Patents

Literature

43results about How to "Stable pressure output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

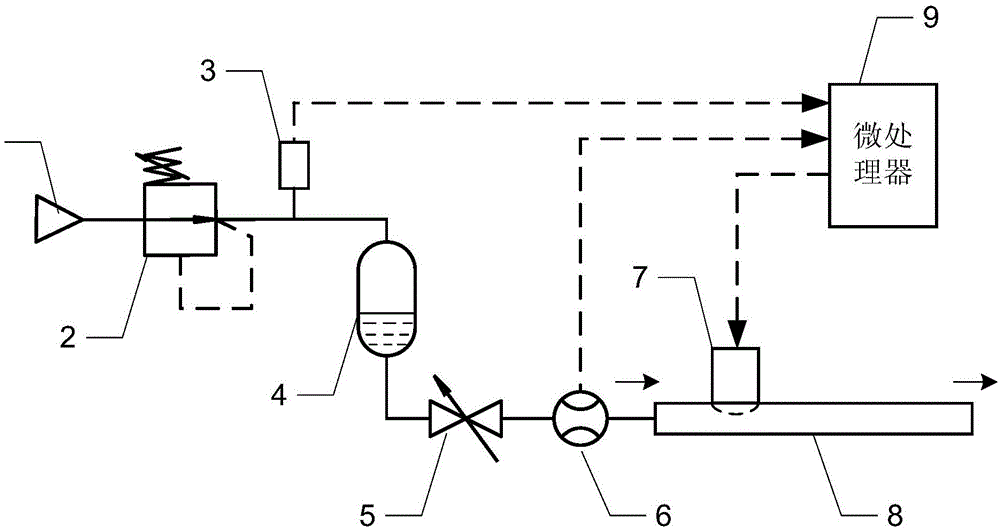

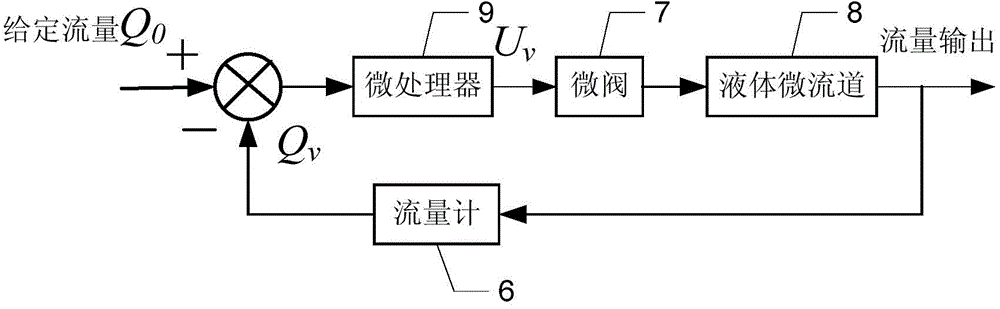

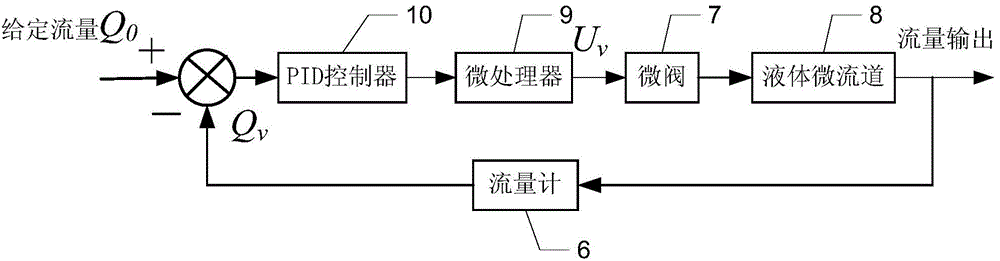

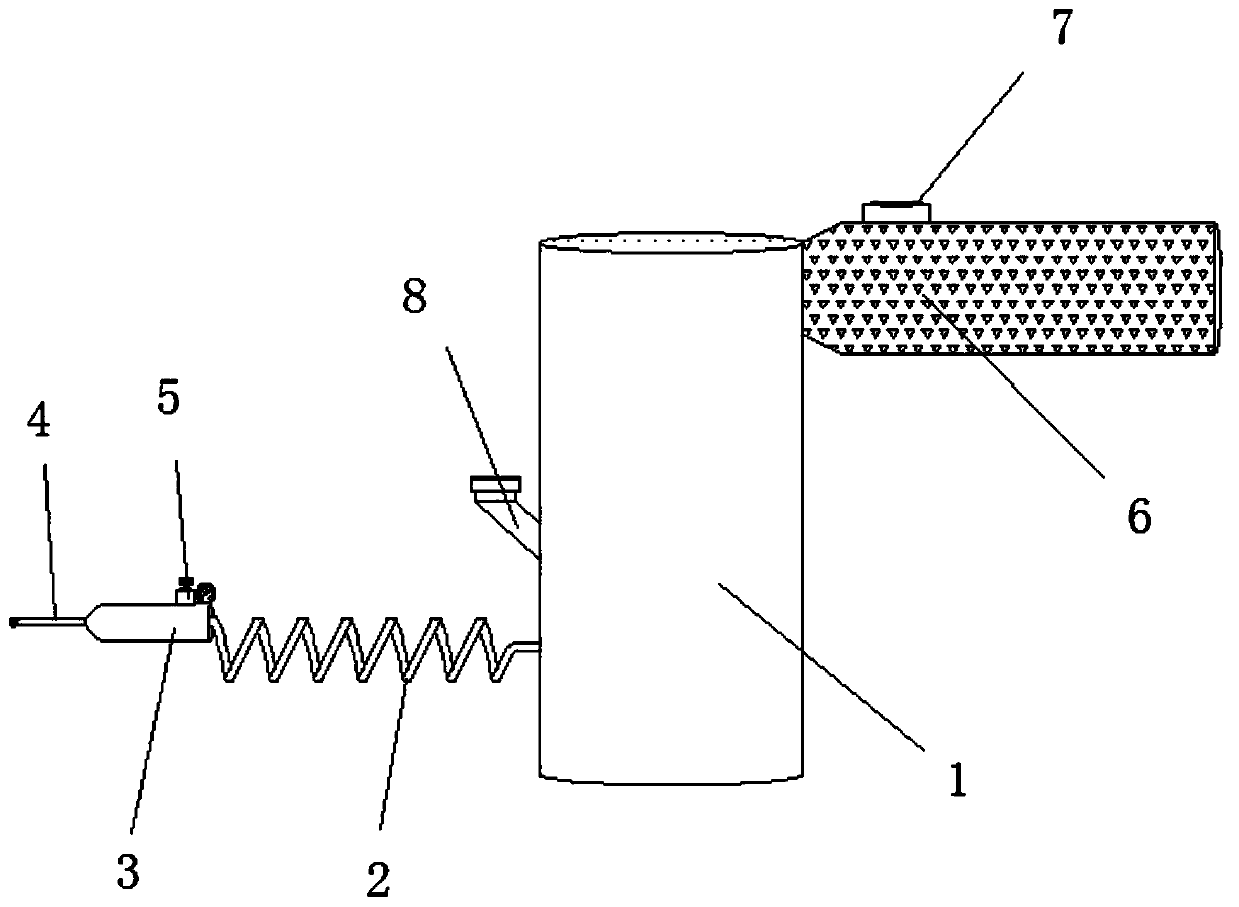

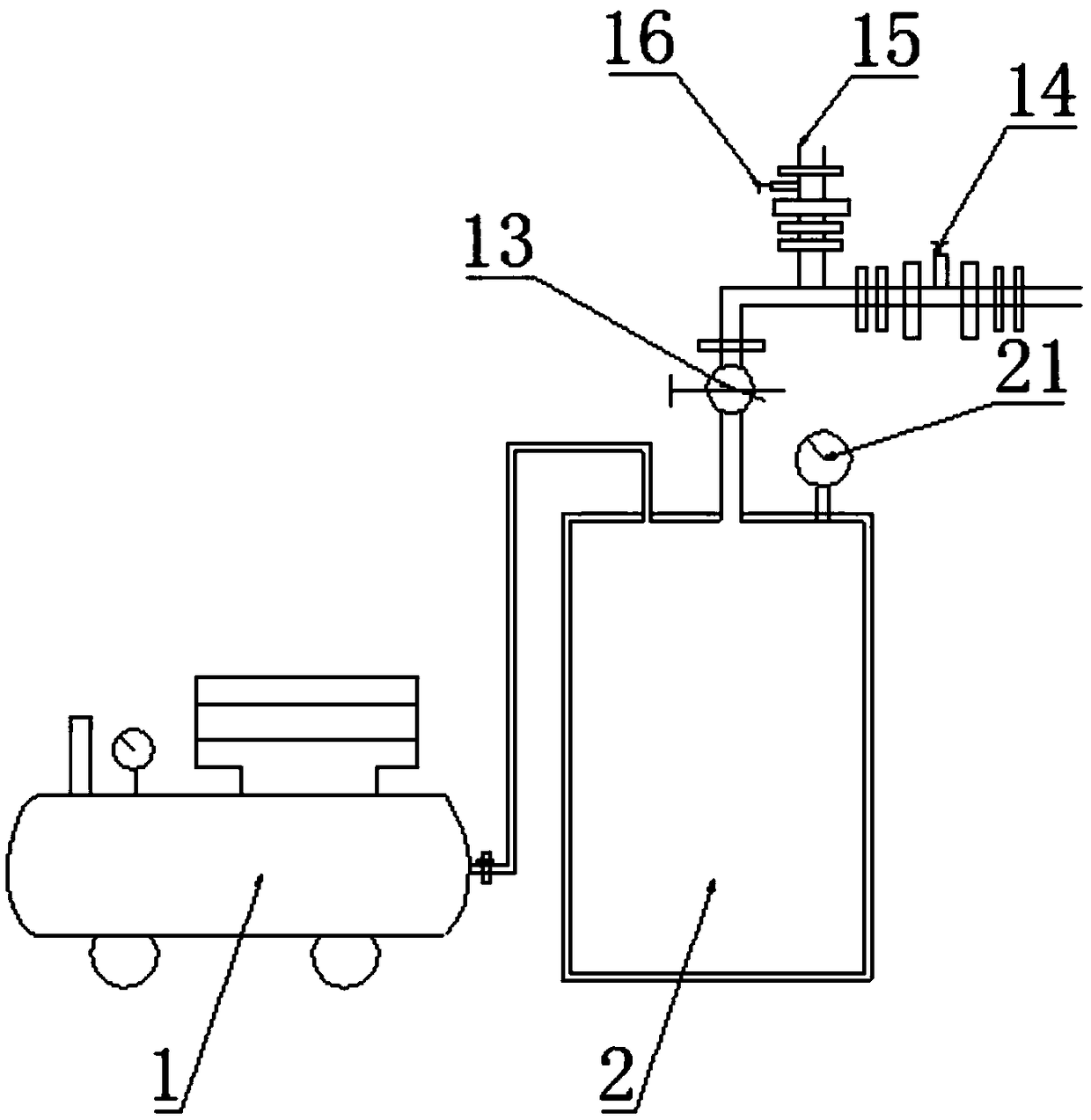

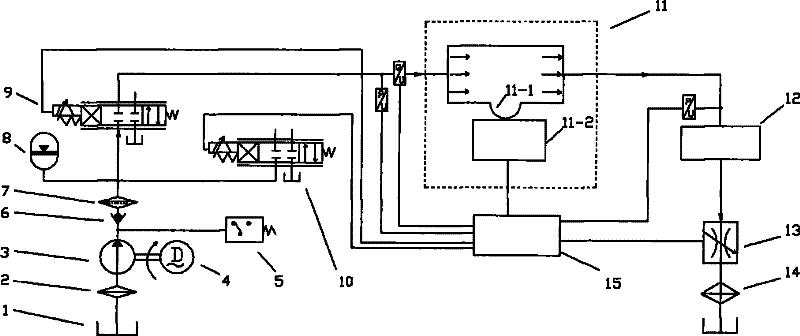

Micro fluid flow adjusting device based on air pressure drive

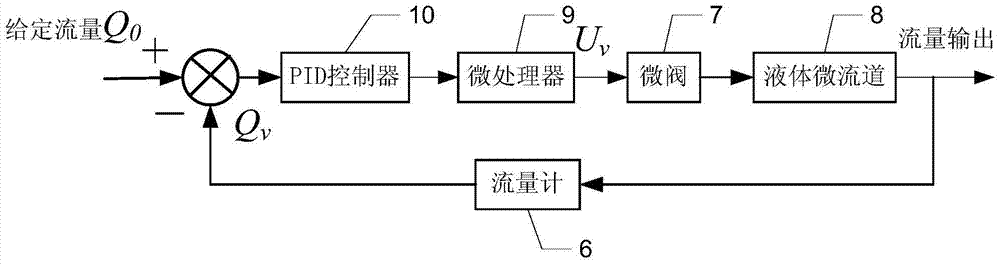

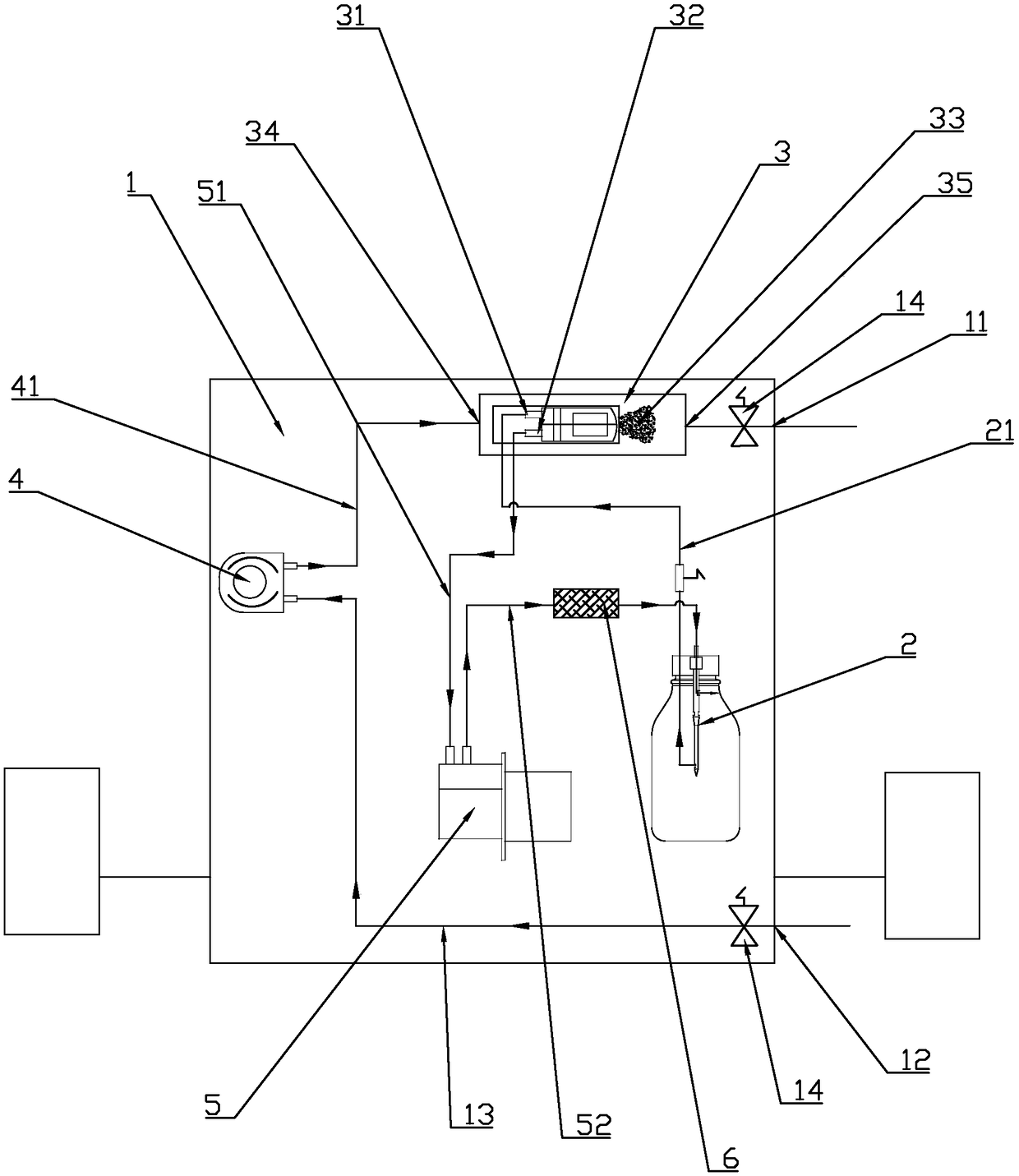

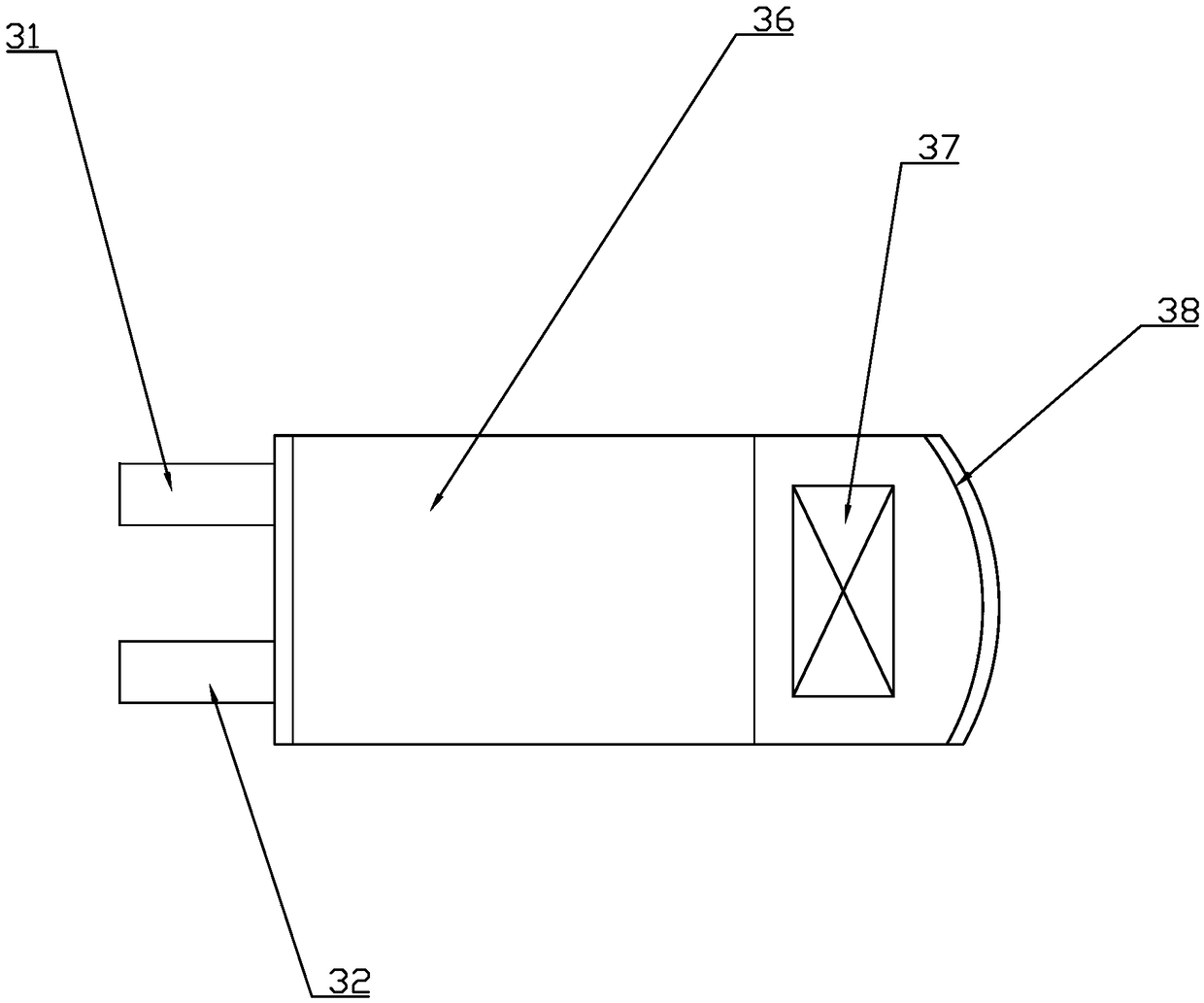

ActiveCN104696706AEasy to adjustRealize closed-loop controlPipeline systemsControl signalPressure.drive

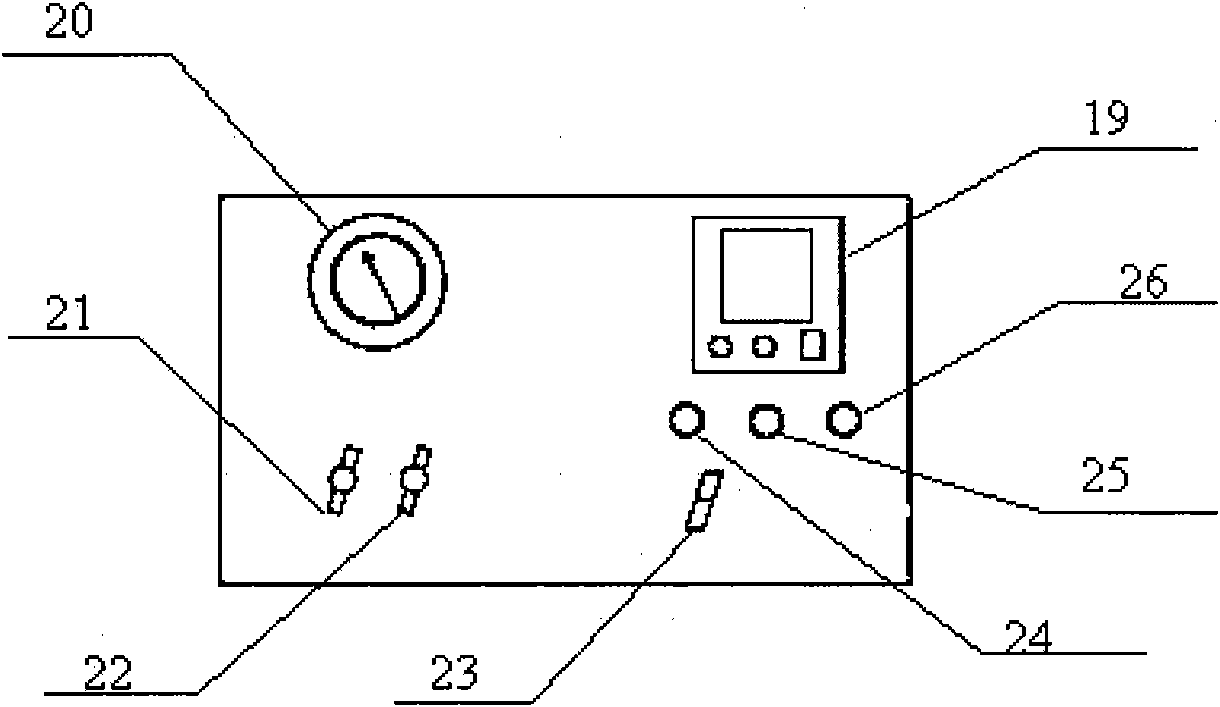

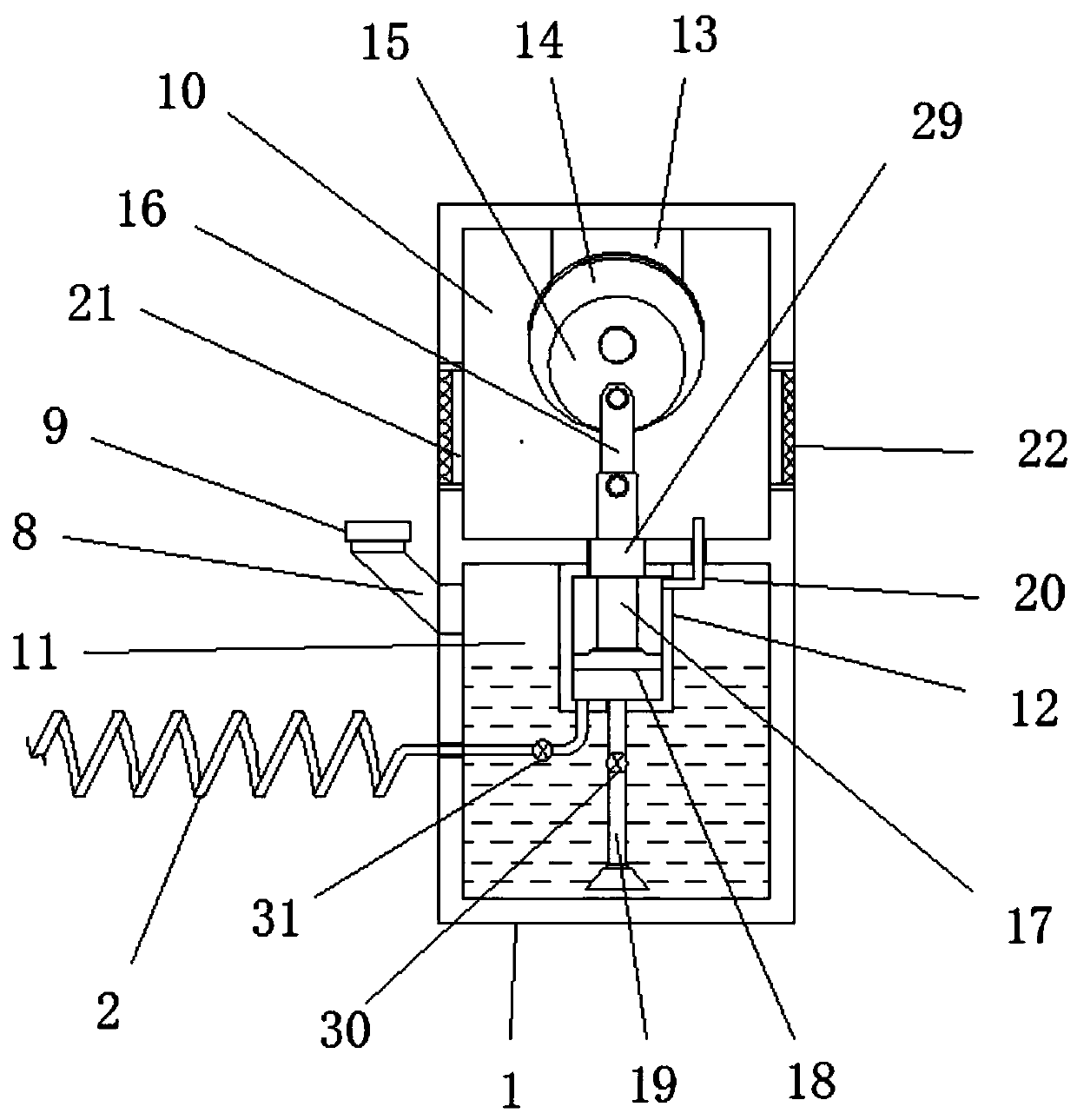

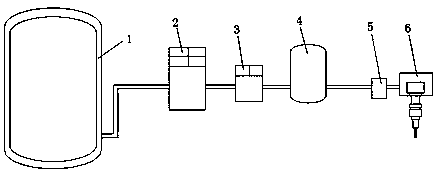

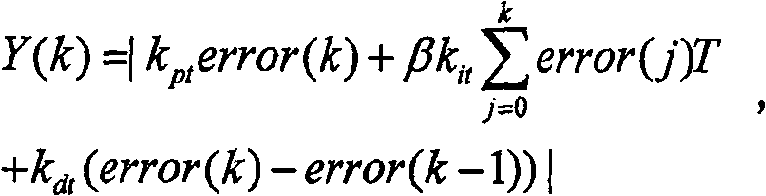

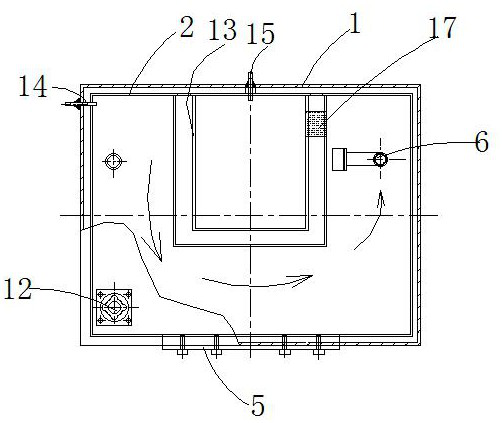

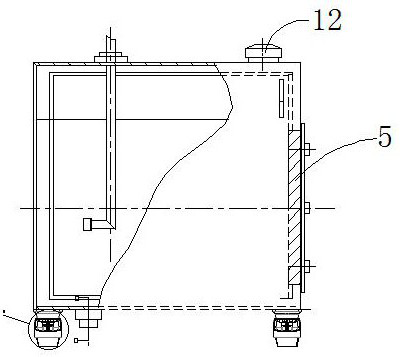

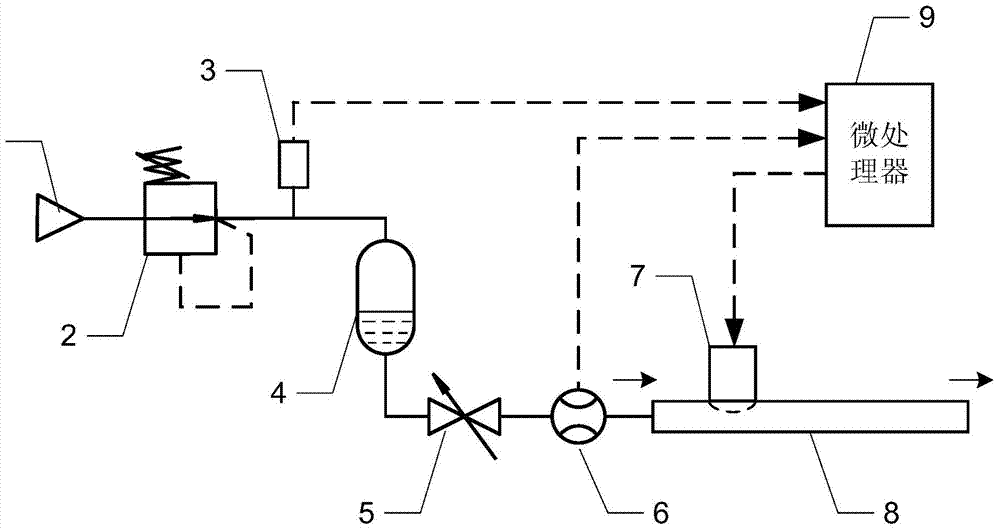

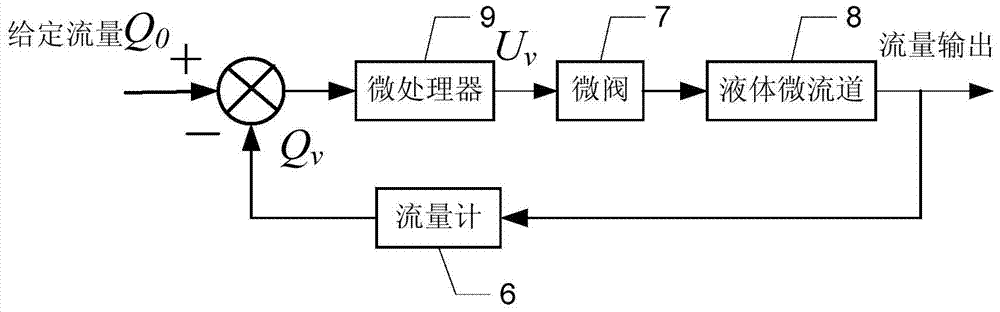

The invention provides a micro fluid flow adjusting device based on air pressure drive, belongs to the field of micro fluids, and aims to solve the problems of low flow adjusting precision, low dynamic response speed and absence of capacity of measuring actual flow when an injection pump is adopted to adjust the flow in a micro fluid system. The micro fluid flow adjusting device adopts an air pressure drive mode, an air supply source supplies compressed air, outlet pressure is adjusted and set by a pressure reducing valve to obtain stable air supply pressure, the pressure is measured by a pressure sensor, a liquid in a liquid container passes a valve and a flow meter to enter a liquid micro-channel under the pushing of the air pressure, the actual liquid flow is measured by the flow meter and fed back to a microprocessor, the microprocessor outputs a control signal to change the working state of a micro valve, the liquid flow of the liquid micro-channel is adjusted, and closed-loop control of the flow is realized; further, a PID (proportion integration differentiation) control algorithm can be adopted, the adjusting precision and the dynamic response speed of the flow can be increased, and the liquid flow in the micro-channel can be adjusted accurately and rapidly.

