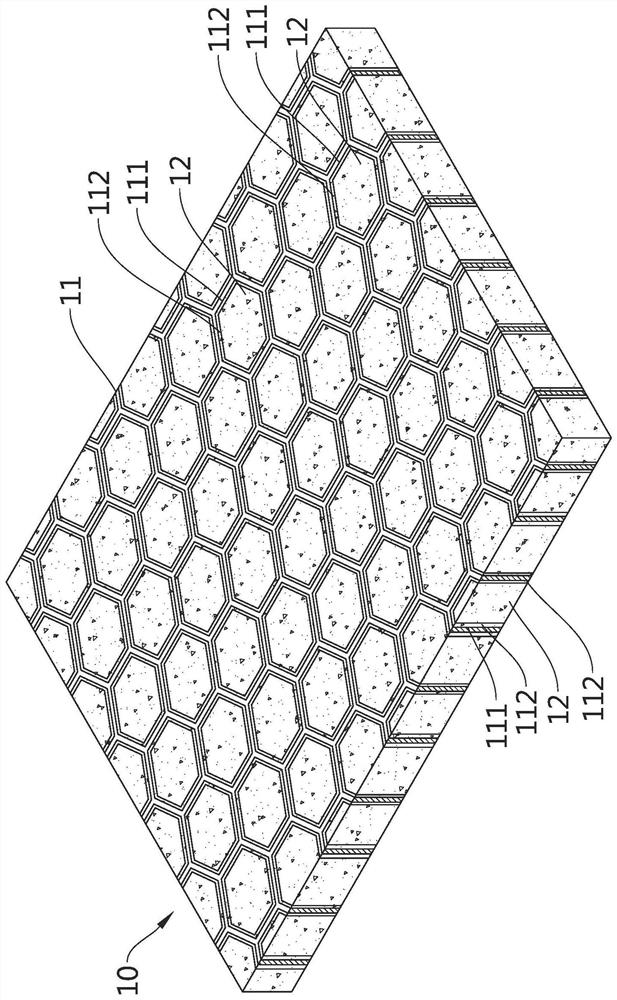

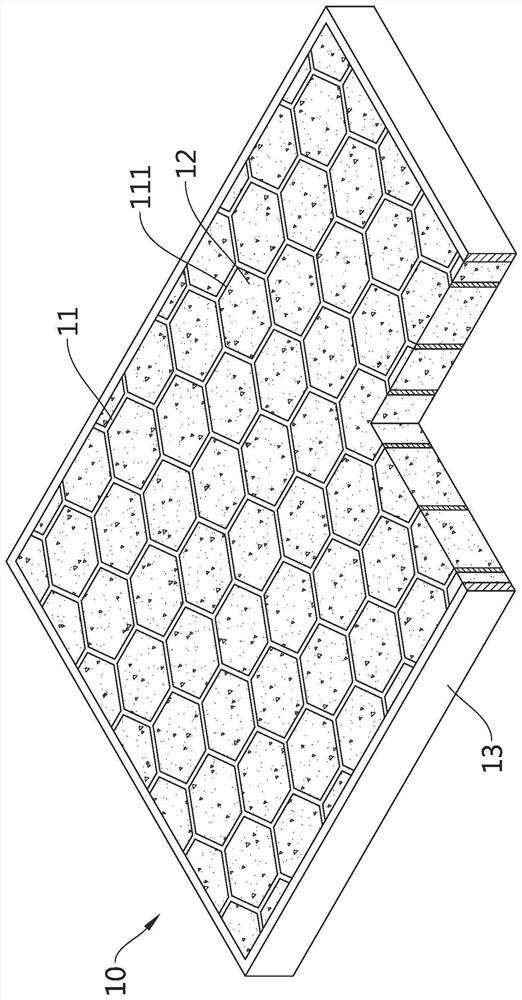

[0062] see Figure 1A , which is the first schematic diagram of the honeycomb core material of the present invention. As shown in the figure, the honeycomb core material 10 of the present invention includes a honeycomb board 11 and a plurality of foam layers 12 . The honeycomb plate 11 includes a plurality of honeycomb holes 111, and each of the honeycomb holes 111 runs through the opposite sides of the honeycomb plate 11 in a straight direction (Z-axis direction). The thickness of the distance between the two opposite surfaces of the plu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com