Patents

Literature

35results about How to "Avoid manual" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

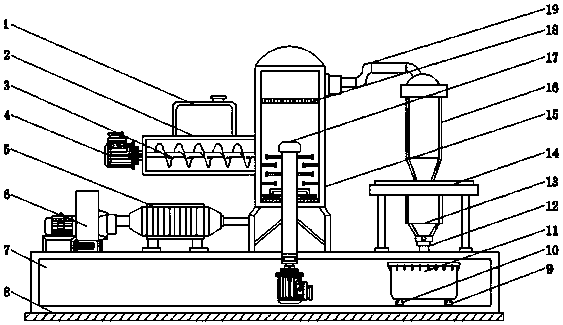

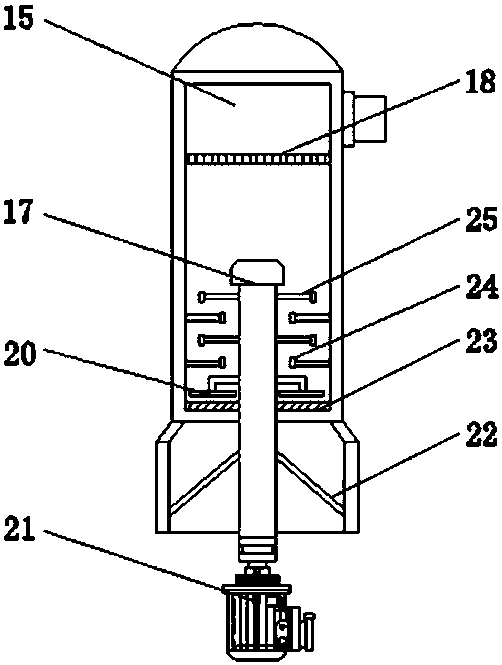

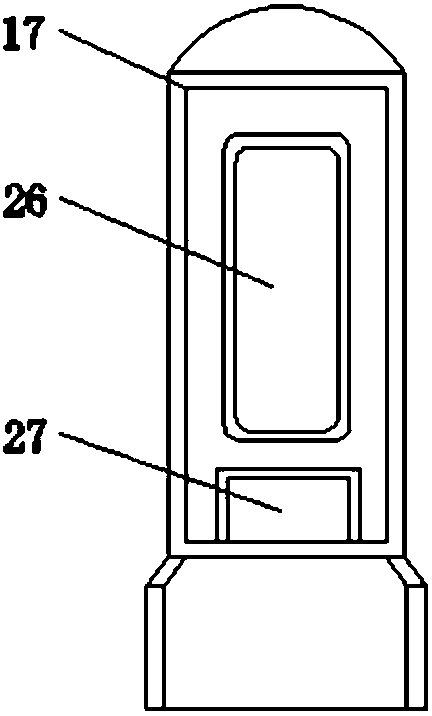

Efficient sodium alginate flashing drying machine

InactiveCN107606906AKeep dryNot easy to stickDrying gas arrangementsDrying machines with non-progressive movementsDrive motorPulp and paper industry

The invention discloses an efficient sodium alginate flashing drying machine which comprises a spiral feeding chute, a base, a flashing drying machine body and a cyclone separator, wherein a second drive motor is mounted in the base; a collecting barrel is mounted at one end of the interior of the base; an air blower is mounted at the end, far away from the collecting barrel, of the base; a steamradiator is mounted at the top end of the base and at the position on the side, close to the second driving motor, of the air blower; and the flashing dryer body is mounted at the top end of the baseand at the position on the side, away from the air blower, of the steam radiator. According to the efficient sodium alginate flashing drying machine, through mounting the cyclone separator, a discharging hopper and the collecting barrel, sodium alginate can be further dried by the cyclone separator after being dried by the flashing drying machine body, so that the drying effect is the best; and ataking out opening is formed in the bottom of the obverse side of the flashing drying machine body, so that internal blocked material can be conveniently cleared, and high rapidity and convenience arerealized.

