High-pressure and hydraulic pulsation test system of aircraft

A test system and aircraft technology, applied in the field of hydraulic pulsation test system, can solve the problems of low hydraulic pressure level and pulse control accuracy, failure to meet test requirements, insufficient control accuracy, etc., to improve test performance, simple structure, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

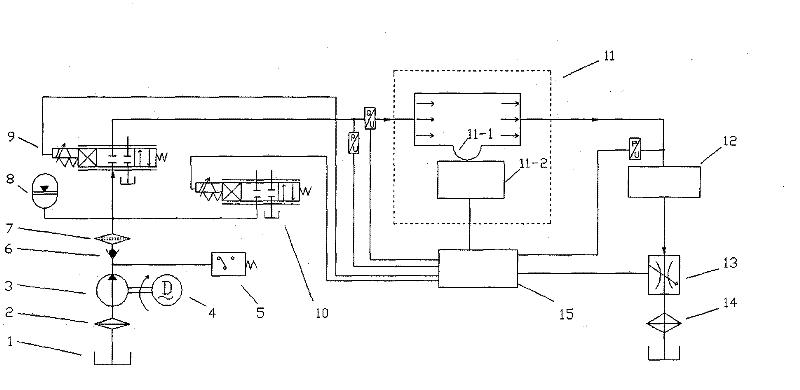

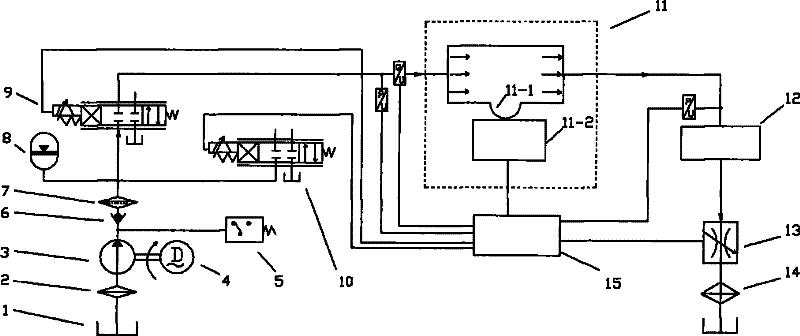

[0016] As shown in the figure, it is a schematic diagram of the system structure of the present invention. The working oil is filtered by the oil tank 1 through the coarse oil filter 2 and then enters the high-pressure internal gear pump 3 for pressurization. The coarse oil filter 2 adopts WU with simple structure and large oil passage capacity. -63×80-J mesh oil filter to protect the high-pressure internal gear pump. The high-pressure internal gear pump adopts a double-connected high-pressure internal gear pump QT43-31.5, the maximum pressure is 32Mpa, and the flow rate is 4 when driven by a 4-pole motor 42.2L / min; the pressure of the high-pressure liquid flow is monitored by the pressure relay 5 installed at the outlet of the high-pressure internal gear pump. The outlet of the gear pump 3 is connected to the inlet of the check valve 6, and the check valve 6 is a CRK2 check valve, the maximum working pressure is 50Mpa, the maximum opening pressure is 0.5Mpa, and the maximum fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com