Owner:HARBIN INST OF TECH

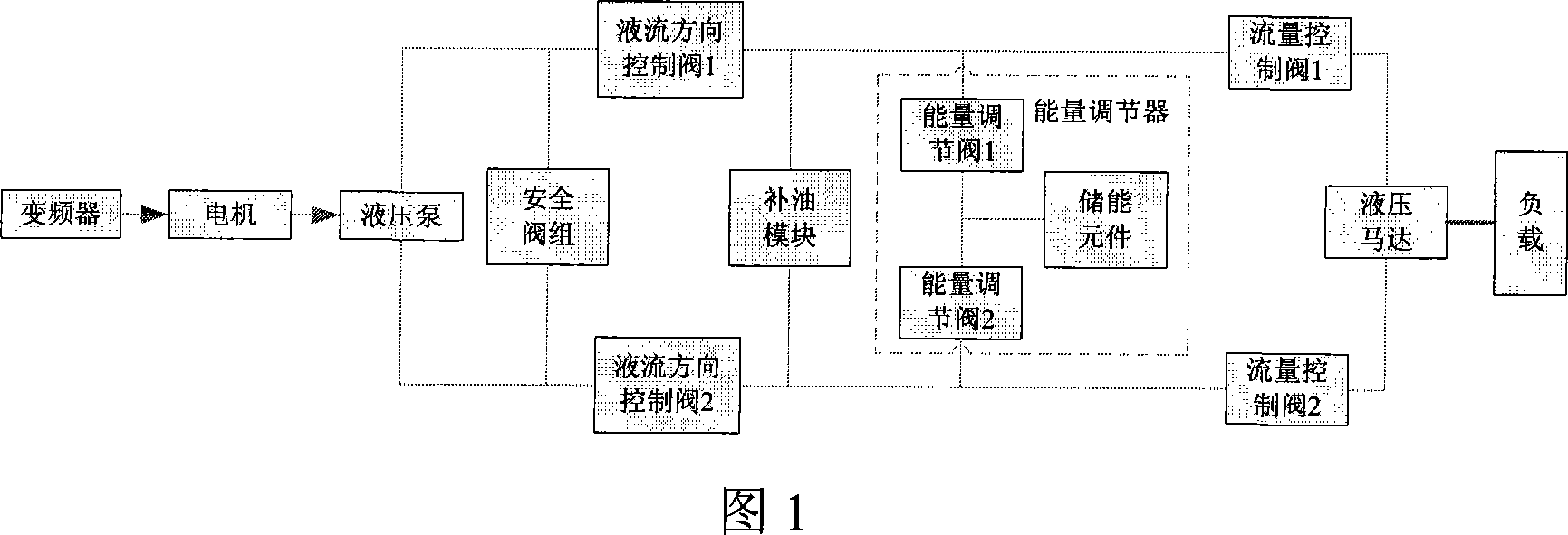

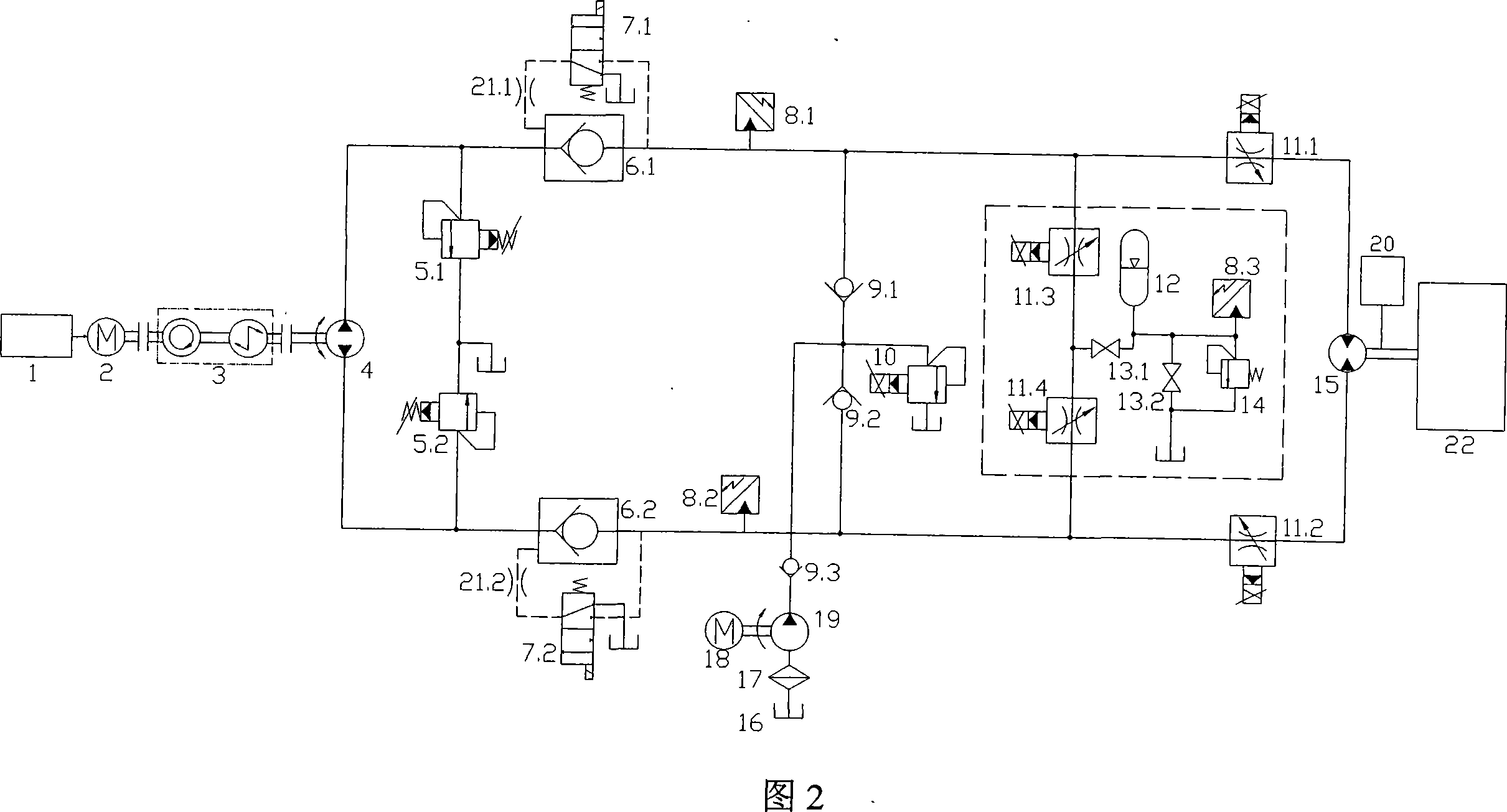

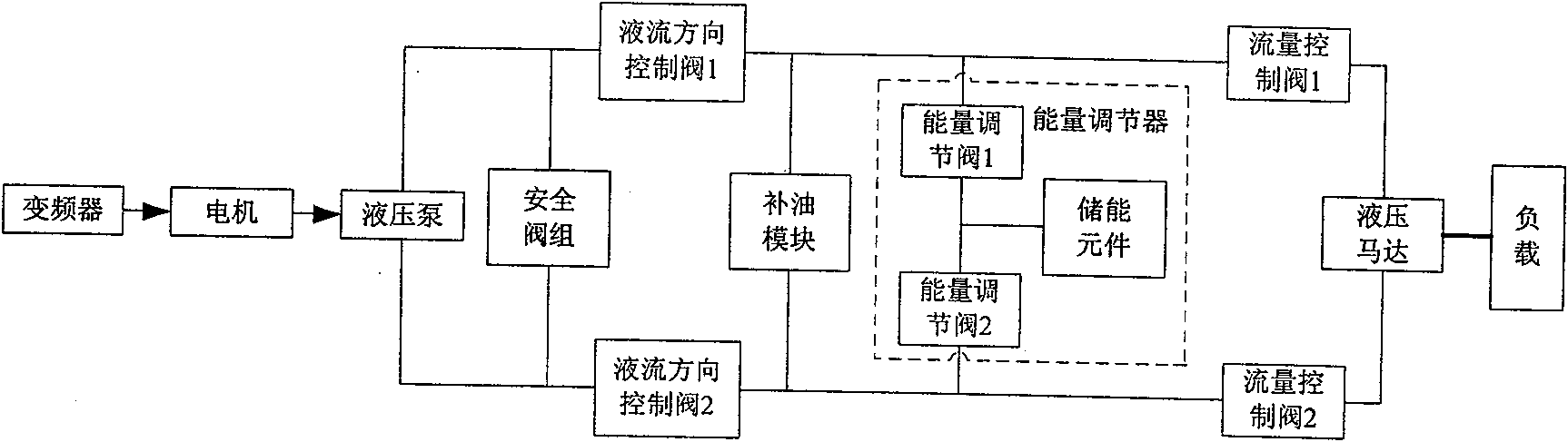

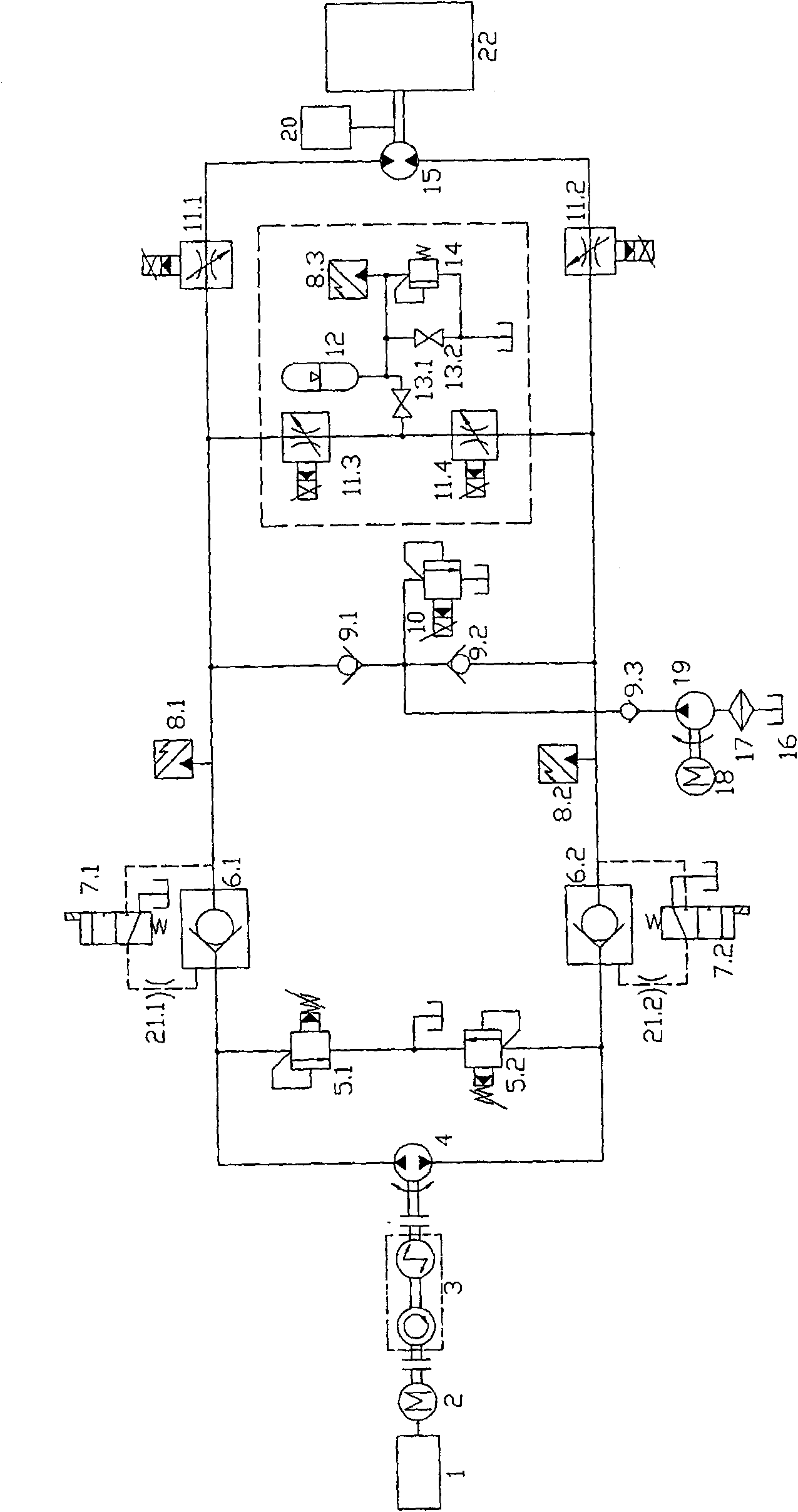

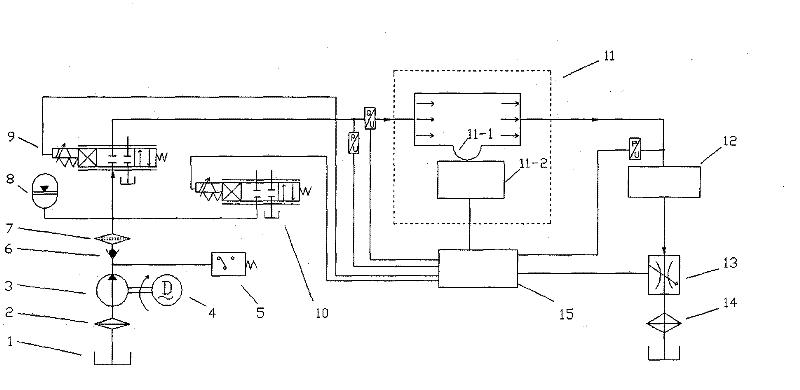

Variable frequency pump-control-motor closed circuit based on energy regulation

InactiveCN101201069AReduce lossQuick responseServomotor componentsServomotorsFrequency changerThrottle control

The invention discloses a closed loop of a variable frequency pump-control motor, which is based on the energy regulating. The invention includes an inverter, a motor, a hydraulic pump, a safety valve group, an oil supplementing module and a hydraulic motor. The inverter drives the motor which drives the hydraulic pump. The safety valve group, the oil supplementing module and the hydraulic motor are connected astride in the closed circuit. An energy regulator is connected astride in the main circuit between the oil supplementing module and the hydraulic motor. A flow direction control valve is respectively arranged in the upper main circuit and the lower main circuit between the safety valve bank and the oil supplementing module. A flow control valve is respectively arranged in the upper main circuit and the lower main circuit between the energy regulator and the hydraulic motor. Based on the energy regulating, the energy regulator and throttle control are added to the traditional closed circuit of the pump-control motor, which speeds up the booster response of the system greatly. The invention has good energy saving effect.