Owner:南宁钛银科技有限公司

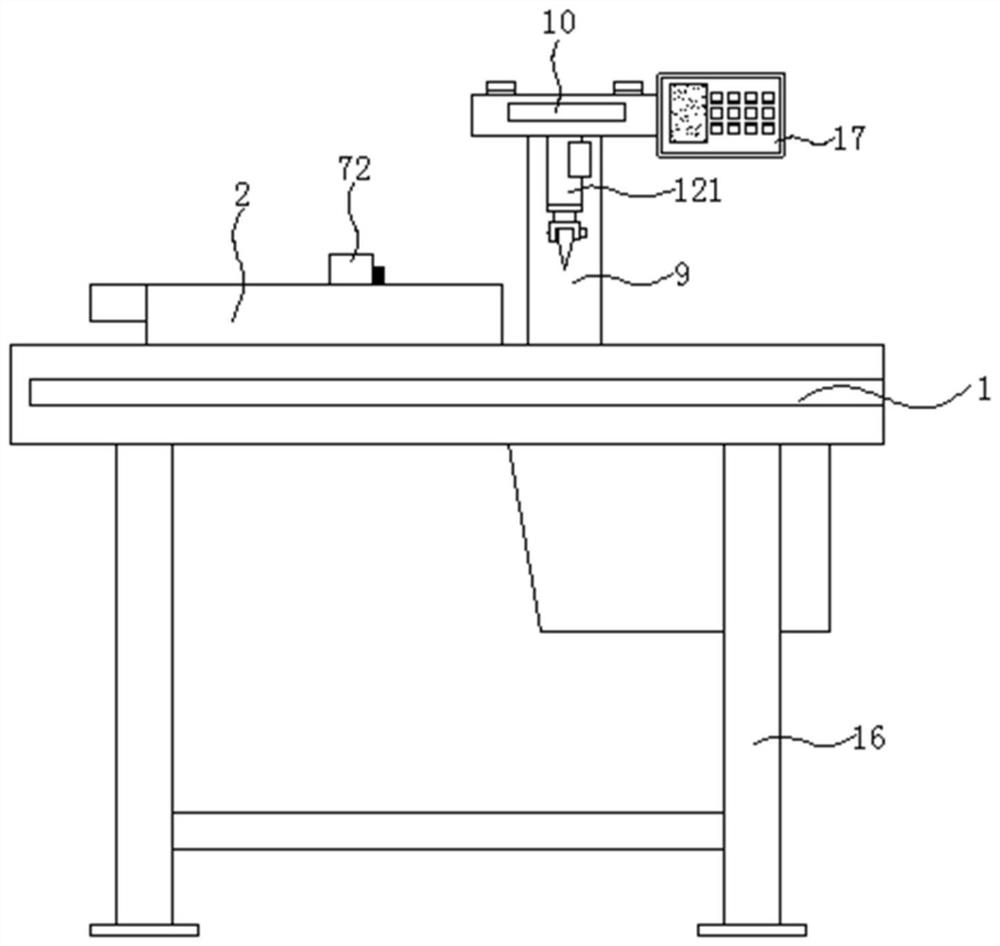

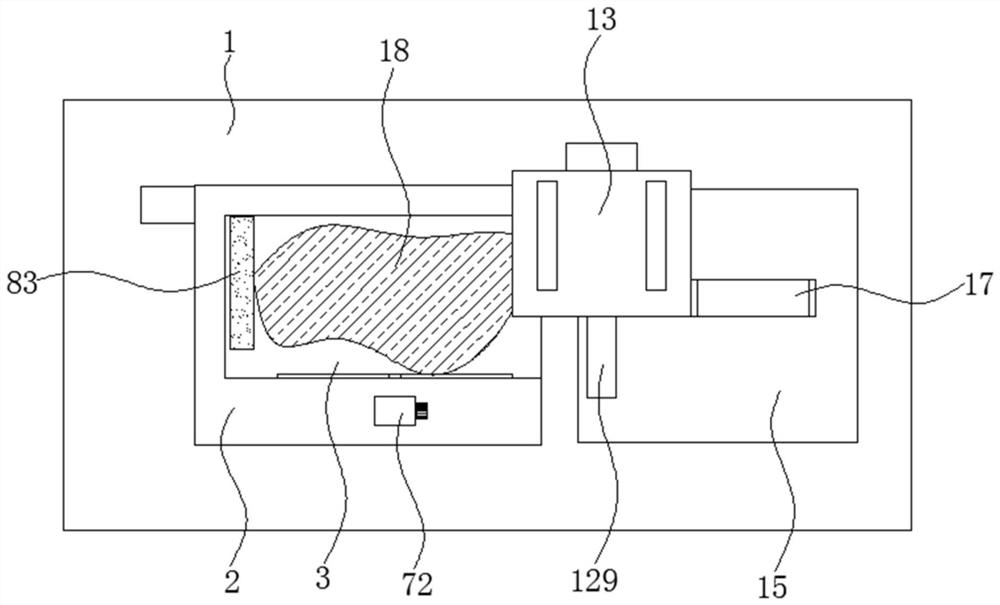

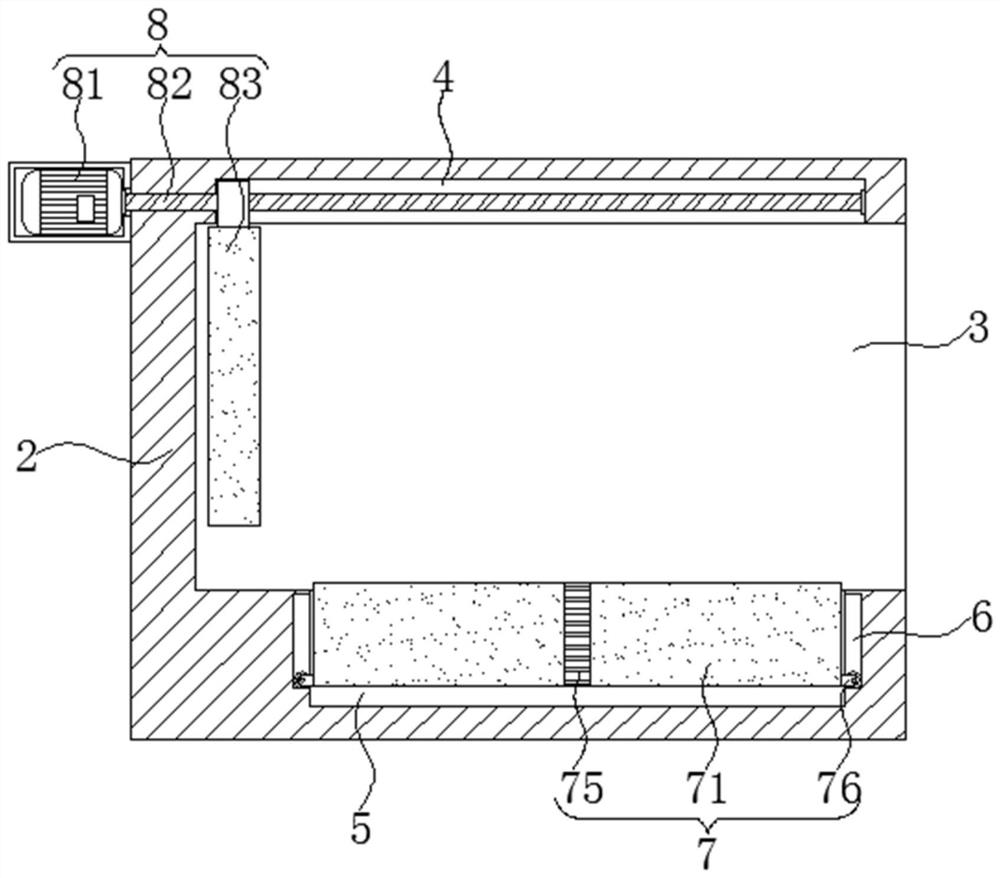

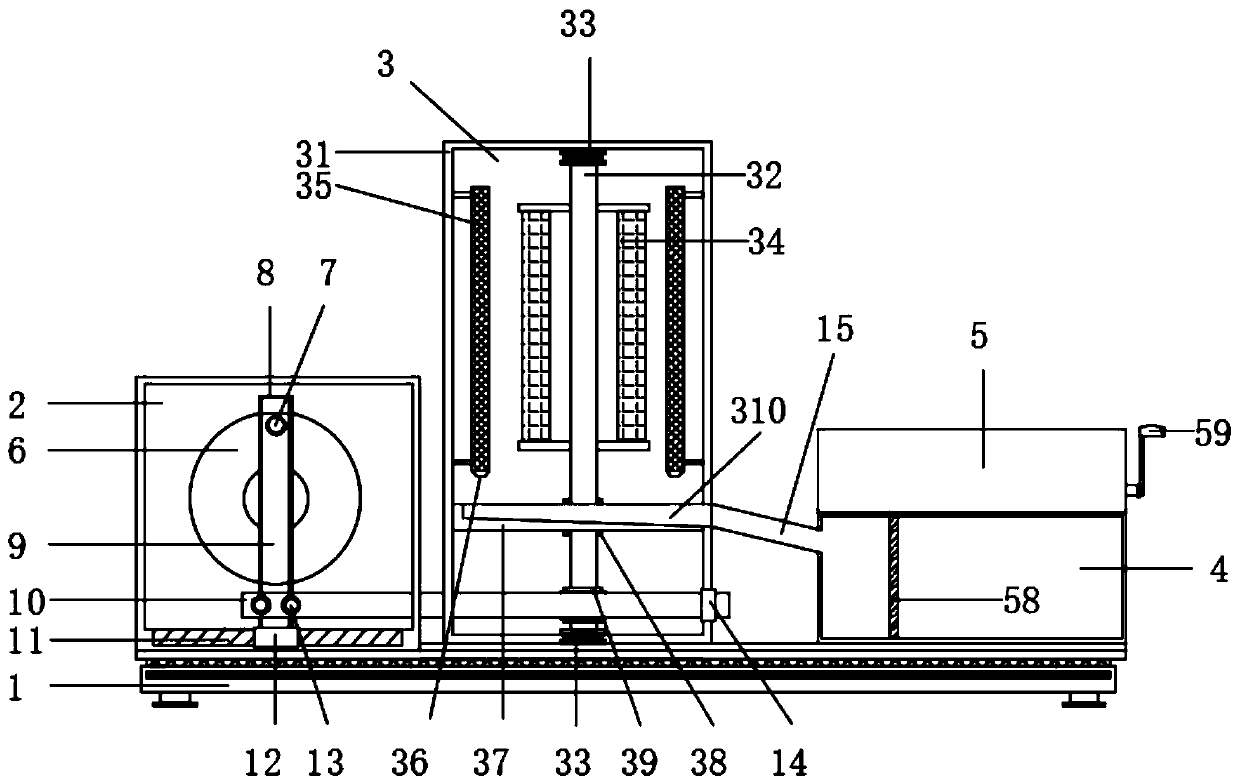

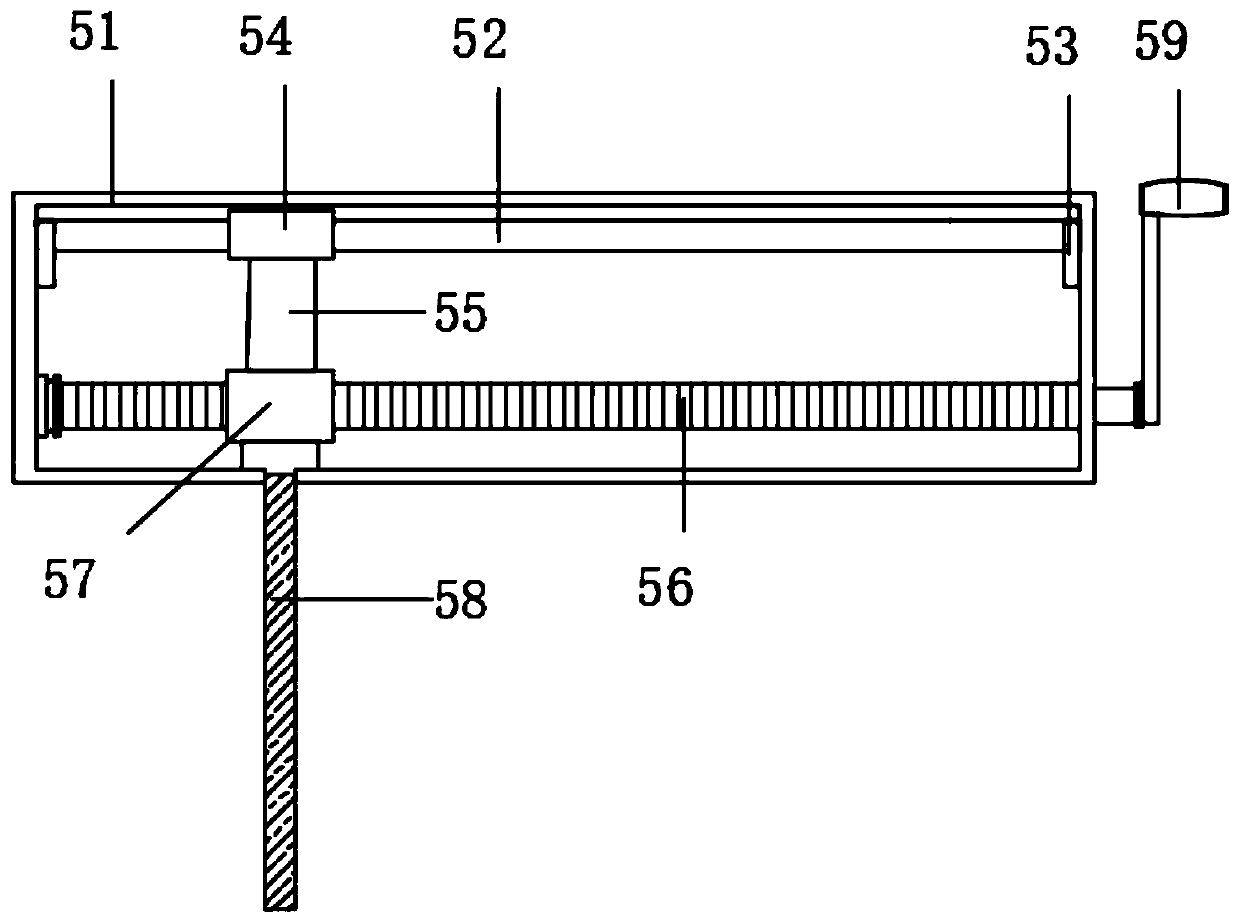

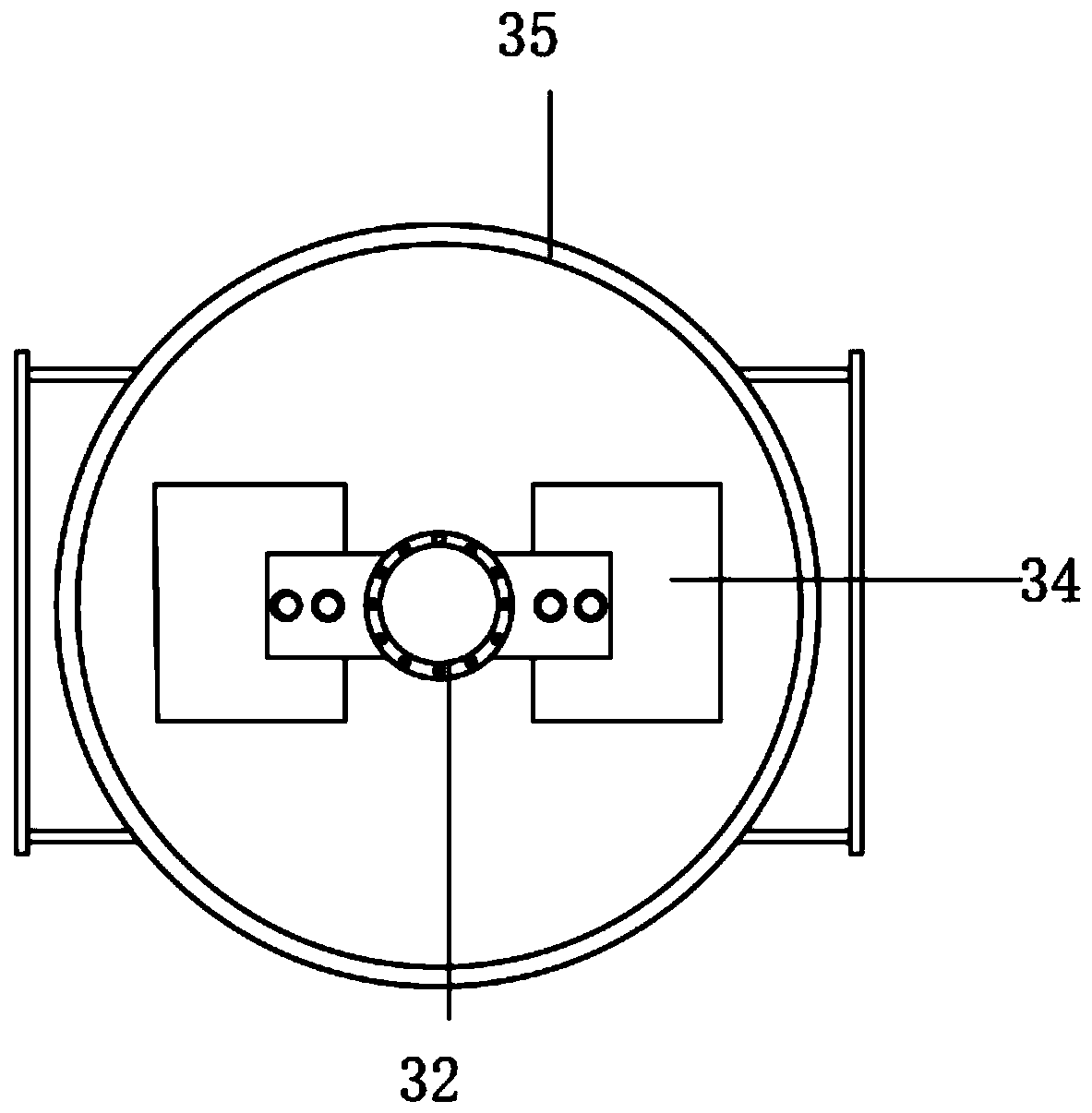

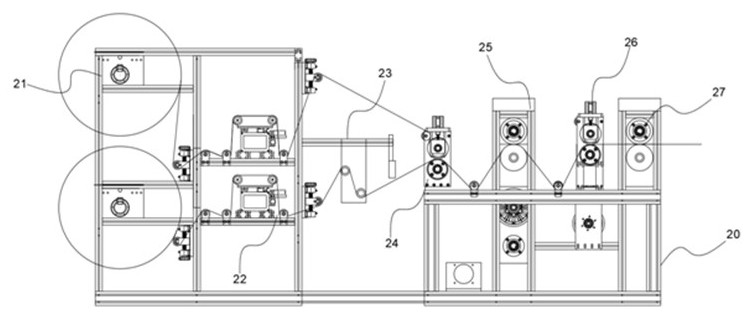

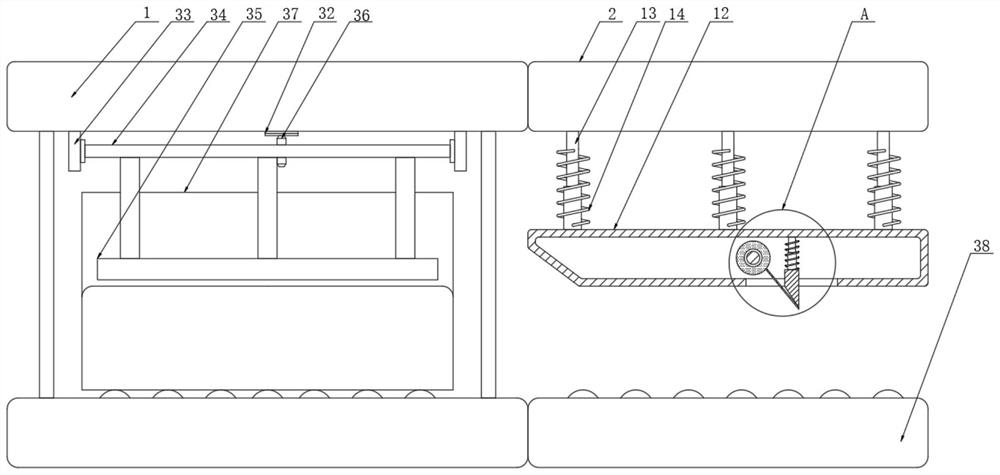

Full-automatic efficient cutting machine for bus bar

PendingCN108274241APrevent slippingAvoid offsetOther manufacturing equipments/toolsEngineeringMechanical engineering

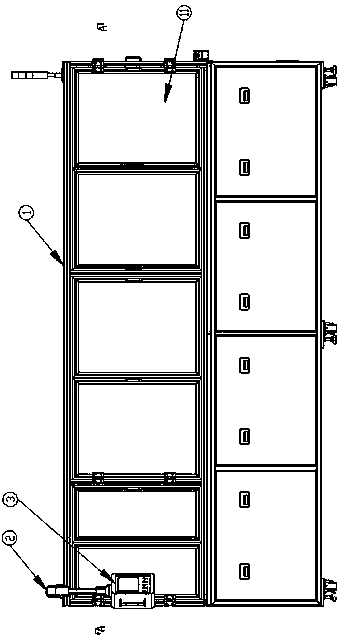

A full-automatic efficient cutting machine for a bus bar is characterized in that the full-automatic efficient cutting machine comprises a square cutting machine shell; a controller support is arranged on the top of the cutting machine shell; one end of the controller support is fixed to the top of the cutting machine shell, and a controller is fixed to the bottom of the other end of the controller support and is a PLC; and an operation room is arranged on the upper portion of the cutting machine shell, and a discharging assembly, a deburring mechanism, a straightening mechanism, a compressionfeeding mechanism, a cutting mechanism and a traction mechanism are sequentially arranged on a bottom plate of the operation room from left to right. Using of manual work is avoided, labor force is liberated, the time and labor are saved in operation, and the requirement of enterprises for large-scale mechanical production is met conveniently.

Owner:苏州市中辰昊科技有限公司

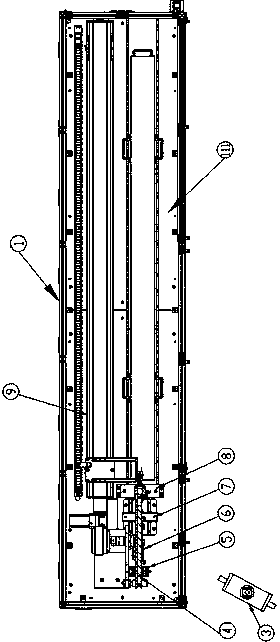

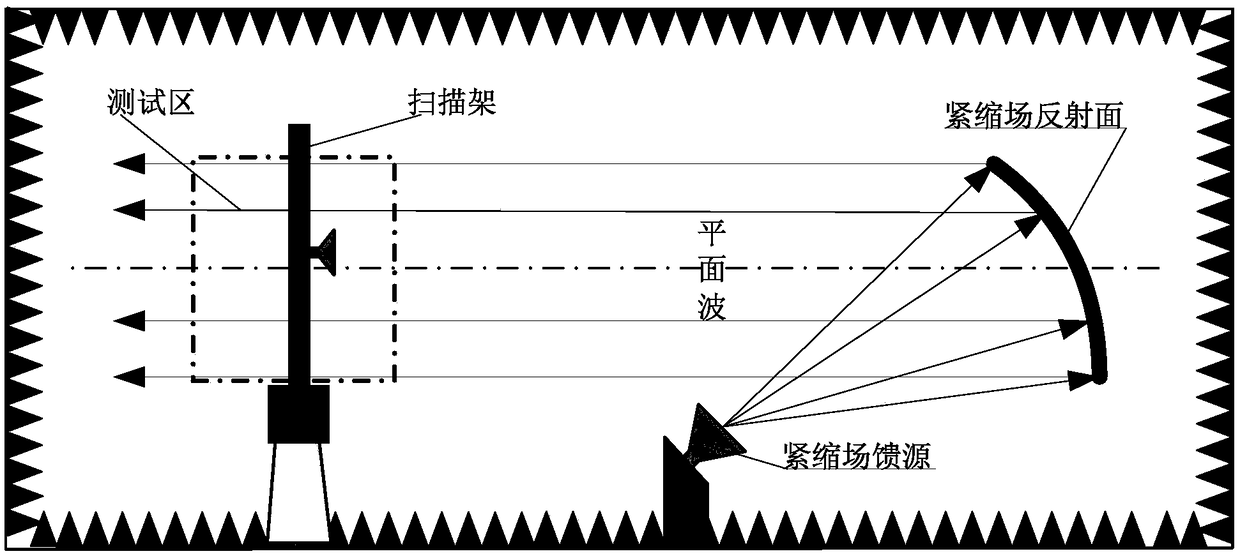

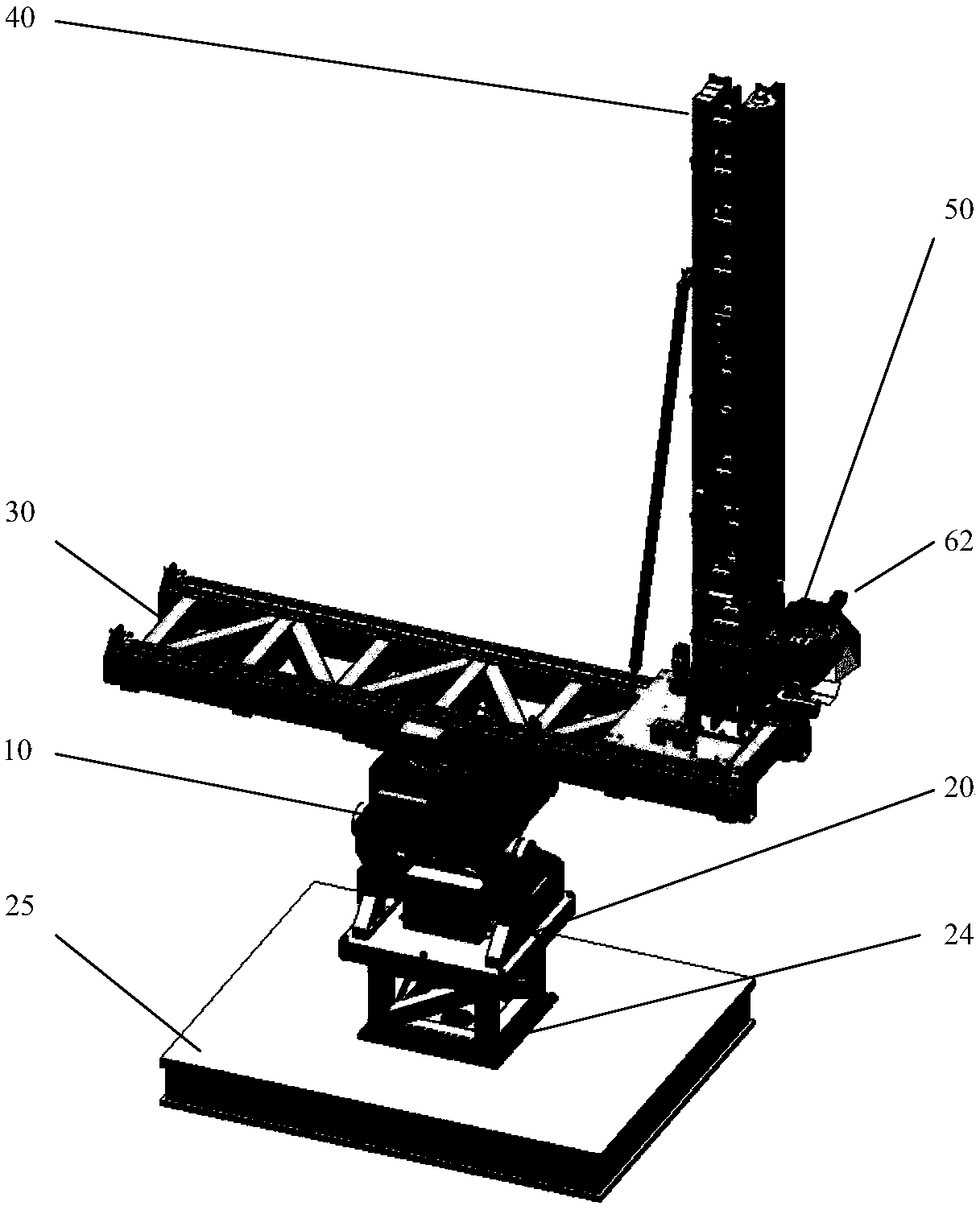

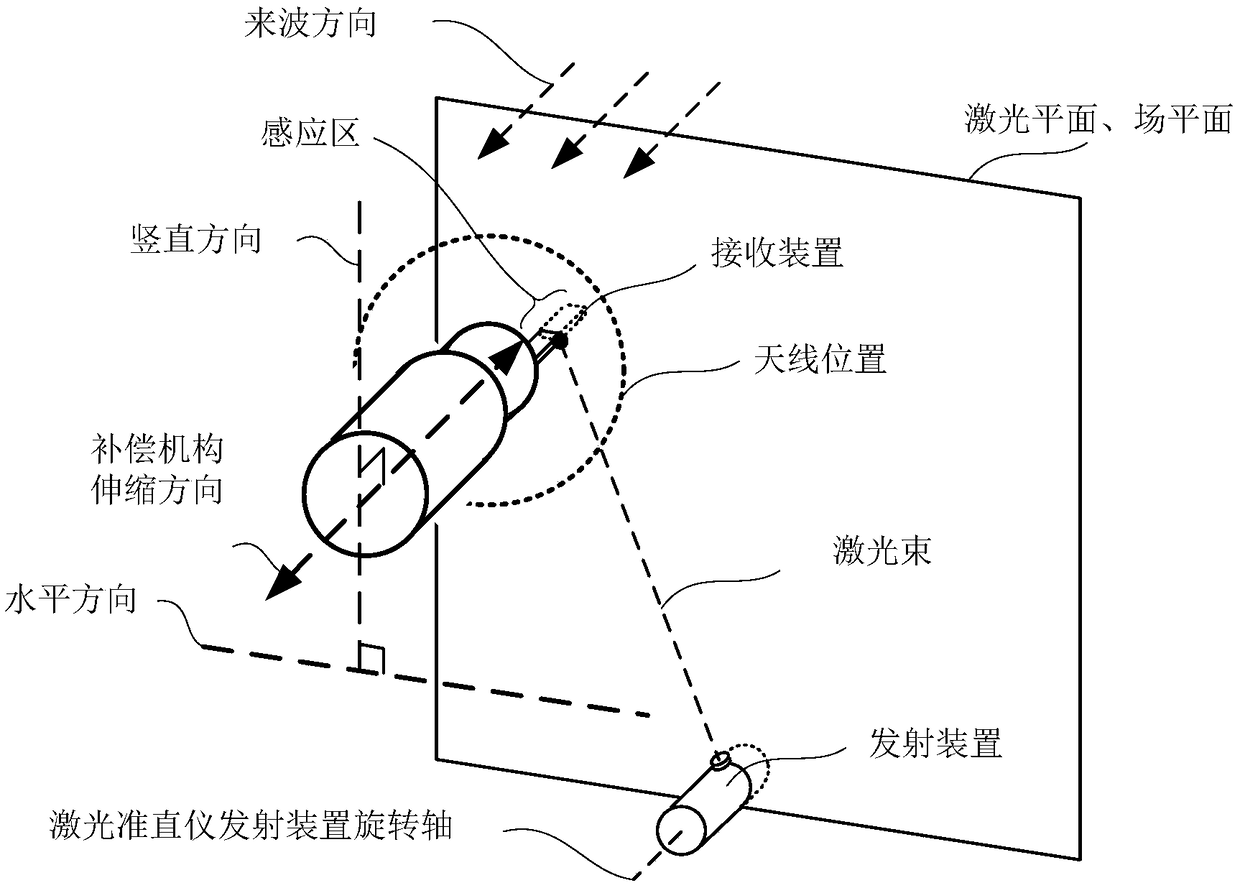

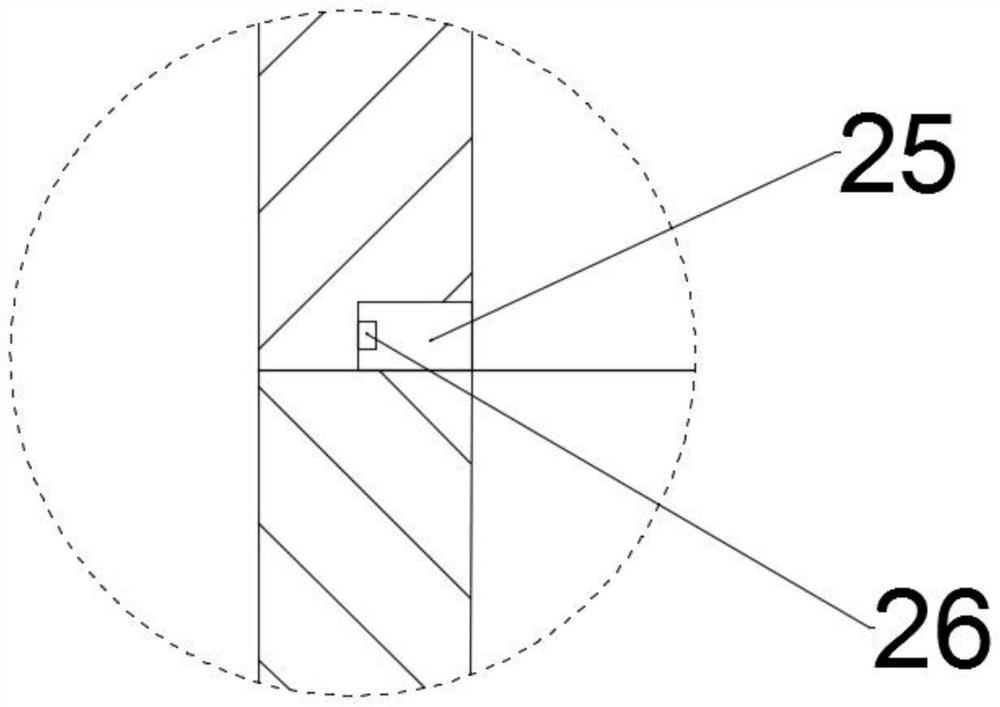

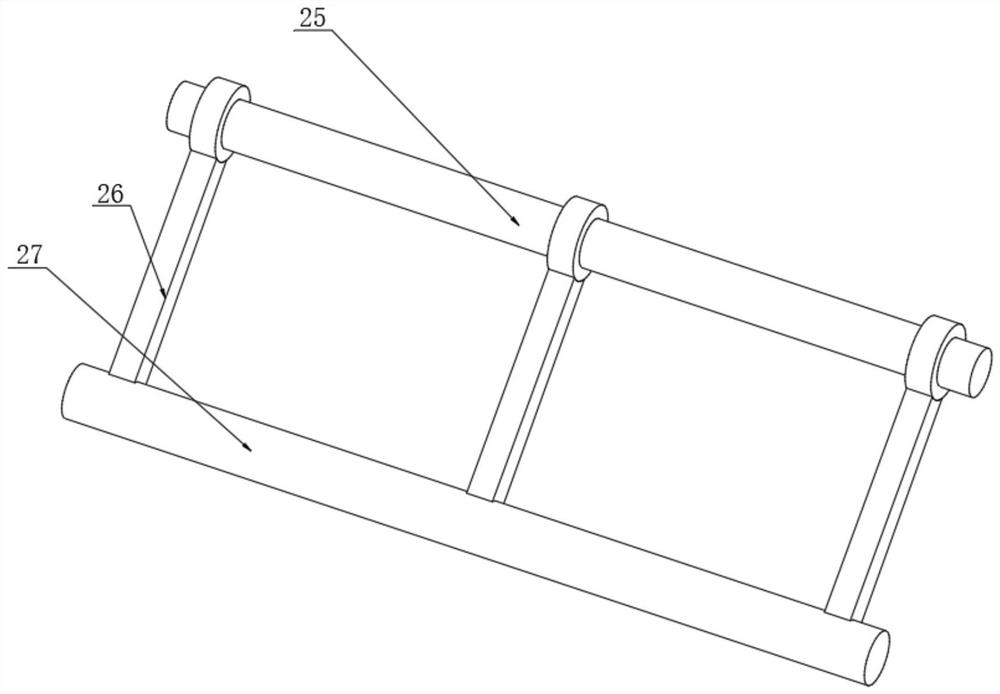

Compact field scanning device

InactiveCN108802501AMeet Phase Detection RequirementsImprove Phase Detection AccuracyElectromagentic field characteristicsObservational errorLow speed

The invention discloses a compact field scanning device, solving the problem that a scanning rack of the prior art is big in the measurement error. The compact field scanning device includes a scanning rack and a laser collimator, wherein the scanning rack includes an orientation adjusting mechanism, a pitch adjusting mechanism, a horizontal scanning rack, a vertical scanning rack, and a compensation mechanism; the laser collimator includes a transmitting device and a receiving device; the transmitting device is located at a fixed point above the ground for generating a laser beam parallel toa field plane; the receiving device is fixed at an end portion of a motion tube for receiving the laser beam; after receiving the laser beam, the receiving device detects an offset; and a control unitreceives the offset, and controls the compensation mechanism to reduce the offset. The compact field scanning device can improve the compact field plane wave phase detection accuracy, and can avoid the defects of manual operation, low efficiency, low speed and the like.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

