MXene coating textile force sensor and fabrication method thereof

A technology for textiles and sensors, applied in the field of MXene-coated textile force-sensitive sensors and its preparation, can solve the problems of restricting the development of flexible sensors and high prices, and achieve the effects of simple and easy preparation methods, low cost, and low requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The preparation process of MXene:

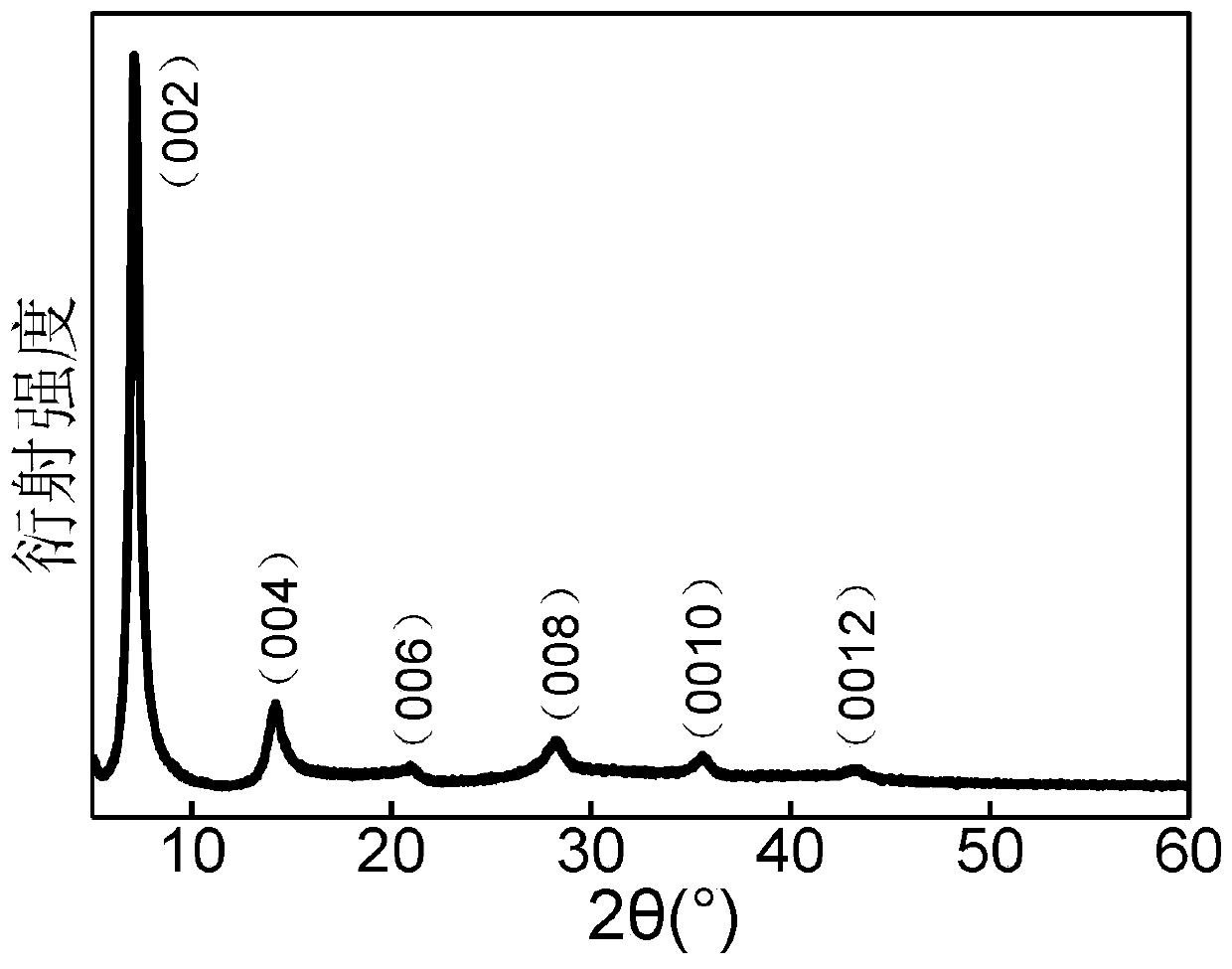

[0032] The etching solution of LiF, hydrochloric acid and ultrapure water with a mass ratio of 1.5:18.3924:5 was fully stirred, and 1gMAX phase (Ti 3 AlC 2 ) Powder, continue to stir for 24h until the etching is complete. Centrifuge at 3500r / min for several times to wash until the pH of the supernatant is close to 7. Then, the obtained precipitate was fully dispersed in deionized water, and the upper black liquid was collected by centrifugation at 3500 r / min for 5 minutes, which was the MXene dispersion. figure 1 Based on the XRD pattern of MXene prepared in Example 1, it can be seen that MXene is completely etched.

