Welding gas energy-saving comprehensive control system

A comprehensive control and welding gas technology, applied in control/regulation system, fluid pressure control, electric fluid pressure control, etc., can solve the problems of simple pipeline layout, large transient pressure drop, lack of effective management of gas supply system, etc. , to achieve the effect of ensuring gas pressure output and stabilizing gas pressure output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

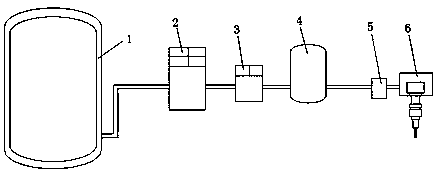

[0038] like figure 1As shown, the present invention provides a welding gas energy-saving comprehensive control system, which includes: a gas supply station 1, which is used to provide a gas source for welding equipment; Mixing of different proportions; the front-end master control unit 3 is used to manage the gas supply on and off of the pipeline and perform automatic adjustment management according to the feedback data; the middle section constant pressure control unit 4 is used for automatic adjustment management according to the state parameters of the gas to ensure Stable gas pressure output; the terminal intelligent gas control instrument unit 5 is used to automatically match a reasonable gas flow according to the needs of the welding equipment; the welding equipment 6 is connected to the terminal intelligent gas control instrument unit 5 through pipelines.

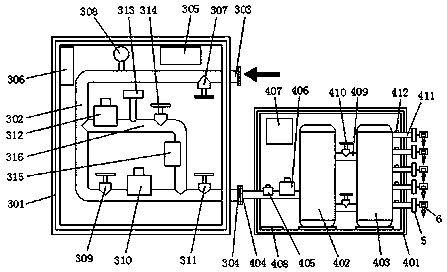

[0039] like figure 2 As shown, in this embodiment, the front-end master control unit 3 includes a first box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com