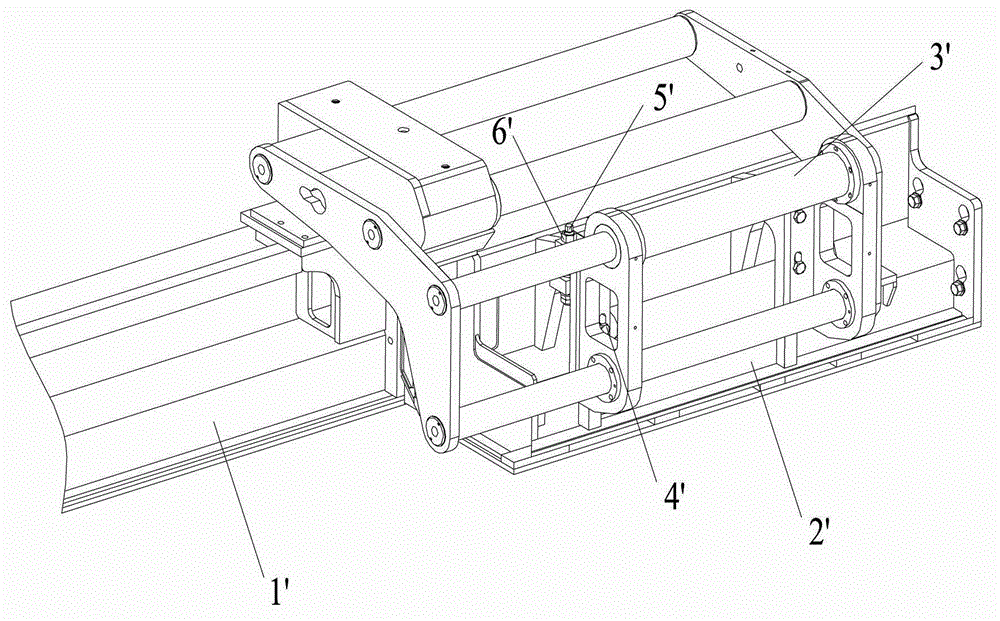

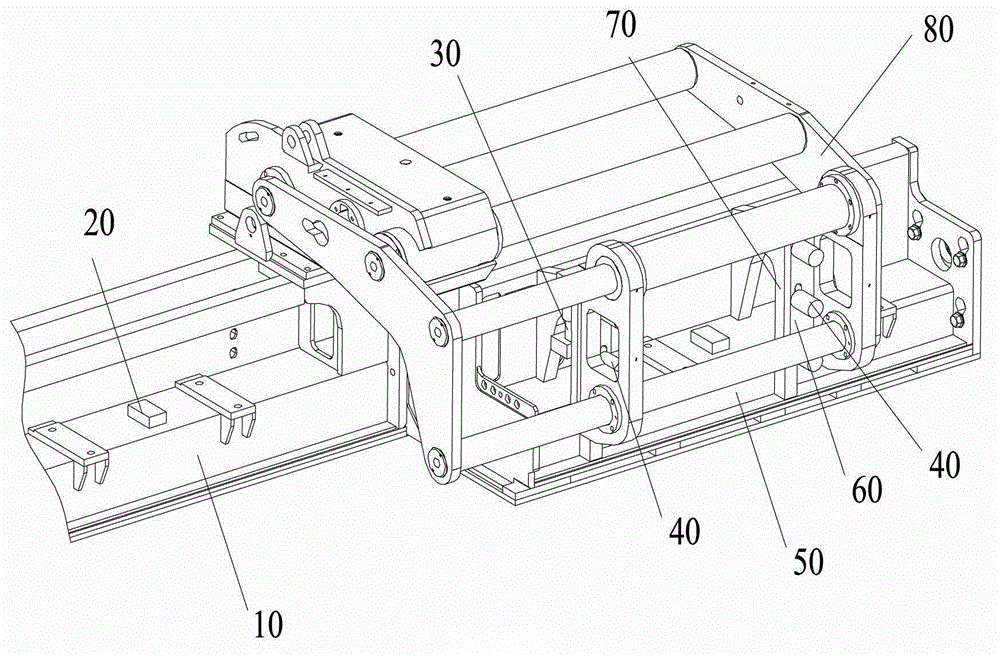

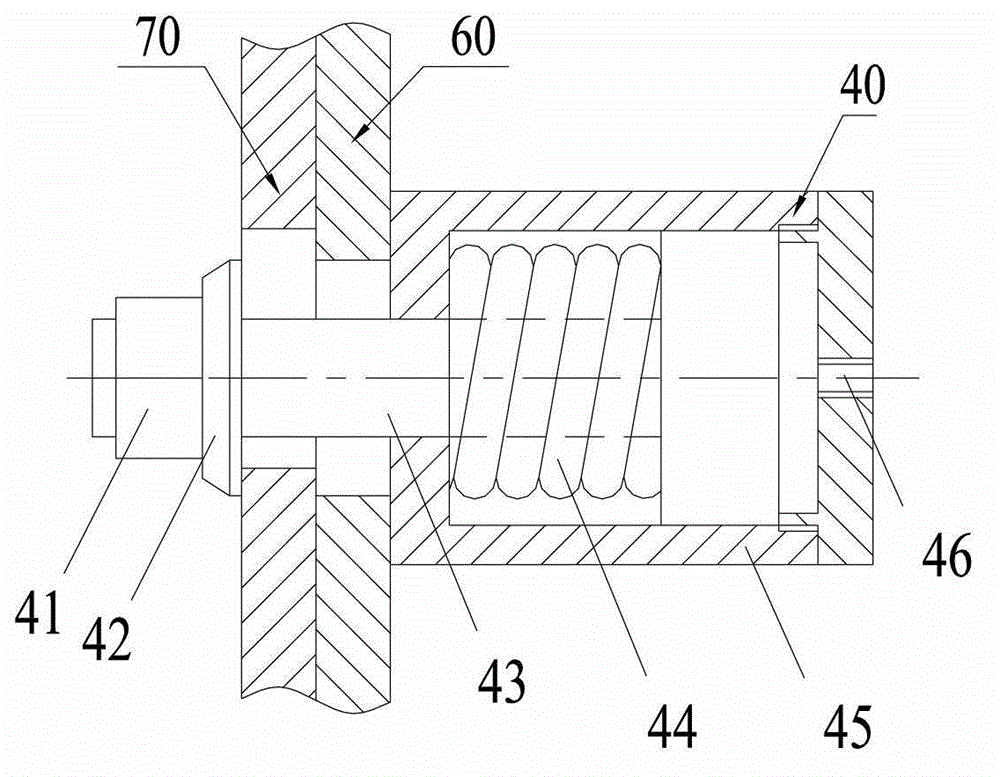

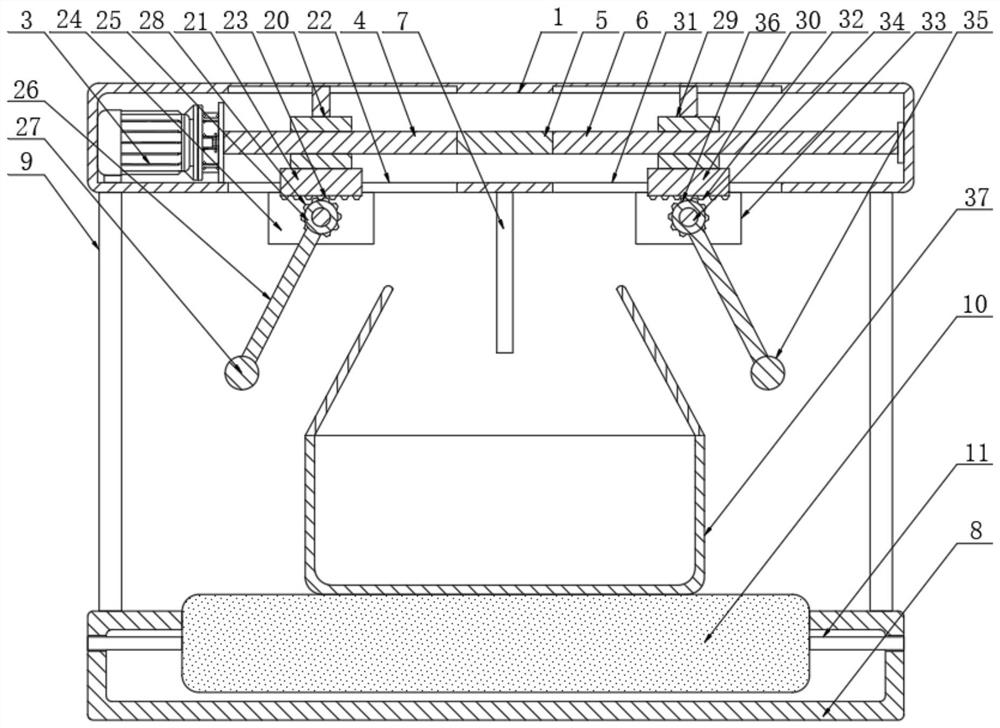

Screed height-difference adjusting device, paver and screed high-difference adjusting method

Owner:ZOOMLION HEAVY IND CO LTD

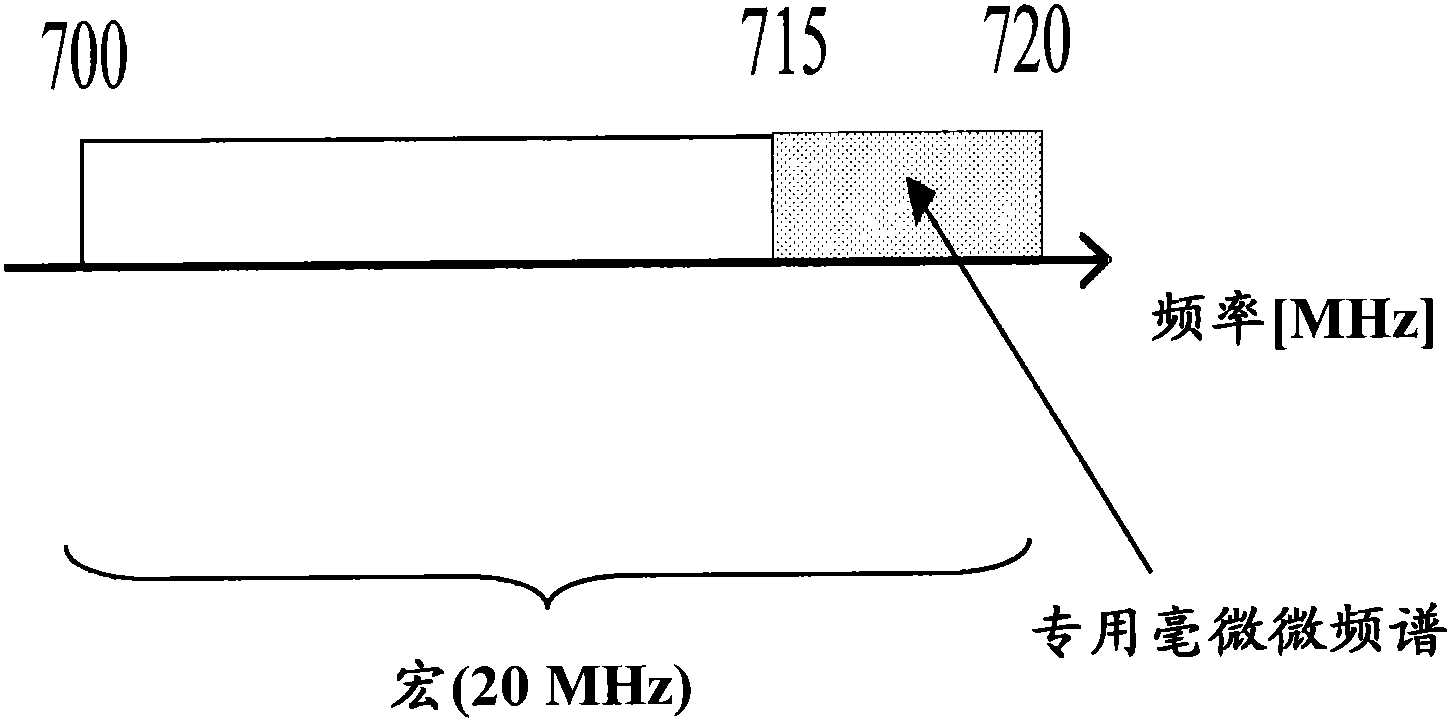

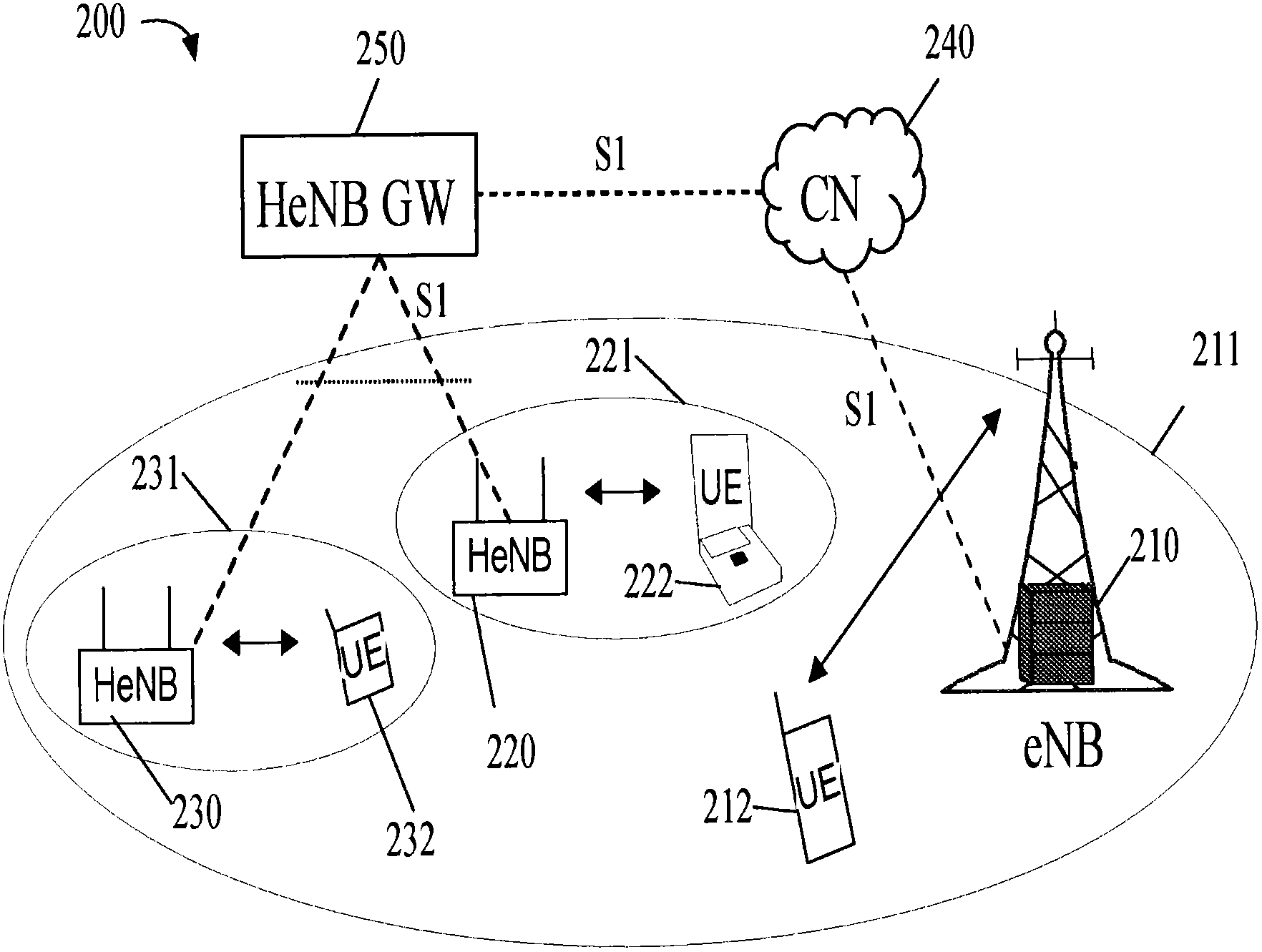

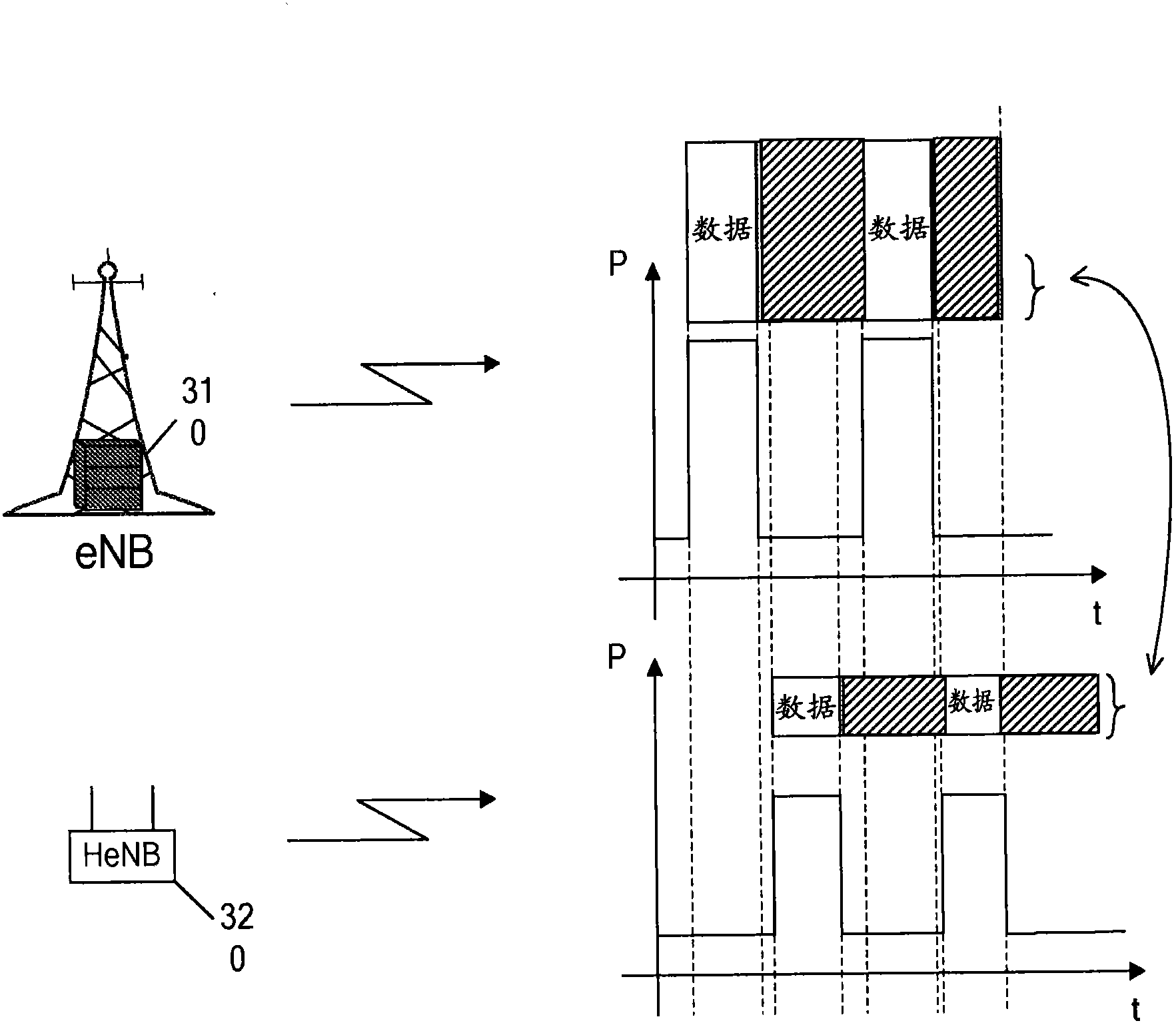

Methods and apparatuses for facilitating reduction of interference in a wireless telecommunications system

ActiveCN102498744AAvoid manualAvoid static configurationNetwork traffic/resource managementNetwork planningRadio Base StationRadio resource

The exemplary embodiments of the present invention relate to methods and apparatuses (800, 900) for facilitating reduction of interference in a network. According to exemplary embodiments, an apparatus acting as a first radio base station (macro or femto) (800, 900) is configured to acquire information including a scheduling scheme indicating information on how radio resources are allocated in second radio base station (femto or macro). The information is then used by a scheduler to allocate radio resources which are disjoint the radio resources already allocated by the scheduler of second radio base station.