Owner:ZHEJIANG UNIV

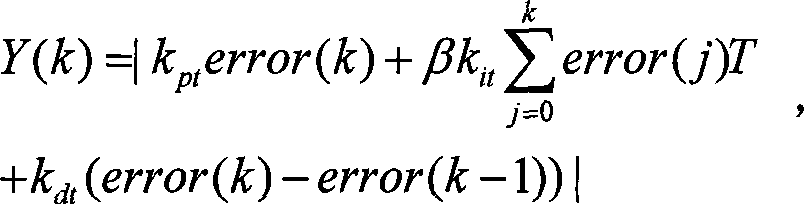

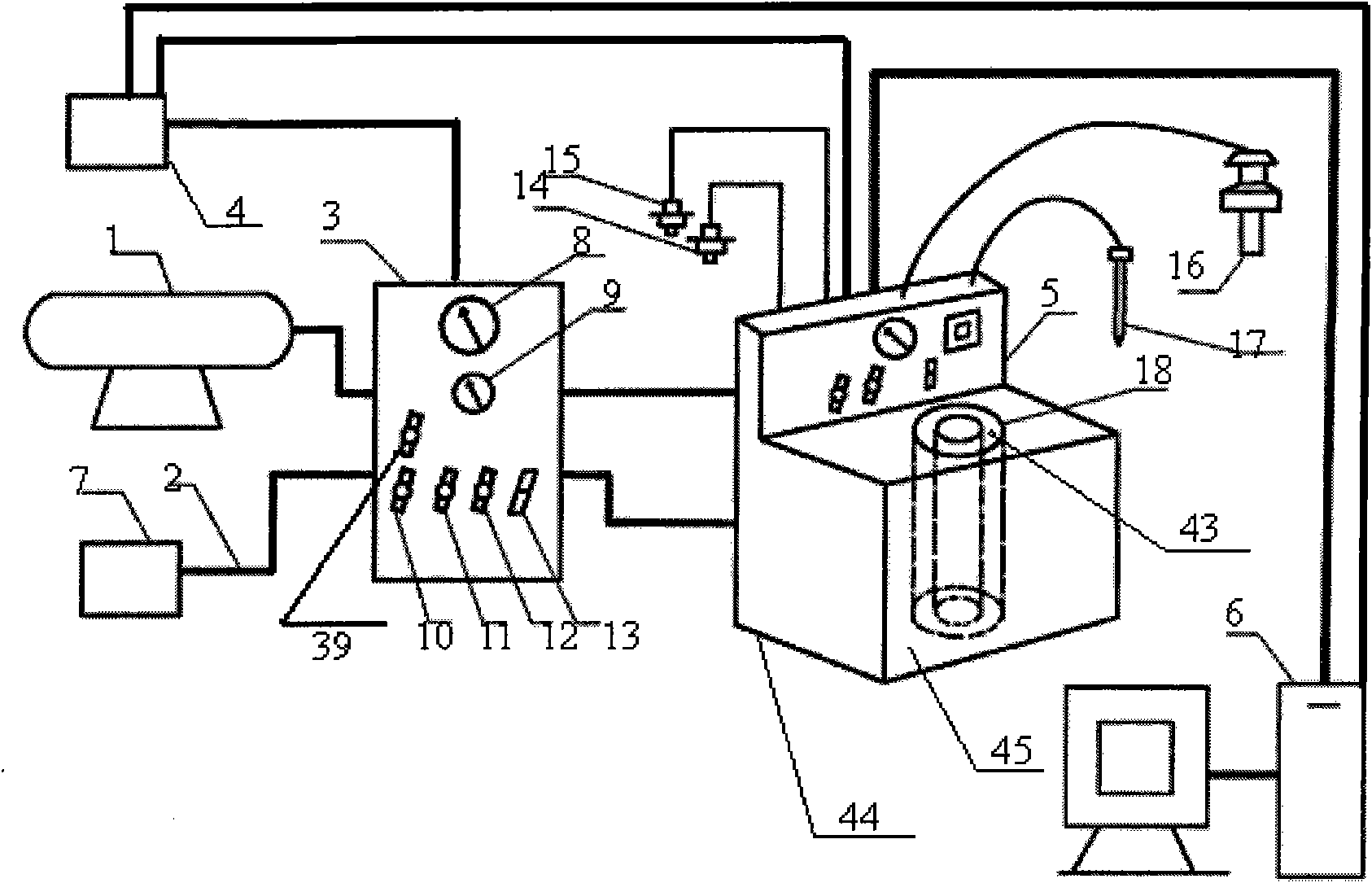

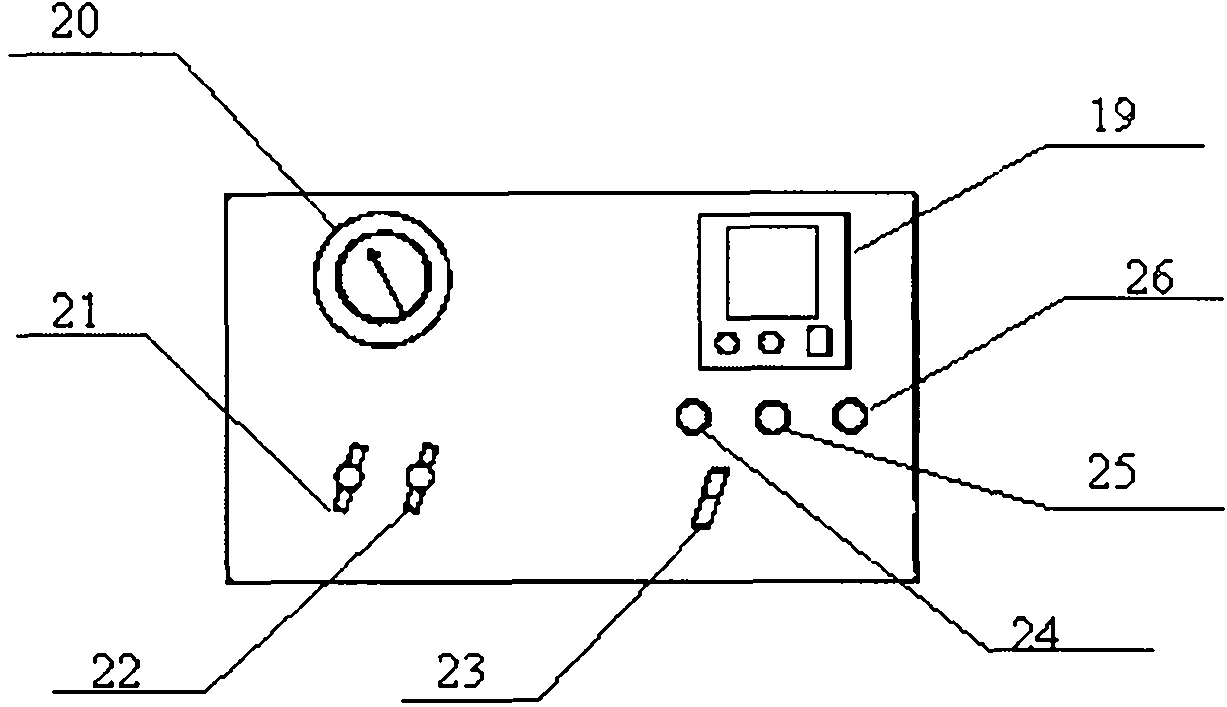

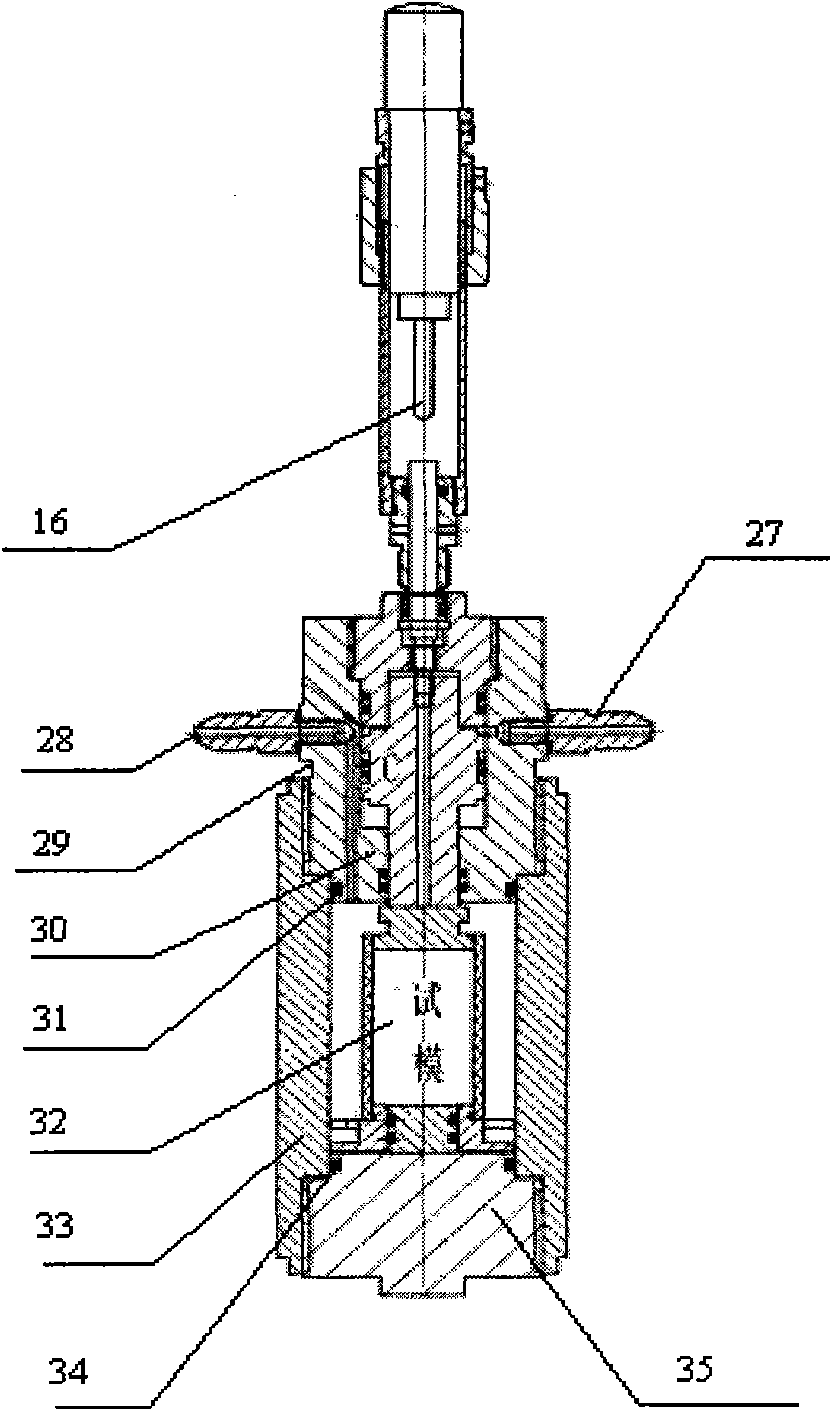

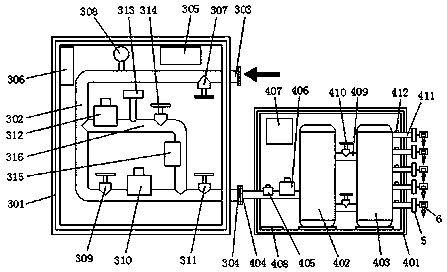

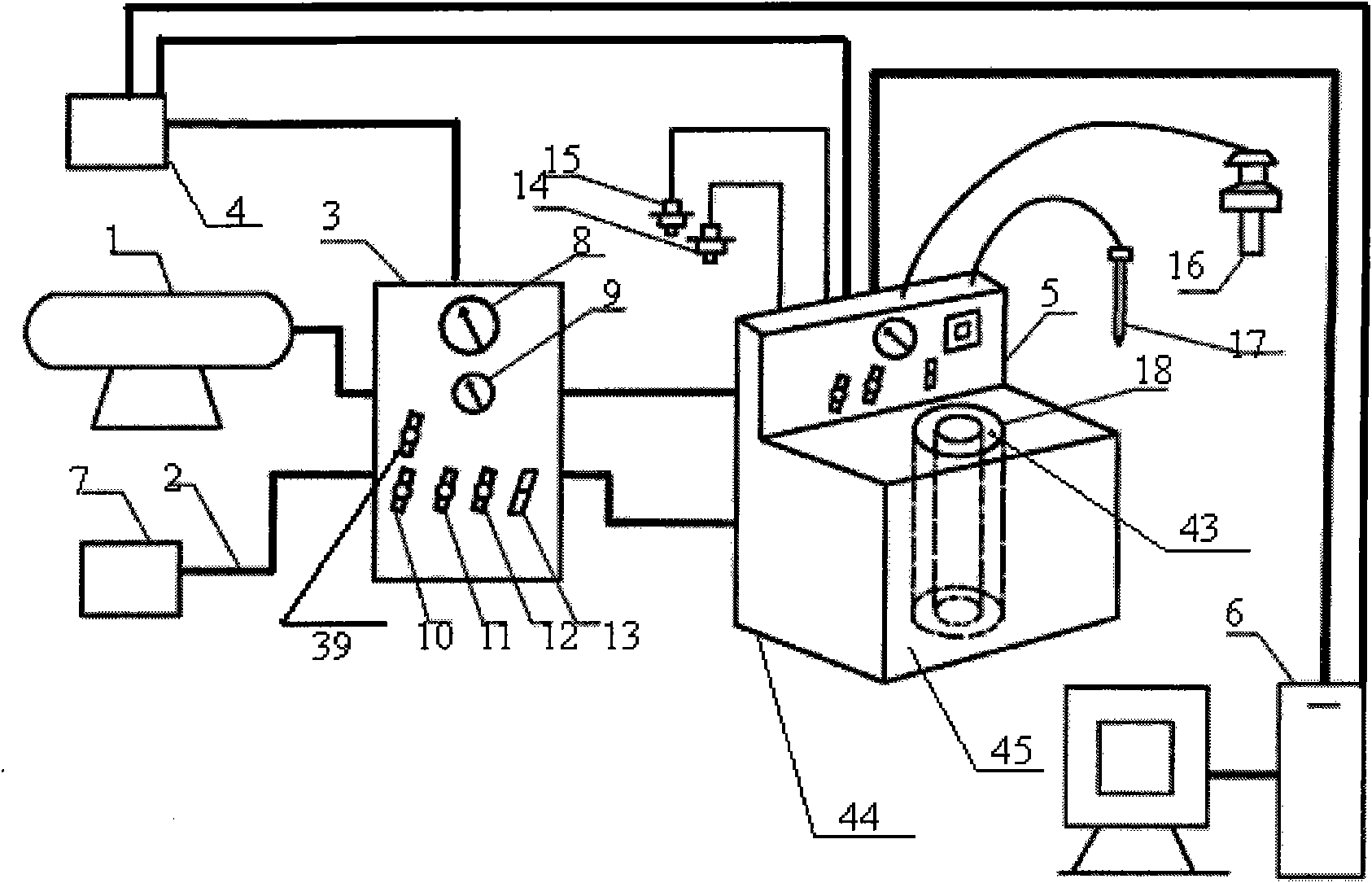

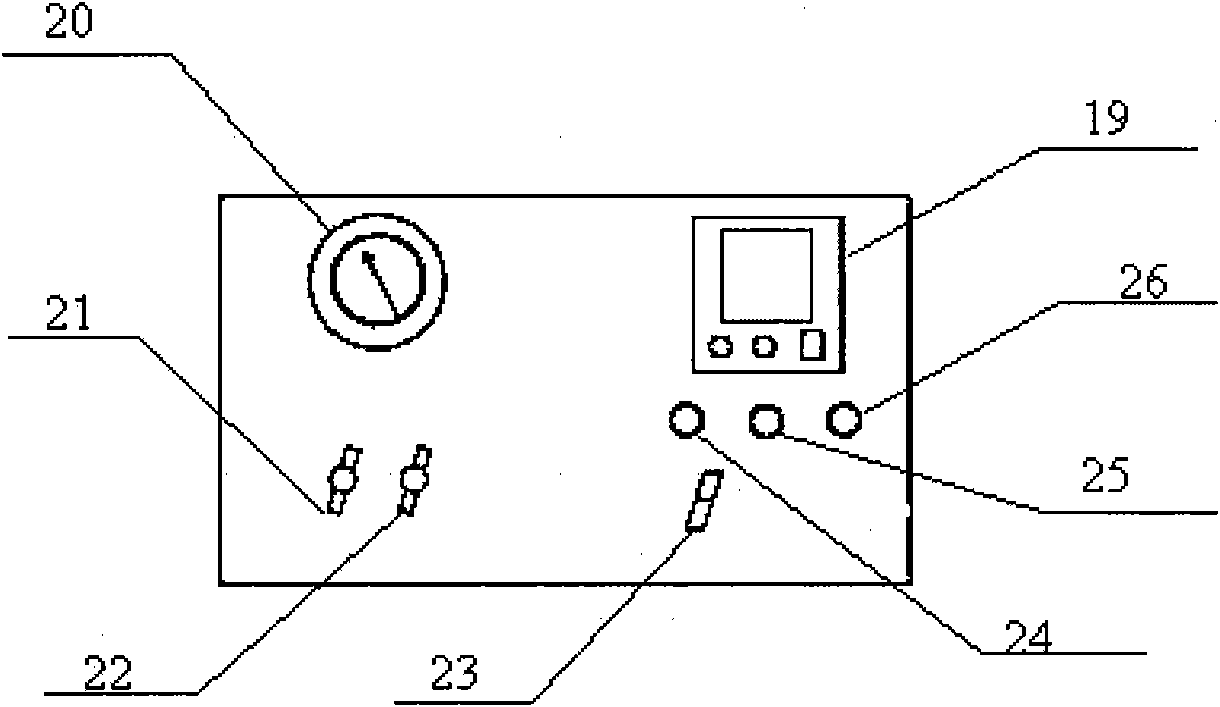

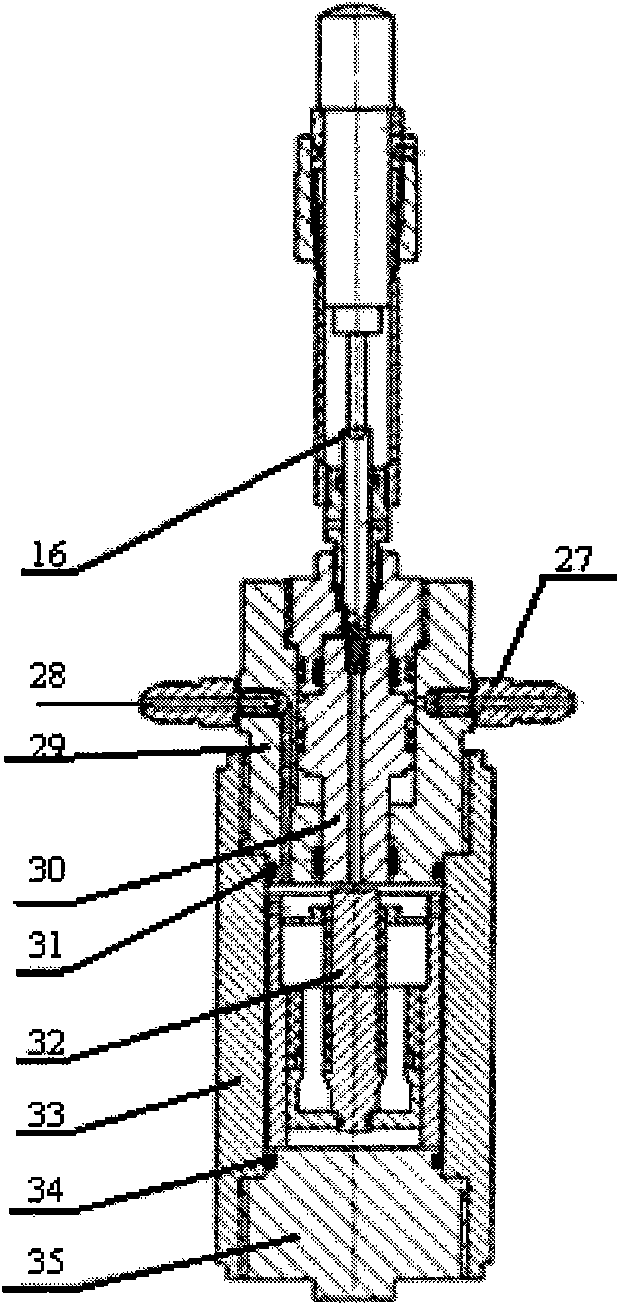

High-temperature high-pressure tensile stress strain system of oil well cement and test method thereof

ActiveCN102401770AEnables evaluation of tensile stress-strain curvesStable pressure outputThermometers using electric/magnetic elementsMaterial strength using tensile/compressive forcesTemperature controlTemperature stress

The invention relates to a high-temperature high-pressure tensile stress strain system of oil well cement. The system comprises a cement tensile test assembly, a power supply and pressure control unit, a temperature control unit, a signal control processing unit and pipelines. By adopting the system of the invention, the temperature and the pressure for the bottom maintenance can be simulated, the tensile stress strain of the oil well cement can be continuously measured under conditions of the temperature and the pressure, and the temperature pressure curve and the tensile stress strain curve are recorded. The system and the measure method of the invention are in favor of the intuitional test, the comparison of tensile resistances of different cement paste systems and the design of the cement paste formula, so cement paste systems which can satisfy on-site construction requirements are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