[0033] (2) MXene / fabric adsorption treatment:

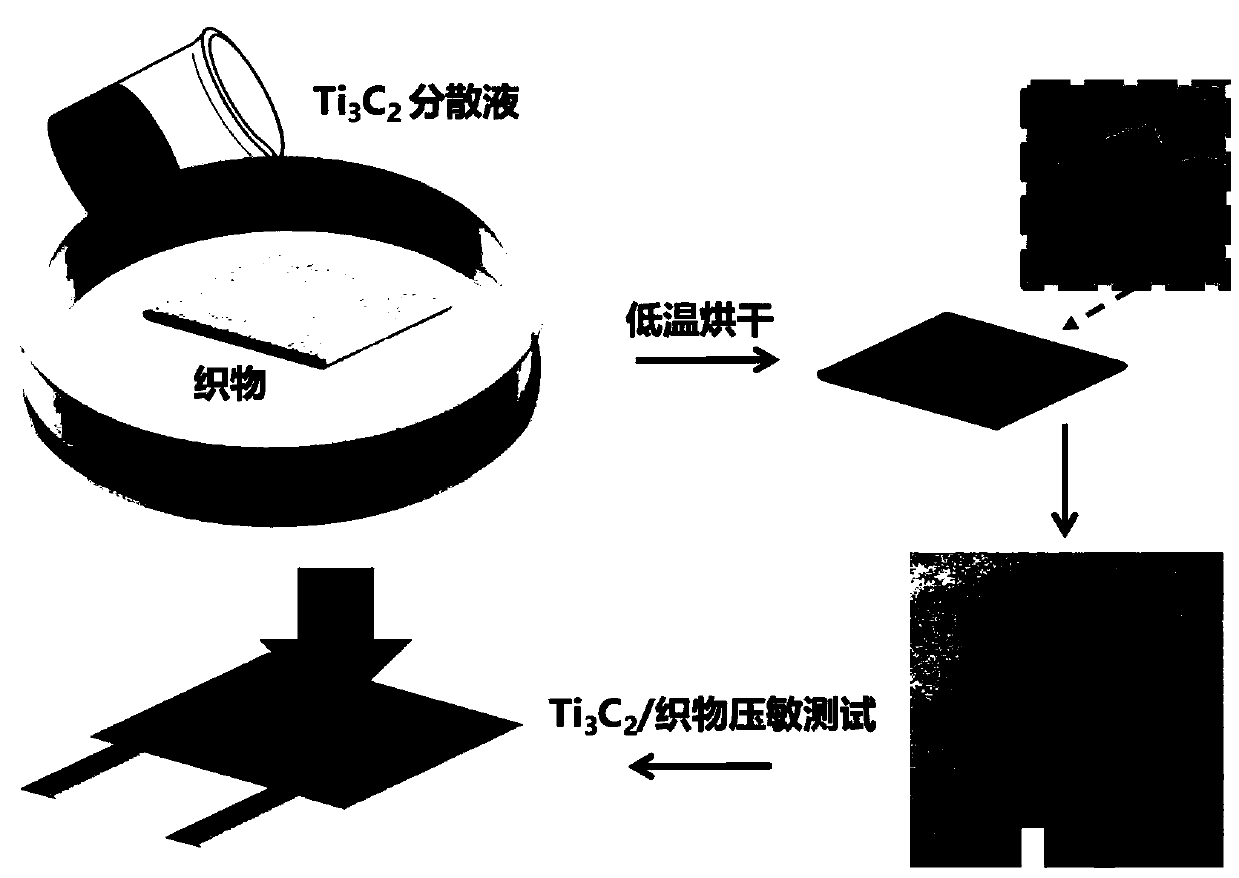

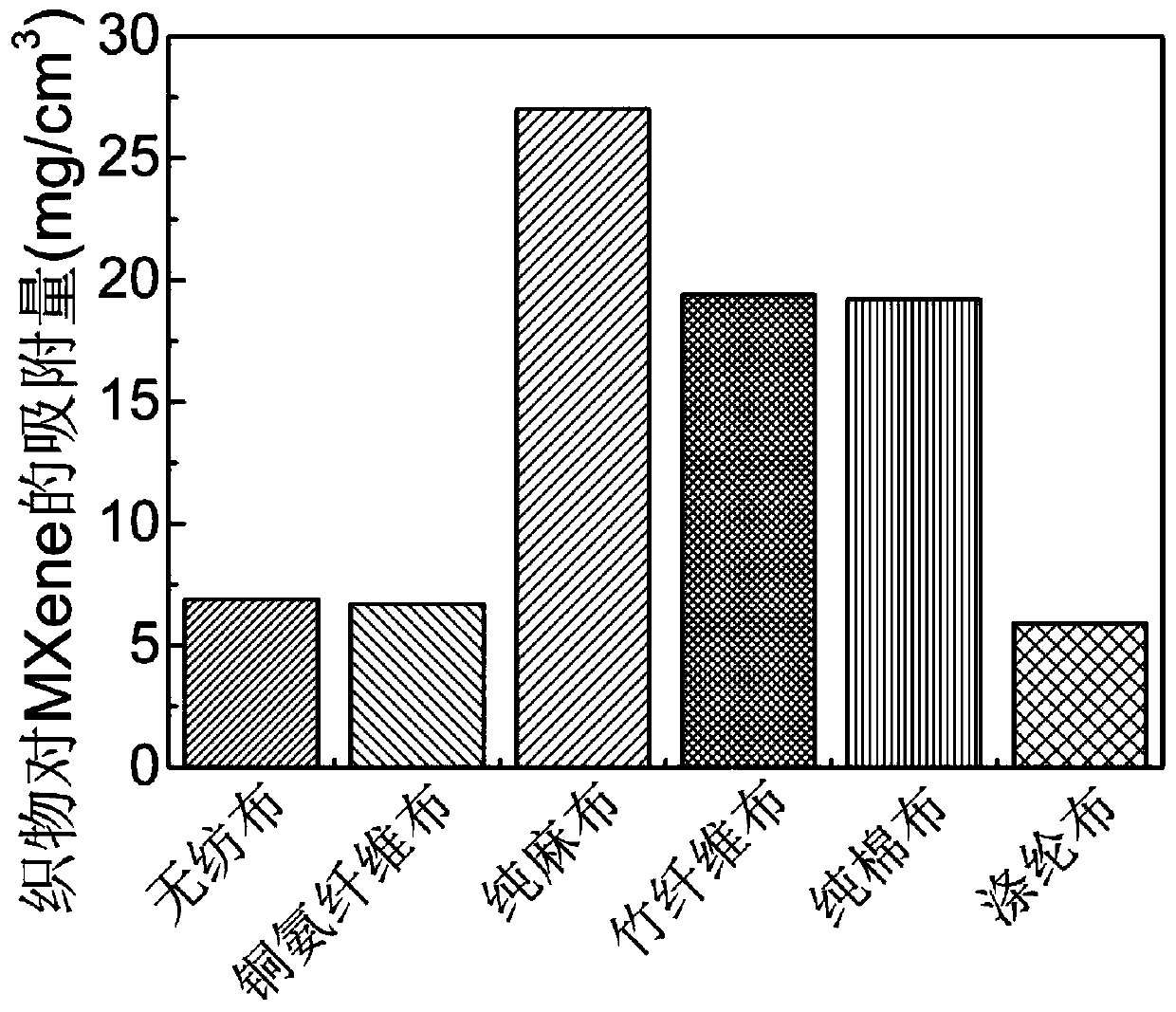

[0034] Put a certain size of pure cotton cloth into the petri dish containing the MXene\water dispersion obtained in step (1), take it out and dry it in cold air after it is fully immersed, such as figure 2 Shown. Combine image 3 with Figure 4 , It can be seen that the p...

Embodiment 2

[0039] (1) The preparation process of MXene:

[0040] The etching solution of LiF, hydrochloric acid and ultrapure water with a mass ratio of 1.0:15.0312:5 was fully stirred, and 1gMAX phase (Ti 3 AlC 2 ) Powder, continue to stir for 25h until the etching is complete. Centrifuge at 3600r / min for several times to wash until the pH of the supernatant is close to 7. Then, the obtained precipitate was fully dispersed in deionized water, and the upper black liquid was collected by centrifugation at 3600r / min for 6min, which was the MXene dispersion.

[0041] (2) MXene / fabric adsorption treatment:

[0042] Put a certain size of cupra into a petri dish containing the MXene\water dispersion obtained in step (1), take it out after immersion and dry it with cold air, such as figure 2 Shown. Combine image 3 with Figure 4 It can be seen that the cupro ammonia cloth has a large amount of adsorption to MXene, good adhesion, and it is not easy to fall off after washing for a long time, and the...

Embodiment 3

[0047] (1) The preparation process of MXene:

[0048] The etching solution of LiF, hydrochloric acid and ultrapure water with a mass ratio of 1.25:21.6936:5 was fully stirred, and 1gMAX phase (Ti 3 AlC 2 ) Powder, continue to stir for 26h until the etching is complete. Centrifuge at 3700r / min for several times for washing until the pH of the supernatant is close to 7. Then, the obtained precipitate was fully dispersed in deionized water, and the upper black liquid was collected by centrifugation at 3700 r / min for 7 minutes, which was the MXene dispersion.

[0049] (2) MXene / fabric adsorption treatment:

[0050] Put a certain size of non-woven fabric into the petri dish containing the MXene\water dispersion obtained in step (1), take it out after being fully immersed and dry it with cold air, such as figure 2 Shown. Combine image 3 with Figure 4 It can be seen that the non-woven fabric has a large amount of MXene adsorption, good adhesion, and it is not easy to fall off after a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com