Owner:TELEFON AB LM ERICSSON (PUBL)

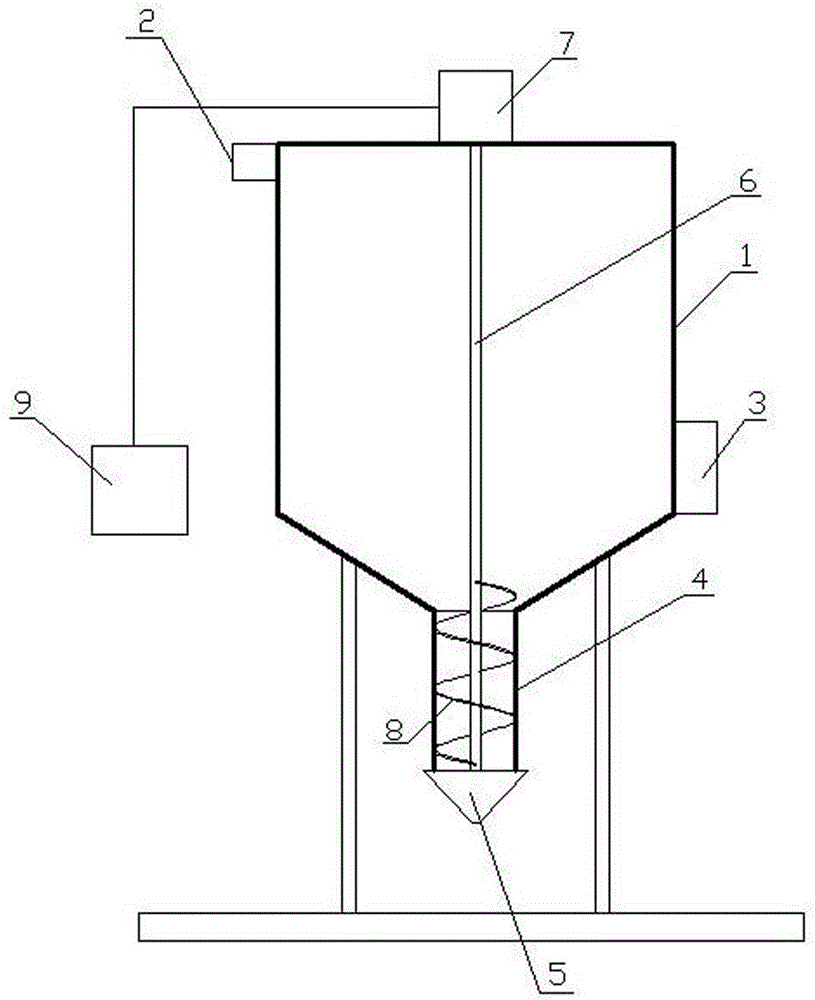

Small quantitative charging machine

InactiveCN106394952ASimple structureReduce manufacturing costConveyorsLarge containersEngineeringGuide wires

The invention relates to a charging device, in particular to a small quantitative charging machine used during food powder material packaging. The small quantitative charging machine comprises a material barrel which is vertically arranged; the upper portion of the side wall of the material barrel is provided with a feeding port; and the side wall of the material barrel is provided with a vibrator. The bottom of the material barrel is coaxially connected with a discharging guiding pipe; an inner cavity of the discharging guiding pipe is communicated with an inner cavity of the material barrel; and the lower end of the discharging guiding pipe is connected with a funnel. A coaxially-arranged rotating shaft is arranged in the material barrel; and the upper end of the rotating shaft penetrates the top of the material barrel to stretch outwards, and the end of the rotating shaft is connected with an output shaft of a motor. The lower end of the rotating shaft stretches into the discharging guiding pipe; and the lower side edge of the rotating shaft is flush with the lower side edge of the discharging guiding pipe. The segment, located in the discharging guiding pipe, of the rotating shaft is provided with a spiral conveying blade penetrating the longitudinal direction of the discharging guiding pipe and continuously arranged; and the outer side edge of the spiral conveying blade is matched with the inner wall of the discharging guiding pipe in a rotating seal manner. The motor is connected with a controller through a guide wire. The quantitative charging machine can be applicable to a small food processing factory and is high in work efficiency.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

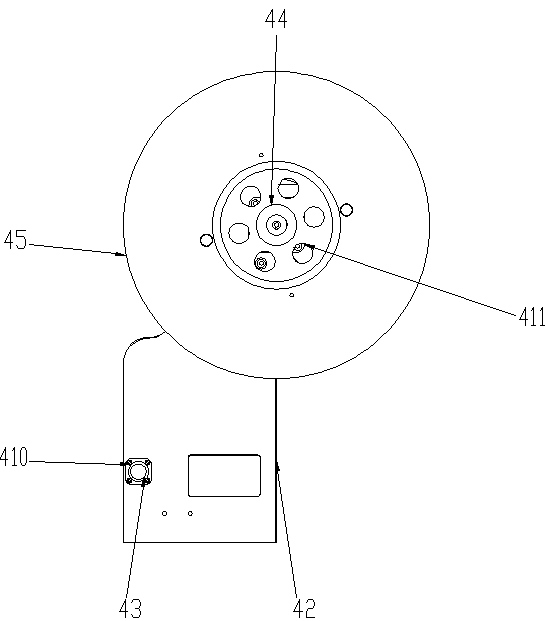

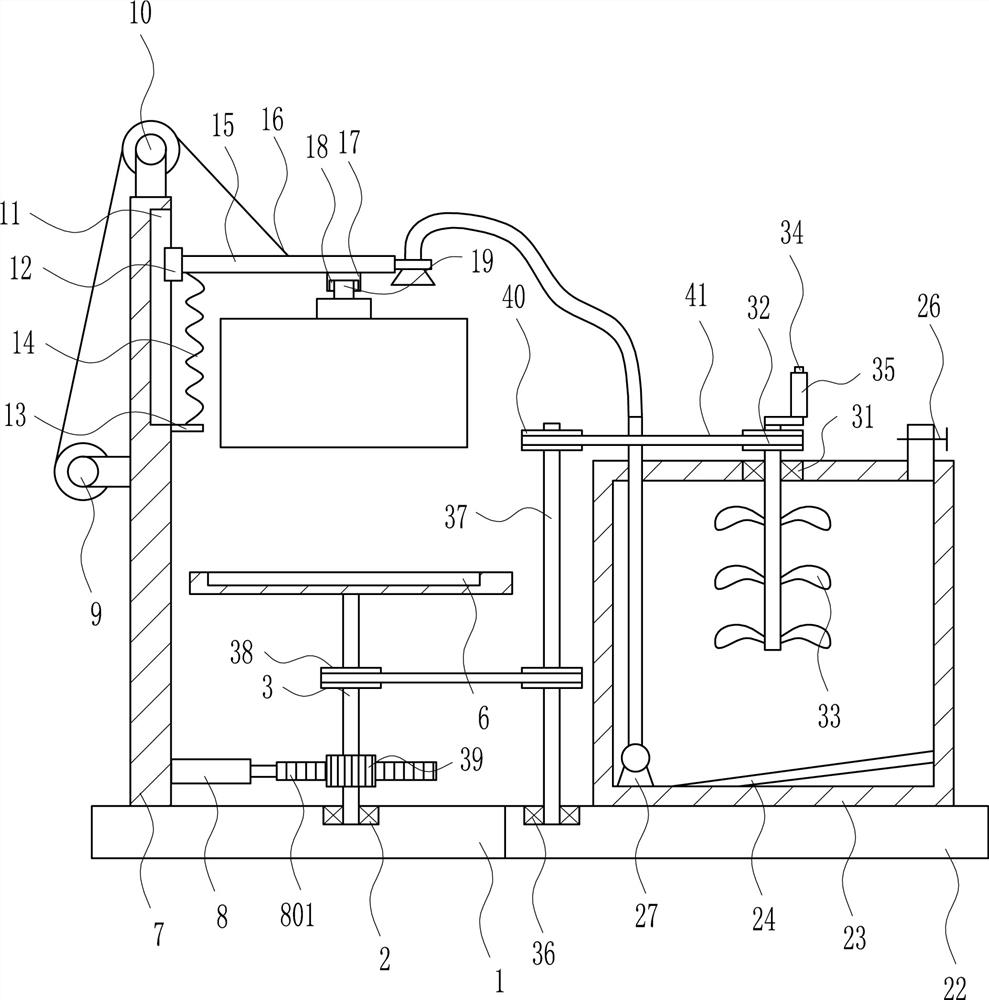

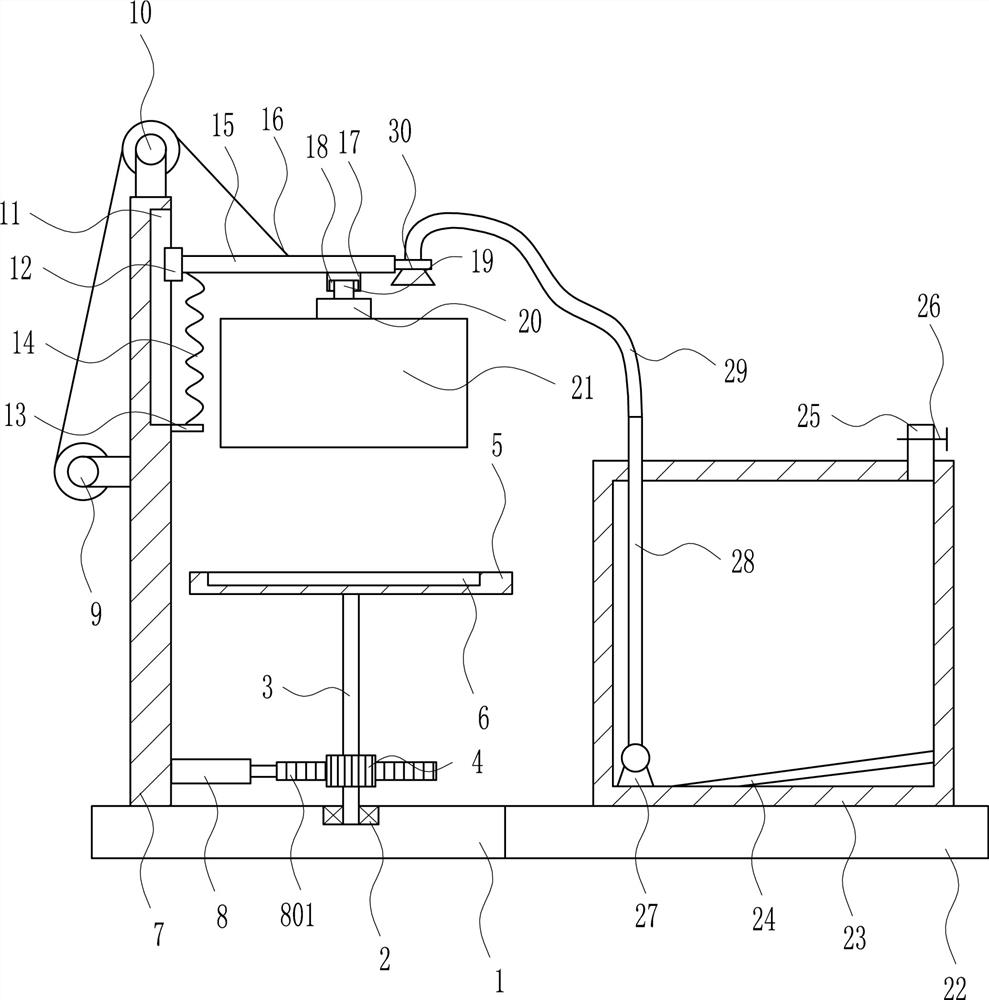

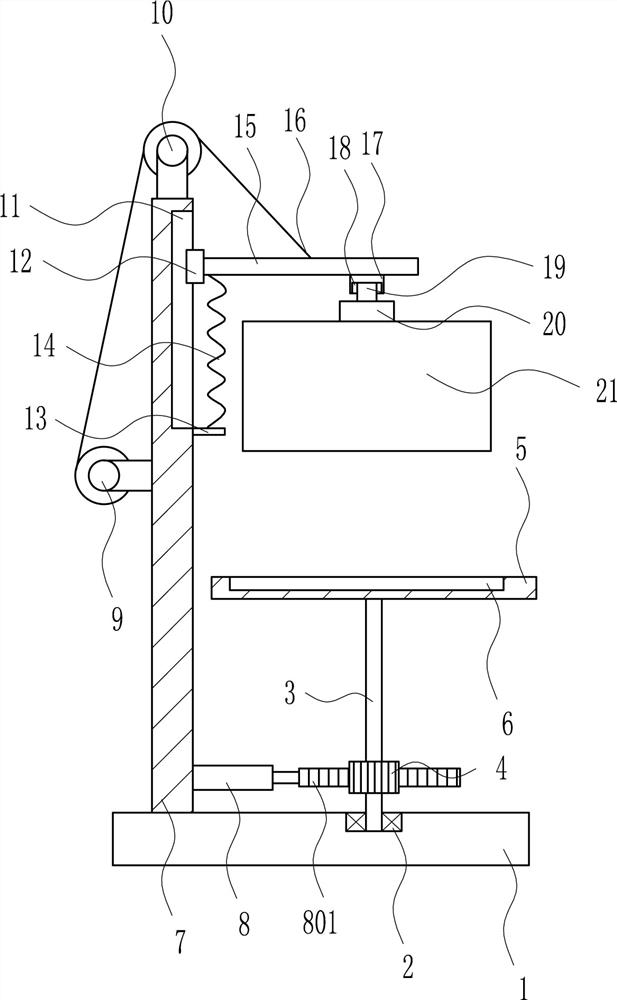

Improved intermittent blanking type fruit juice preparation machine

InactiveCN110901131ARealize intermittent feedingEffective filteringWine preparationPressesVitis viniferaFruit juice

The invention relates to the technical field of fruit juice large-scale preparation, in particular to an improved intermittent blanking type fruit juice preparation machine. The design that a rotatingdisc is arranged in a mounting base of a hollow cylindrical structure is adopted, and the rotating disc is used for rotating, so that a channel used for intermediately storing materials on the rotating disc intermittently communicates with a hopper and a blanking pipe, and intermittent blanking of grapes is achieved. The grapes are placed in a vibration box, and are guided to cams below the vibration box through the power of a driving piece motor, the vibration box is driven to move up and down through the rotation of the cams, and is impacted with a baffle of the hopper, the grapes in the vibration box are driven to vibrate, the bunched grapes are scattered through vibration, particles of the grapes are separated from branches, and manual picking and taking are avoided; and on the basisof the rotation principle of a screw rod, pressing plates are driven to be away from or close to each other through the movement of moving nuts to correspond to blanking or juicing of the grapes, anda mechanical structure is adopted to realize juicing work on the grapes.