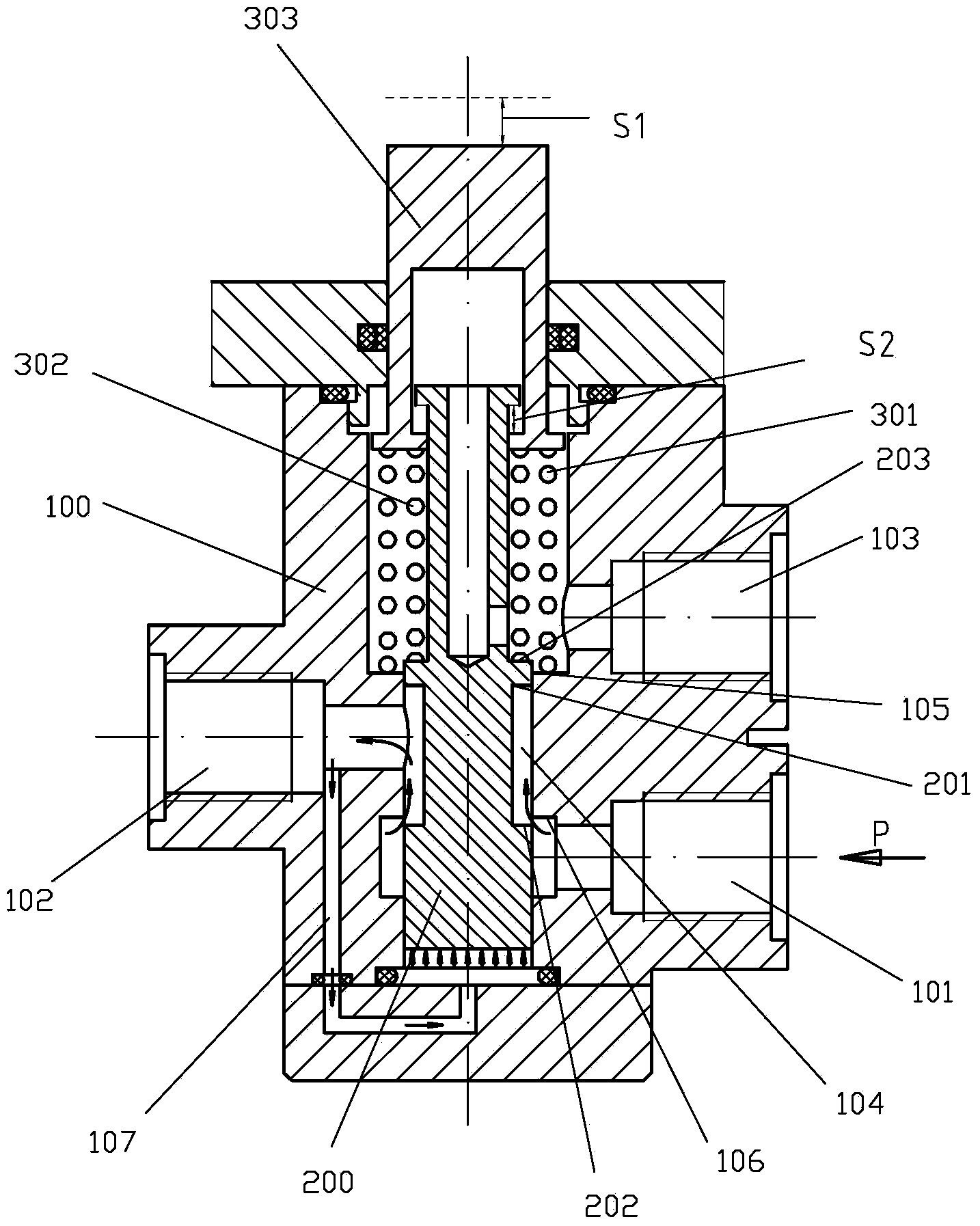

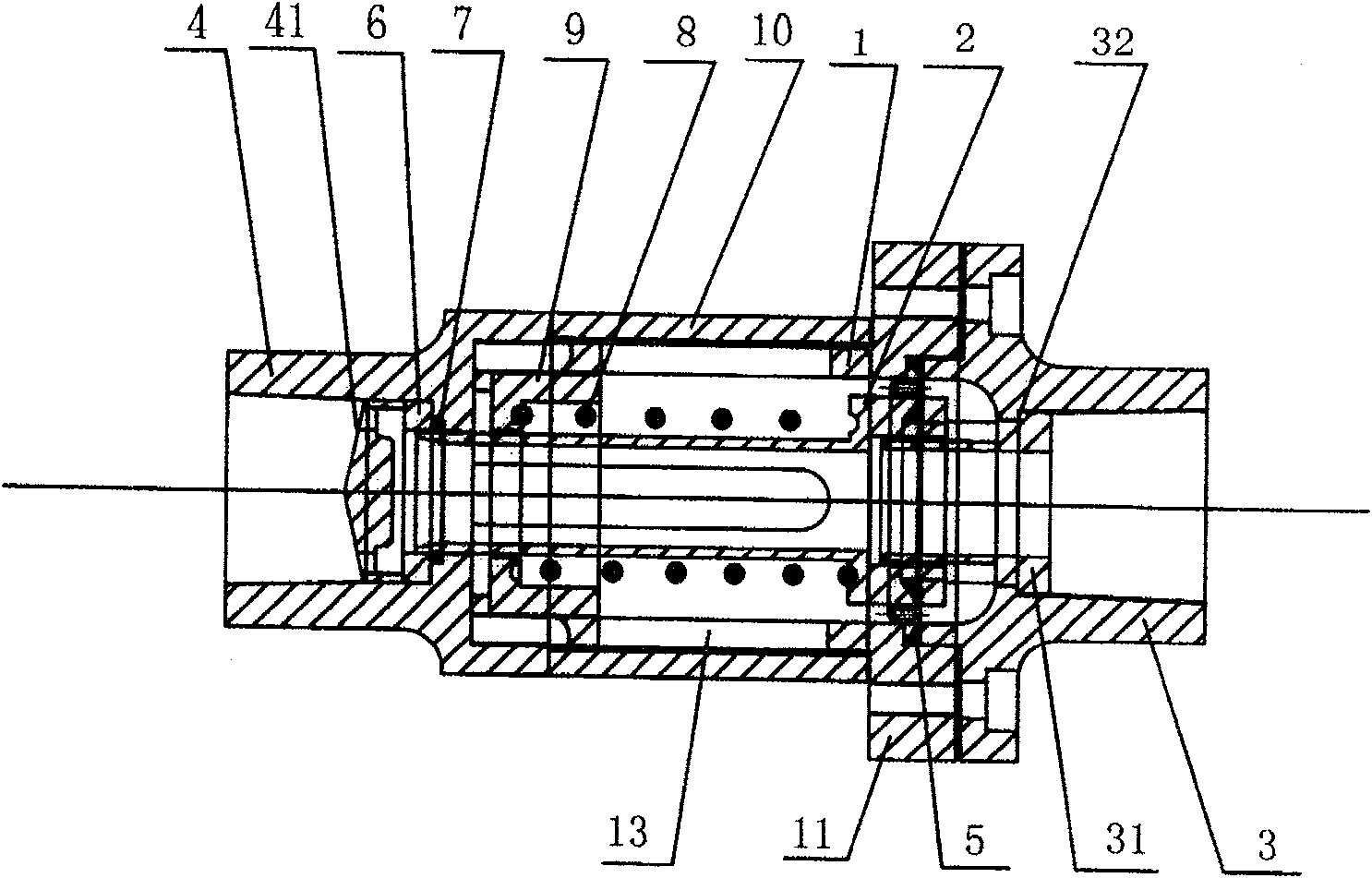

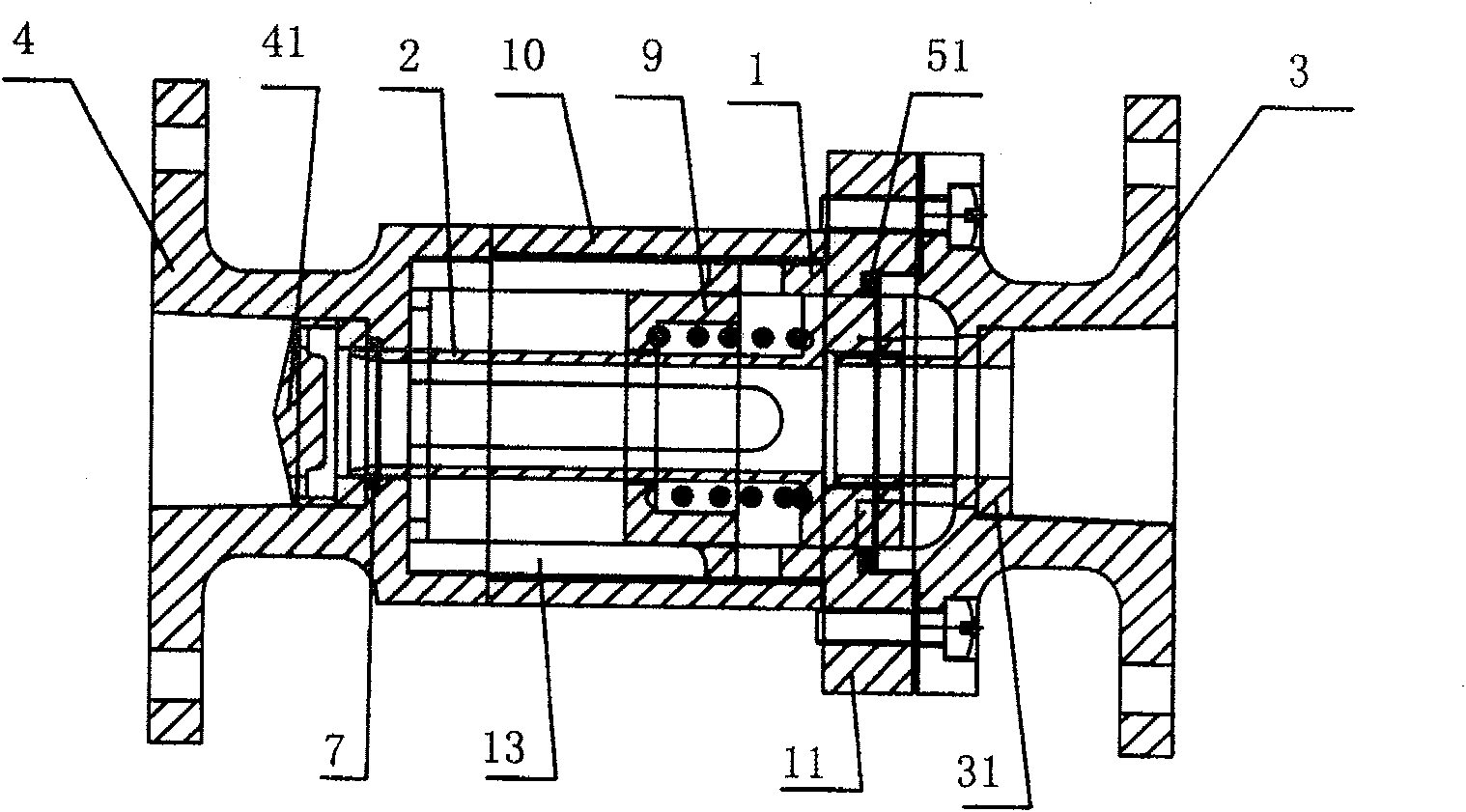

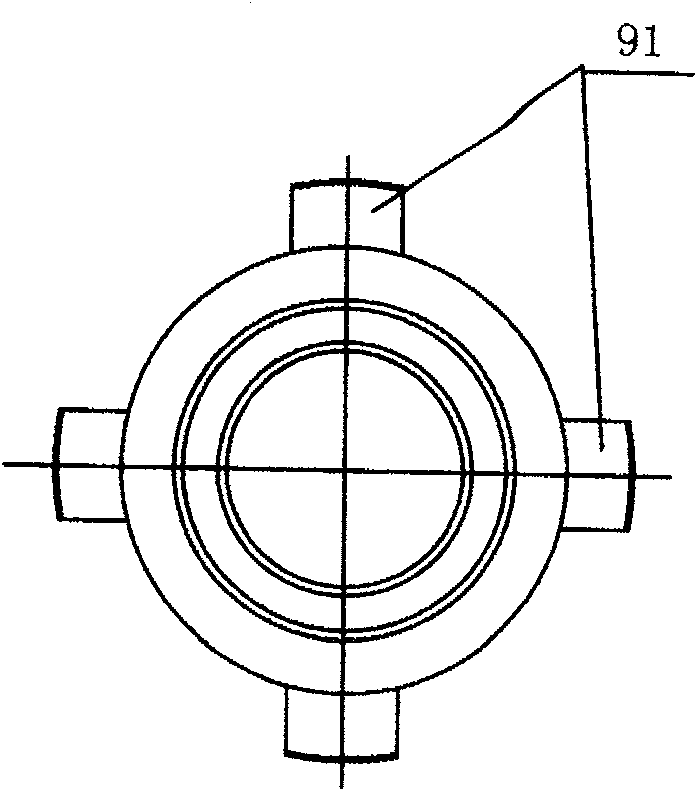

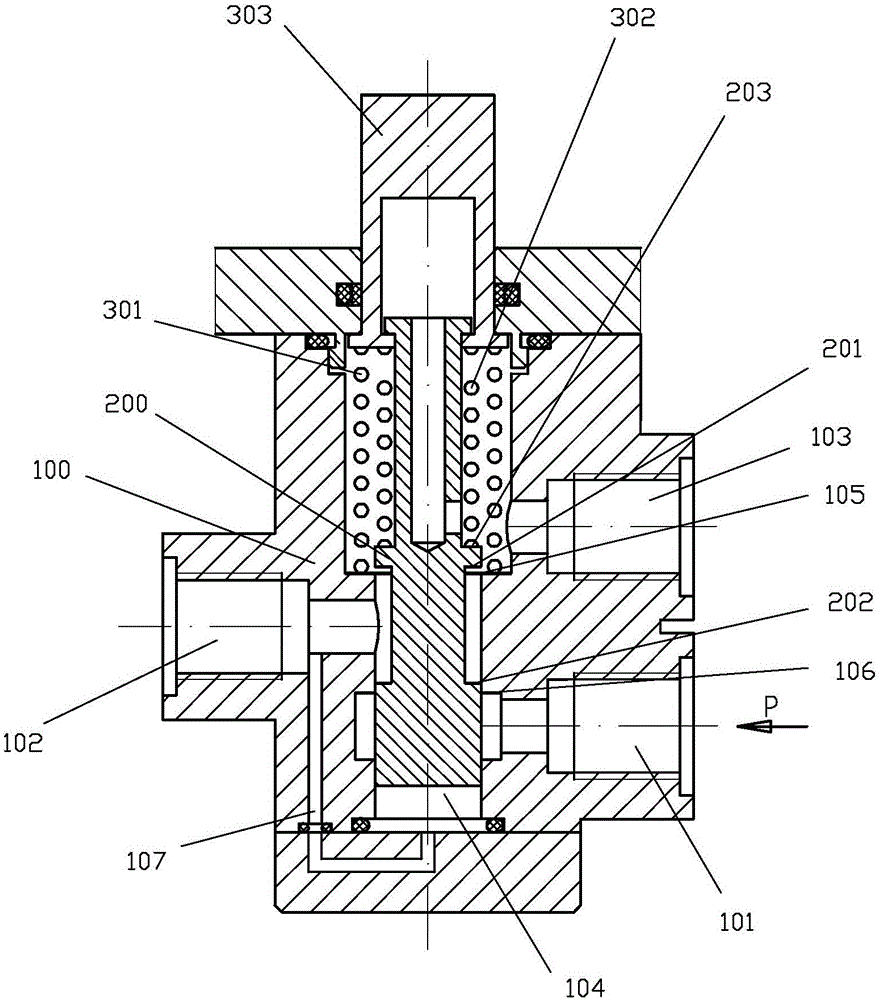

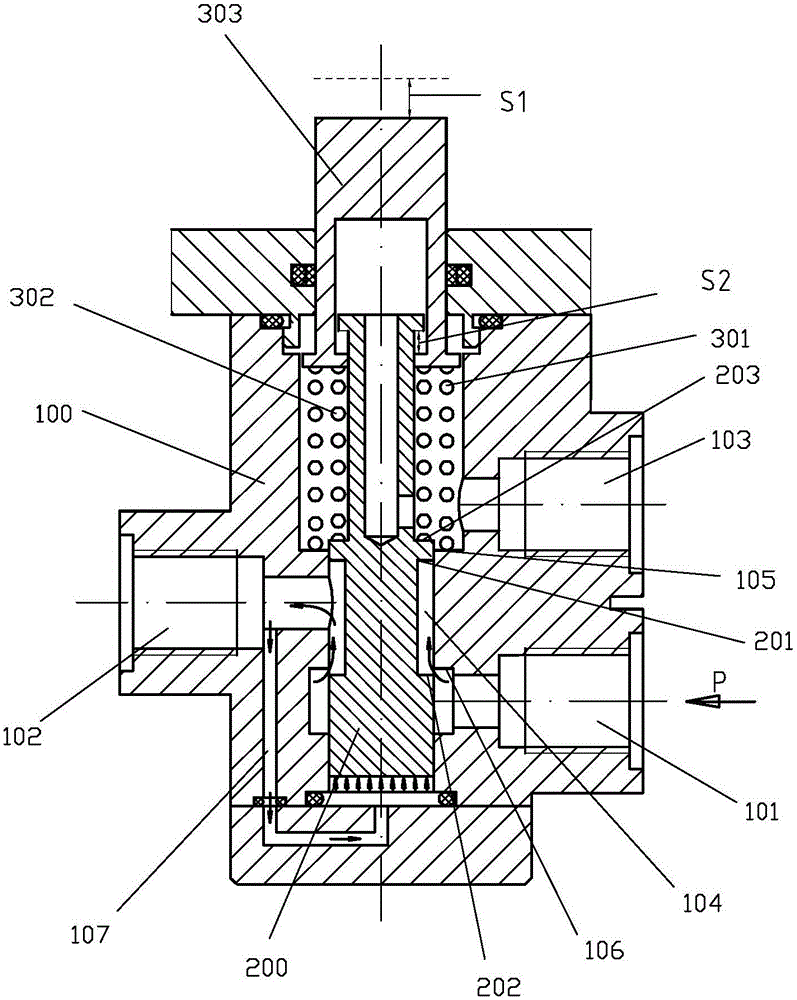

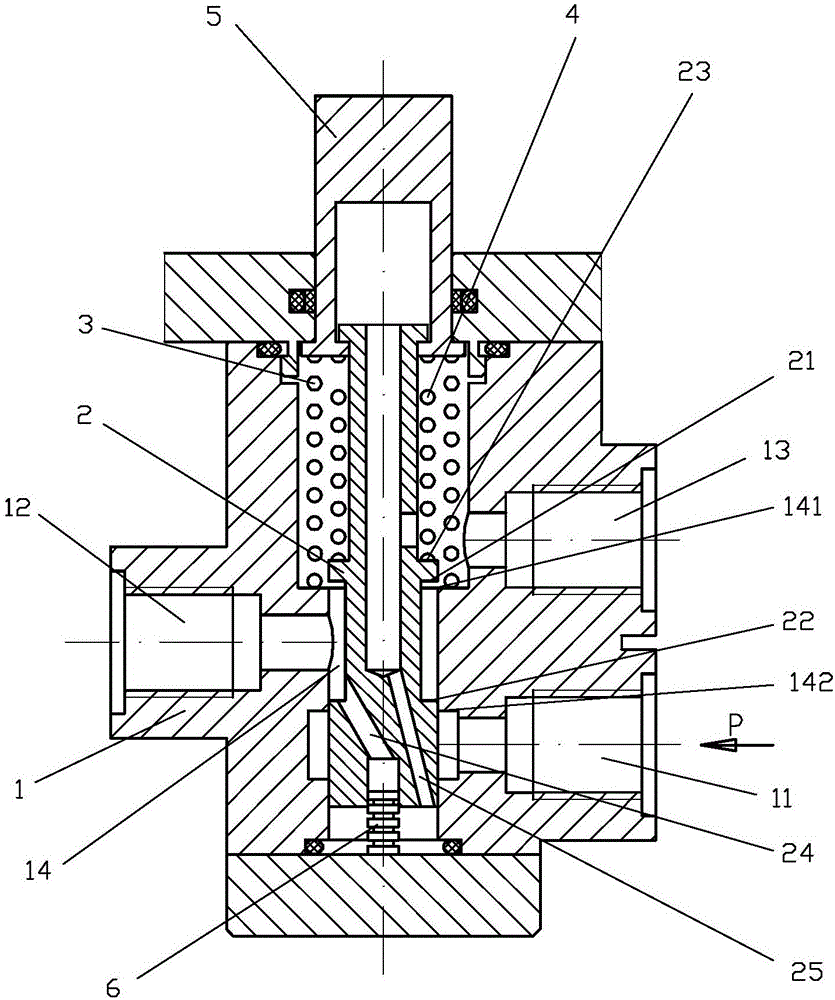

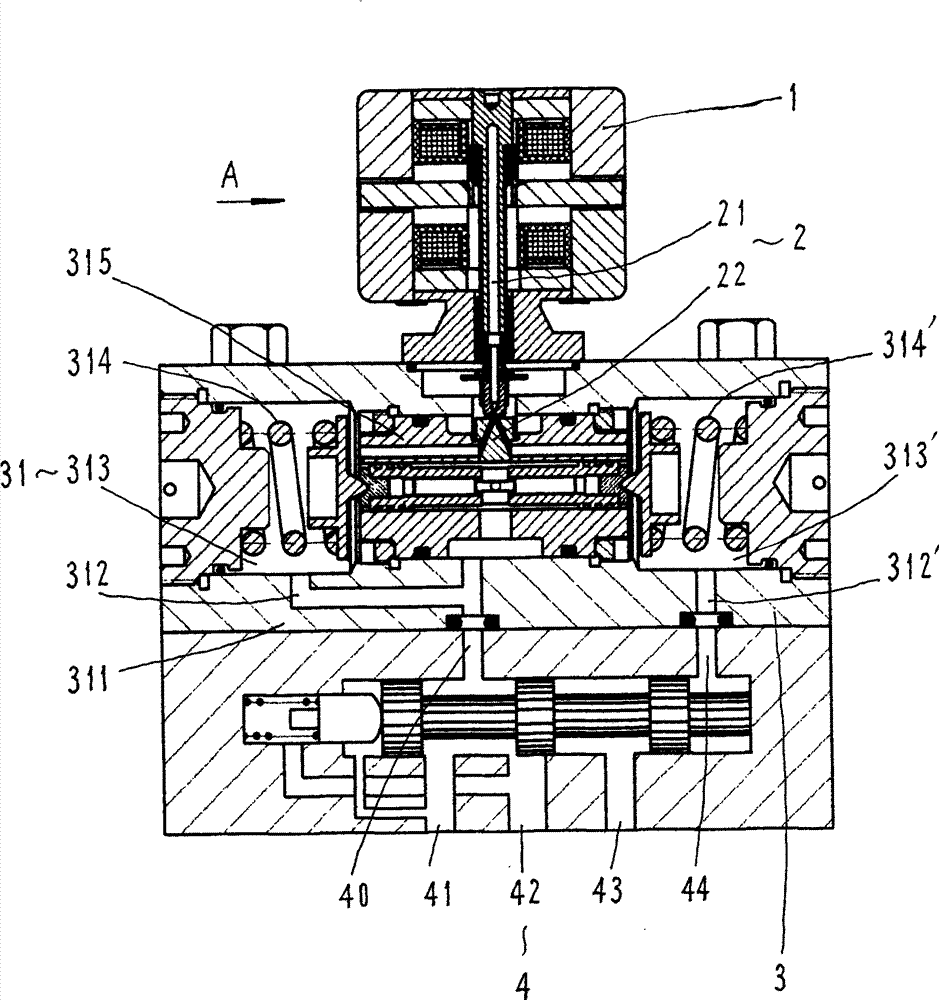

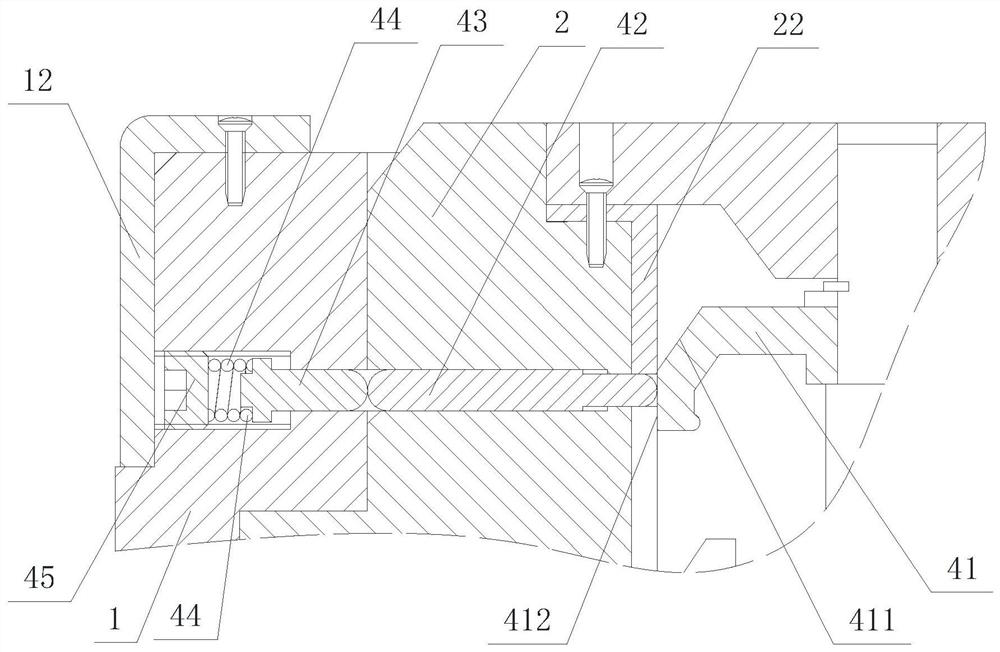

Pressure servo valve feedback mechanism

ActiveCN101725745AStable pressure outputImprove controllabilityProgramme controlOperating means/releasing devices for valvesSpool valveTorque motor

A pressure servo valve feedback mechanism mainly solves the technical problems of non-linear property and the like of a pressure servo valve. The invention adopts the technical scheme that a feedback mechanism is arranged under a torque motor and a fluidic amplifier and above a main valve, the feedback mechanism consists of a control valve set and a feedback rod set, one end of the feedback rod set is connected with the control valve set, the other end of the feedback rod set is connected with the fluidic amplifier which is connected with a pore canal of the control valve set, the control valve set is connected with the pore canal of the main valve, and left and right spring assemblies are arranged at two ends of a slide valve assembly of the control valve set respectively. The pressure servo valve feedback mechanism is applicable to various pressure servo valves.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

Oil well cement high-temperature high-pressure compressive stress strain system

ActiveCN102401769AStable pressure outputAutomatic pressure reductionThermometers using electric/magnetic elementsMaterial strength using tensile/compressive forcesPressure curveStress–strain curve

The invention relates to an oil well cement high-temperature high-pressure compressive stress strain system comprising a cement compression testing module, a power source, a pressure controlling unit, a temperature controlling unit, a signal controlling and processing unit, and pipelines. With the invention, temperature and pressure of bottom hole maintenance can be simulated. The compressive stress of oil well cement stones can be continuously measured under the temperature and pressure, and a temperature-pressure curve and a compressive stress-strain curve can be recorded. With the system and the method, anti-compression properties of different cement slurry systems can be directly measured and compared. The system and the method are beneficial for the design of cement slurry formulas. With the system and the method, cement slurry systems satisfying in-field construction requirements can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydraulic brake valve of feedback piston of valve core

InactiveCN103453178ASimple structureSmall control forceEqualizing valvesMultiple way valvesPistonEngineering

The invention discloses a hydraulic brake valve of a feedback piston of a valve core. The hydraulic brake valve comprises a valve body, the valve core, a return spring, a balance spring and a push rod, wherein the valve body is provided with an input port, an output port, an oil return port and a valve core cavity, the input port, the output port and the oil return port are respectively communicated through the valve core cavity, the valve core is connected to the valve core cavity in a sliding manner, and the push rod is movably connected to the upper end of the valve core; a feedback passage is arranged in the valve core, and the feedback channel is communicated between the output port of the valve body and the bottom end of the valve core cavity; the hydraulic brake valve further comprises the feedback piston, wherein the upper part of the feedback piston is contained in the feedback passage, and the bottom end face of the feedback piston is in contact with the bottom surface of the valve core cavity. According to the invention, through redesigning the structure of the feedback passage and adding the feedback piston, the hydraulic brake valve has the characteristics of high flow, low control force, stable output pressure and controllable size.

Owner:JIMEI UNIV

Adjustable ear-nose-throat department clinical spray device

The invention discloses an adjustable ear-nose-throat department clinical spray device, including a spray device shell, wherein the spray device shell is provided with a hollow cavity and a medicinalliquid storage cavity below the hollow cavity; a spray piston barrel is fixedly connected with an internal wall of the top of the medicinal liquid storage cavity; the spray piston barrel is internallyprovided with a rubber plug. The adjustable ear-nose-throat department clinical spray device can enable the pressure output of spray to be stable and is favorable in atomized spray effect. People canadjust and select the pressure of spray according to different parts. The defect that it is heavy for doctors to hold a spray device to spray because a storage bottle in the spray device is integrated with a spray head is avoided; the operation is convenient; a metal shaping hose is easy to bend and shape at random; spray can be performed flexibly according to different positions and angles; thedevice can be used conveniently.

Owner:赵伟霞

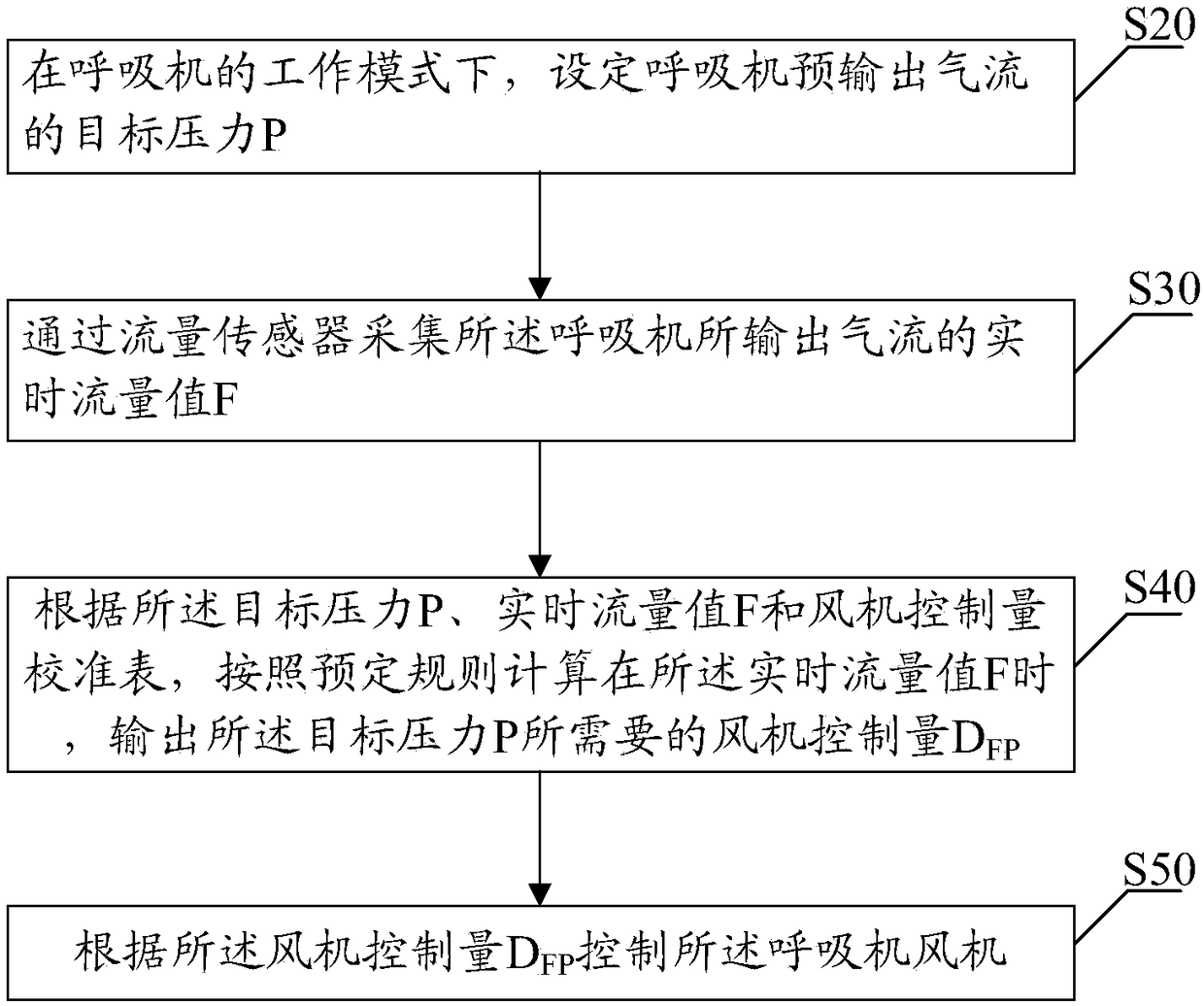

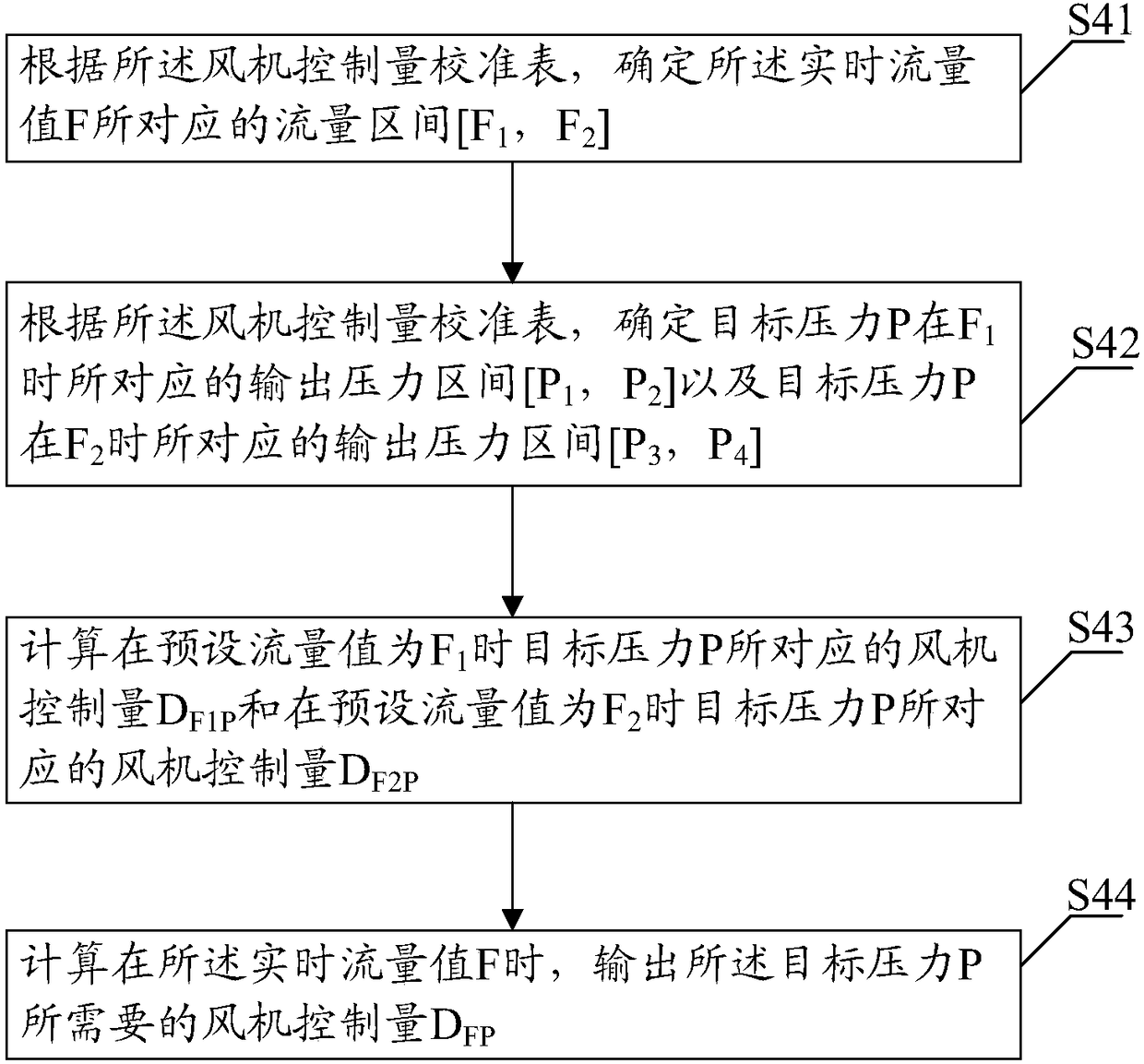

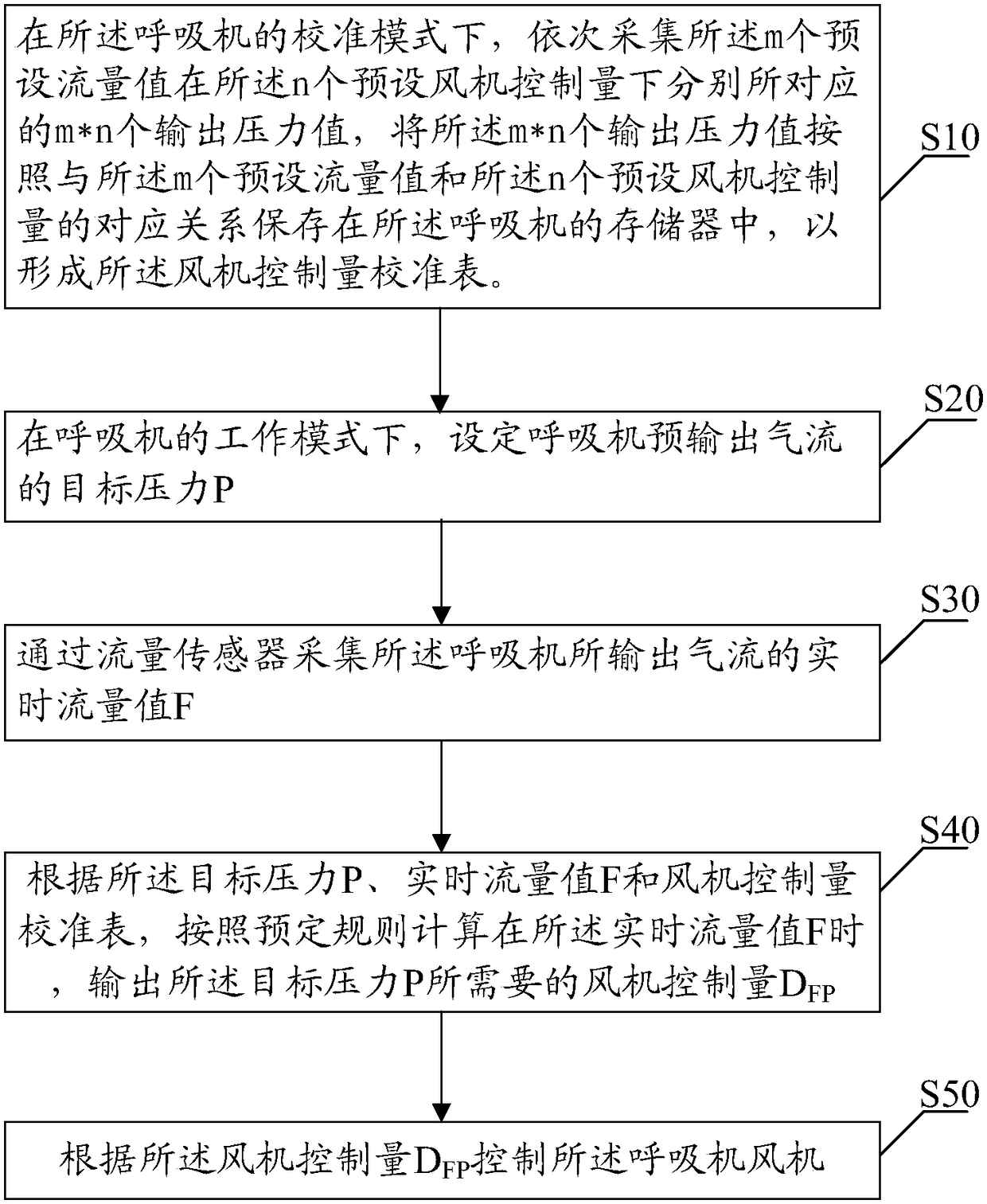

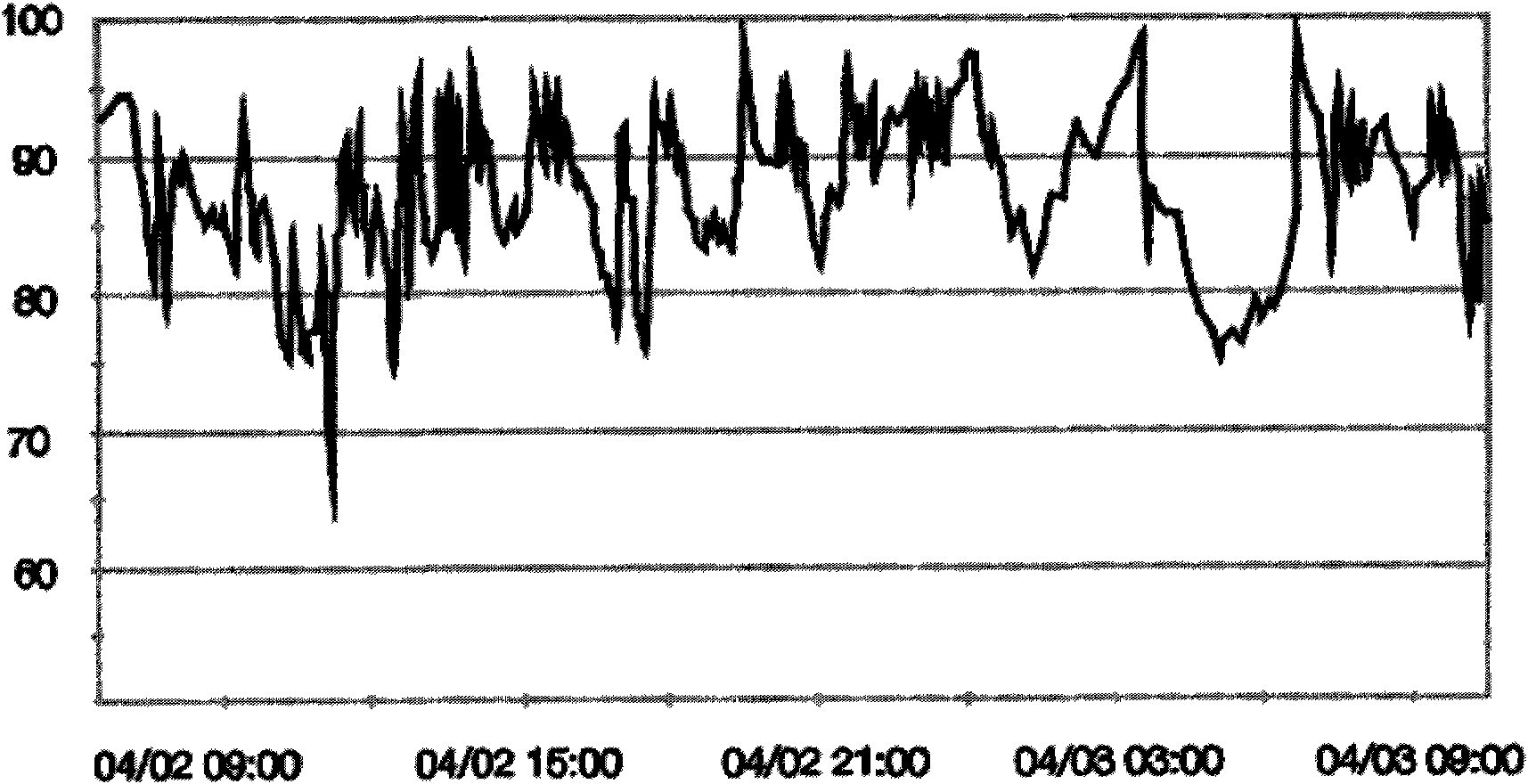

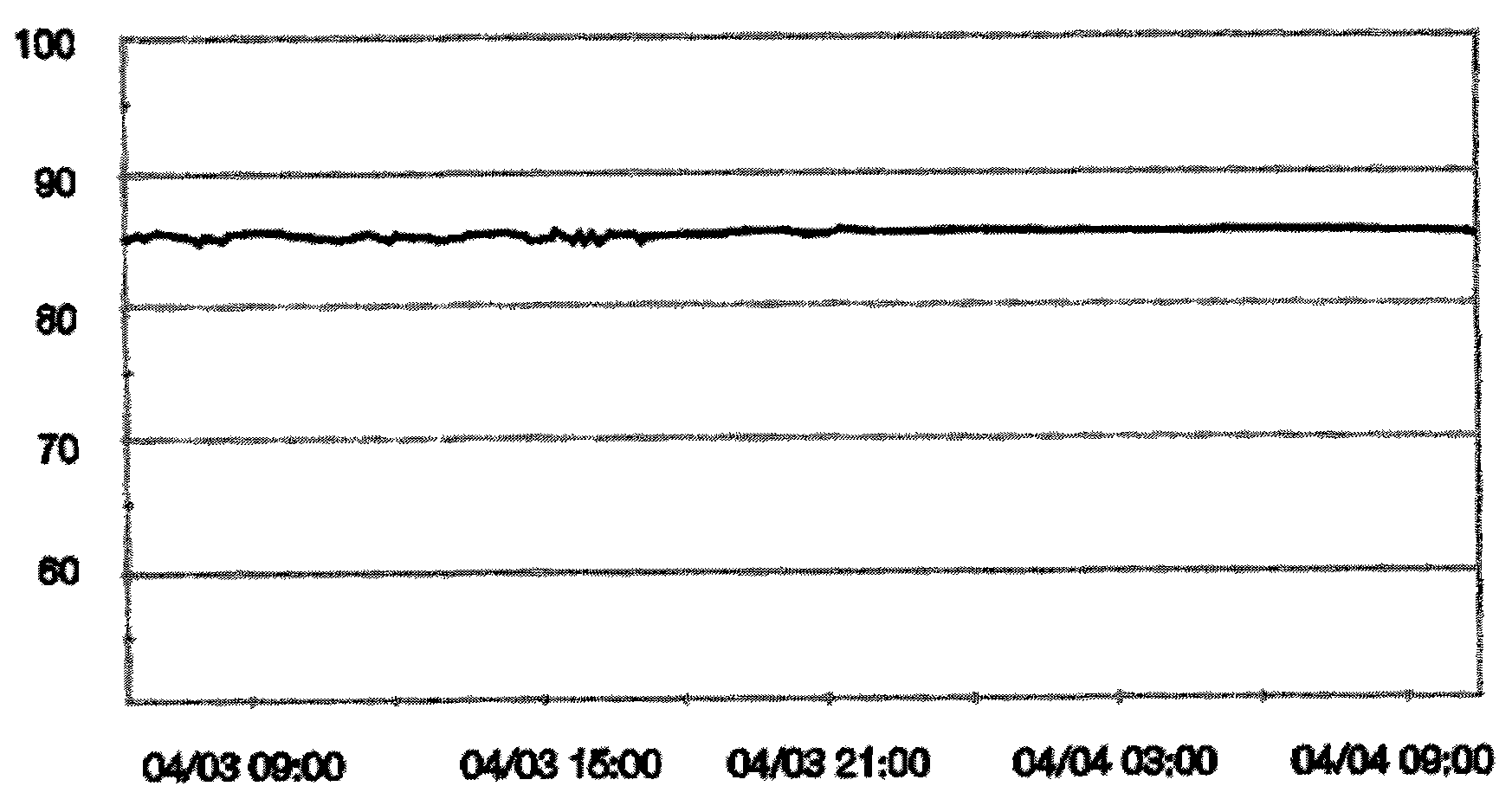

Open-loop control method and system of fan of breathing machine

ActiveCN105944197AImprove stabilityReduces the possibility of bouncing up and downRespiratorsMedical devicesLoop controlControl system

