Cutting device for high-precision barb suture lines

A cutting device and high-precision technology, applied in metal processing, surgical instruments, trocars, etc., can solve problems affecting the quality of sutures, achieve a wide range of pressure output, high resolution accuracy, and ensure cutting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

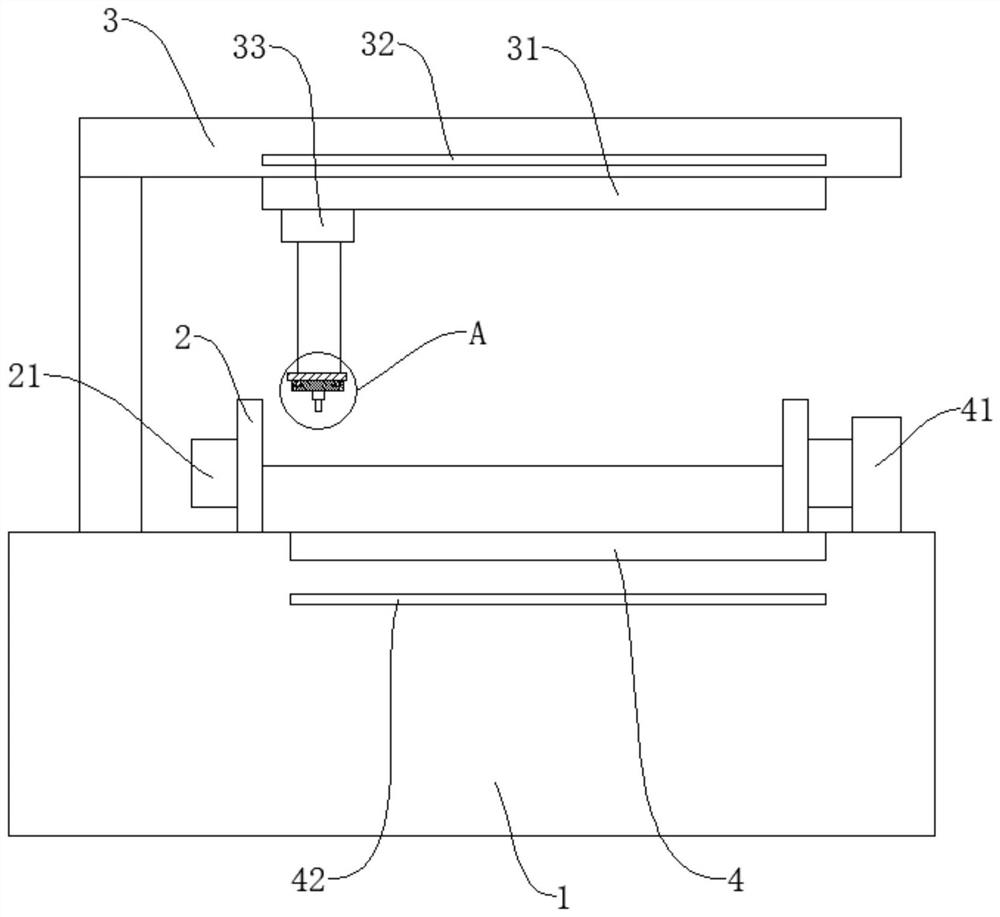

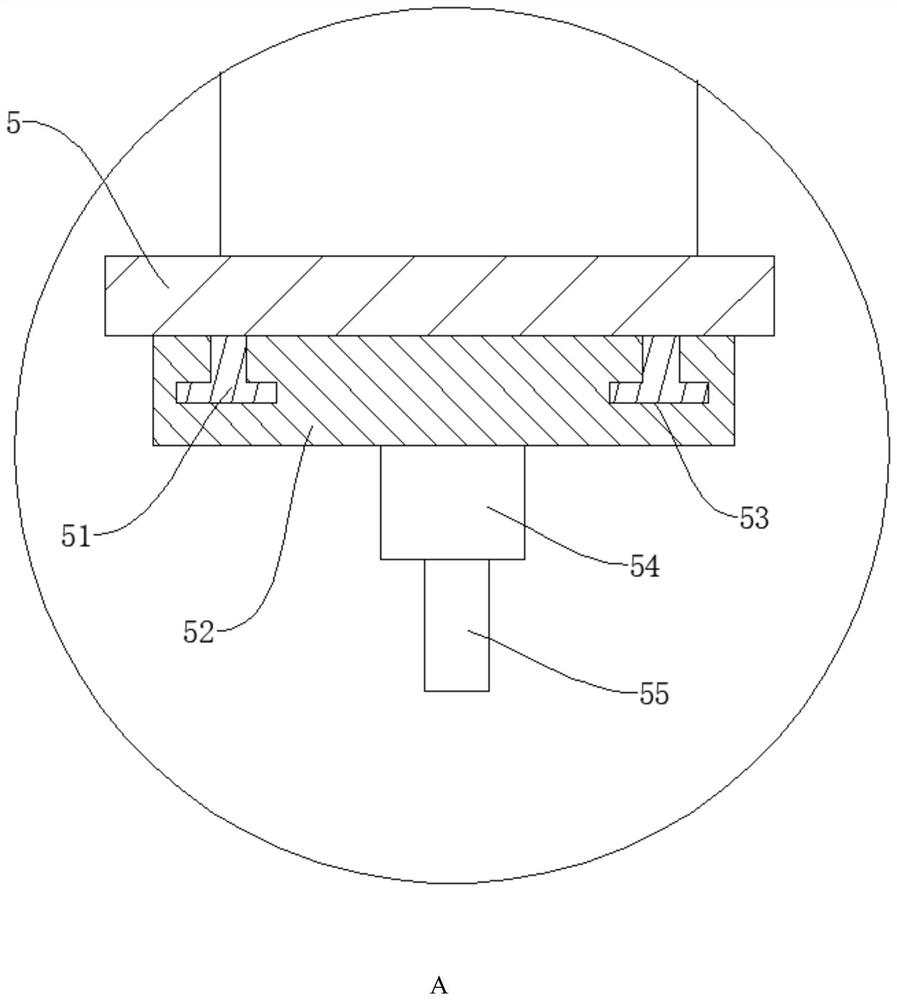

[0021] refer to figure 1 , the invention discloses a cutting device for high-precision barbed sutures, which includes a workbench, on which chucks are respectively located at both ends of the workbench, and the chucks are connected with a first rotating motor that drives the chucks to rotate, The chucks respectively fix the corresponding ends of the sutures; a horizontal bar is arranged above the workbench along the horizontal direction, and the cross bar is provided with a first guide rail and a first grating scale extending along the length direction of the sutures, and a first linear scale is provided at one end of the first guide rail. Line motor, the output end of the first linear motor is fixed with a cutting part slidingly installed on the first guide rail, a photoelectric sensor is fixed on the cross bar, a sensor sheet is fixed on the cutting part corresponding to the photoelectric sensor, and the cutting part corresponds to the first grating The ruler is fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com