Owner:安徽源渠通讯科技有限公司

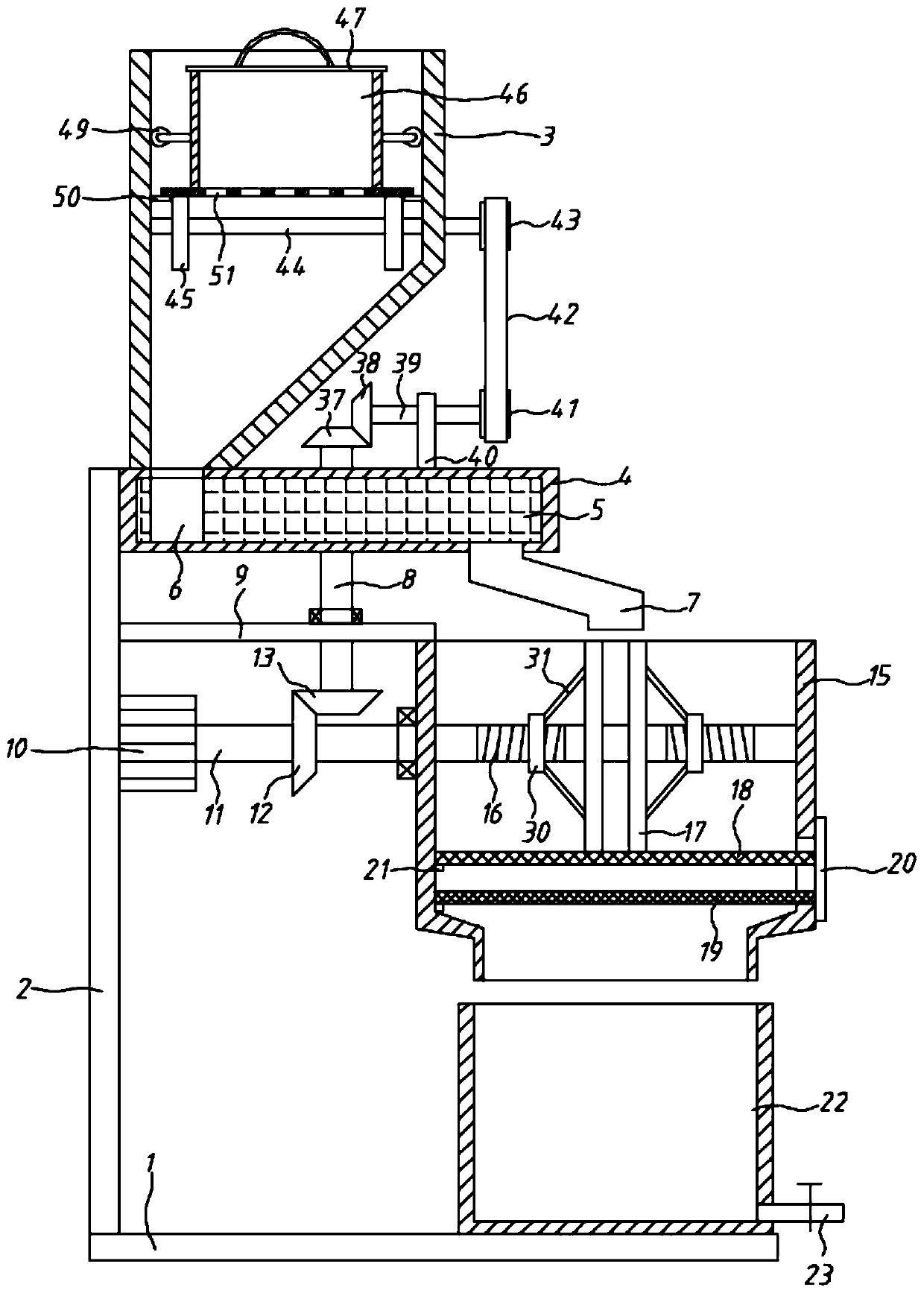

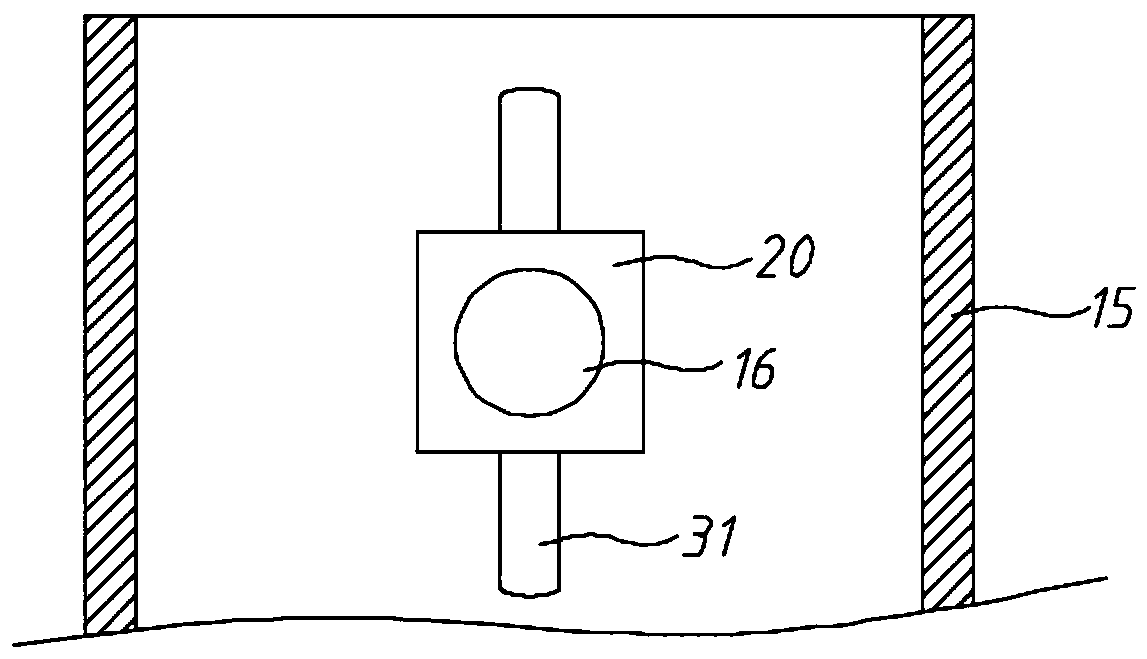

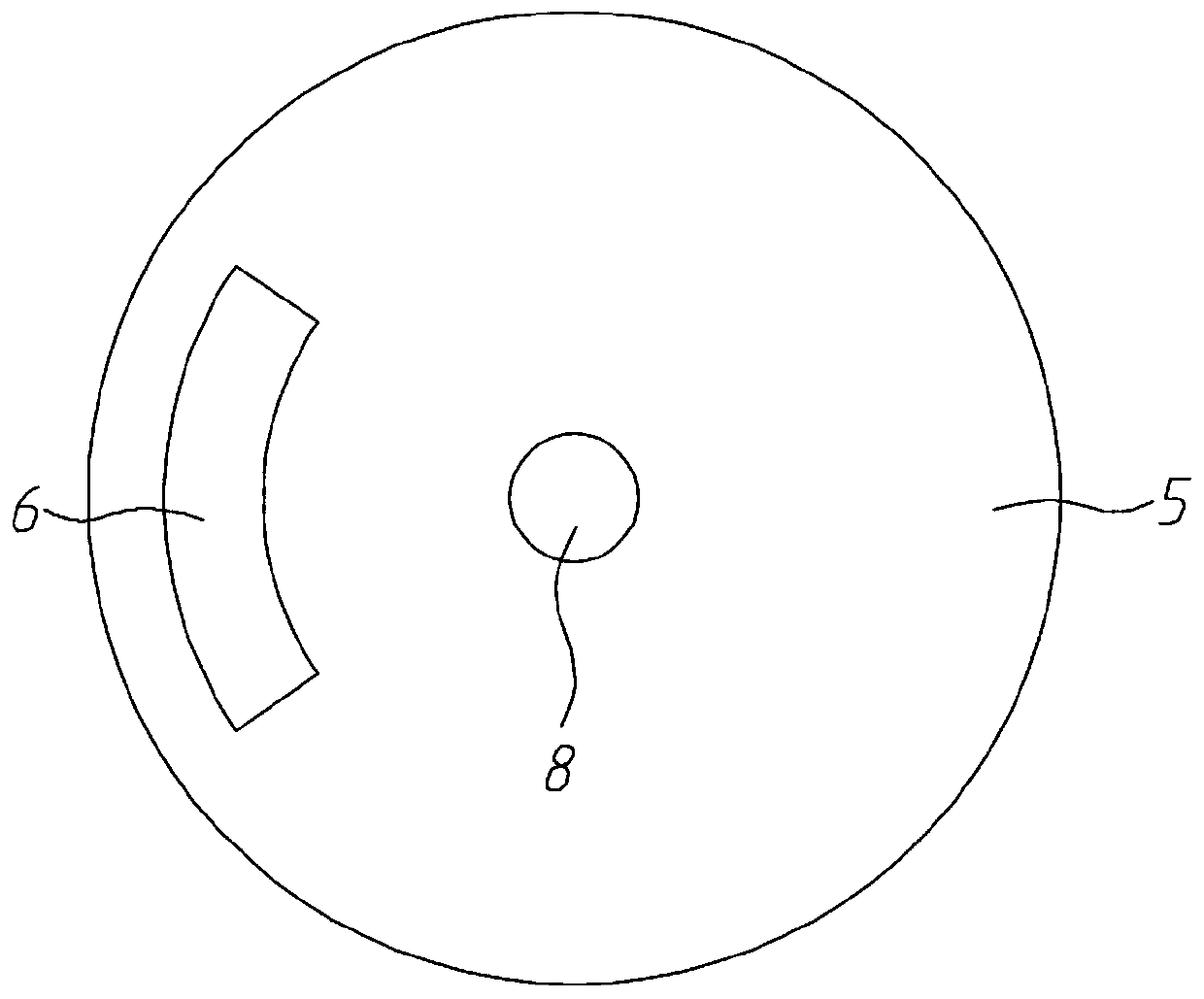

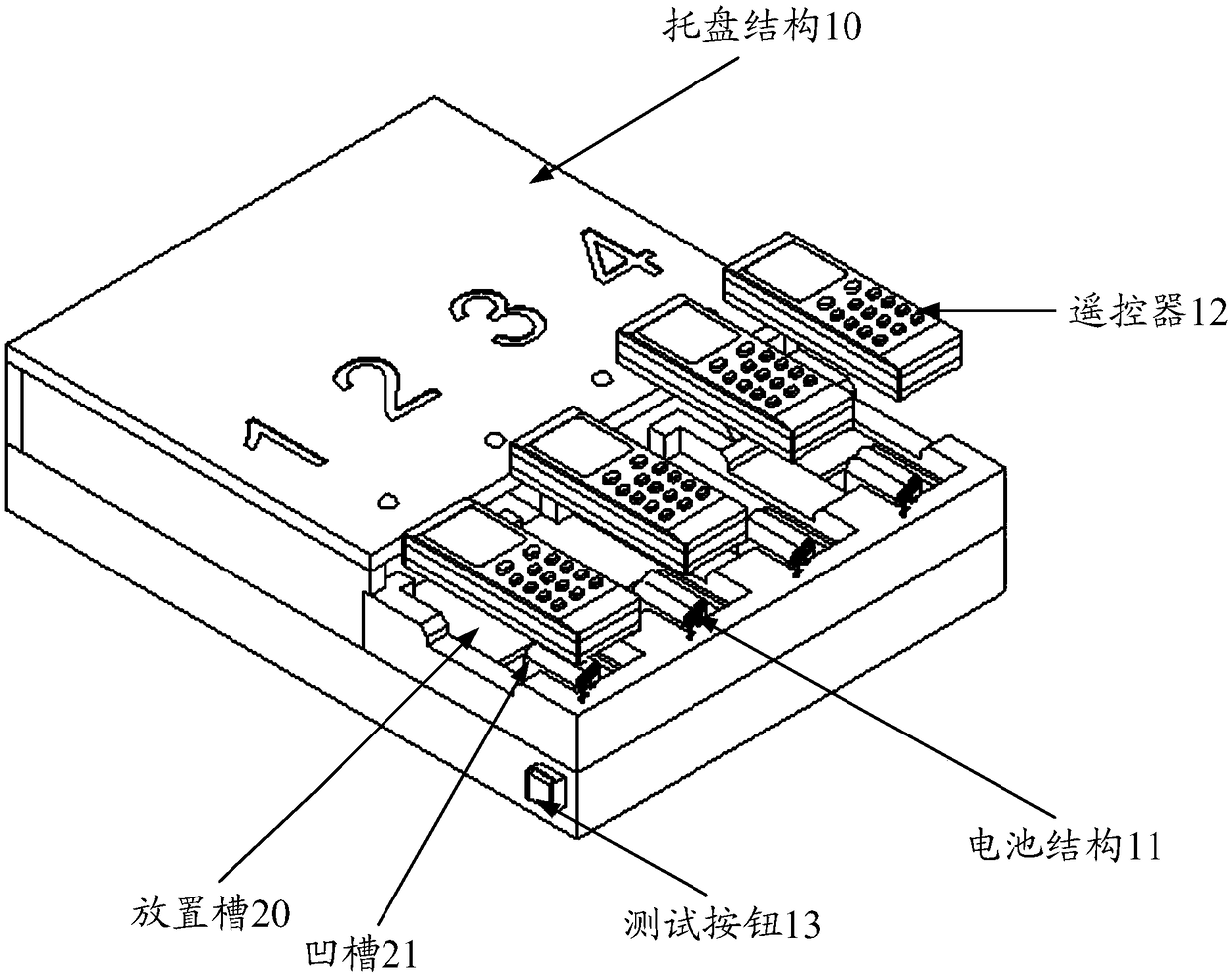

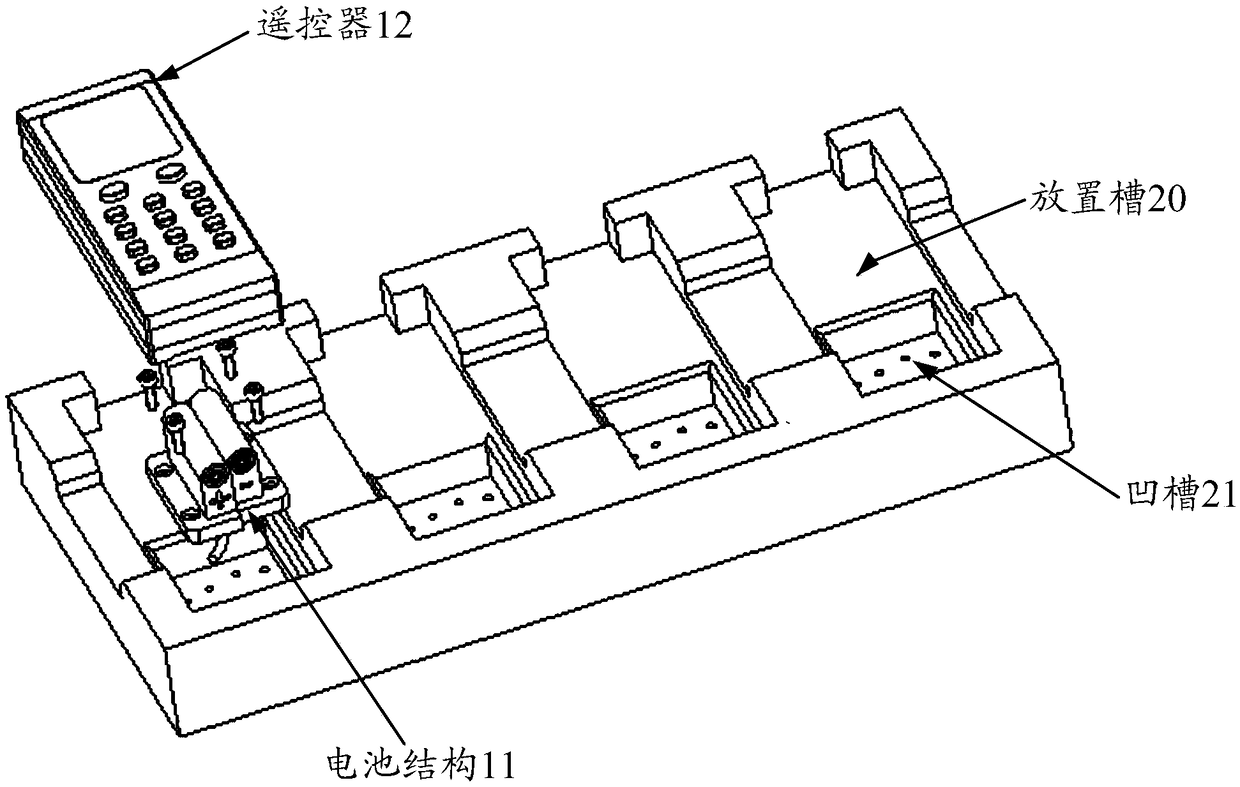

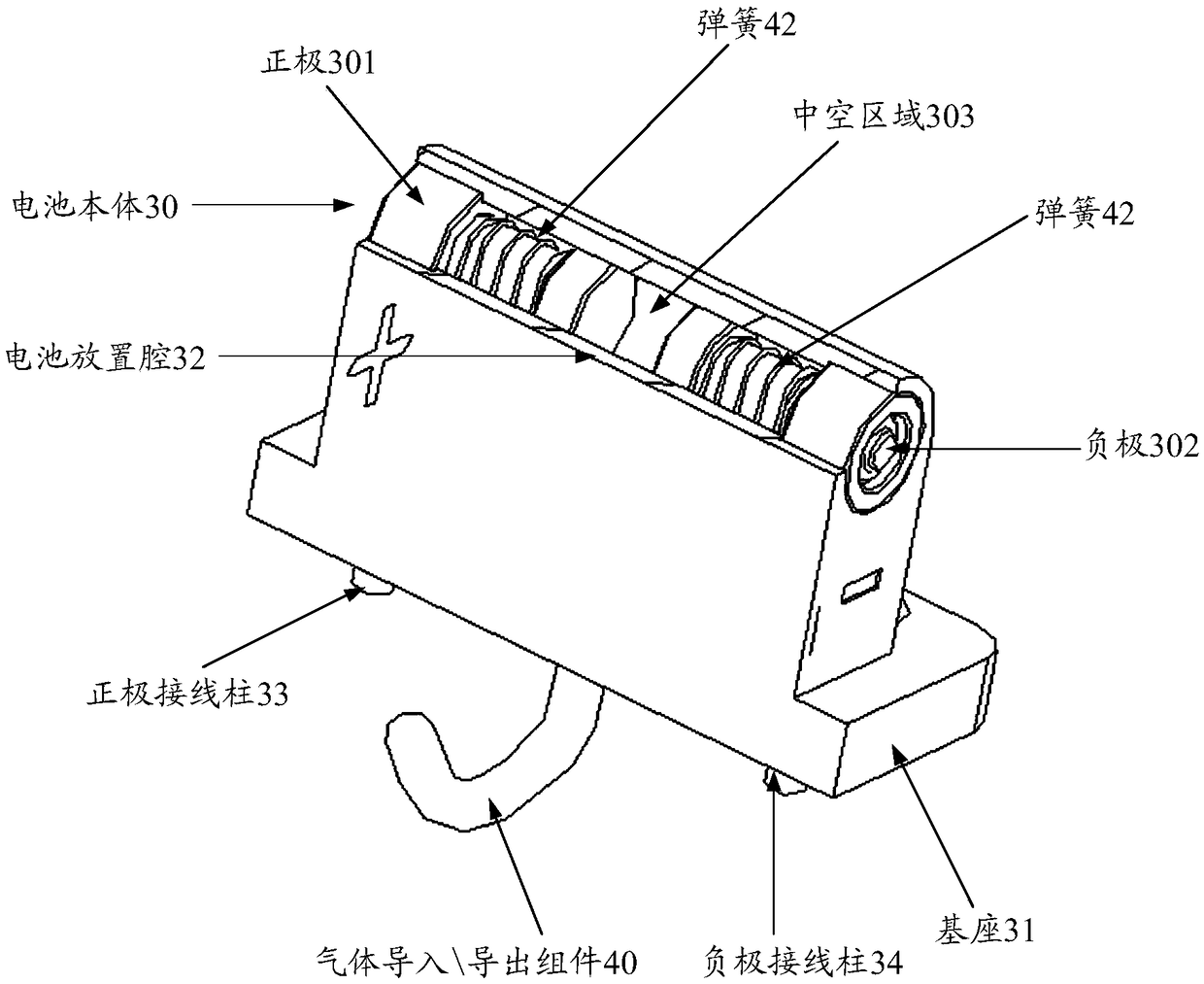

A power-on device for a remote control

InactiveCN109065990AAvoid power onAvoid power offSecondary cells charging/dischargingRemote controlEngineering

The invention discloses a power-on device of a remote controller, comprising a tray structure: a placing groove is arranged on the tray structure, and the placing groove is used for placing a remote controller to be tested; a battery structure: the battery structure is installed in the placing groove, and the battery structure comprises a battery body, which is used for supplying electric power tothe remote controller; a telescopic structure: the telescopic structure is connect with the battery structure; wherein, when the remote controller is placed on the placing groove for testing, the positive and negative electrodes of the battery body are controlled to be butted with the positive and negative electrodes of the battery port of the remote controller by the telescopic structure, thereby supplying electric power to the remote controller; After the test of the remote controller is completed, the positive and negative electrodes of the battery body are controlled to be disconnected from the positive and negative electrodes of the battery port by the telescopic structure, thereby stopping the power supply to the remote controller.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

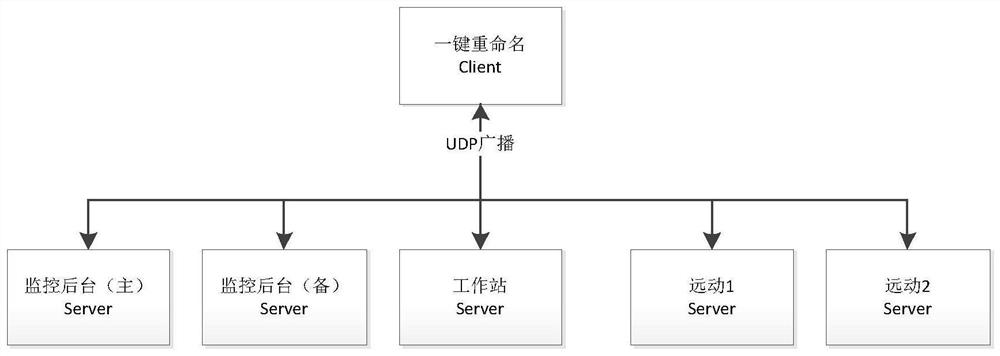

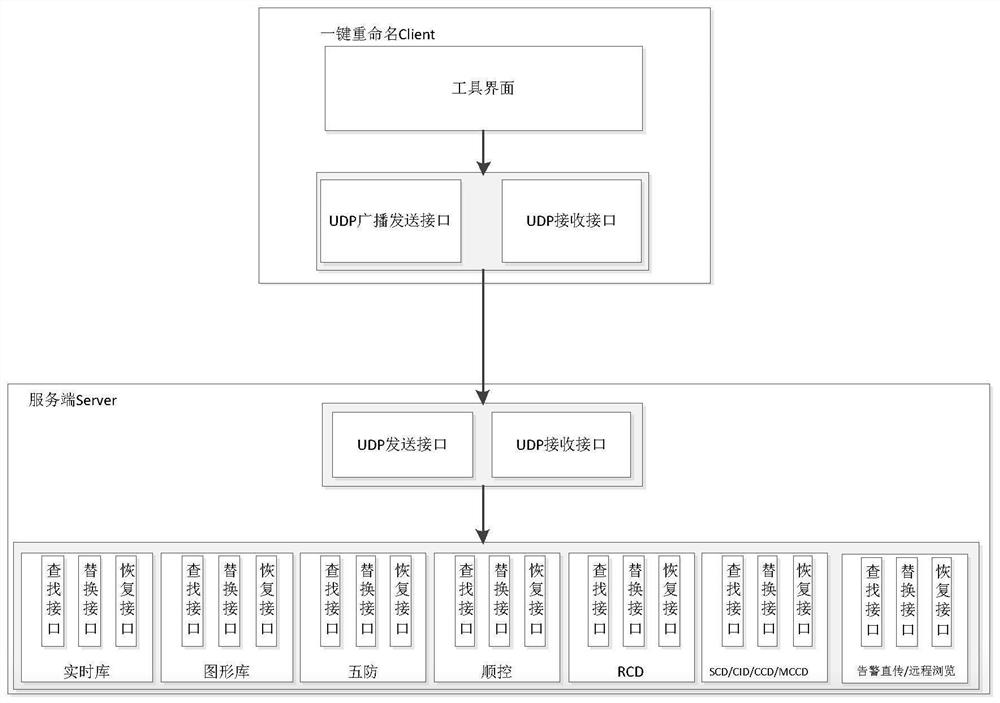

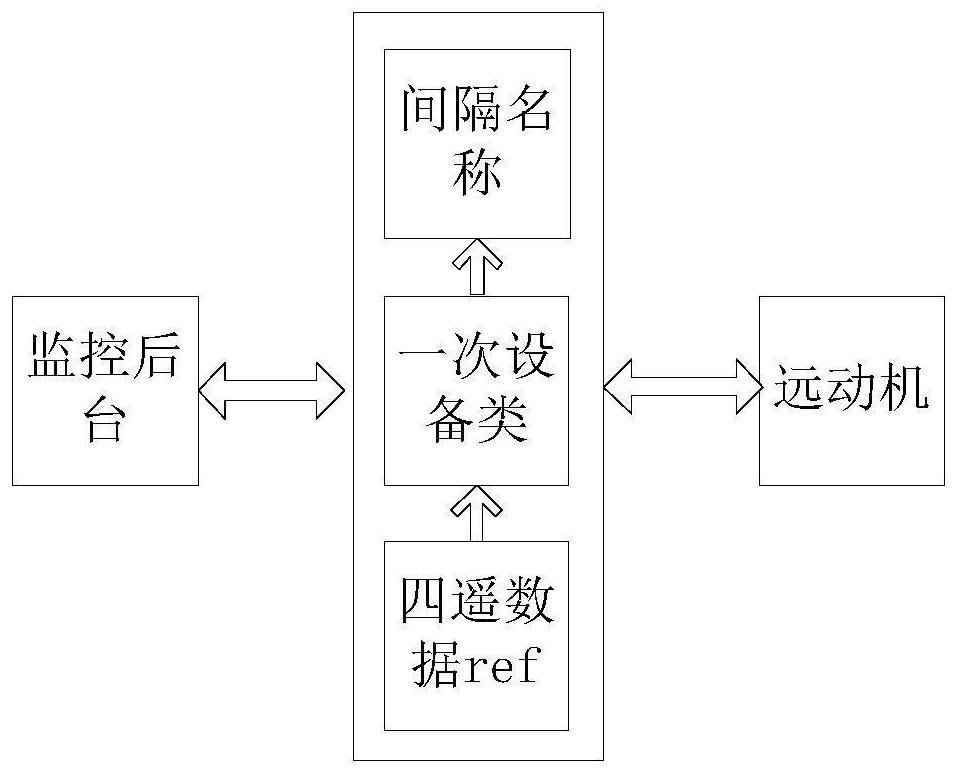

One-key renaming method based on panoramic data of plant station end monitoring system

ActiveCN113407497AImprove operational safetyImprove the convenience of operation and maintenanceData processing applicationsFile/folder operationsSequence controlOriginal data

The invention discloses a one-key renaming method based on panoramic data of a plant station end monitoring system. The modification range mainly comprises a real-time database, a graphics library, a five-prevention library, a sequence control library, a report library, an alarm direct transmission / remote browsing file, an SCD model, an RCD model, a CID / CCD file of equipment, a check code description file MCCD and the like. After information such as line names or scheduling numbers in a library is renamed by a monitoring host and standby machine, a work station and a gateway machine according to a naming rule, a modification record file is generated locally, the modification record file comprises modification time, modifiers, data before modification and data after modification, it is guaranteed that modification records are traceable, and meanwhile, the original data can be recovered according to the content of the modification record file, and abnormal operation of the plant-station end monitoring system caused by modification errors is prevented. On the premise of ensuring stable operation of a plant station end monitoring system, information such as a line name or a scheduling number of a plant station end can be modified by one key, the information is transmitted to each application, and description information synchronization is realized.