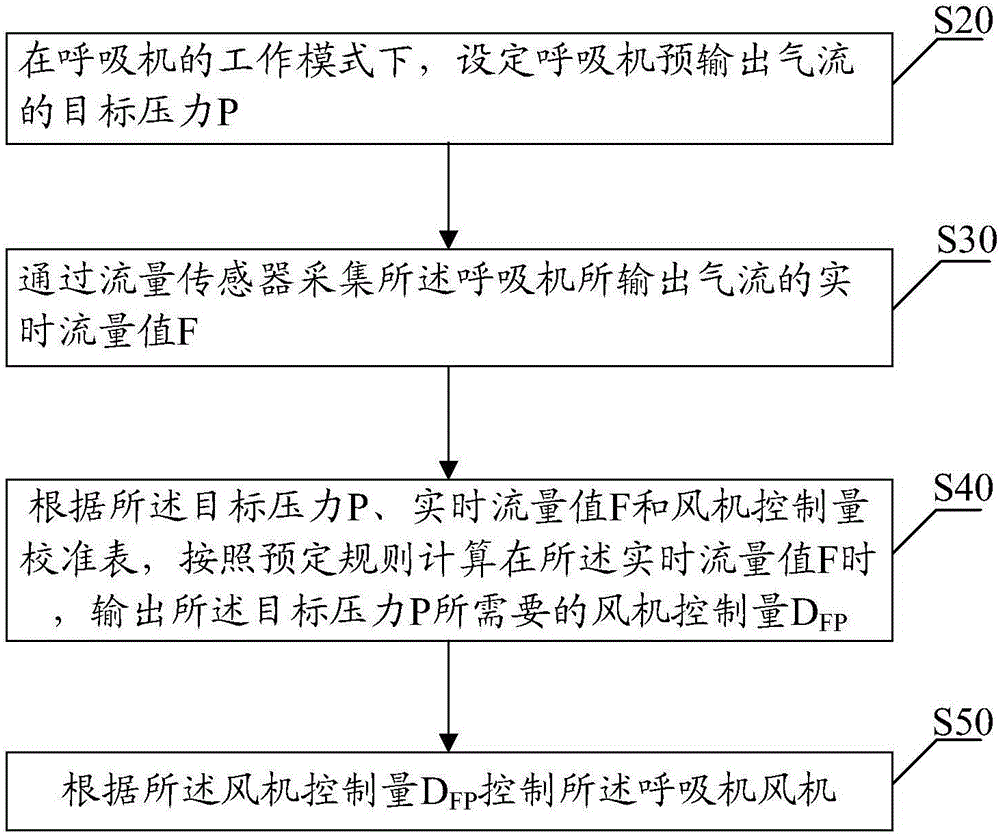

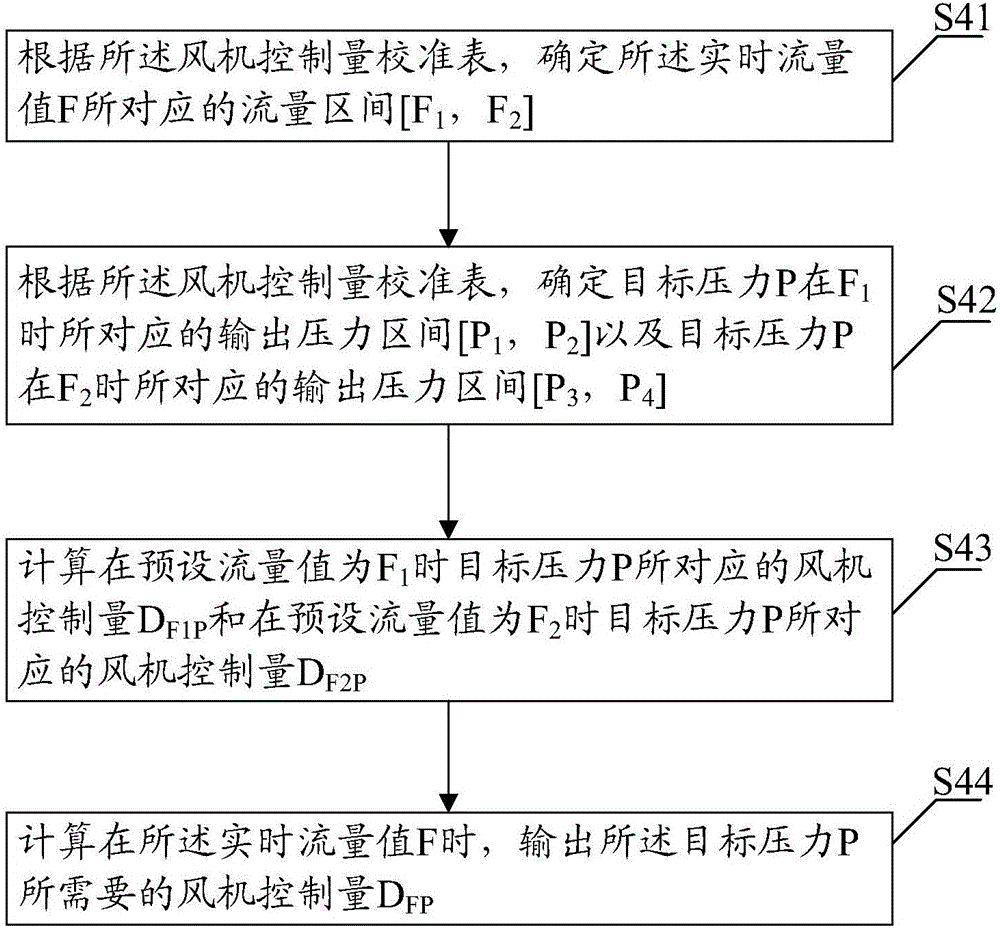

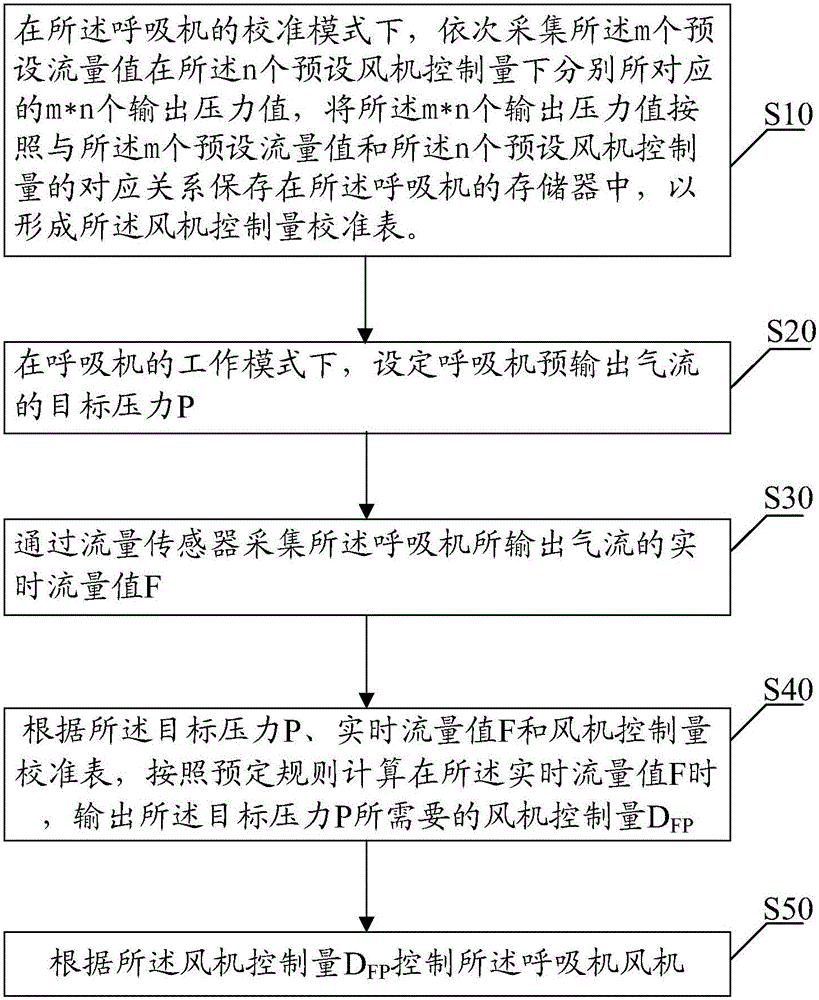

The invention discloses an open-loop control method and a control system of a fan of a breathing machine. The open-loop control method comprises the following steps: under a working mode of the breathing machine, setting a target pressure P of a pre-outputted airflow of the breathing machine; collecting a real-time flow value F of the airflow outputted by the breathing machine by virtue of a flow sensor; in accordance with the target pressure P, the real-time flow value F and a fan control volume calibration table, calculating a fan control volume DFP required by outputting the target pressure P at the real-time flow value F in accordance with a preset rule, wherein m*n pieces of output pressure values, which are in corresponding to m pieces of preset flow values under n pieces of preset fan control volumes, are saved in the fan control volume calibration table, and both m and n are positive integer; and controlling the fan of the breathing machine in accordance with the fan control volume DFP. According to the control method and the control system disclosed by the invention, the possibility that the output pressure is fluctuated can be reduced, and the fan of the breathing machine can keep stable pressure output under different flow rates.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

Welding gas energy-saving comprehensive control system

InactiveCN110653457AEfficient management of state parametersEfficient managementFluid pressure control using electric meansWelding accessoriesControl systemControl engineering

The invention discloses a welding gas energy-saving comprehensive control system. The welding gas energy-saving comprehensive control system comprises a gas supply station, a gas distribution cabinet,a front-end main control unit, a middle-section constant-pressure control unit, a tail-end intelligent gas control instrument unit and a welding device, wherein the gas supply station is used for providing a gas source for the welding device; the gas distribution cabinet is used for mixing the welding seam shielding gas in proportion according to actual needs; the front-end main control unit is used for managing gas supply on-off of a pipeline and performing automatic regulation and management according to feedback data; the middle-section constant-pressure control unit is used for automatically adjusting and managing according to state parameters of the gas so as to ensure the stable gas pressure output ; the tail-end intelligent gas control instrument unit is used for automatically matching reasonable gas flow according to the requirements of the welding device; and the welding device is in pipeline connection with the tail-end intelligent gas control instrument unit. According to the welding gas energy-saving comprehensive control system, by means of the three-in-one integrated intelligent comprehensive control system, the pipeline gas supply on-off of a user can be effectivelymanaged, automatic regulation and management can be carried out according to the feedback data, stable gas pressure output is guaranteed, and efficient energy conservation is effectively achieved.

Owner:桥兴能源科技(广东)有限公司

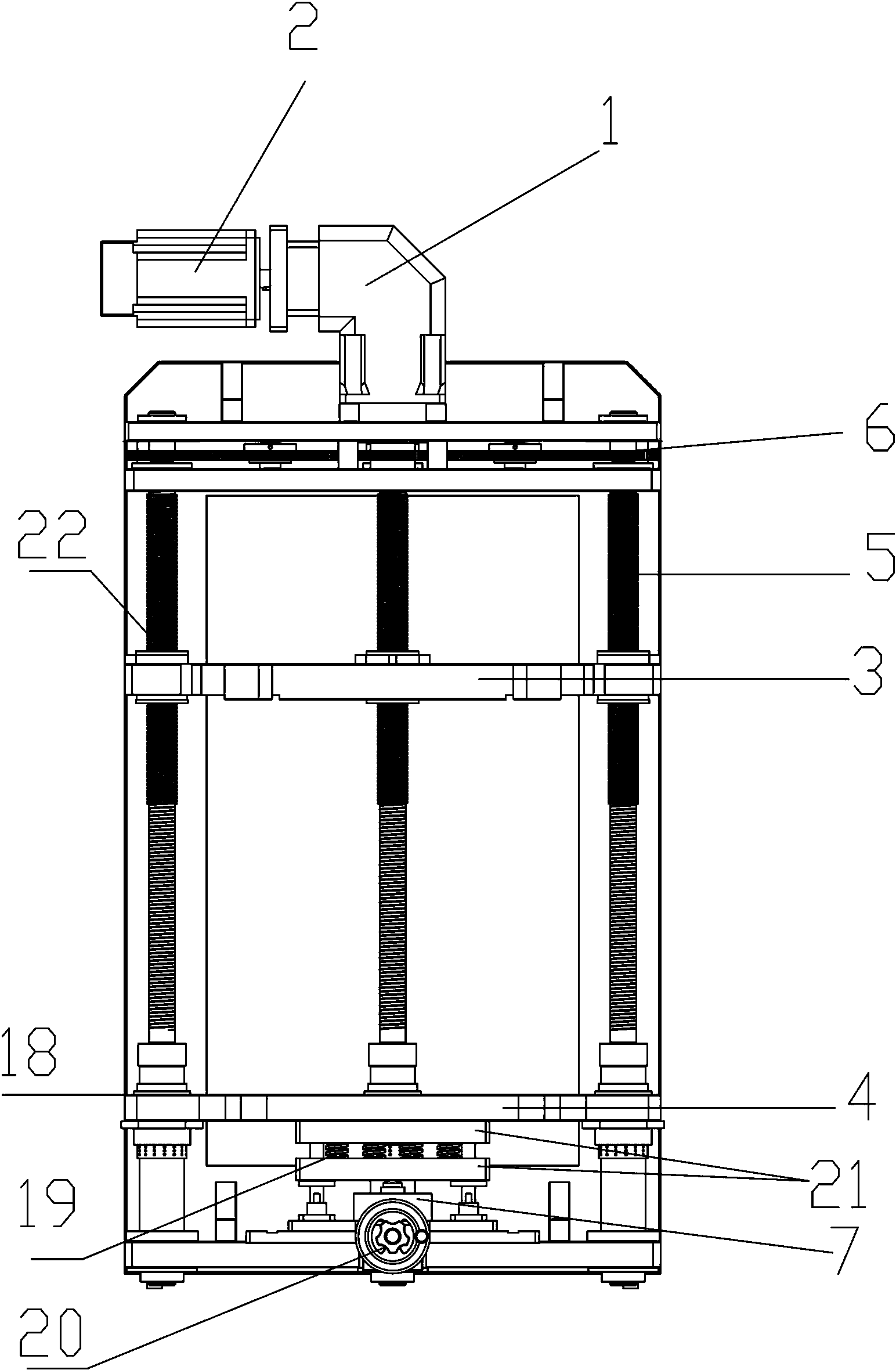

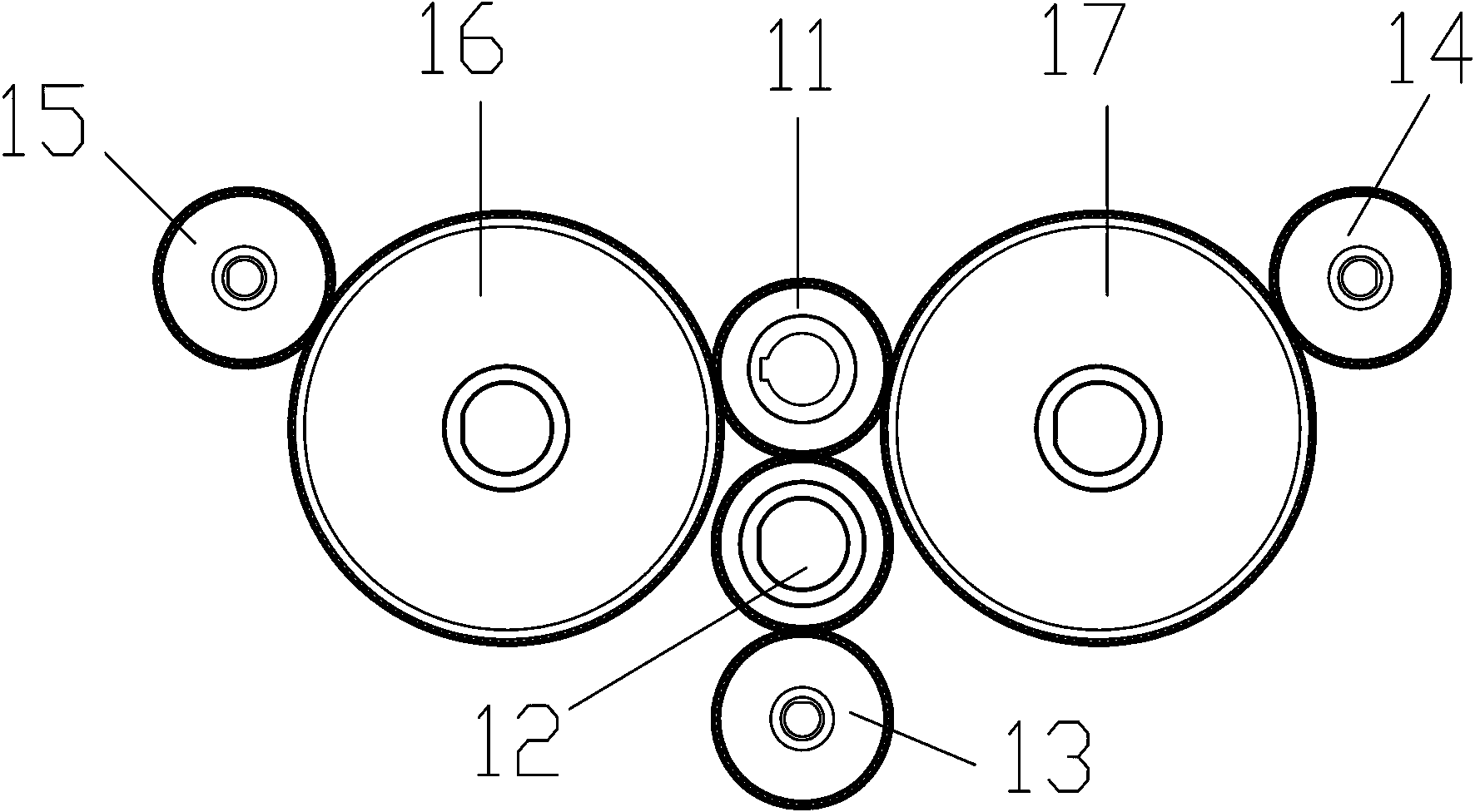

Battery pack thermocompressor

The invention discloses a battery pack thermocompressor. The battery pack thermocompressor comprises a machine body, wherein a speed changer and a motor are arranged on the machine body; the speed changer is matched with a gear transmission mechanism; a head plate and a tail plate are arranged in the machine body; the head plate is assembled on three lead screws in a screw driving manner; one ends of the lead screws are matched with the gear transmission mechanism, and the other ends thereof are connected with the machine body; vibration damping plates are arranged under the tail plate; a spring is arranged between the two vibration damping plates; a pressure sensor is matched with the vibration damping plate under the spring. The gear transmission mechanism disclosed by the invention can reach the rated transmission rotating speed through action of a reducer; With transmission of the gear mechanism, the motion of one shaft is transmitted to rotation of three lead screws at the same speed; the gear mechanism comprising seven gears not only transmits torque, and further shunts three types of equal rotating speed; with coordination of the head plate and the tail plate, the stable voltage output can be provided.

Owner:CHINA THREE GORGES UNIV

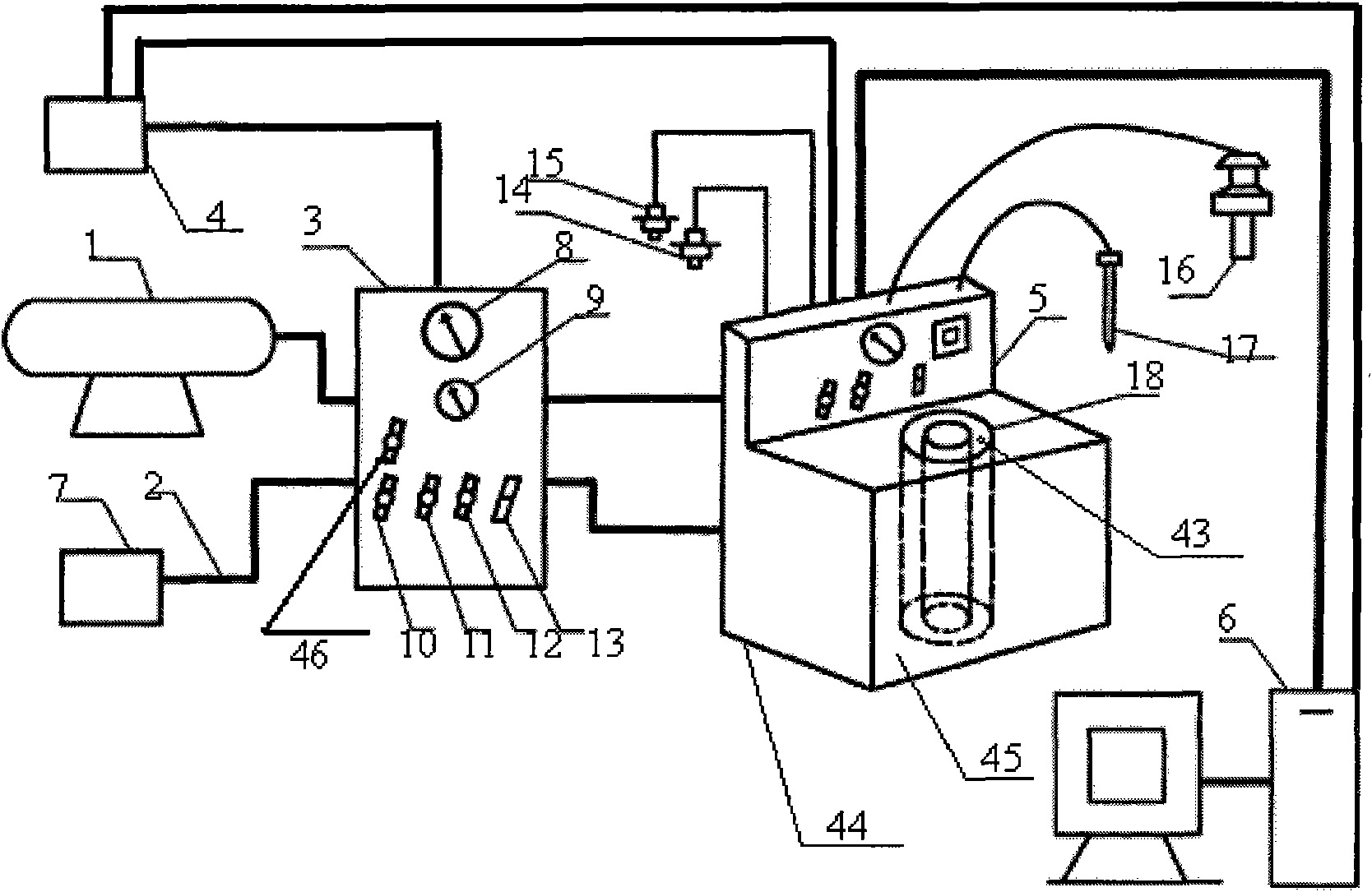

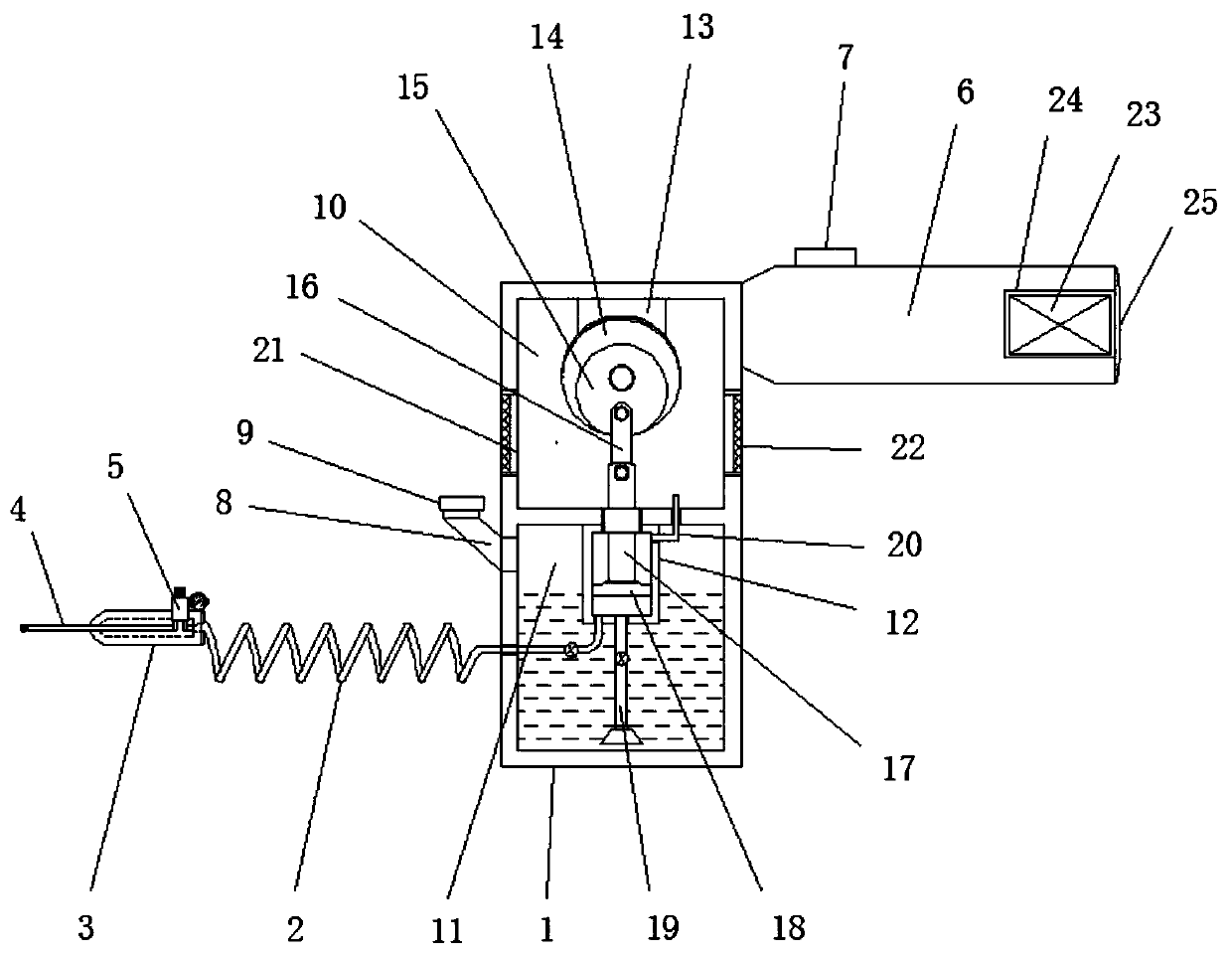

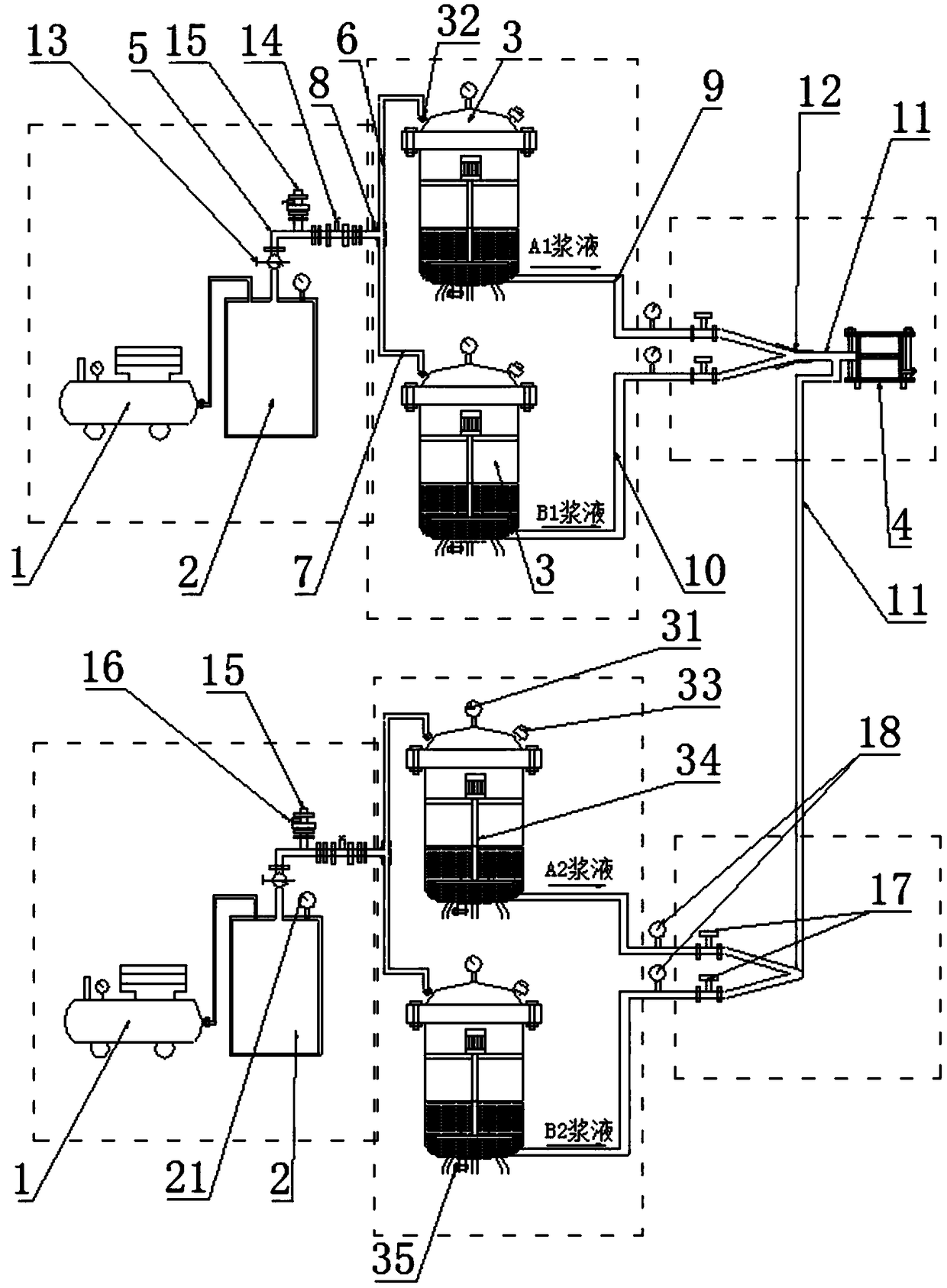

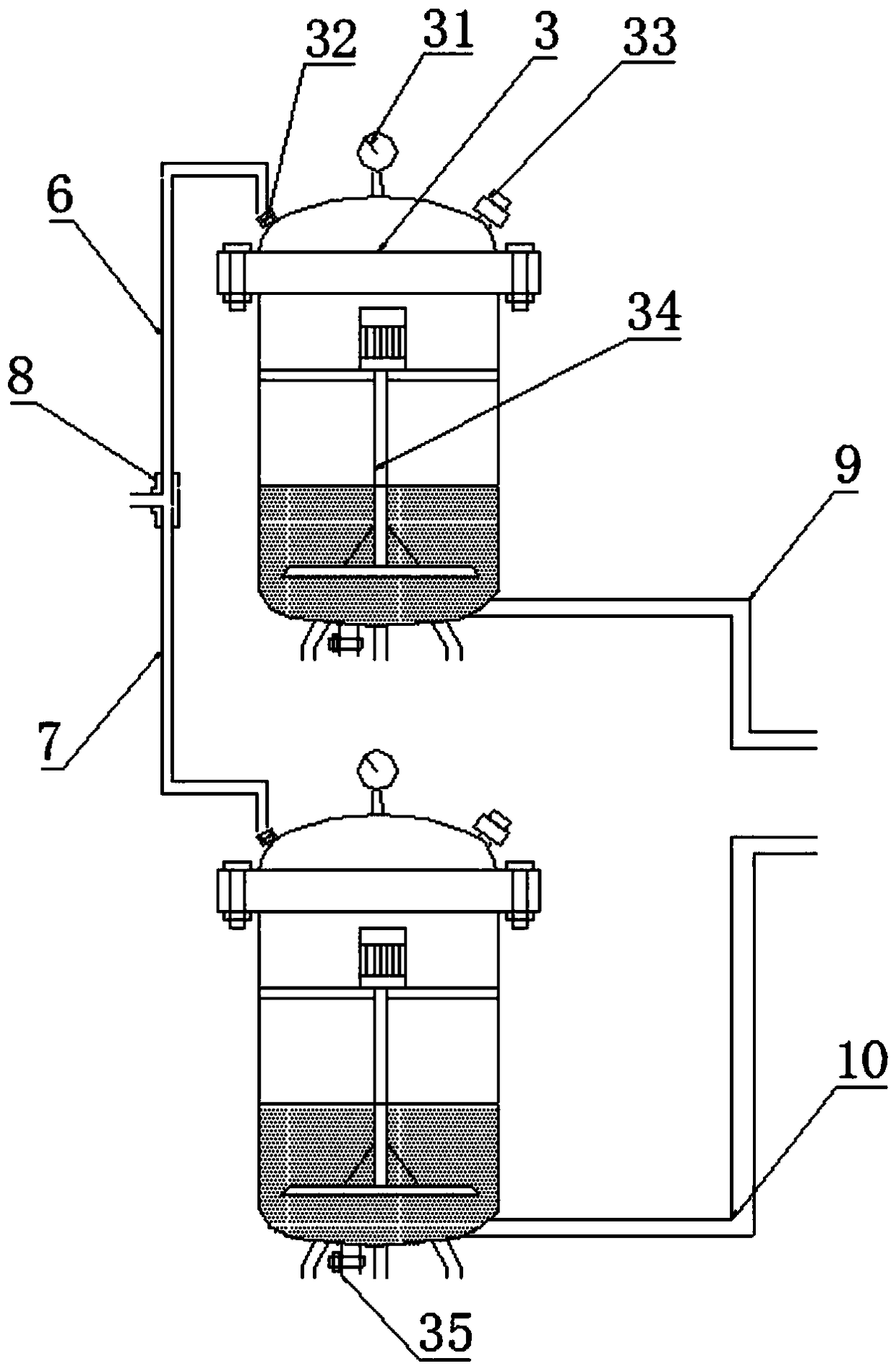

Laboratory multi-slurry high-pressure grouting device and grouting method

The invention provides a laboratory multi-slurry high-pressure grouting device and a grouting method. The laboratory multi-slurry high-pressure grouting device comprises a gas supply system, a slurrying system, a mould injecting system and a plurality of pipelines; the gas supply system comprises a plurality of gas pumps and a plurality of pressure stabilizing tanks, outlets of the gas pumps are connected with inlets of the pressure stabilizing tanks, and the gas pumps deliver and store generated gas into the pressure stabilizing tanks; the slurrying system comprises a plurality of slurrying units, and each slurrying unit comprises two high-pressure tanks, wherein grouting holes and gas feeding holes are formed in the upper parts of tank bodies of the two high-pressure tanks correspondingly, an outlet of each pressure stabilizing tank is connected with the gas feeding holes of the two corresponding high-pressure tanks to provide high-pressure gas for the high-pressure tanks, and the high-pressure tanks are used for storing slurry and maintaining slurry fluidity; and the mould injecting system comprises a grouting mould. According to the laboratory multi-slurry high-pressure grouting device, multi-slurry continuous high-pressure grouting can be achieved, double-slurry or multi-slurry accurate mixing of various proportions can be achieved, operation is convenient and quick, the pressure bearing capacity is high, the pressure is stable, and the grouting effect is good.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH

Variable frequency pump-control-motor closed circuit based on energy regulation

InactiveCN100595440CReduce lossQuick responseServomotor componentsServomotorsThrottle controlFrequency changer

The invention discloses a closed loop of a variable frequency pump-control motor, which is based on the energy regulating. The invention includes an inverter, a motor, a hydraulic pump, a safety valvegroup, an oil supplementing module and a hydraulic motor. The inverter drives the motor which drives the hydraulic pump. The safety valve group, the oil supplementing module and the hydraulic motor are connected astride in the closed circuit. An energy regulator is connected astride in the main circuit between the oil supplementing module and the hydraulic motor. A flow direction control valve isrespectively arranged in the upper main circuit and the lower main circuit between the safety valve bank and the oil supplementing module. A flow control valve is respectively arranged in the upper main circuit and the lower main circuit between the energy regulator and the hydraulic motor. Based on the energy regulating, the energy regulator and throttle control are added to the traditional closed circuit of the pump-control motor, which speeds up the booster response of the system greatly. The invention has good energy saving effect.

