Fully-automatic intelligent glue preparation online mixing epoxy insulation core rod injection pultrusion process

A technology of insulating mandrel and pultrusion process, which is applied in the field of fully automatic intelligent glue dispensing and online mixing epoxy insulating mandrel injection pultrusion process, which can solve the problem of low precision of artificial glue dispensing, affecting product performance, and large human error, etc. problems, to achieve the effect of very little micro-bubble content, excellent electromechanical performance, and stable pressure output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Such as figure 1 As shown in the flow chart of the fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, a fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, the specific steps are as follows:

[0029] Step 1. Glass fiber positioning: After the glass fiber is positioned and preformed by the yarn guide, it enters the continuous resin transfer molding mold;

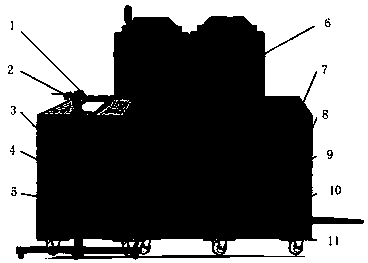

[0030] Step 2. Intelligent glue dispensing: epoxy resin and curing agent are loaded into the two-component epoxy resin injection system by the feed pump ( figure 2 Shown) A, B storage tank ( figure 2 6), the material storage tank is equipped with stirring and moisture absorbing devices to ensure the safety of raw materials storage, the calculation method of the optimal ratio of epoxy resin and curing agent is based on the epoxy resin purchased in each batch Calculate the optimal ratio of epoxy re...

Embodiment 2

[0036] Such as figure 1 As shown in the flow chart of the fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, a fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, the specific steps are as follows:

[0037] Step 1. Glass fiber positioning: After the glass fiber is positioned and preformed by the yarn guide, it enters the continuous resin transfer molding mold;

[0038]Step 2. Intelligent glue dispensing: epoxy resin and curing agent are loaded into the two-component epoxy resin injection system by the feed pump ( figure 2 Shown) A, B storage tank ( figure 2 6), the material storage tank is equipped with stirring and moisture absorbing devices to ensure the safety of raw materials storage, the calculation method of the optimal ratio of epoxy resin and curing agent is based on the epoxy resin purchased in each batch Calculate the optimal ratio of epoxy res...

Embodiment 3

[0044] Such as figure 1 As shown in the flow chart of the fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, a fully automatic intelligent glue dispensing online mixed epoxy insulating mandrel injection pultrusion process, the specific steps are as follows:

[0045] Step 1. Glass fiber positioning: After the glass fiber is positioned and preformed by the yarn guide, it enters the continuous resin transfer molding mold;

[0046] Step 2. Intelligent glue dispensing: epoxy resin and curing agent are loaded into the two-component epoxy resin injection system by the feed pump ( figure 2 Shown) A, B storage tank ( figure 2 6), the material storage tank is equipped with stirring and moisture absorbing devices to ensure the safety of raw materials storage, the calculation method of the optimal ratio of epoxy resin and curing agent is based on the epoxy resin purchased in each batch Calculate the optimal ratio of epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com