Owner:NANJING NARI GROUP CORP +2

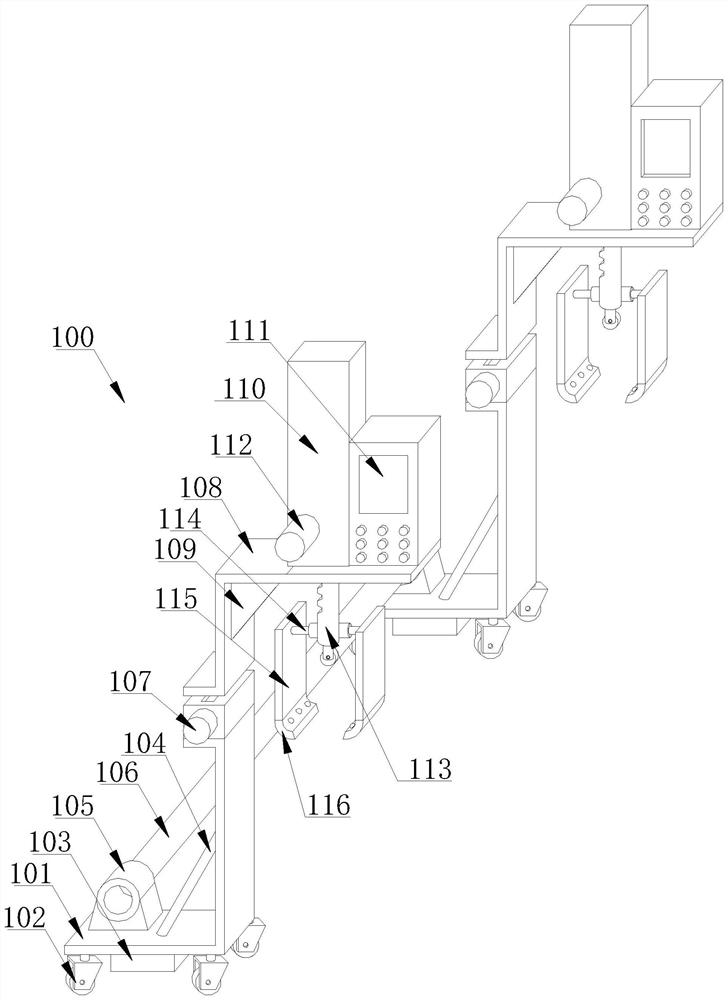

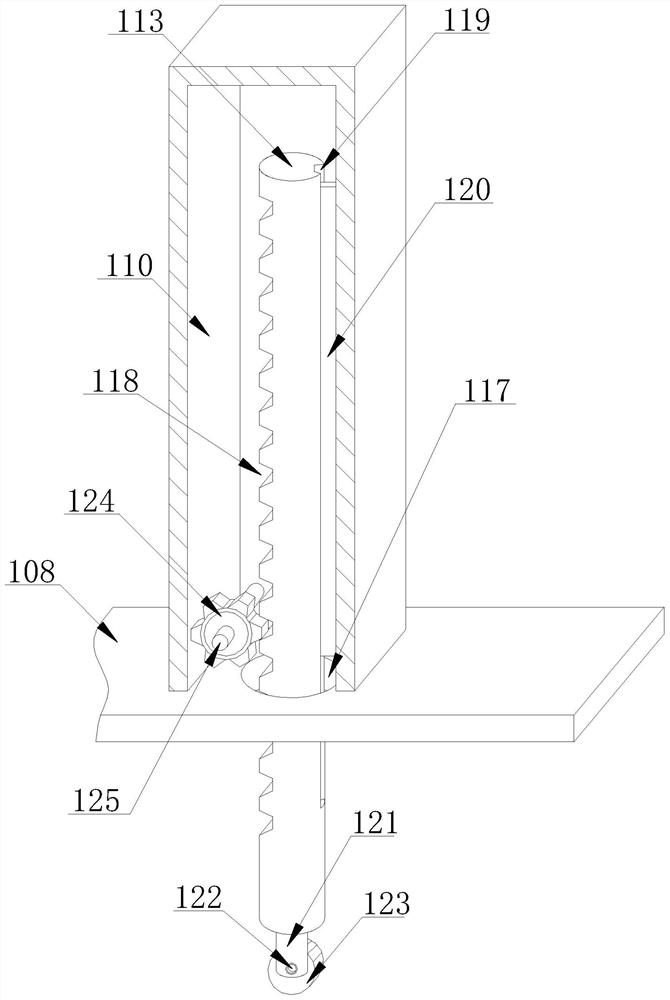

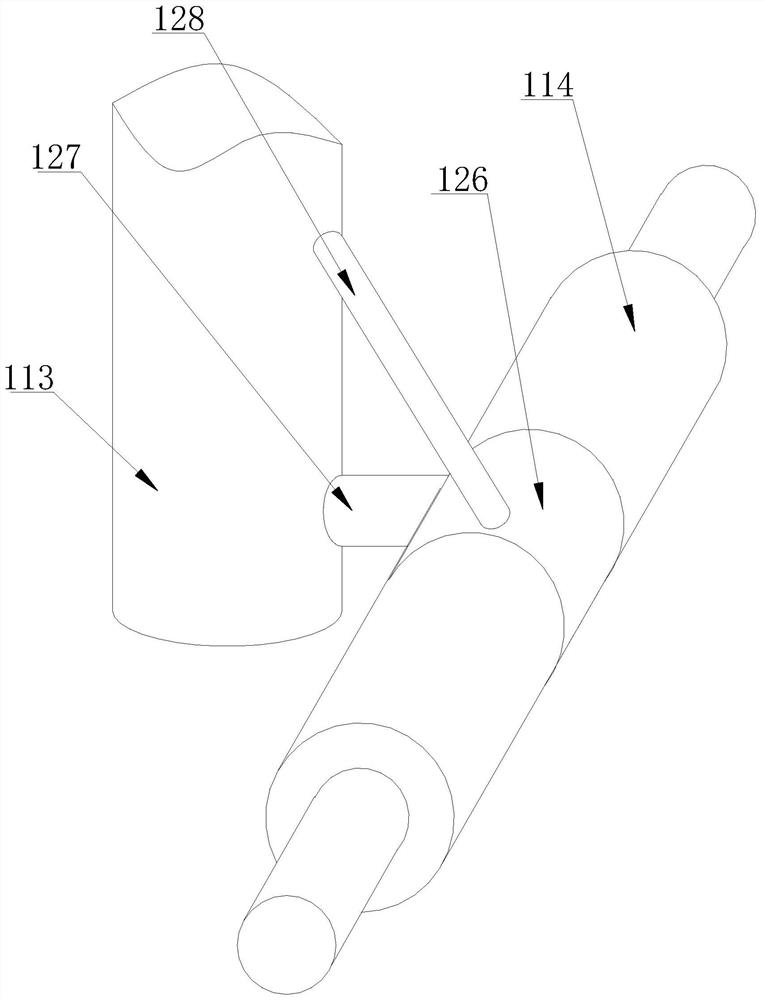

Auxiliary drainage pipeline connection device for municipal engineering road water supply and drainage

ActiveCN113089803ARealize automatic rotationReduce labor intensitySewer pipelinesSet screwElectric machinery

The invention discloses an auxiliary drainage pipeline connection device for municipal engineering road water supply and drainage. The auxiliary drainage pipeline connection device comprises a base, trundles, a balancing weight, a reinforcing supporting rod, a connecting seat, an adjustable longitudinal rod, an outer sleeve, a straight rod, a positioning hole, a fixing nut, a positioning screw, a longitudinal driving seat, a shell, a servo motor, a screw rod, a movable nut, a guide block, a guide groove, a top seat, a reinforcing rib plate, a protective cover, a controller, a first driving motor, a vertical rod, a first air cylinder, a vertical plate, an arc-shaped strip plate, a plate body, an embedding hole, a baffle ring, a first ball, a through hole, a tooth groove, a guide strip groove, a guide strip, a second air cylinder, a rotating shaft, a round wheel, a cylindrical gear, a connecting shaft, a connecting block, a connecting rod, an inclined rod, a second driving motor, a groove, a second ball, a concave hole and a short shaft. The auxiliary drainage pipeline connection device has the beneficial effects that clamping and lifting operation of a pipeline can be achieved through a pipeline bearing clamp, lifting adjustment of the pipeline can be achieved in cooperation with the lifting effect of a vertical lifting mechanism, and lifting is facilitated.

Owner:刘建辉

Workbench with spacing and blocking-proof function for food processing, and use method of workbench

InactiveCN112056360APlay a limiting roleEasy to operateMeat holding apparatusMetal working apparatusStructural engineeringWorkbench

The invention provides a workbench with a spacing and blocking-proof function for food processing, and a use method of the workbench. The workbench comprises an operation table and a placement plate,wherein the placement plate is fixedly connected to the top of the operation table; the top of the placement plate is provided with a placement groove; and two sides of the inner surface of the placement groove independently communicate with a movement groove and a movable groove. The invention provides the workbench with the spacing and blocking-proof function for the food processing, and the usemethod of the workbench. Since a spacing structure is arranged, when frozen meat blocks are cut, the meat blocks can be effectively spaced. When the workbench is used, a rotation element on the outerpart of a device box rotates to enable a spacing plate to extend to the outside of the movable groove, so that the meat blocks are positioned between the placement groove and a spacing plate so as toperform an effective spacing function for the meta blocks, people do not need to press the meat blocks with hands, a cutting operation is convenient and saves more labor, accidental situations are avoided, and cutting safety is improved.