Owner:ZHEJIANG UNIV

Fully-automatic intelligent glue preparation online mixing epoxy insulation core rod injection pultrusion process

The invention discloses a fully-automatic intelligent glue preparation online mixing epoxy insulation core rod injection pultrusion process. The process specifically comprises the following steps of firstly, glass fiber positioning; secondly, intelligent glue preparation; thirdly, online mixing; fourthly, injection; fifthly, solidification; and sixthly, cutting. The utilized two-component epoxy glue injection system is different from other colloid conveying equipment, the whole glue preparation, stirring mixing and glue injection process is fully automatic, no manual operation is needed, clashmixing in a mixer can be realized, the mixing effect of raw materials is guaranteed, it can also be guaranteed that pressure output is stable, metering is accurate, and the quality of a product is guaranteed fundamentally; meanwhile the process has the characteristics that the delivery capacity and the proportion are precise and adjustable, work is stable and reliable, and the process is suitablefor continuous production; and the content of microbubbles in the obtained epoxy insulation core rod product is very few, and the electromechanical properties are good.

Owner:郑州聚成电气技术有限公司

Water-cooling aluminum alloy airplane hydraulic oil tank

InactiveCN111894915AStable pressure outputIncrease flow timePump assembliesFluid-pressure actuator componentsThermodynamicsEngineering

The invention discloses a water-cooling aluminum alloy airplane hydraulic oil tank. The water-cooling aluminum alloy airplane hydraulic oil tank comprises an oil tank outer tank body and an oil tank inner tank body which are made of aluminum alloy materials, the independent oil tank inner tank body is arranged in the inner part of the oil tank outer tank body, the bottom of the oil tank inner tankbody is fixedly connected with the surface of the lower inner wall of the oil tank outer tank body through an inner tank body supporting seat, a cooling cavity with the periphery which communicates is formed between the oil tank outer tank body and the oil tank inner tank body, a sub-tank body is further arranged in the inner part of the oil tank inner tank body, the lower end of the sub-tank body is fixedly connected with the lower surface of the oil tank inner tank body, the side face of the sub-tank body is fixedly connected with the side face of the oil tank inner tank body, a concentric-square-shaped sub-cooling cavity is formed in the inner part of the sub-tank body, and the sub-cooling cavity communicates with the cooling cavity and filled with flowing non-Newtonian fluid cooling liquid. According to the structure, the heat dissipation effect is improved, and the water-cooling aluminum alloy airplane hydraulic oil tank has the cooling and heat dissipation functions and has theanti-impact performance at the same time.

Owner:MAANSHAN JULI SCI & TECH

Microfluidic Flow Regulator Based on Pneumatic Drive

ActiveCN104696706BEasy to adjustRealize closed-loop controlPipeline systemsControl signalPressure.drive

A microfluidic flow regulating device driven by air pressure belongs to the field of microfluidics. The invention aims to solve the problems of low flow regulation accuracy, slow dynamic response speed and unmeasurable actual flow rate in microfluidic systems when using syringe pumps to regulate flow. The present invention adopts the air pressure drive method, the air supply source provides compressed air, and the outlet pressure is adjusted through the pressure reducing valve to obtain a stable air supply pressure and the pressure is measured by the pressure sensor. The liquid in the liquid container is driven by the air pressure, passes through the valve, The flowmeter enters the liquid microchannel, and the actual liquid flow rate is measured by the flowmeter and fed back to the microprocessor. The microprocessor outputs a control signal to change the working state of the microvalve, adjust the liquid flow rate of the liquid microchannel, and realize the closed-loop control of the flow rate. Further, PID control algorithm can be used to improve the adjustment accuracy and dynamic response speed of the flow rate, and can accurately and quickly adjust the liquid flow rate of the microchannel.

Owner:HARBIN INST OF TECH

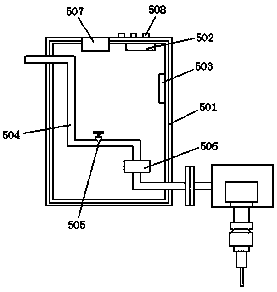

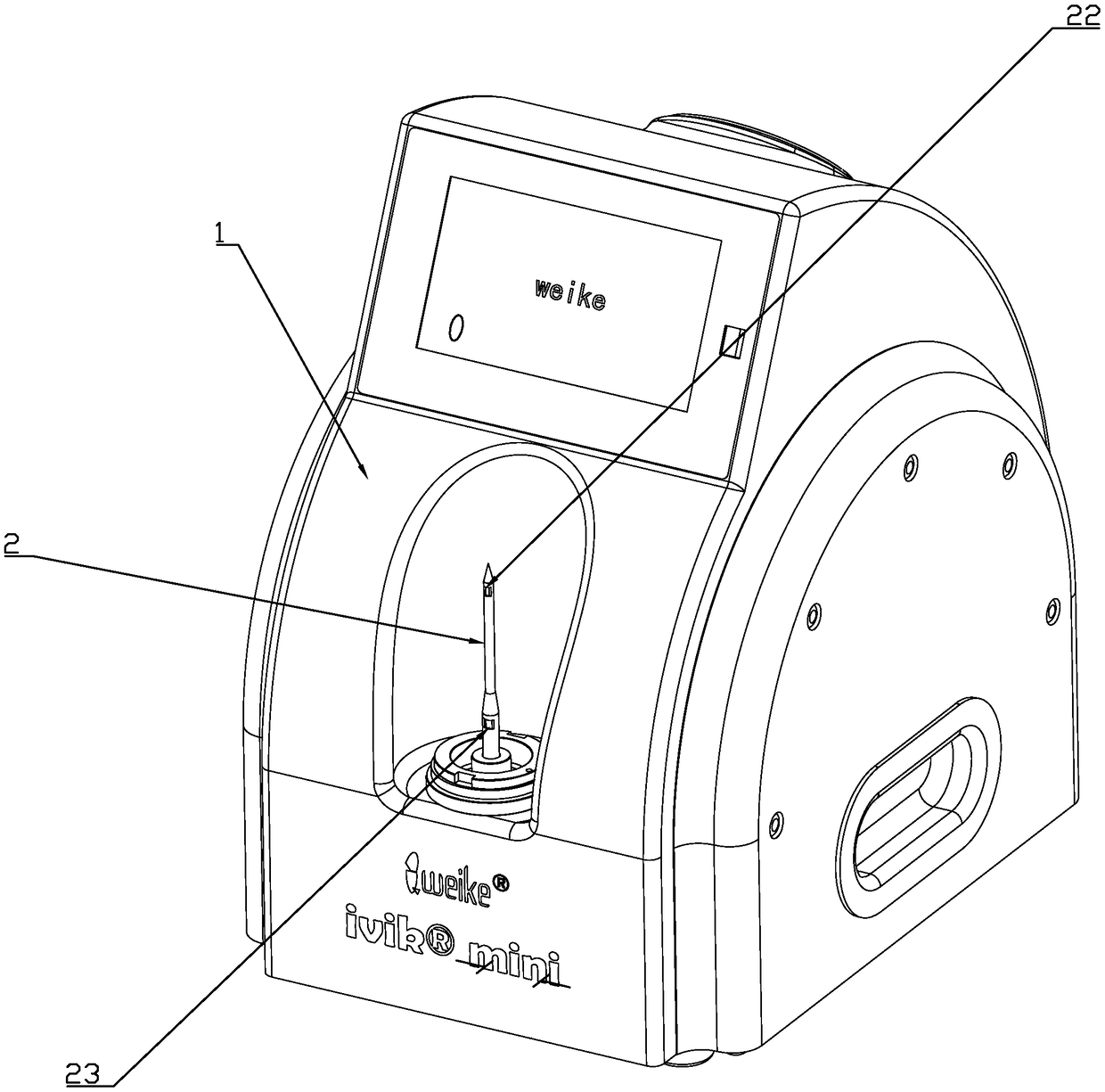

Sterilizing device for biosafety cabinet

PendingCN109481712AEasy to formulateIncrease profitLavatory sanitoryChemicalsSpray nozzleEngineering

The invention discloses a sterilizing device for a biosafety cabinet. The device comprises a shell. An objective table is arranged on the shell, a liquid suction needle head is arranged on the objective table; a cold evaporator, a blower and a metering pump which provides a suction power source are also arranged in the shell; a liquid inlet and a liquid return port are formed in one end of the cold evaporator, a spray nozzle is arranged at the other end, the liquid suction needle head is connected to a liquid inlet pipe, the liquid inlet pipe is connected to a liquid inlet, the metering pump is arranged between the cold evaporator and a reagent bottle, one end of the metering pump is connected to the liquid return port thorough a first liquid return pipe while the other end of the meteringpump is connected to the liquid suction needle head through a second liquid return pipe, the cold evaporator is provided with an air inlet and an air outlet, an air outlet pipe is arranged at the output end of the blower, the air outlet pipe is connected to the air inlet, and the spray nozzle is arranged close to the air outlet. The sterilizing device atomizes a sterilizing reagent fully and doesnot damage the original chemical structure of the sterilizing reagent, and the sterilizing reagent can be fully diffused to a-to-be-sterilized environment.

