Water-cooling aluminum alloy airplane hydraulic oil tank

An aircraft hydraulic and aluminum alloy technology, which is applied in the direction of fuel supply tank devices, mechanical equipment, fluid pressure actuators, etc., can solve the problems of lack of impact resistance, inconvenient movement, large heat dissipation volume, etc., and achieve stable pressure output , reduce the size and weight, the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

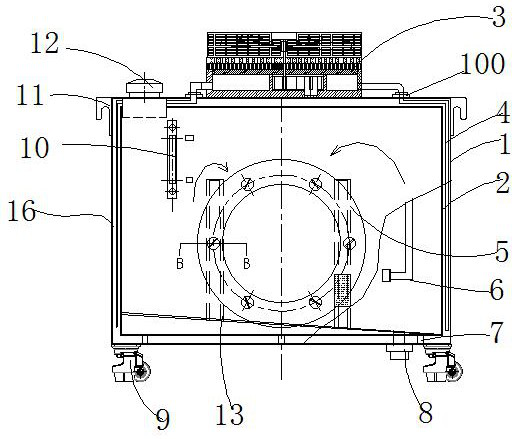

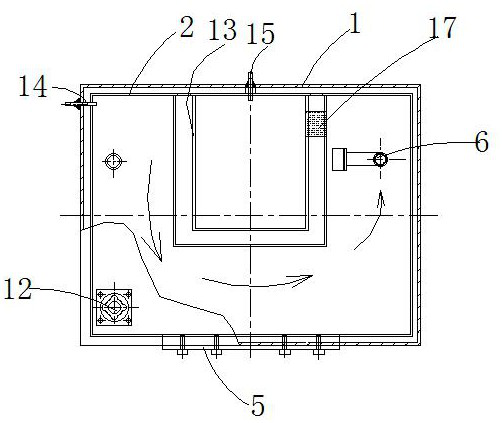

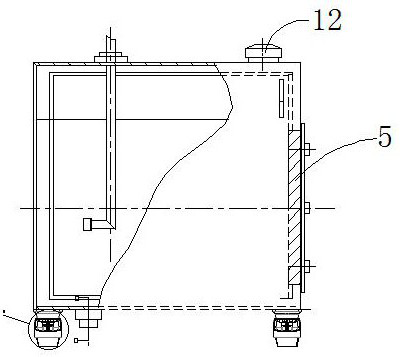

[0035] Such as Figure 1-3 Shown; A kind of water-cooled aluminum alloy aircraft hydraulic oil tank, comprises the fuel tank outer casing 1 and the fuel tank inner casing 2 that aluminum alloy material is made, and described fuel tank outer casing 1 is provided with an independent fuel tank inner casing 2, The bottom of the inner casing 2 of the fuel tank is fixedly connected to the lower inner wall surface of the outer casing 1 of the fuel tank through the inner casing support seat 7, and a cooling cavity 16 communicating with each other is formed between the outer casing 1 of the fuel tank and the inner casing 2 of the fuel tank. The inside of the inner casing 2 of the fuel tank is also provided with a sub-case 13, the lower end of the sub-case 13 is fixedly connected to the lower surface of the inner casing 2 of the fuel tank, and the side of the sub-case 13 is fixed to the side of the inner casing 2 of the fuel tank. connected, the inside of the sub-casing 13 is provided w...

specific Embodiment 2

[0047] Such as Figure 8 As shown, the others are the same as the first embodiment, the difference is that the structure of the radiator shell 301 of the heat dissipation assembly 3 is different.

[0048] The radiator shell 301 includes a housing box 3011, a spiral shield 3012, a support frame 3013, and a cooling motor mount 3014;

[0049] A spiral protective cover 3012 is installed on the upper surface of the shell box 3011. The spiral protective cover 3012 is made of a hollow copper tube and is in a spiral shape. The spiral protective cover 3012 is divided into an upper protective cover and a lower plate cover; the lower plate cover It communicates with the upper protective cover up and down, and the inside is filled with volatile coolant;

[0050] The upper protective cover is fixedly connected with the shell box body 3011 through the support frame 3013, the end of the support frame 3013 is fixedly connected with the shell box body 3011, and the center part of the support ...

specific Embodiment 3

[0053] Such as Figure 9-13 As shown, the others are the same as in Embodiment 1, the difference is that a vibration generating assembly 100 is installed on the outer tank body 1 of the fuel tank; the vibration generating assembly 100 includes a lower base 101, an upper cover 102, a lower vibration ring 103, an upper vibration Ring 104, spring 105, pressure plate 106, seal 107; the middle part of the lower base 101 is provided with a step installation hole, the step installation hole is equipped with a lower vibrating ring 103, and the upper end of the lower base 101 is equipped with an upper vibrating ring 104 , the lower base 101 is covered with an upper cover 102, the upper end of the upper cover 102 is fixed with a pressure plate 106, and an upper vibrating ring 104 is arranged between the lower surface of the pressure plate 106 and the lower base 101; A through hole is arranged inside the middle of the base 101, and the through hole is used to install the main pipe of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com