Owner:安徽悠之优味食品有限公司

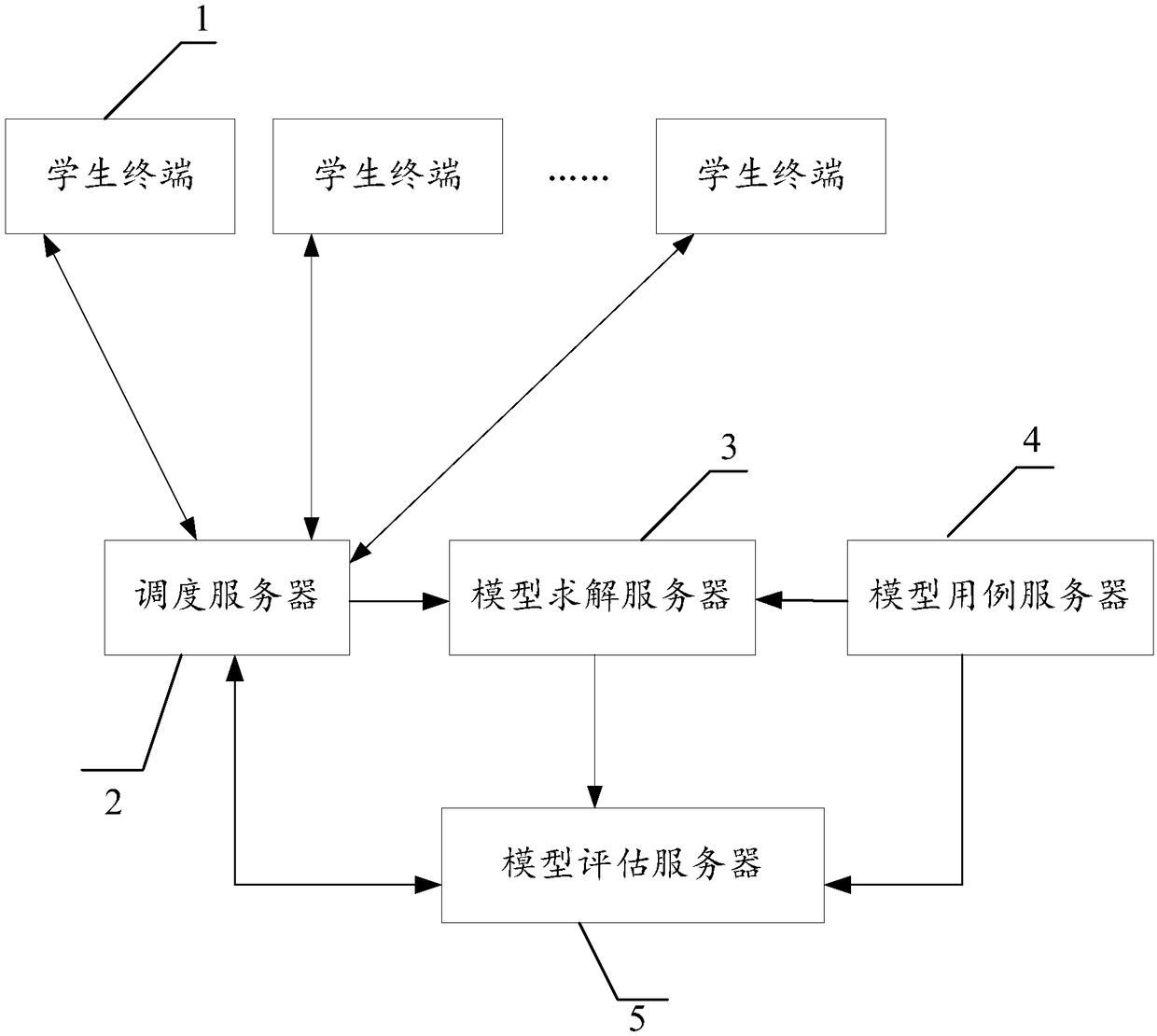

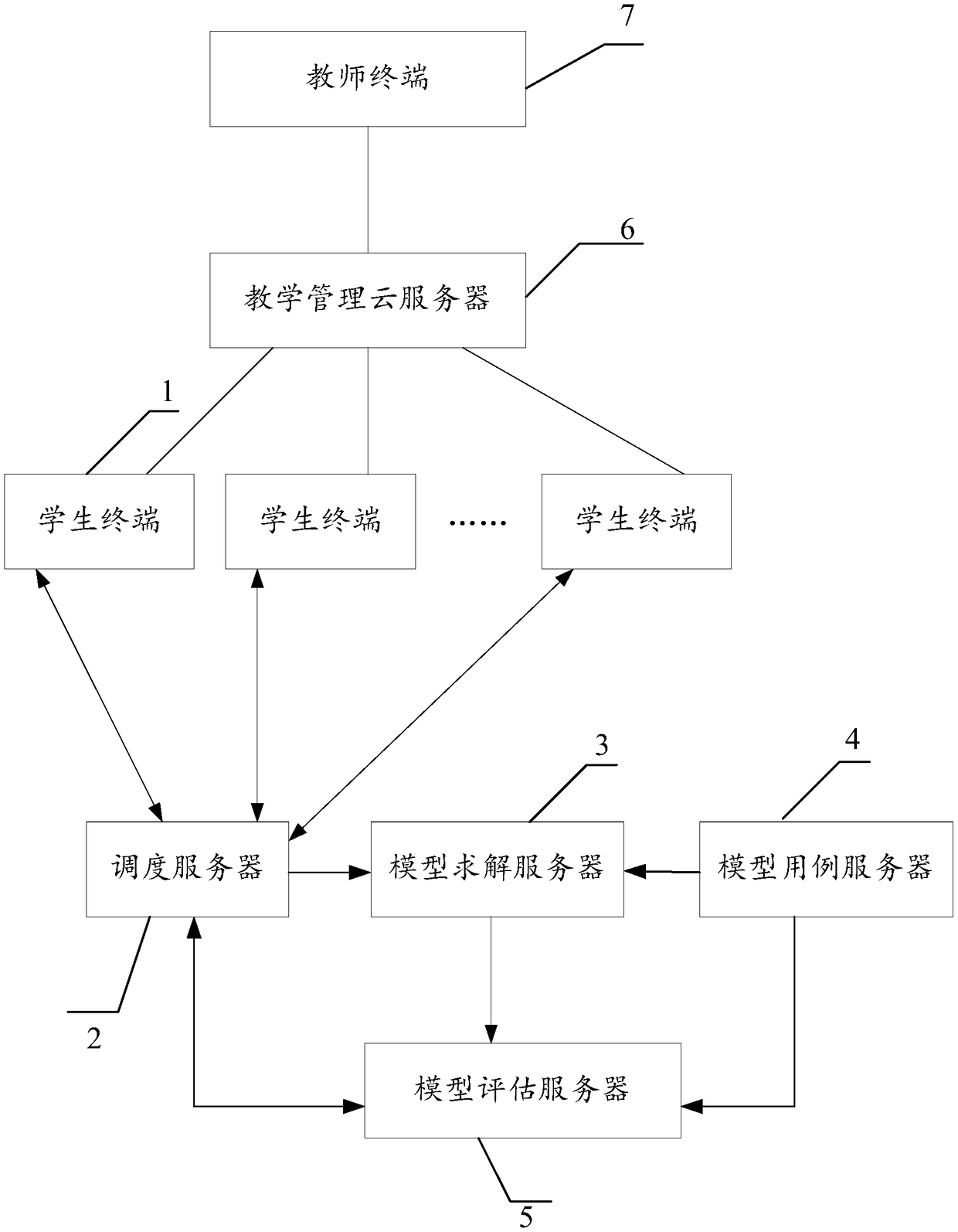

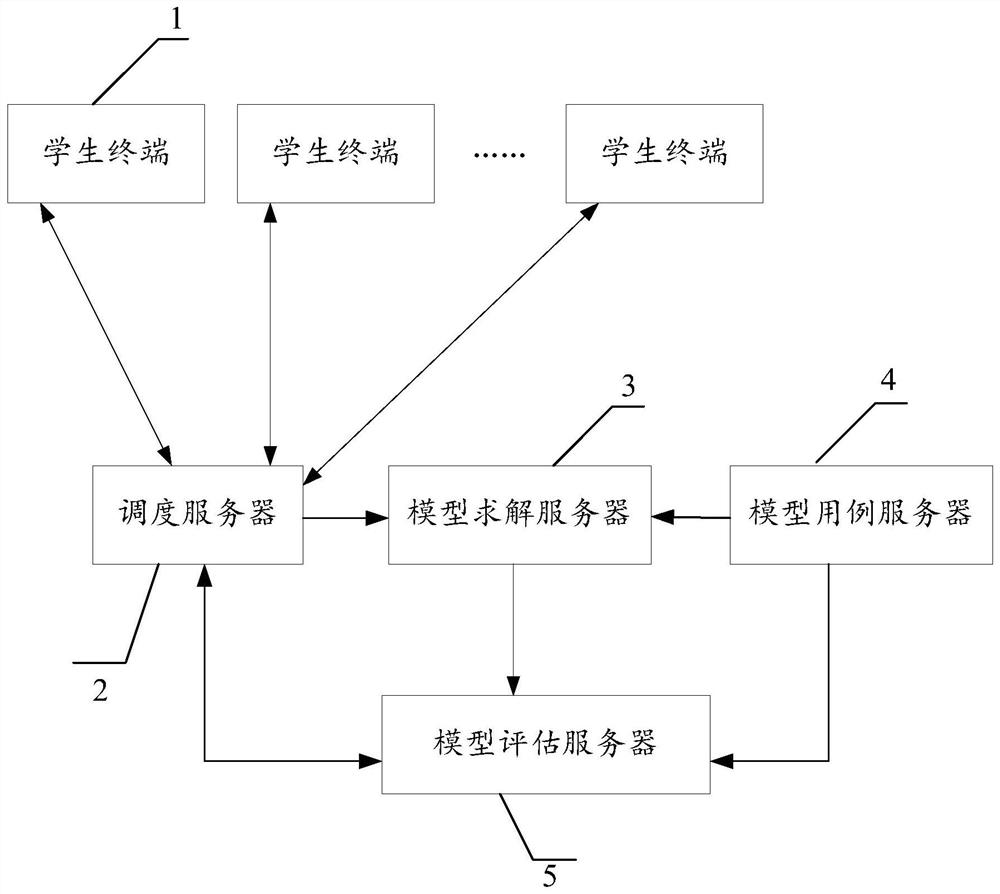

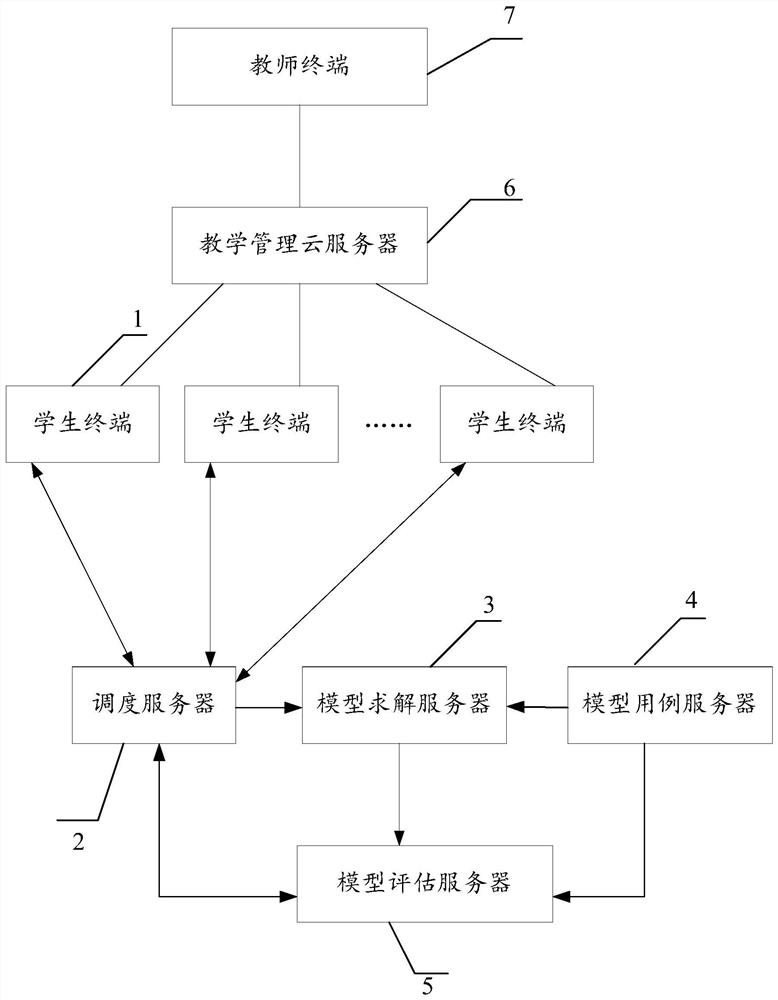

Mathematical-modeling teaching learning system

ActiveCN108614771AAvoid congestionImprove test efficiencyData processing applicationsSoftware testing/debuggingTest efficiencyMathematical model

The invention discloses a mathematical-modeling teaching learning system, and relates to the field of mathematical teaching. The mathematical-modeling teaching learning system includes: a plurality ofstudent terminals, a scheduling server, a model solving server, a model evaluation server and a model case server. The model solving server compiles mathematical-model code, retrieves test case datafrom the model case server according to a test case number, tests the mathematical-model code after compiling completion according to the test case data, and sends a test result and the test case number to the model evaluation server. The model evaluation server retrieves a reference result, which corresponds to the test case number, from the model case server according to the test case number, and compares the reference result with the test result to calculate an error. Through the system, a process of verifying a model to count the error is enabled to become an automated process, test efficiency of the model is improved, and improvement of teaching efficiency of a teacher is facilitated.

Owner:ANYANG NORMAL UNIV

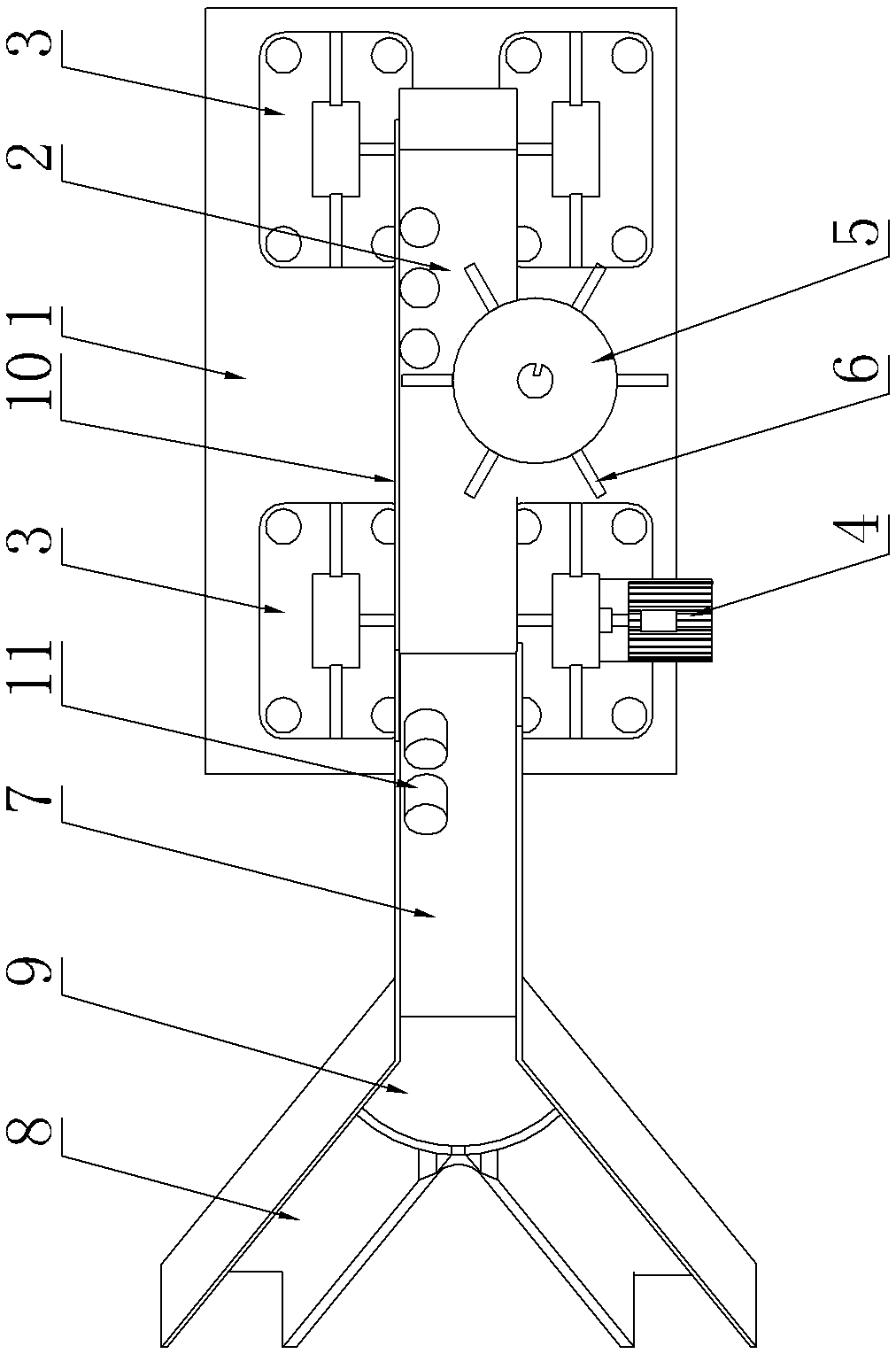

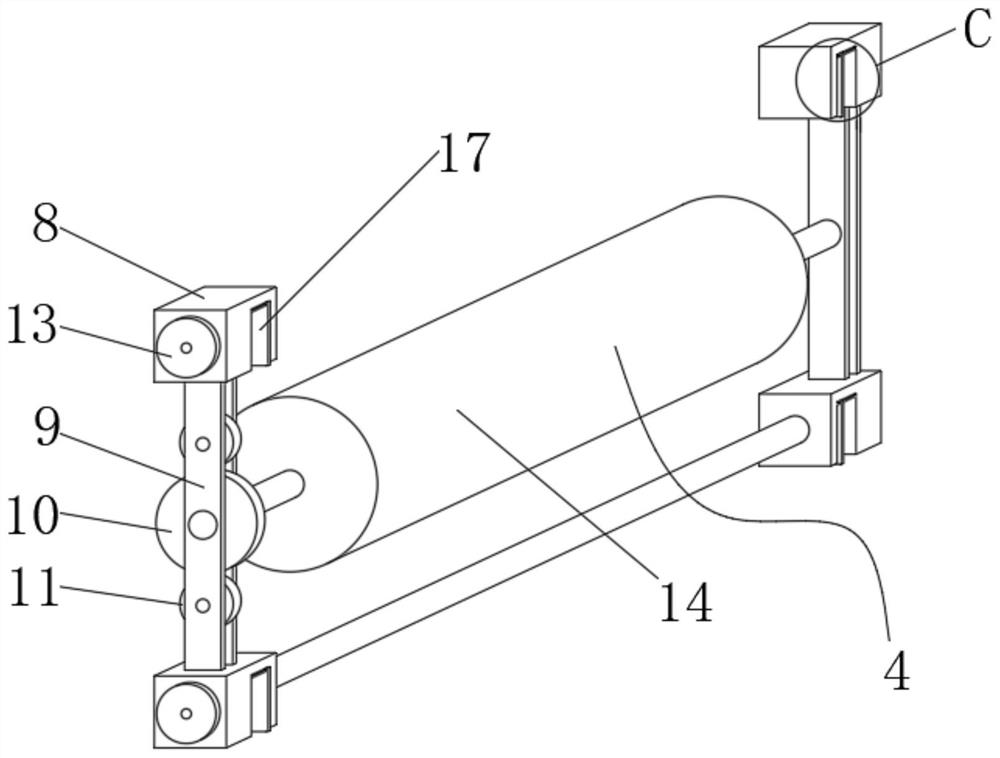

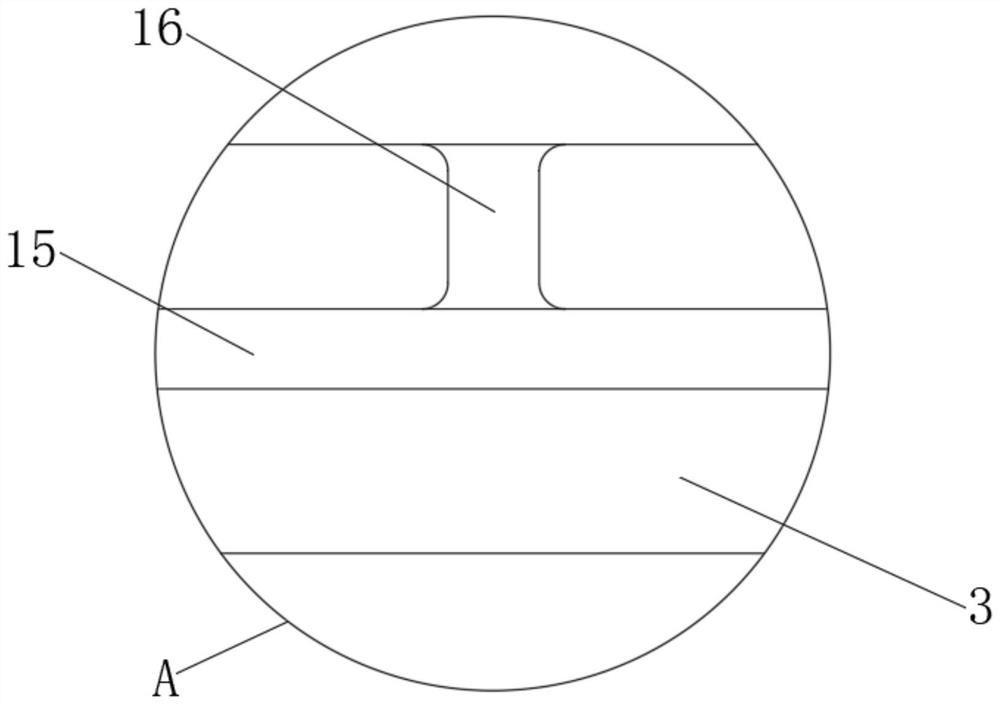

Sub-packaging and conveying device of columnar parts

The invention provides a sub-packaging and conveying device of columnar parts. The technical problems that labor is wasted in existing manual sub-packaging, and sub-packaging equipment is complex in structure and high in price can be solved. The sub-packaging and conveying device comprises a conveying belt mechanism, a quantitative transfer mechanism and a sub-packaging mechanism. The quantitativetransfer mechanism comprises a dividing wheel, the dividing wheel is arranged above a conveying belt and driven by a second motor, dividing plates arranged around the axis are fixed to the side portion of the dividing wheel, and the adjacent dividing plates are used for separating two parts. The sub-packaging mechanism comprises a sliding groove of an inverted Y-shaped structure and an arc-shapedpositioning plate. The sliding groove is formed in a downward inclined manner. The sliding groove comprises a main groove body and two sub-packaging groove bodies communicating with the lower end ofthe main groove body and forming a forky structure, an opening in the upper end of the main groove body is linked with the conveying belt, a penetrating groove matched with the positioning plate is formed in the forky juncture position of the sub-packaging groove bodies, an arc-shaped notch of the penetrating groove is formed upwards, and the positioning plate is fixed to the end of a piston rod of an oil cylinder.

Owner:WUXI CHANGZHISHENG MACHINERY MFG CO LTD

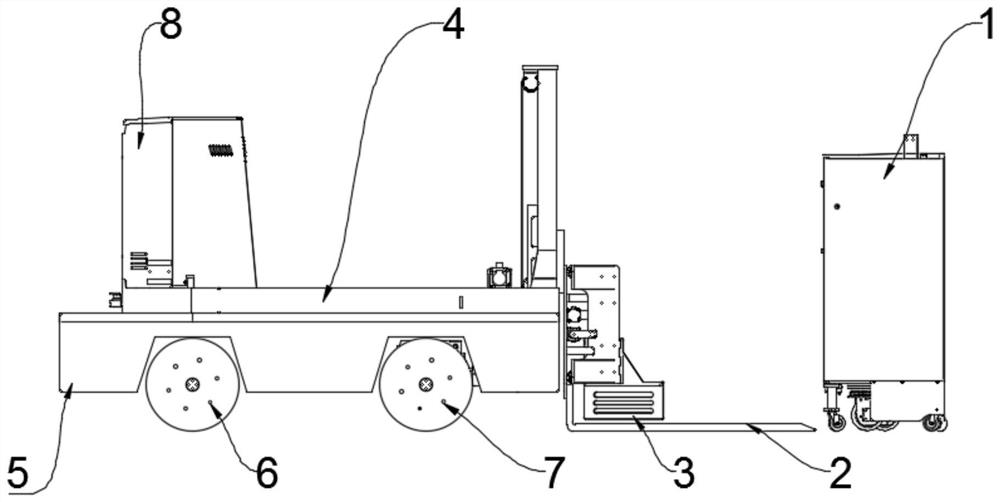

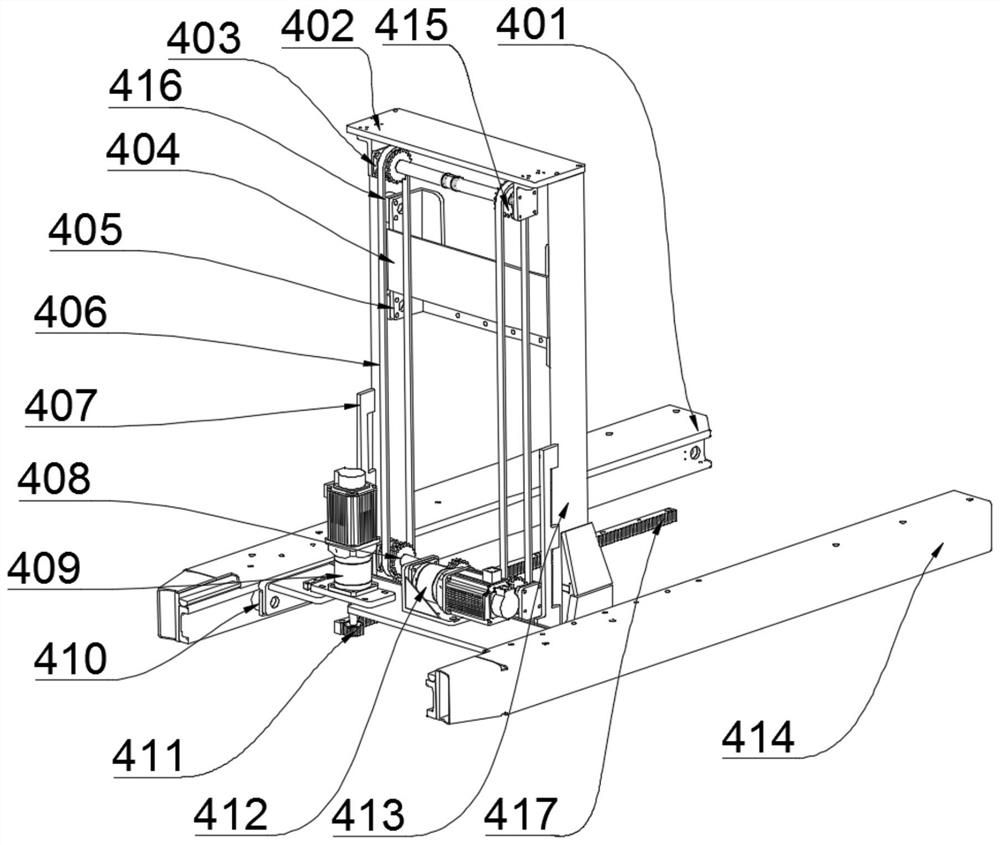

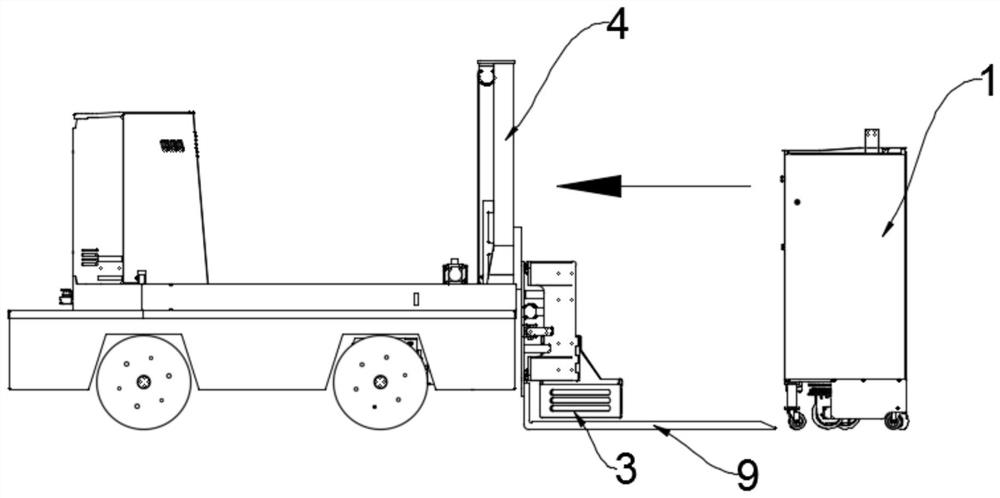

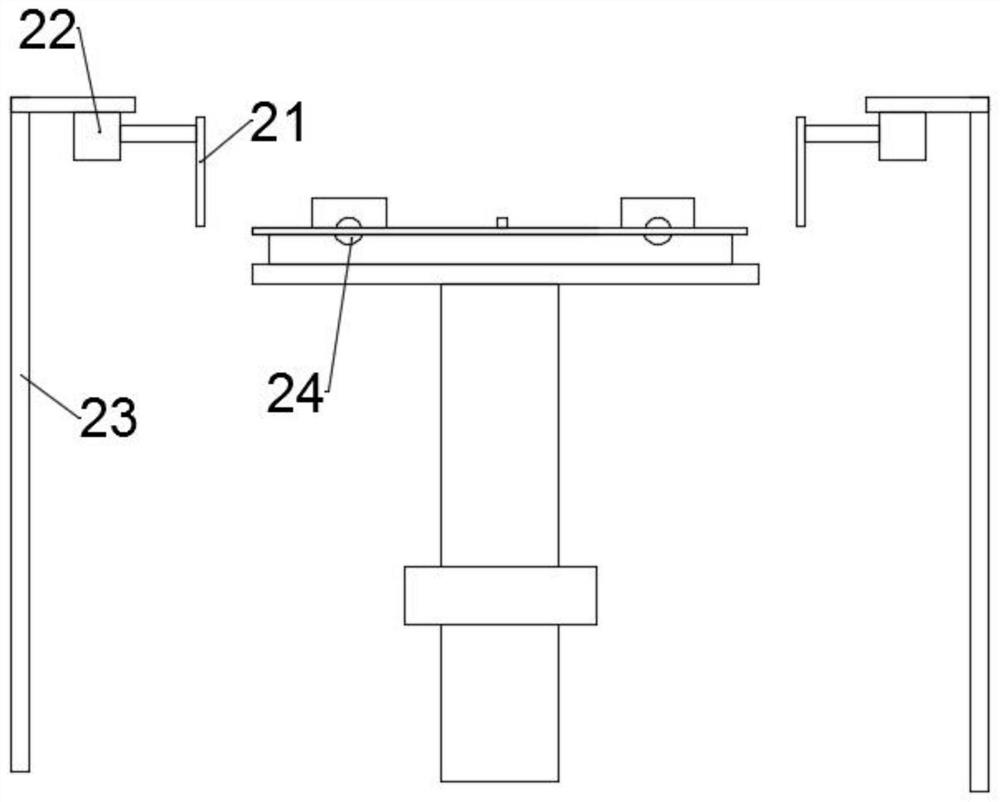

Carrying device, site transfer control method, electronic equipment and storage medium