Owner:WENZHOU WEIKE BIOLOGICAL LAB EQUIP

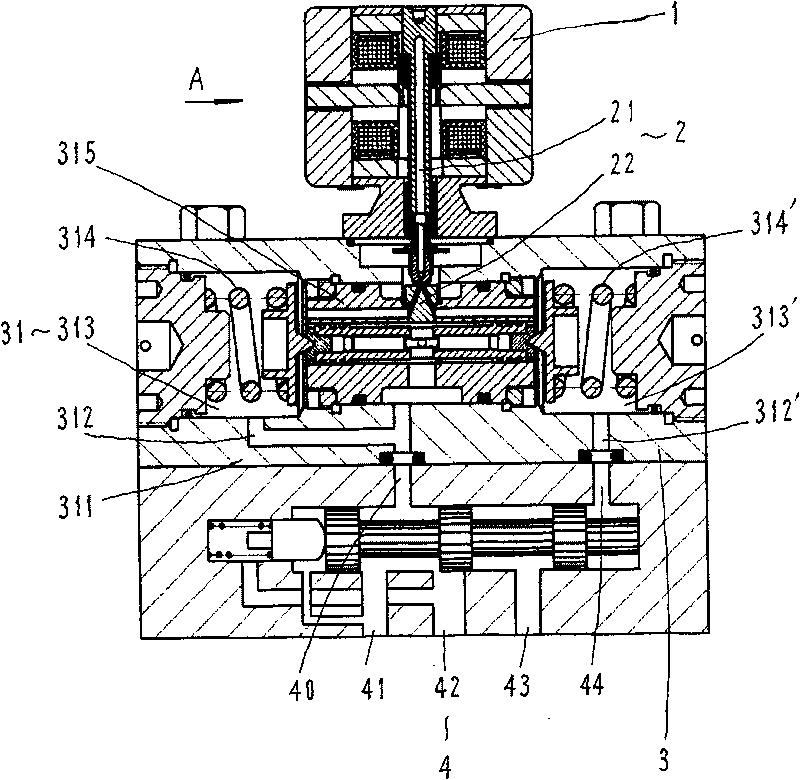

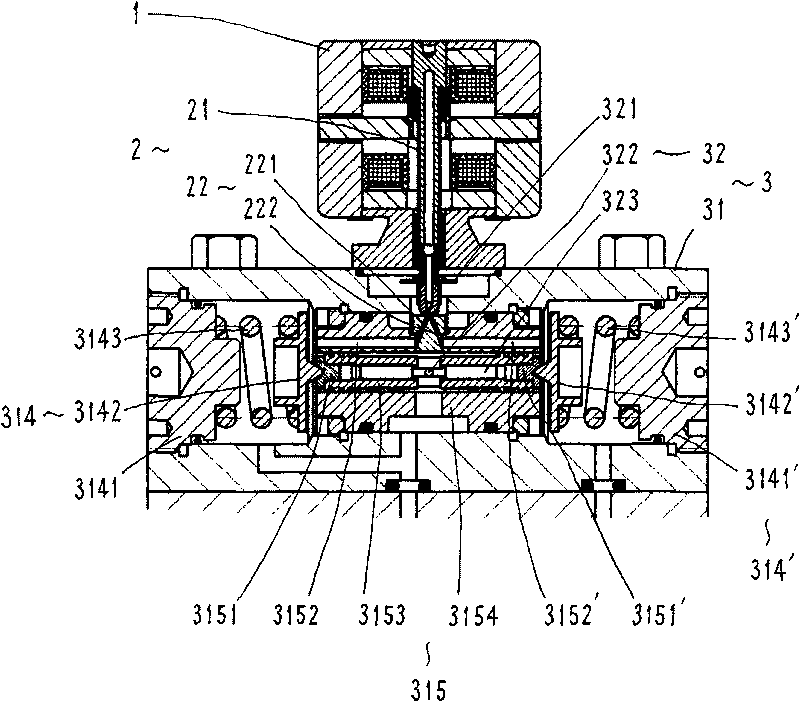

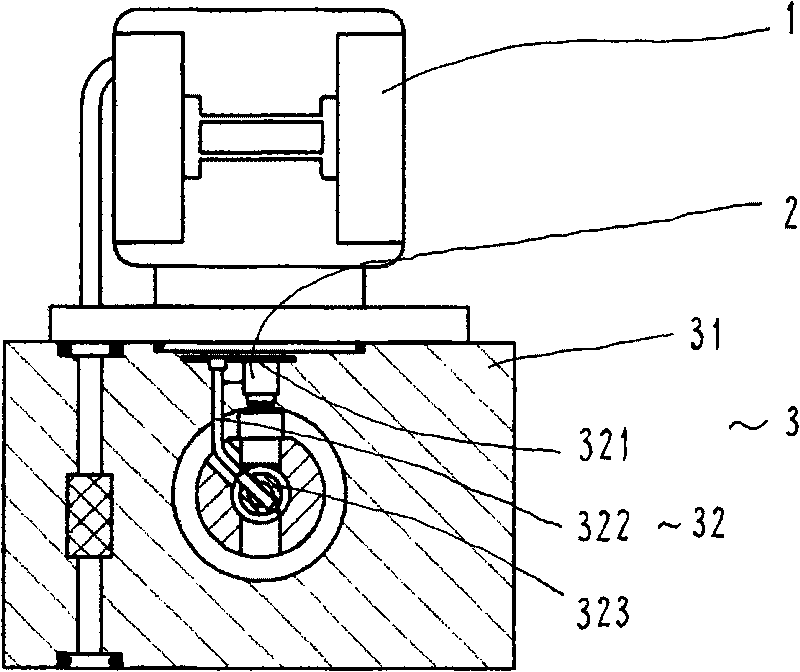

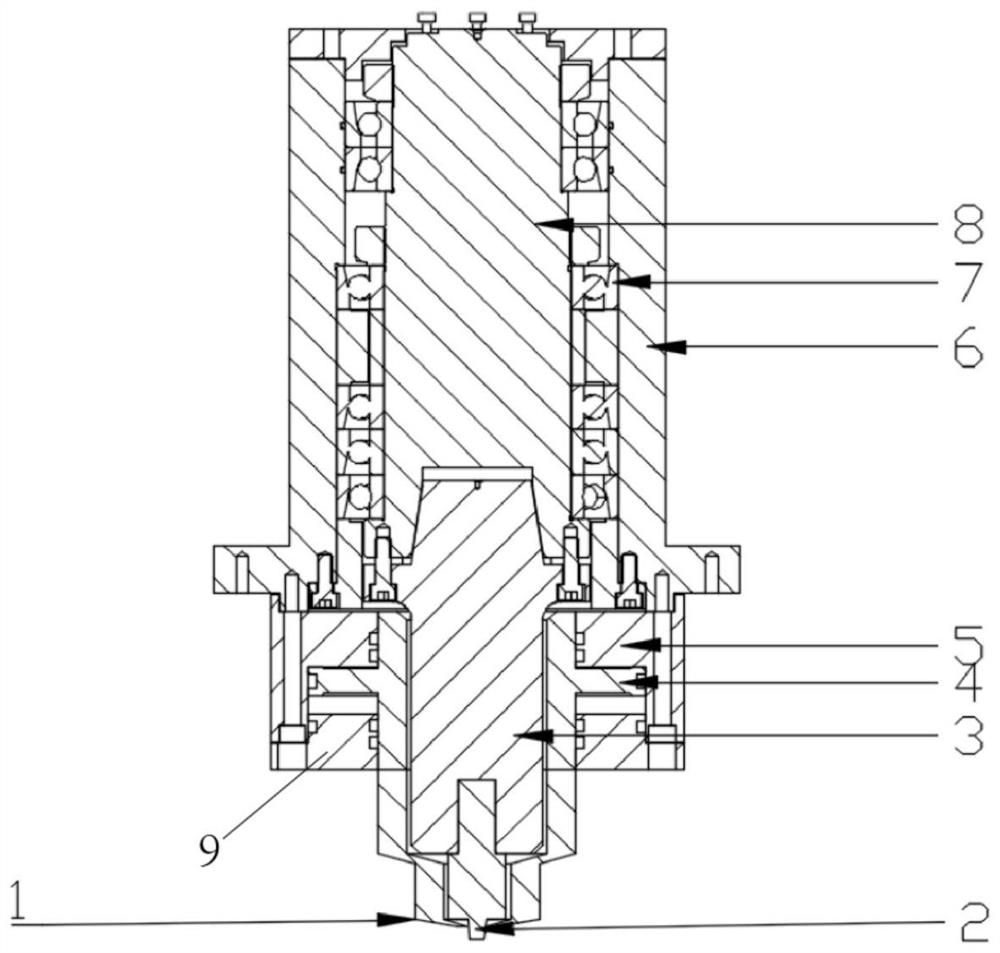

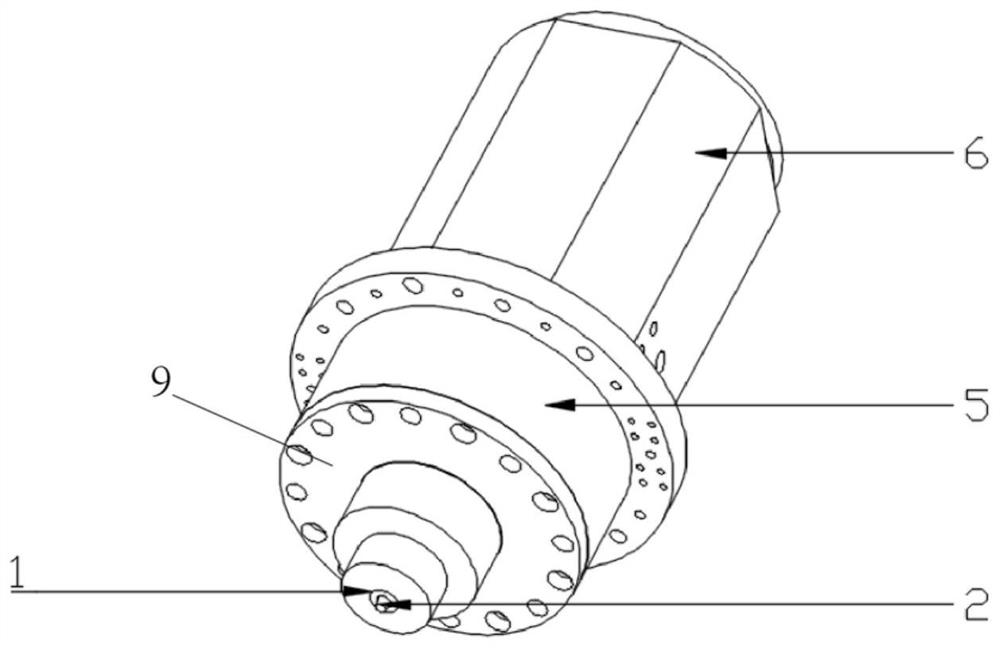

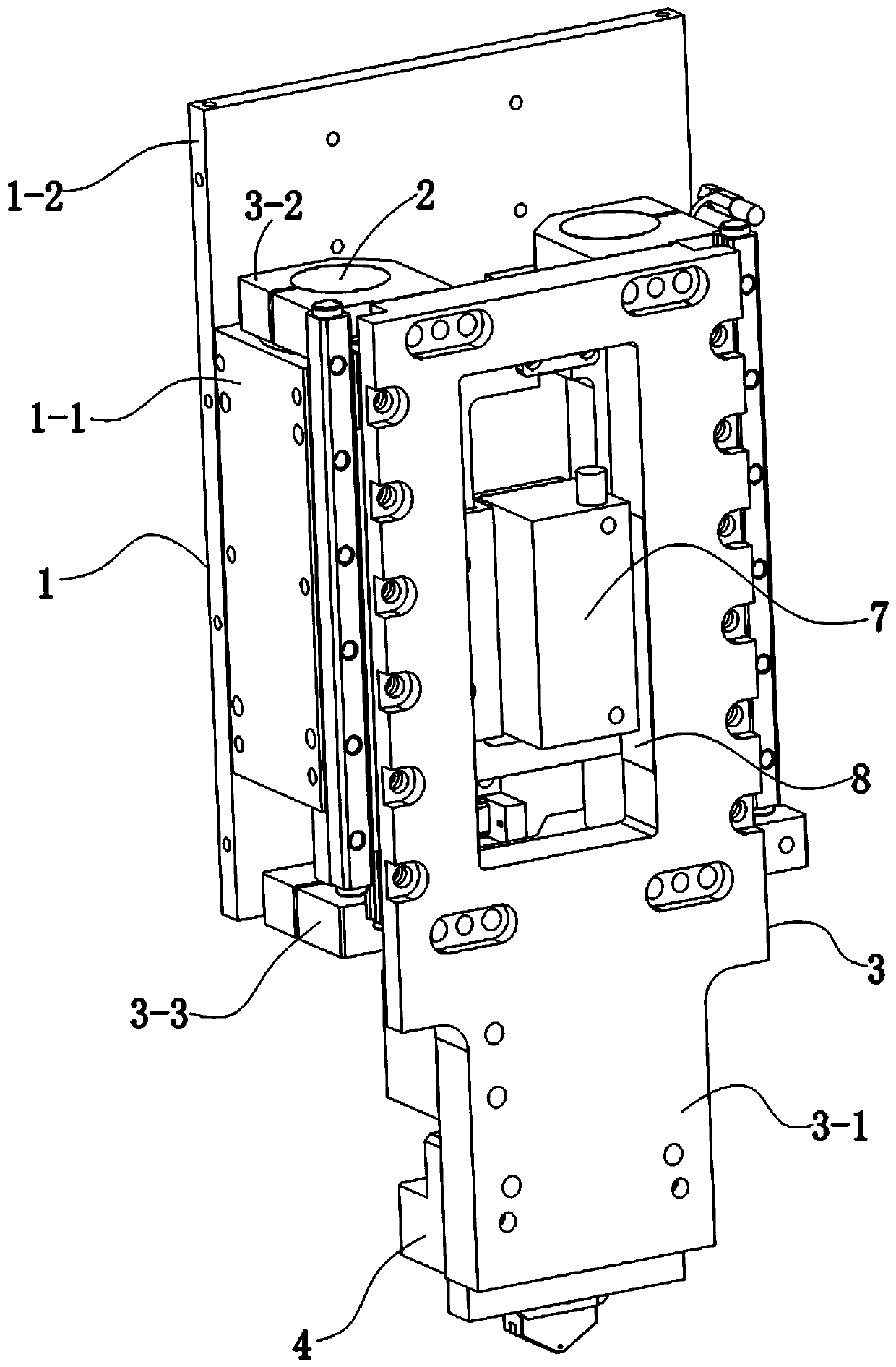

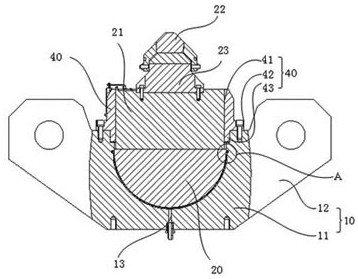

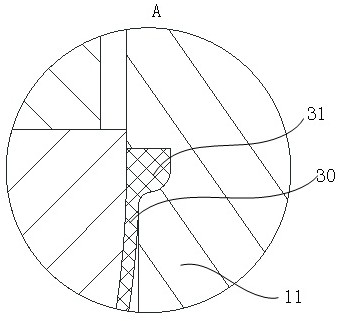

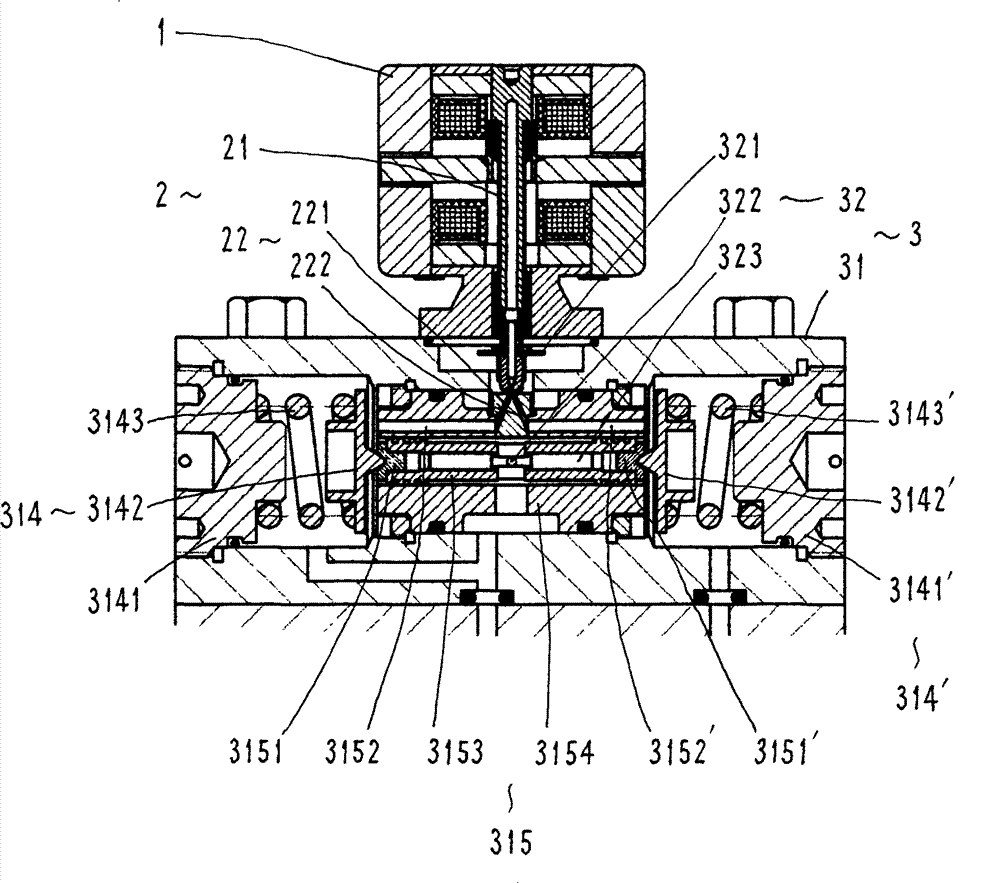

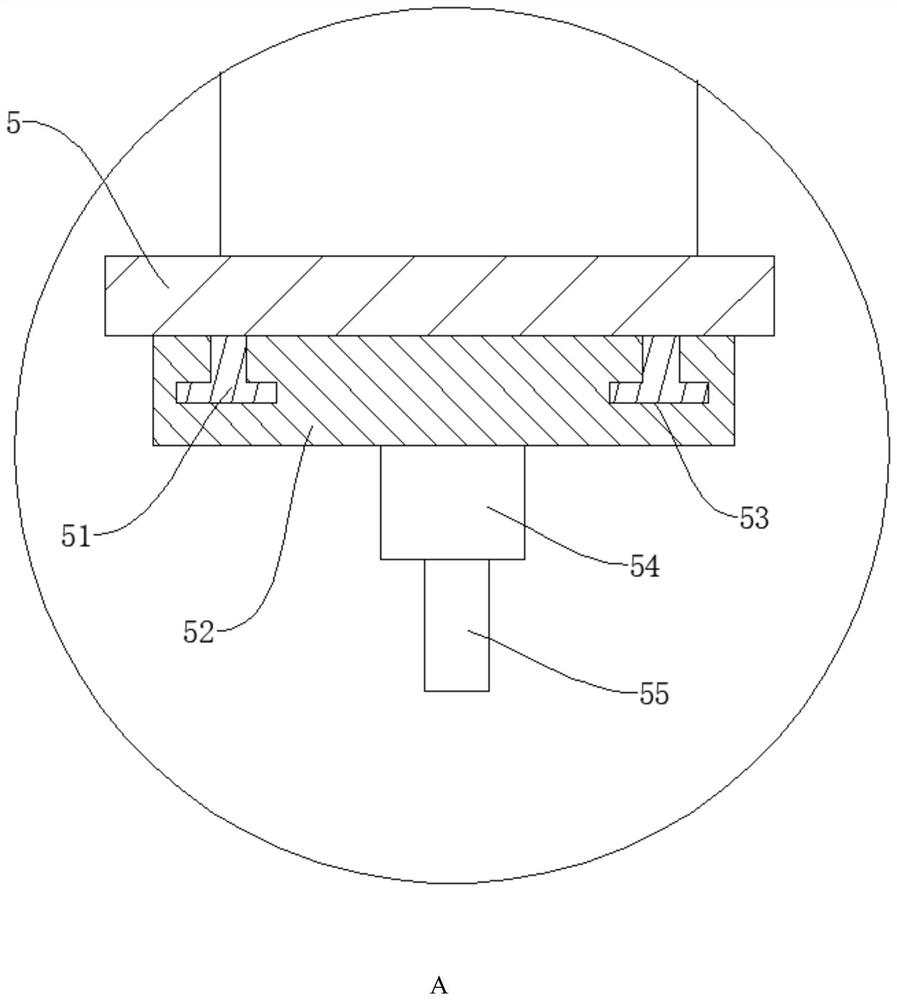

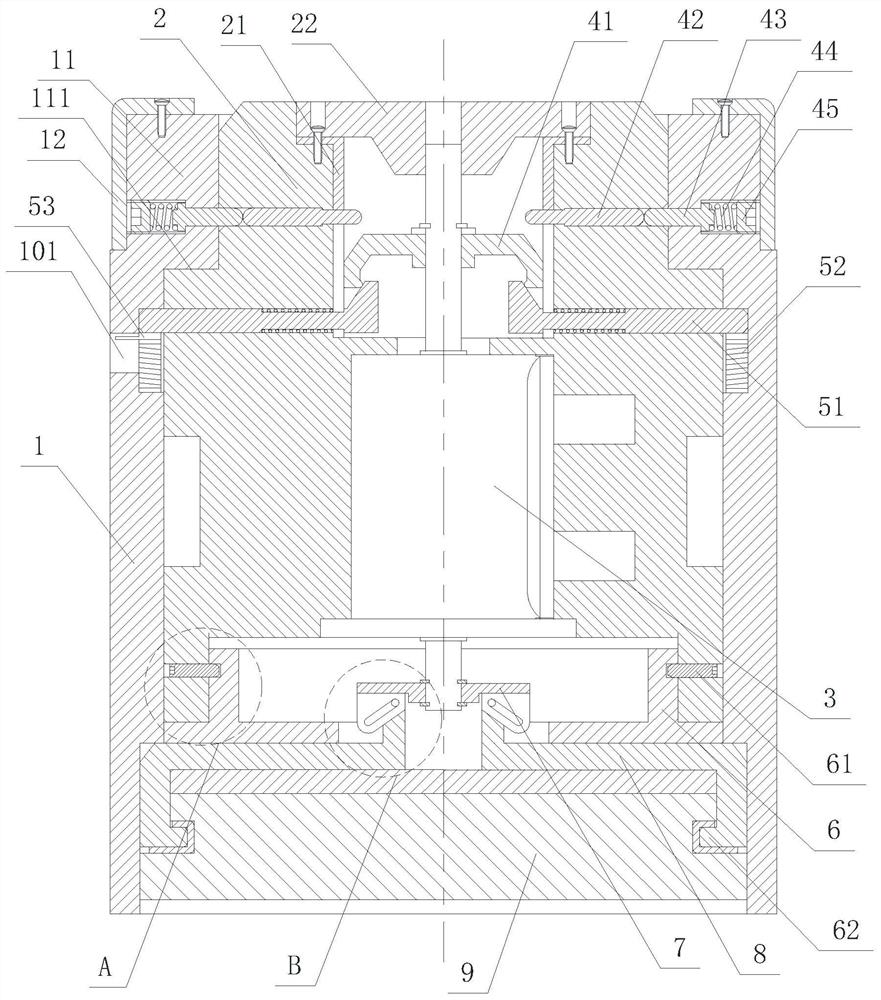

Spindle head device capable of realizing closed-loop control of shoulder and welding pin in stationary shoulder friction stir welding technology

PendingCN113492257ARealize constant pressure closed-loop controlStable pressure outputNon-electric welding apparatusAxial displacementLoop control

The invention provides a spindle head device capable of realizing closed-loop control of a shoulder and a welding pin in a stationary shoulder friction stir welding technology. A spindle shell is of a hollow structure, a spindle is arranged in the spindle shell through a bearing pack, and the tail end of the spindle is connected with the head end of the welding pin through a cutter handle; and the head end of a shell of an oil cylinder is connected with the tail end of the spindle shell, a piston rod is arranged in the oil cylinder, the tail end of the piston rod penetrates through an oil cylinder cover to be connected with the head end of a static shoulder, and the piston rod can move up and down on the oil cylinder cover so as to achieve axial extending of the piston rod and further achieve the purpose of adjusting a distance between the static shoulder and a workpiece to be welded. The welding pin is separated from the stationary shoulder, the axial displacement of the welding pin can be adjusted in real time according to the requirements of a control system in a welding process, and closed-loop control over the axial displacement of the welding pin is achieved; and the device has the advantages of reasonable and flexible structural design and the like.

Owner:天津益普科技发展有限公司

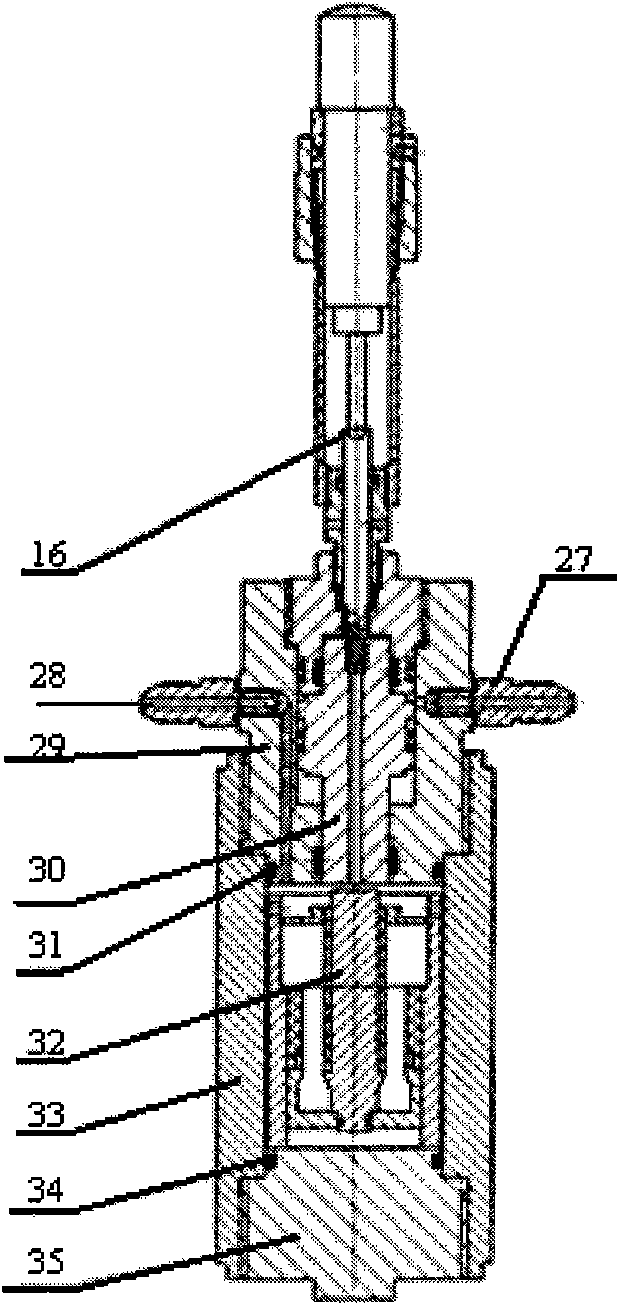

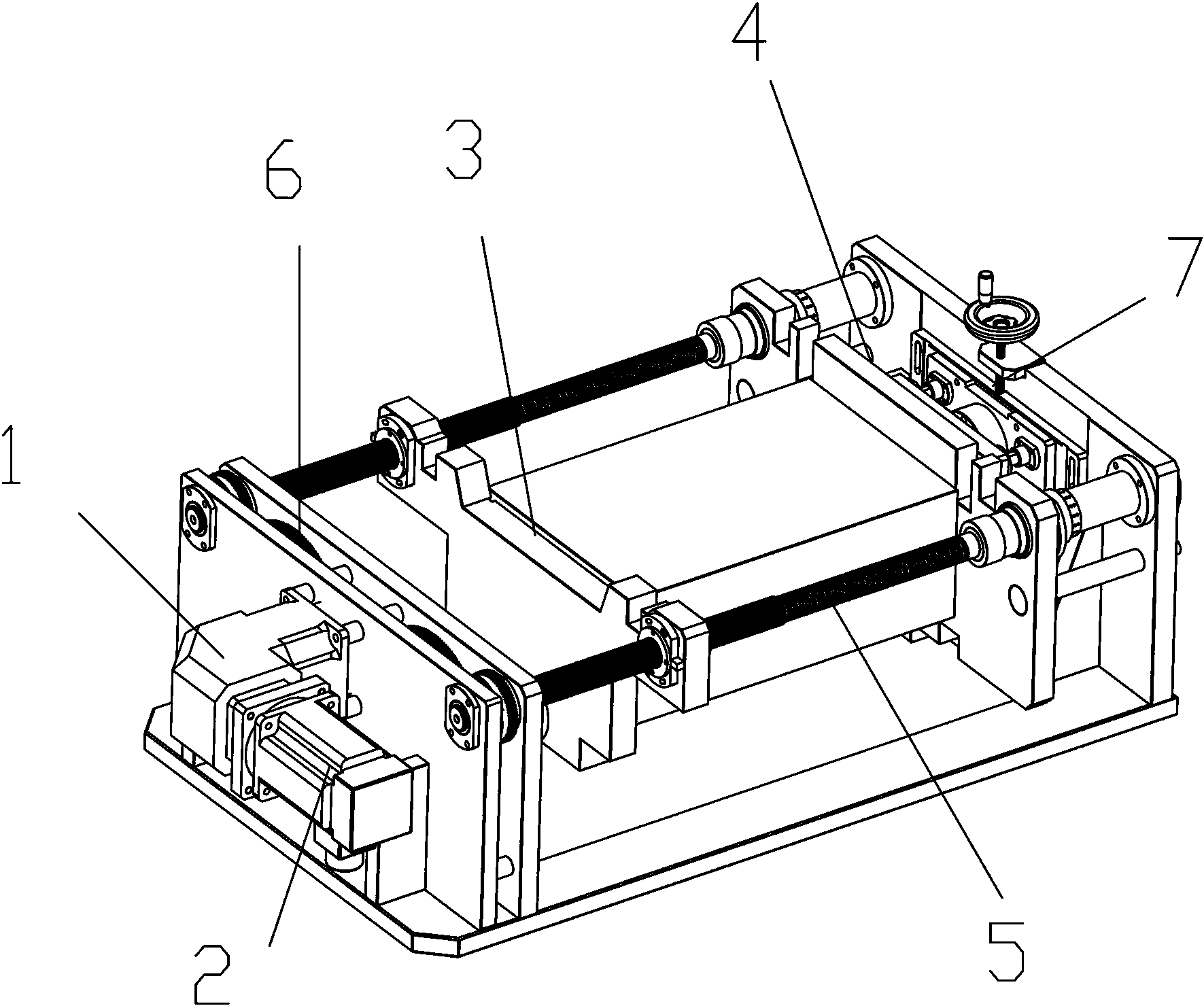

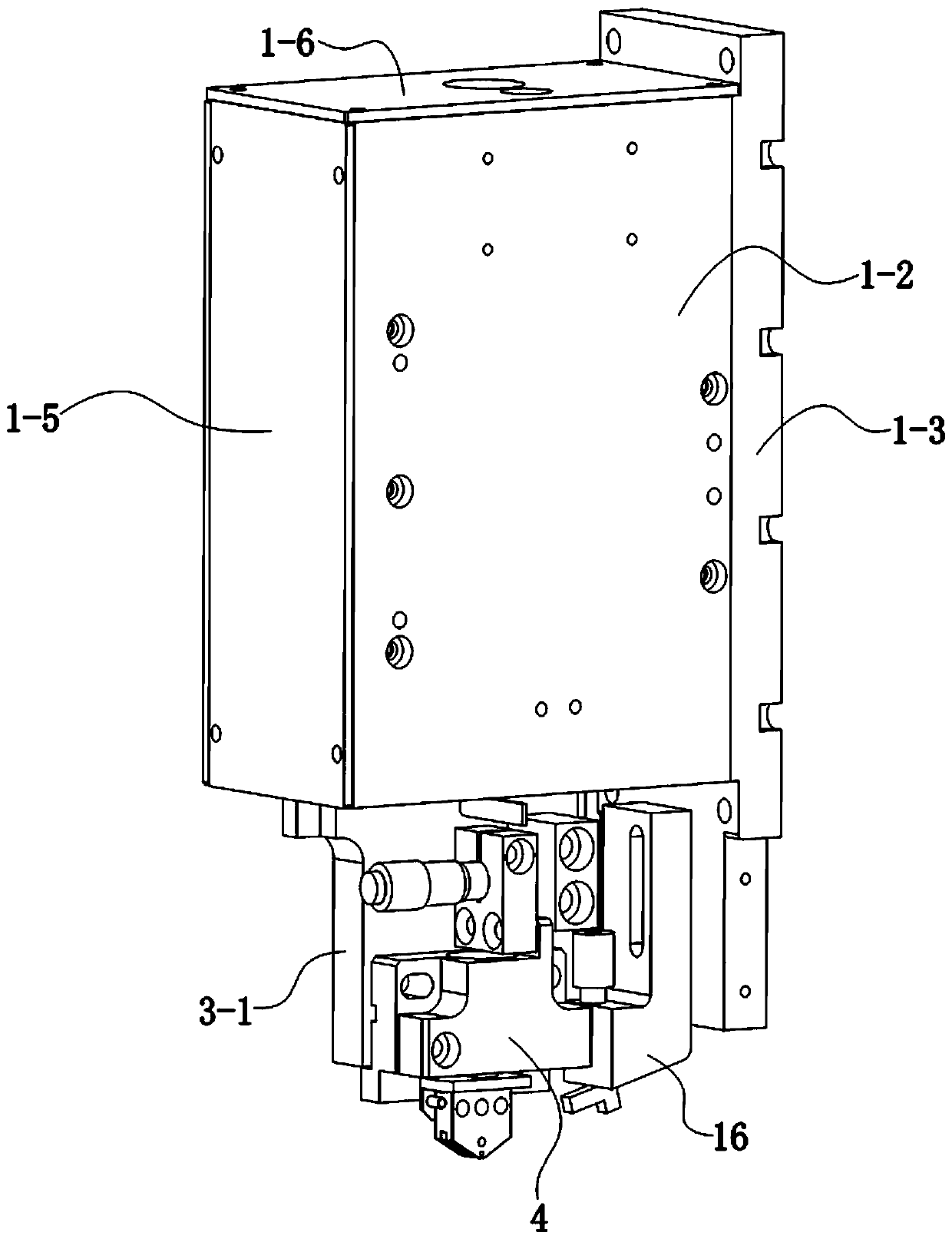

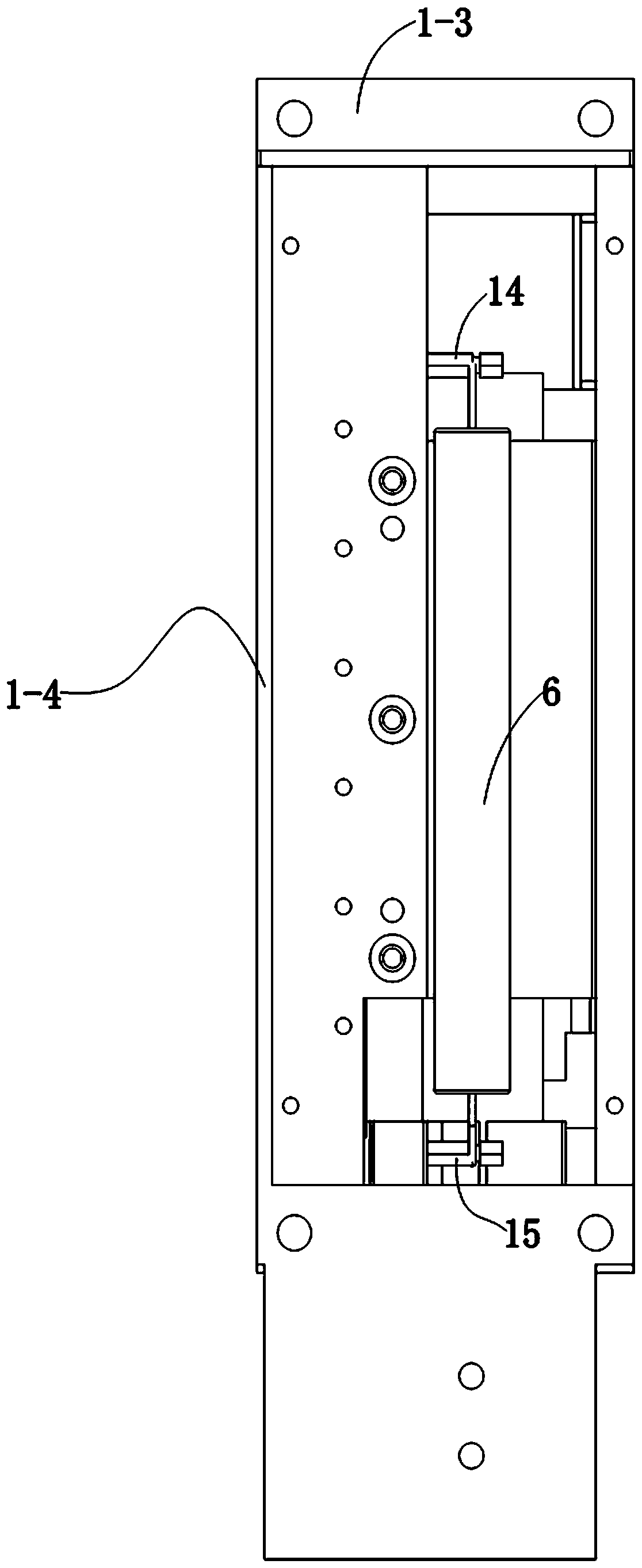

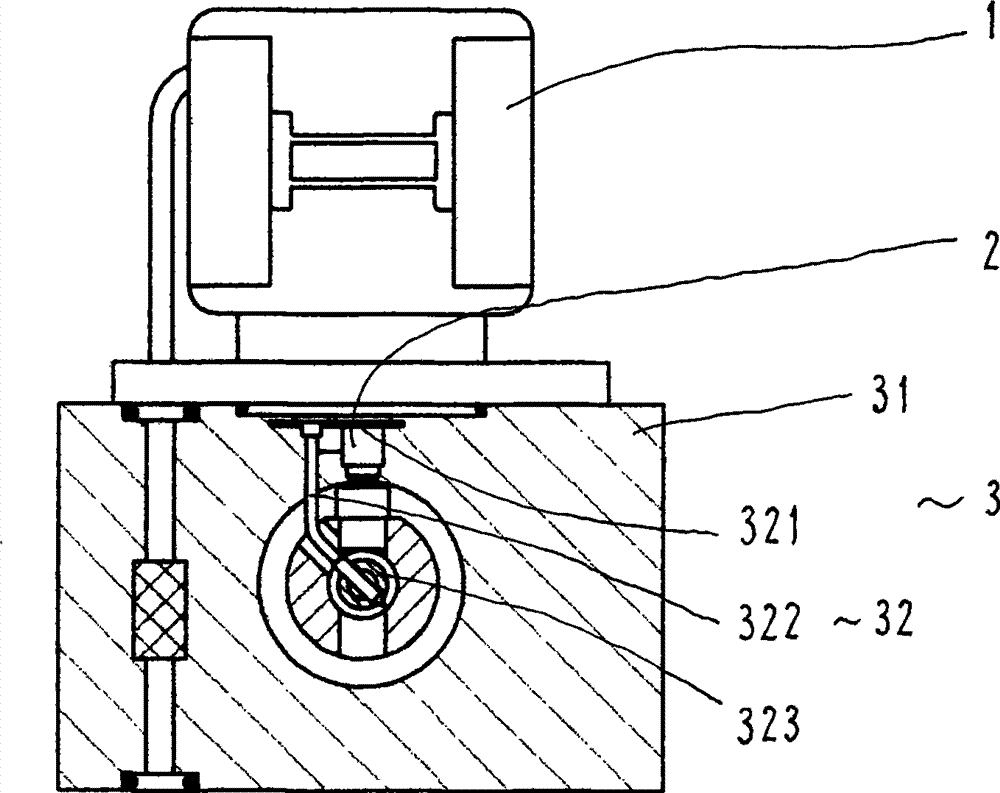

High-precision glass cutting tool bit device

PendingCN110272198AStable pressure outputWide pressure output rangeGlass severing apparatusGratingFixed frame

The invention relates to the panel display industry, in particular to a high-precision glass cutting tool bit device which is aimed at solving the technical problem that an existing glass cutting tool bit device is low in precision. The high-precision glass cutting tool bit device comprises a fixed frame, a linear motor, a slide frame and a knife flywheel mechanism. A stator of the linear motor is fixedly connected with the fixed frame. A rotor of the linear motor is fixedly connected with the slide frame. The fixed frame is slidingly connected with the slide frame through a guide rail pair. The fixed frame is connected with the slide frame through a tension spring. The axis of the linear motor, the guide rail pair and the tension spring are parallel to one another. The knife flywheel mechanism is fixed to the slide frame. A reading head or grating ruler is installed on the fixed frame. A corresponding grating ruler or reading head is arranged on the slide frame. A photoelectric sensor is arranged on the fixed frame. A corresponding sensor piece is arranged on the slide frame. The high-precision glass cutting tool bit device further comprises a controller. The reading heads, the photoelectric sensor are all electrically connected with the controller. The controller controls the linear motor to act in a position mode or a constant-force mode.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

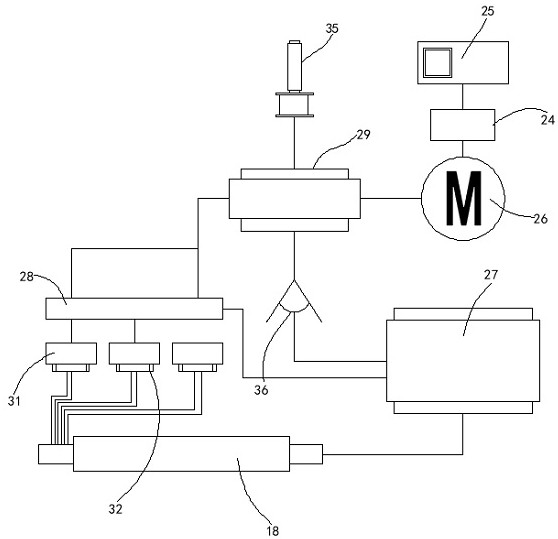

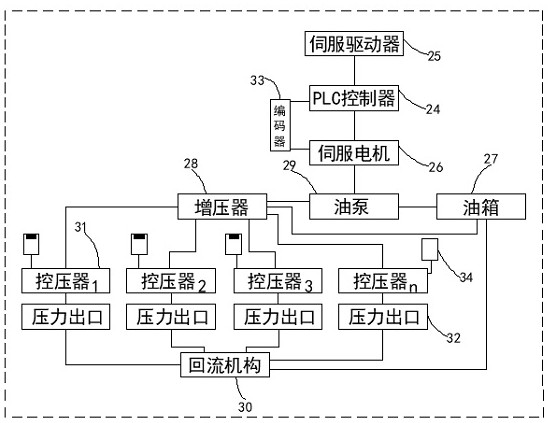

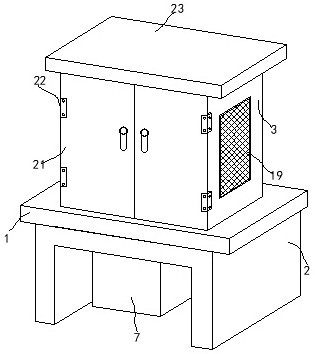

Grate cooler servo hydraulic driving control system device

PendingCN112964074AAvoid wastingGuaranteed uptimeHandling discharged materialControl devices for furnacesProgrammable logic controllerControl system

The invention relates to the technical field of grate coolers, in particular to a grate cooler servo hydraulic driving control system device. The device comprises a control machine, a servo driver, a servo motor, an oil tank, a supercharger, an oil pump, a backflow mechanism, a plurality of pressure controllers and a plurality of pressure outlets corresponding to the pressure controllers, wherein a PLC (programmable logic controller) is arranged in the control machine, the servo driver is connected with the control machine and conducts signal interaction with the servo motor through an encoder, the servo motor is connected with the oil pump, and the oil pump is connected with the oil tank. According to the grate cooler servo hydraulic driving control system device, the multiple pressure controllers have constant pressure output, output pressure is more stable, all the pressure controllers are mutually independent, and the working efficiency is high; the backflow mechanism can recycle pressure-controlled medium liquid to avoid resource waste; and linked multi-range heat dissipation mechanisms in an element can ensure the normal operation of the equipment element and avoid high-temperature damage.

Owner:NANJING RUITAI CEMENT MFG EQUIP CO LTD

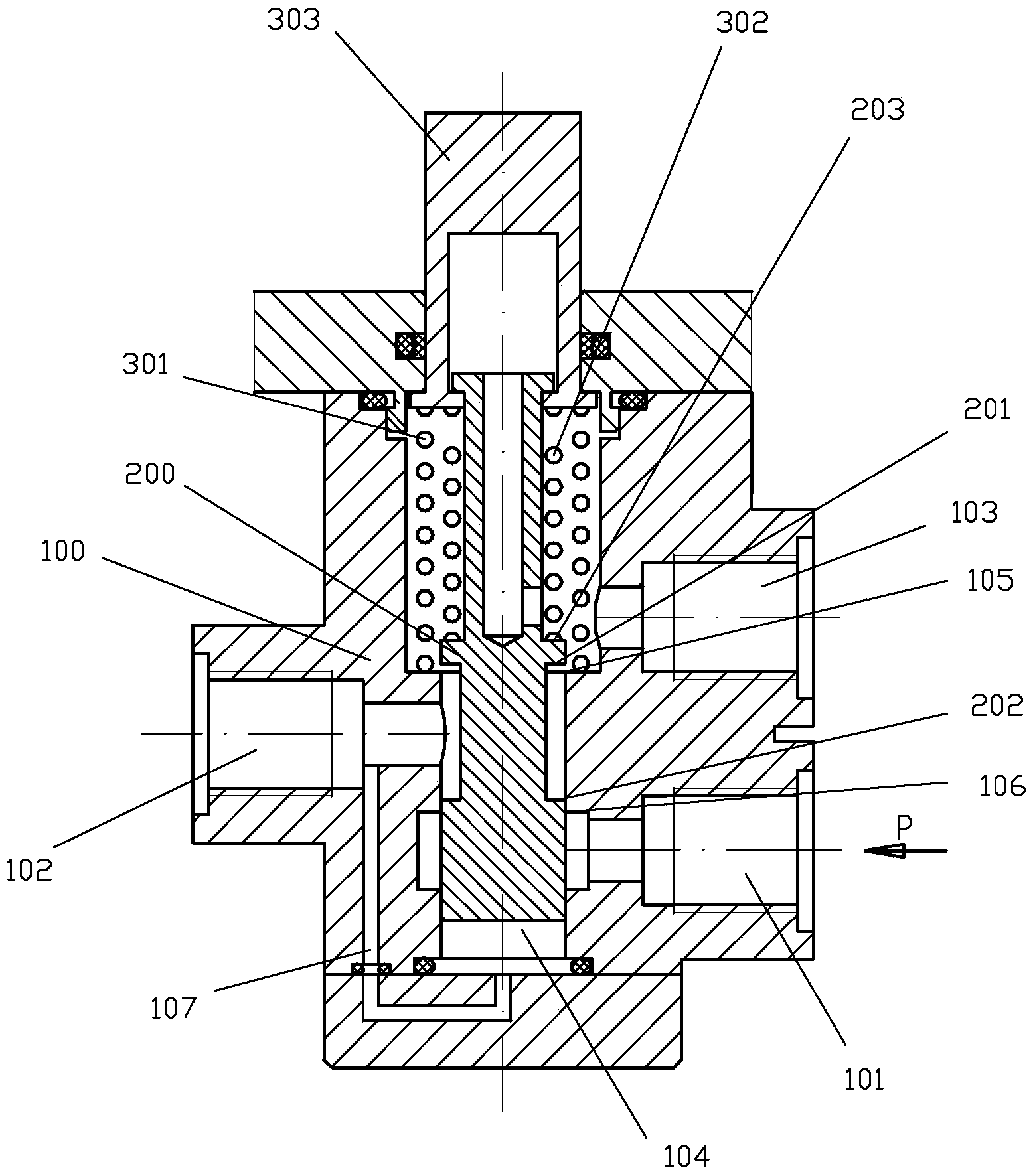

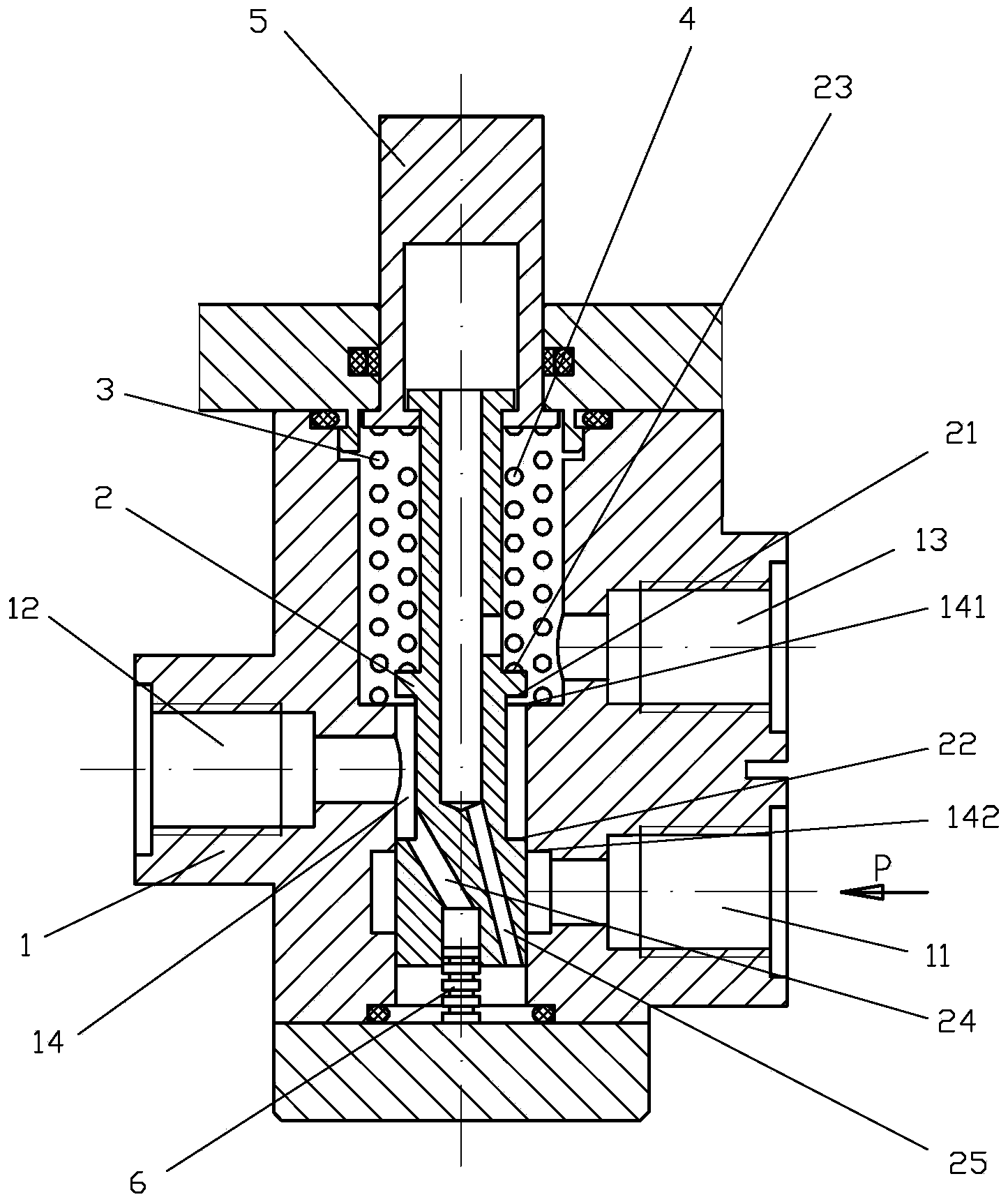

Pressure controller

InactiveCN100572874CGood orientationStable pressure outputEqualizing valvesSafety valvesDifferential pressureInlet pressure

The invention relates to a pressure regulator, in particular to a pressure controller applied to a fluid system. It includes a valve body, a valve core is arranged in the valve body, a spring is connected outside the valve core, seals are provided at both ends of the valve core, a number of guide grooves are arranged in the axial direction on the valve body, and the spring is close to the inlet end. One side is provided with an adjusting cap, and the adjusting cap is sleeved on the valve core. The adjusting cap is provided with a number of angles, and the angles are inserted into the guide groove and fit with the guide groove. The present invention mainly provides a pressure controller that can continuously adjust the outlet pressure when the inlet pressure is constant, and has good versatility; it solves the problem that the pressure difference between the inlet and outlet of the pressure controller in the prior art is constant , a technical problem with poor versatility.

Owner:佛罗德・卡特

Open-loop control method and system for ventilator fan

ActiveCN105944197BImprove stabilityReduces the possibility of bouncing up and downRespiratorsMedical devicesLoop controlControl system

The invention discloses an open-loop control method and a control system of a fan of a breathing machine. The open-loop control method comprises the following steps: under a working mode of the breathing machine, setting a target pressure P of a pre-outputted airflow of the breathing machine; collecting a real-time flow value F of the airflow outputted by the breathing machine by virtue of a flow sensor; in accordance with the target pressure P, the real-time flow value F and a fan control volume calibration table, calculating a fan control volume DFP required by outputting the target pressure P at the real-time flow value F in accordance with a preset rule, wherein m*n pieces of output pressure values, which are in corresponding to m pieces of preset flow values under n pieces of preset fan control volumes, are saved in the fan control volume calibration table, and both m and n are positive integer; and controlling the fan of the breathing machine in accordance with the fan control volume DFP. According to the control method and the control system disclosed by the invention, the possibility that the output pressure is fluctuated can be reduced, and the fan of the breathing machine can keep stable pressure output under different flow rates.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

A spool feedback piston hydraulic brake valve

InactiveCN103453178BStable pressure outputSmall control forceEqualizing valvesMultiple way valvesRe engineeringHydraulic brake

The invention discloses a hydraulic brake valve of a feedback piston of a valve core. The hydraulic brake valve comprises a valve body, the valve core, a return spring, a balance spring and a push rod, wherein the valve body is provided with an input port, an output port, an oil return port and a valve core cavity, the input port, the output port and the oil return port are respectively communicated through the valve core cavity, the valve core is connected to the valve core cavity in a sliding manner, and the push rod is movably connected to the upper end of the valve core; a feedback passage is arranged in the valve core, and the feedback channel is communicated between the output port of the valve body and the bottom end of the valve core cavity; the hydraulic brake valve further comprises the feedback piston, wherein the upper part of the feedback piston is contained in the feedback passage, and the bottom end face of the feedback piston is in contact with the bottom surface of the valve core cavity. According to the invention, through redesigning the structure of the feedback passage and adding the feedback piston, the hydraulic brake valve has the characteristics of high flow, low control force, stable output pressure and controllable size.

Owner:JIMEI UNIV

High-temperature high-pressure tensile stress strain system of oil well cement and test method thereof

ActiveCN102401770BEnables evaluation of tensile stress-strain curvesStable pressure outputThermometers using electric/magnetic elementsMaterial strength using tensile/compressive forcesTemperature controlTemperature stress

The invention relates to a high-temperature high-pressure tensile stress strain system of oil well cement. The system comprises a cement tensile test assembly, a power supply and pressure control unit, a temperature control unit, a signal control processing unit and pipelines. By adopting the system of the invention, the temperature and the pressure for the bottom maintenance can be simulated, the tensile stress strain of the oil well cement can be continuously measured under conditions of the temperature and the pressure, and the temperature pressure curve and the tensile stress strain curve are recorded. The system and the measure method of the invention are in favor of the intuitional test, the comparison of tensile resistances of different cement paste systems and the design of the cement paste formula, so cement paste systems which can satisfy on-site construction requirements are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

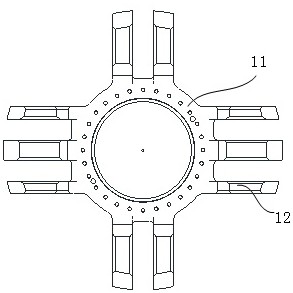

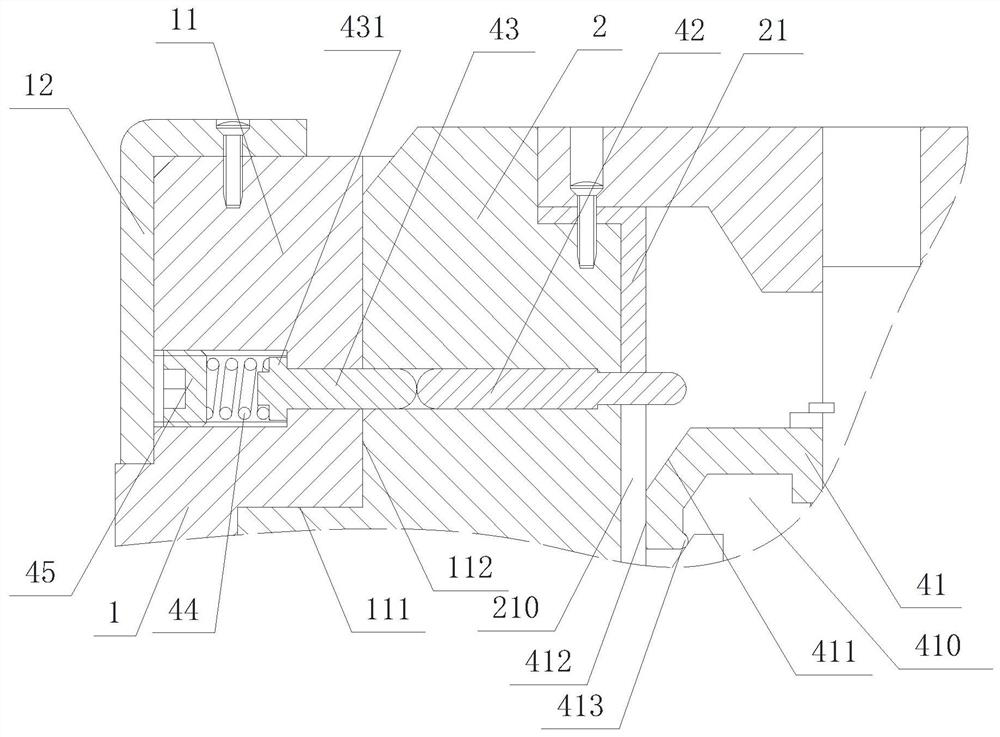

Hinge beam assembly and novel cubic press

ActiveCN112791668ALow processing and manufacturing costsImprove structural strengthUltra-high pressure processesSuperhard materialCylinder block

The invention belongs to the technical field of superhard material synthesis processing equipment, and provides a hinge beam assembly and a novel cubic press. The hinge beam assembly comprises a hinge beam, wherein the hinge beam comprises a cylinder body and a beam lug annularly arranged on the outer side wall of the cylinder body, and the cylinder body is provided with a first inner hole; a spherical plunger which is arranged in the first inner hole, wherein the spherical plunger is in a hemispherical shape, a pressurizing cavity is formed between the bottom wall of the first inner hole and the spherical plunger, an oil inlet hole penetrating through the cylinder body is formed in the bottom wall of the first inner hole, and the cylinder body transmits pressure to the synthesis block through the spherical plunger. The technical scheme provided by the invention has the advantages of low processing and manufacturing cost, high structural strength, excellent sealing performance, stable pressure output, lower system energy consumption, high equipment reliability and the like.

Owner:北京潭龙天钻科技有限公司

Pressure servo valve feedback mechanism

ActiveCN101725745BStable pressure outputImprove controllabilityProgramme controlOperating means/releasing devices for valvesSpool valveTorque motor

A pressure servo valve feedback mechanism mainly solves the technical problems of non-linear property and the like of a pressure servo valve. The invention adopts the technical scheme that a feedback mechanism is arranged under a torque motor and a fluidic amplifier and above a main valve, the feedback mechanism consists of a control valve set and a feedback rod set, one end of the feedback rod set is connected with the control valve set, the other end of the feedback rod set is connected with the fluidic amplifier which is connected with a pore canal of the control valve set, the control valve set is connected with the pore canal of the main valve, and left and right spring assemblies are arranged at two ends of a slide valve assembly of the control valve set respectively. The pressure servo valve feedback mechanism is applicable to various pressure servo valves.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

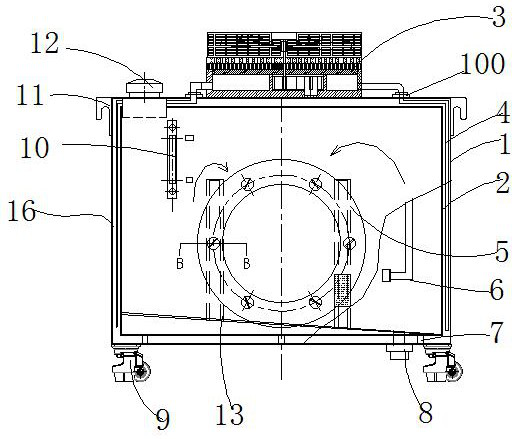

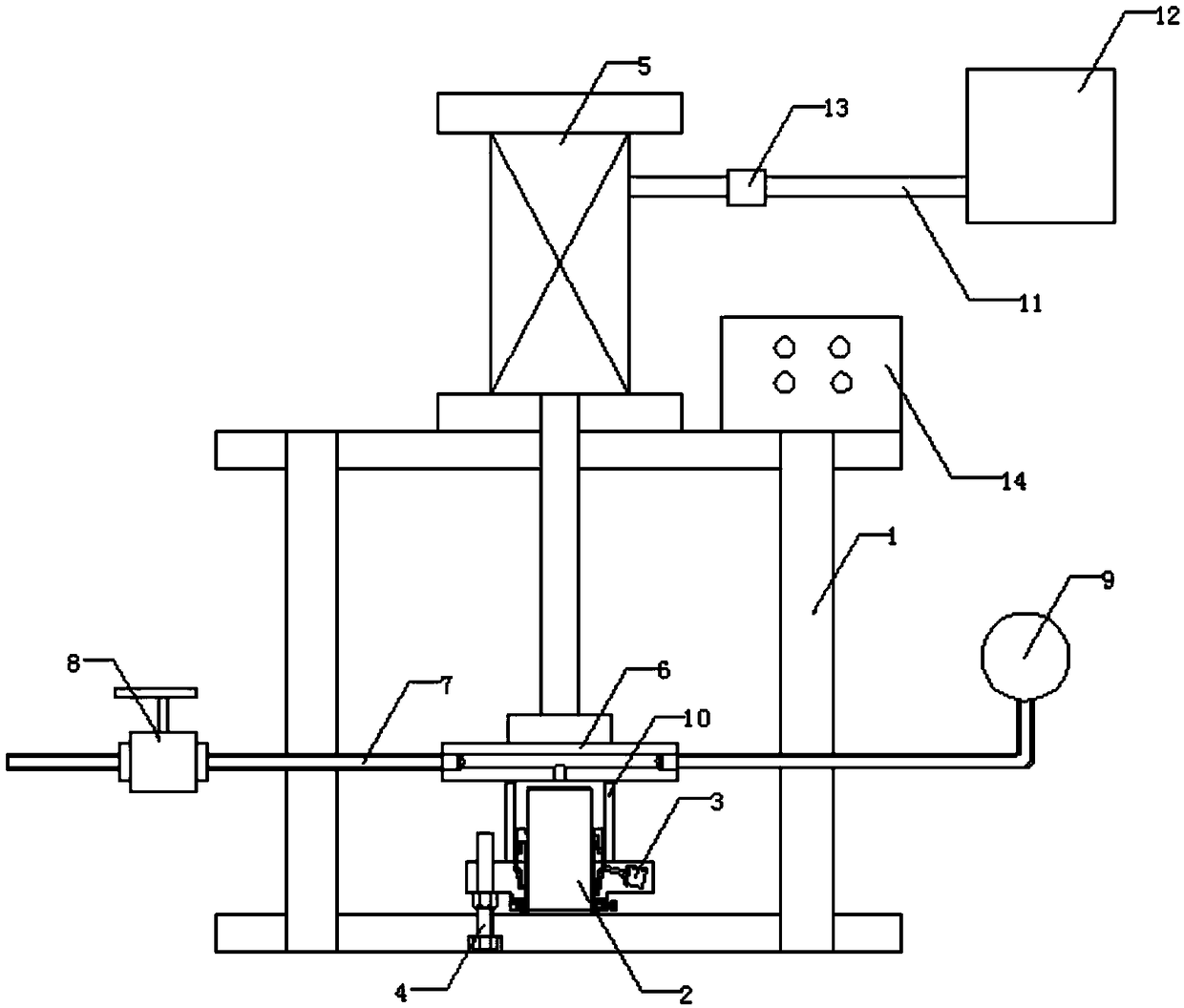

Static pressure testing device for integrated packaging mechanical seal

PendingCN109115426AAvoid manualStable pressure outputMeasurement of fluid loss/gain rateHydraulic cylinderInlet valve

The invention discloses a static pressure testing device for an integrated packaging mechanical seal, which comprises a rack, and is characterized in that the bottom end of the rack is fixedly provided with an integrated packaging mechanical seal, the top end of the rack is fixedly provided with an oil cylinder, a piston rod of the oil cylinder is fixedly connected with the top end of a ventilating disc through a flange, the middle part of the ventilating disc is fixedly provided with an air inlet pipe, one end of the air inlet pipe is fixedly provided with an air inlet valve, the other end ofthe air inlet pipe is fixedly provided with a pressure meter, the middle part of the air inlet pipe is provided with an air outlet, and the bottom end of the ventilating disc is fixedly provided witha cavity. According to the static pressure testing device for the integrated packaging mechanical seal, the ventilating disc, the cavity and the integrated packaging mechanical seal are compressed through extending the piston rod of the oil cylinder so as to quickly form a sealed cavity, the air pressured is charged for testing, the pressure of the hydraulic oil cylinder is provided by a hydraulic station, and the pressure output is stable, so that manual bolt locking is avoided, and the pressure testing efficiency if improved so as to meet the requirement of batch production of the integrated packaging mechanical seal.

Owner:昆山福步工业设备有限公司

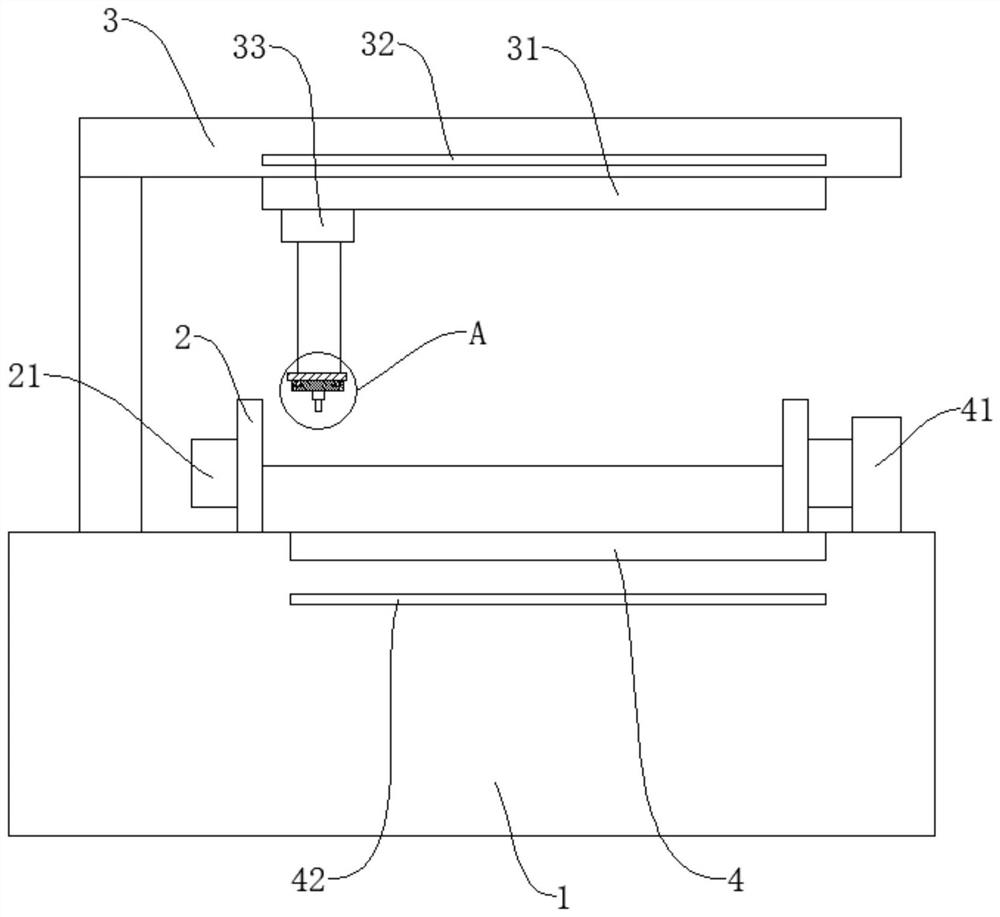

Cutting device for high-precision barb suture lines

PendingCN113172682ADriving force is stableStable pressure outputSuture equipmentsSurgical needlesGratingElectric machinery

The invention discloses a cutting device for high-precision barb suture lines, relates to the technical field of medical suture line processing equipment, and aims to solve the problems that the accuracy cannot be ensured by adjusting the relative position between a cutting head and the suture lines, the quality is influenced. According to the technical scheme, chucks located at the two ends of a workbench respectively are arranged on the workbench, and the chucks fix to the corresponding ends of the suture lines correspondingly; a transverse rod is arranged above the workbench in the horizontal direction and provided with a first guide rail and a first grating ruler which extend in the length direction of the suture lines, a first linear motor is arranged at one end of the first guide rail, a cutting part slidably installed on the first guide rail is fixed to the output end of the first linear motor, and a photoelectric sensor is fixed to the transverse rod; and a sensor sheet corresponding to the photoelectric sensor is fixed to the cutting part, and a first reading head corresponding to the first grating ruler is fixed to the cutting part. According to the cutting device, the precision of adjusting the relative distance between the cutting head and the suture lines is improved, and the cutting precision of the suture lines is improved.

Owner:南京普立蒙医疗科技有限公司

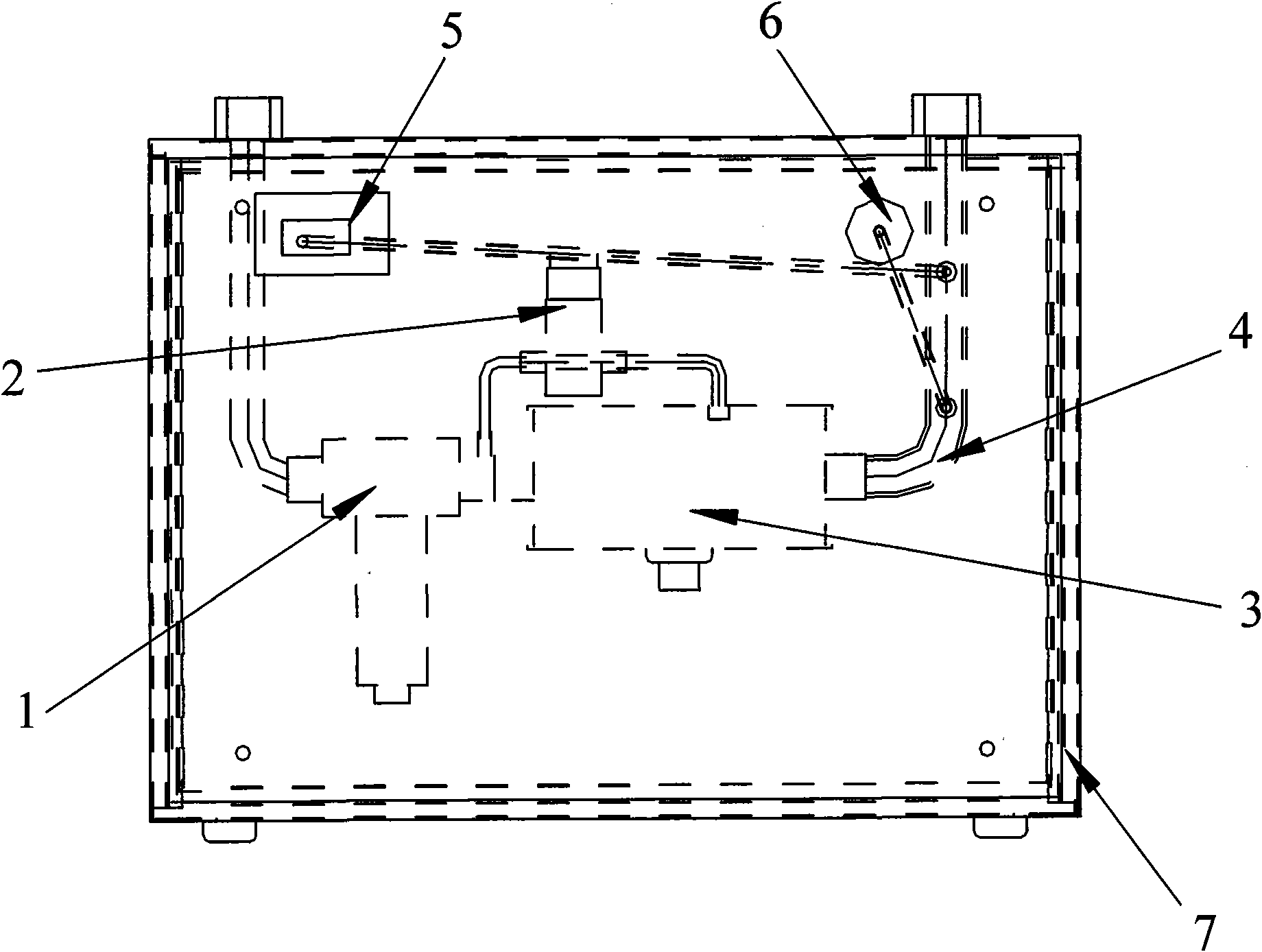

Energy-saving gas pressure stabilizer

InactiveCN101956697AGuarantee normal productionStable pressure outputPump controlPositive-displacement liquid enginesPressure controllerEngineering

The invention discloses an energy-saving gas pressure stabilizer which comprises a filter, a pressure regulating valve, a pressure reducing valve, a pipeline, a pressure controller, a pressure gage and a box body, wherein the filter, the pressure regulating valve, the pressure reducing valve, the pipeline, the pressure controller and the pressure gage are positioned in the box body; one end of the filter is connected with one end of the pressure reducing valve, and the other end of the pressure reducing valve is connected with the pipeline; and the pressure regulating valve is positioned between the filter and the pressure reducing valve, and one end of the pressure controller and one end of the pressure gage are both connected with the pipeline. The invention can keep stable pressure output, reliably guarantee client production and improve product quality.

Owner:SHANGHAI SCREW COMPRESSOR CO LTD

High-pressure and hydraulic pulsation test system of aircraft

InactiveCN101881287BHigh precisionSimple and fast operationFluid-pressure actuator testingGear pumpControl signal

The invention provides a high-pressure and hydraulic pulsation test system of an aircraft, in which a high-pressure internal gear pump driven by a driving motor provides a high-pressure liquid flow for the system, a computer outputs the control signals to a proportional flow servo valve and a proportional pressure servo valve to control a hydraulic system to generate a stable and controllable high-pressure hydraulic pressure incoming flow, and a piezoceramic driver controlled by the computer generates an exciting force to propel the metallic membrane to generate an accurate and controllable pressure pulsation value in the stable and controllable high-pressure hydraulic pressure incoming flow. The invention has the advantages of high accuracy, simple and convenient operation, large adjustable range of flow and pressure, large controllable frequency range, rapid response, simple structure and little interference to the controllable pressure pulsation part.

Owner:JIANGSU BAIXIE PRECISION FORGING MACHINERY +1

Locking type pressing module for pressing type intelligent seal

InactiveCN112810338AQuality improvementAchieve lockingStampingInterference resistanceElastic component

The invention provides a locking type pressing module for a pressing type intelligent seal. The locking type pressing module comprises an outer support, an inner support and a driving device, a first mounting cavity with the upper end and the lower end opened is formed in the outer support, auxiliary bolts and strip-shaped guide grooves are evenly distributed on the side wall of the first mounting cavity in the circumferential direction, the auxiliary bolts are elastic, the heads of the auxiliary bolts can extend into the first mounting cavity, and the length directions of the strip-shaped guide grooves are parallel to the axis of the first mounting cavity; the inner support is vertically matched in the first mounting cavity in a sliding mode, the seal is arranged at the bottom of the inner support, a first pin hole and a main pin are arranged on the inner support, and a first elastic component is arranged in the outer support; and the driving device can push the auxiliary bolts and the main pin to slide. The locking type pressing module for the pressing type intelligent seal is compact in structure, convenient and labor-saving to operate, stable in driving, good in reliability, high in safety, good in anti-interference effect and high in safety, the seal can be rapidly detached and replaced, the seal can be rapidly replaced according to needs, and the cost is reduced.

Owner:陆晓伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com