InactiveCN111606250AReduce wasted man-hoursAddress the degree of automationLifting devicesPosition/course control in two dimensionsPoint cloudControl engineering

The embodiment of the invention provides a carrying device, a site transfer control method, electronic equipment and a storage medium, and relates to the technical field of building equipment. The device comprises a navigation positioning module and a chassis control mechanism, wherein the navigation positioning module is used for planning a walking path according to received map point cloud datato conduct navigating and positioning according to the walking path, the chassis control mechanism comprises a vehicle body frame, a steering control unit, a driving unit and a walking unit, and the steering control unit, the driving unit and the walking unit are arranged below the vehicle body frame; and the steering control unit is used for steering control according to the walking path, and thedriving unit is used for providing power for driving the walking unit and conducting site transfer according to the walking path. The device can be used for carrying a building robot and other devices and assisting the building robot to achieve site transfer, so that the problem that an existing building robot cannot achieve stie transfer automatically, and the problems of low automation degree,low transportation efficiency and additional labor cost caused by adopting artificial site transfer are solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Novel polaroid laminating equipment

The invention discloses novel polaroid laminating equipment in the technical field of polaroid laminating. Theequipment comprises a processing table, the top of the processing table is fixedly connected with a first fixing plate, and the top of the first fixing plate is connected with a press-fit mechanism for downwards pressing and sticking a polaroid. A first rotating rod rotationally connected with the first fixing plate penetrates through the middle of the first fixing plate, and a first sliding groove is formed in the first fixing plate. When polaroids are attached to the two faces of a liquid crystal piece each time, a positioning mechanism is used for accurately determining the liquid crystal piece firstly, so that the accuracy of each time of attaching is guaranteed; and a switching mechanism is matched to enable the liquid crystal piece with one face attached to be turned over stably, so that the liquid crystal piece is protected, the situation that personnel manually participate in turning over the liquid crystal piece many times is avoided, the cleaness of the liquid crystal piece is protected, repeated and tedious cleaning of the liquid crystal piece is avoided, and the laminating efficiency of the polaroid is improved.

Owner:SHENZHEN DEEP HON HAI AUTOMATION EQUIP CO LTD

Honey taking device for bee breeding

The invention discloses a honey taking device for bee breeding. The honey taking device comprises a bearing base, wherein one side of the upper end of the bearing base is provided with a protective box, a centrifugal mechanism is arranged at the upper portion, on one side of the protective box, of the bearing base, and the end, away from the protective box, of the centrifugal mechanism is connected with a connecting pipe; the side, away from the protective box, of the centrifugal mechanism is provided with a honey storage box at the upper portion of the bearing base, and the centrifugal mechanism is connected with the honey storage box through the connecting pipe. According to the honey taking device, by arranging a centrifugal barrel which is driven to rotate mechanically, manual centrifugation can be avoided, the separation efficiency is improved, the waste amount of honey is reduced, and environmental contamination is reduced. Since a movable plate capable of moving horizontally isarranged, impurities in honey are unlikely to block a filter screen at the bottom of the honey storage box through the horizontal movement of the movable plate, and a honey taking process is smoother.According to the design of the honey taking device, an adopted mechanism structure is simple, the efficiency is high, maintenance and care are convenient, the work load of workers can be reduced, andthe operation efficiency of honey taking is greatly improved.

Owner:戴蓓蓓

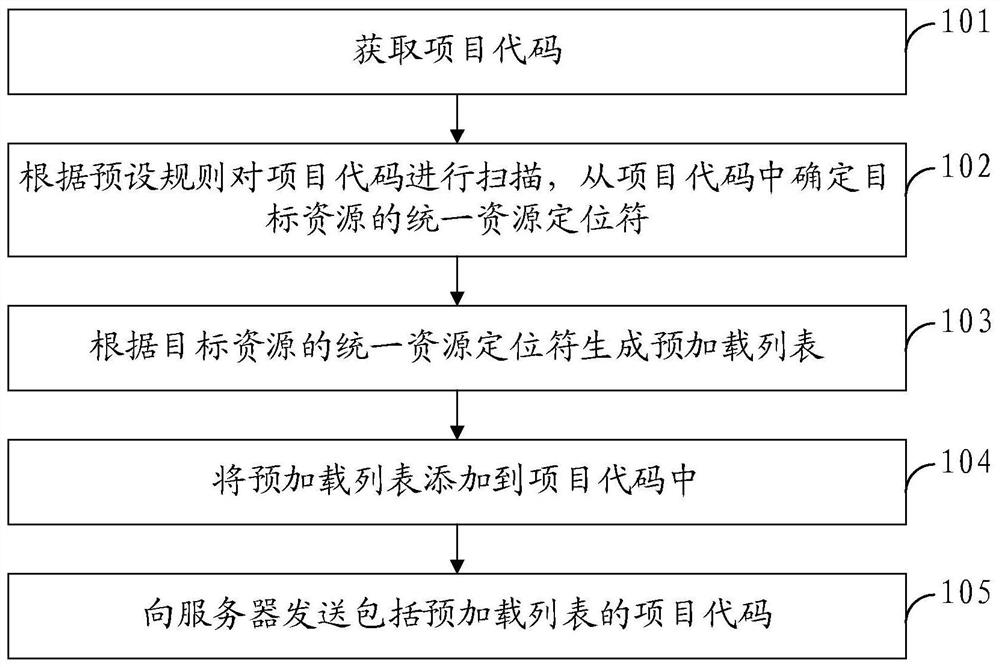

Resource preloading method and device and storage medium

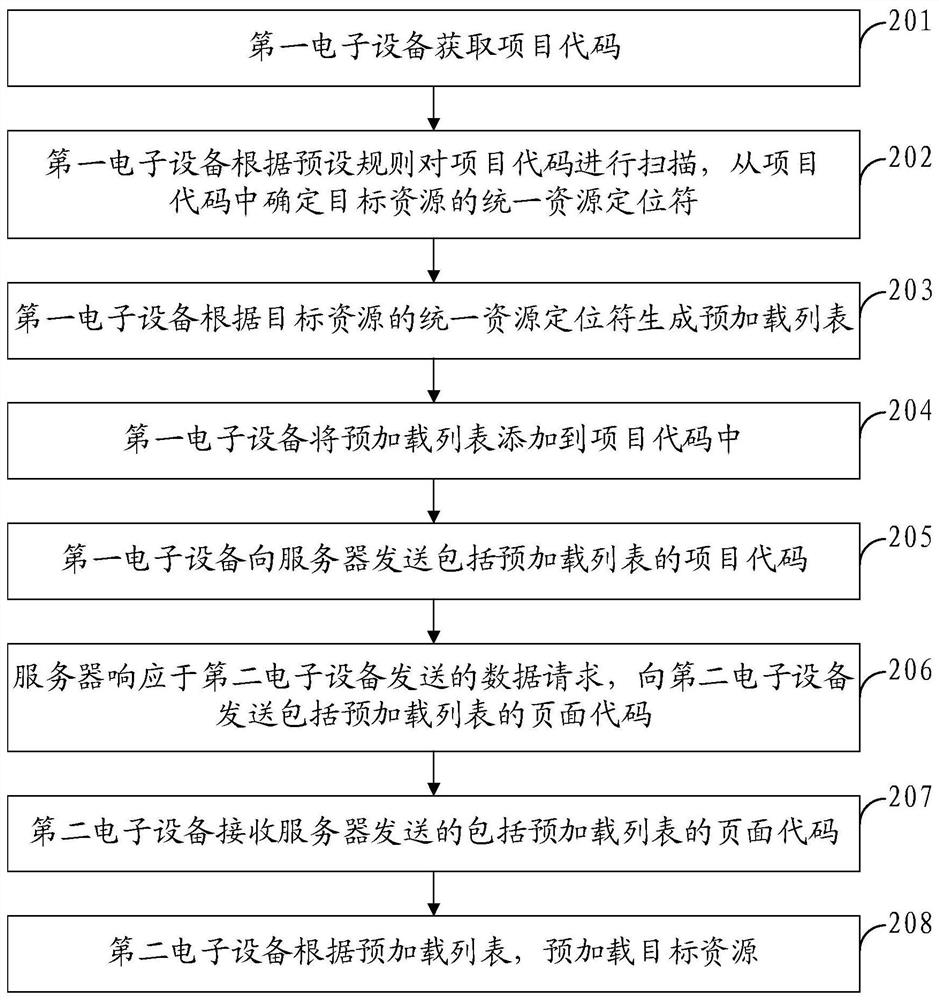

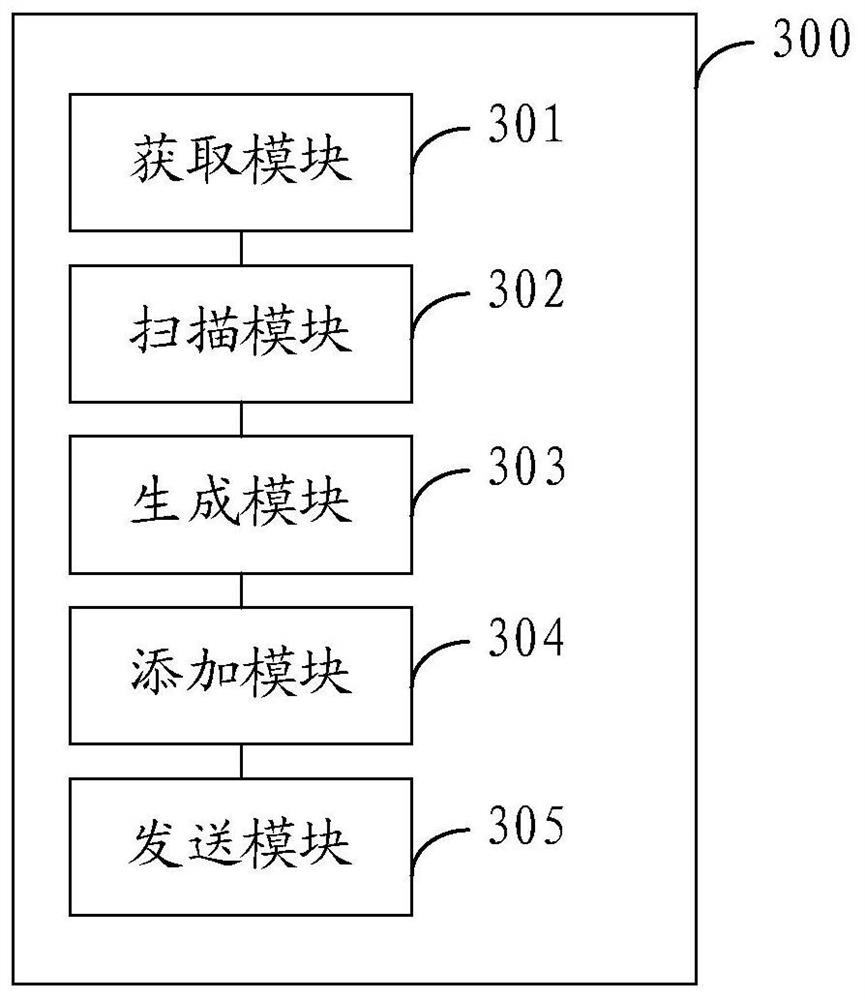

PendingCN111639276AImprove acquisition efficiencySure to avoidSpecial data processing applicationsWeb data retrieval using information identifiersUniform resource locatorDatabase

The invention relates to a resource preloading method and device and a storage medium. The resource pre-loading method comprises the following steps: first electronic equipment acquires a project code, scans the project code according to a preset rule, determines a uniform resource locator of the target resource from the project code, and generates a pre-loading list according to the uniform resource locator of the target resource, adds the pre-loading list to the project code, and sends the project code including the pre-loading list to a server, so that the second electronic device can obtain the pre-loading list from the server, and pre-load the target resource according to the pre-loading list. The project code is directly scanned through the first electronic equipment, the URL of theresources needing to be preloaded is determined from the project code according to the preset rule, the process that a user manually determines and arranges the URL from the project code can be avoided, and the URL obtaining efficiency can be improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

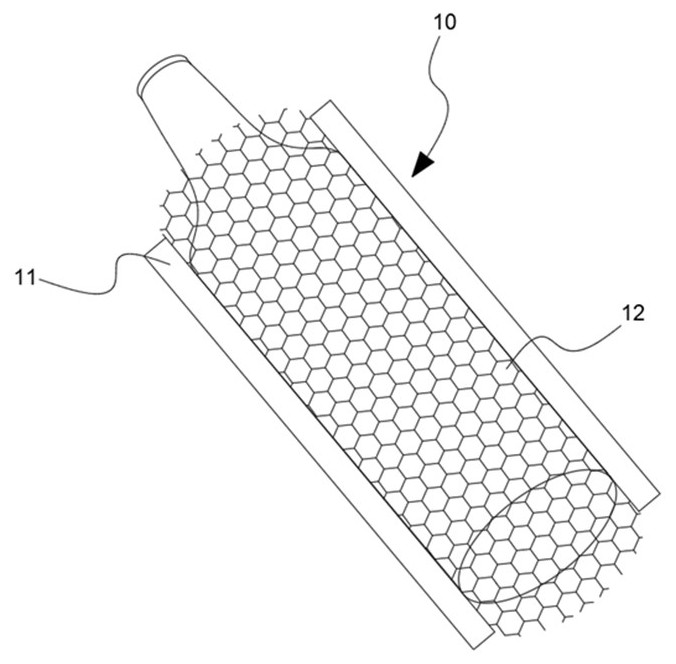

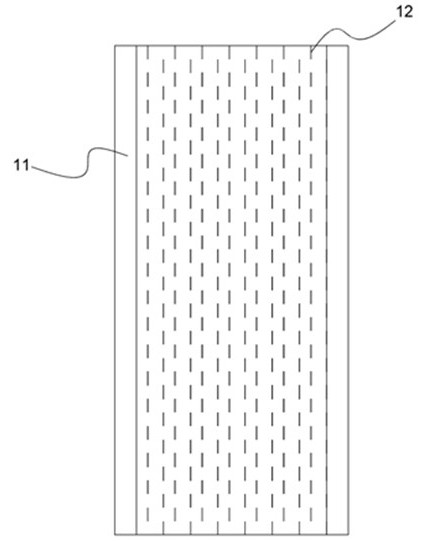

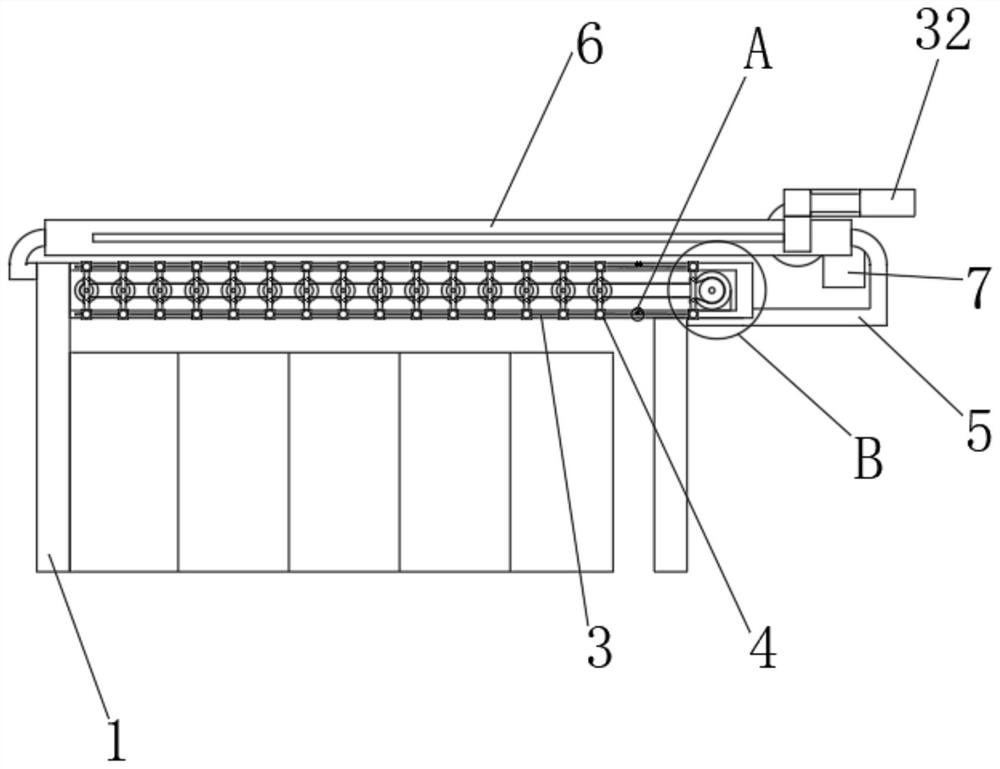

Sleeve-shaped honeycomb packaging paper, manufacturing method and manufacturing equipment

InactiveCN113184324AEffective protectionPrevent fallingPaper/cardboard articlesRigid containersPunchingHoneycomb

The invention discloses sleeve-shaped honeycomb packaging paper, a manufacturing method and manufacturing equipment. The honeycomb packaging paper comprises a packaging paper body, wherein the packaging paper body is of a semi-closed sleeve-shaped structure with the left side and the right side closed and the upper end and the lower end opened; multiple rows of deformable holes are formed between the two closed sides of the packaging paper body; every two adjacent rows of holes are arranged in an up-down staggered mode; and the holes are in a honeycomb shape after being unfolded. The packaging paper disclosed by the invention can be sleeved on a bottle body of a glass product, so that the honeycomb paper is prevented from falling off from the bottle body, and the bottle body is effectively protected. The equipment comprises a rack, wherein a pair of tension wheels used for unwinding raw material paper, a glue spraying station, a pressing rotating roller, a punching rotating roller and a cutter are sequentially arranged on the rack, and the honeycomb packaging paper is manufactured by pressing and punching the two pieces of raw material paper. According to the manufacturing equipment and the manufacturing method, full-automatic production of the sleeve-shaped honeycomb packaging paper can be achieved, manual production is avoided, and profits are saved for enterprises.

Owner:东莞市浩霖包装材料有限公司

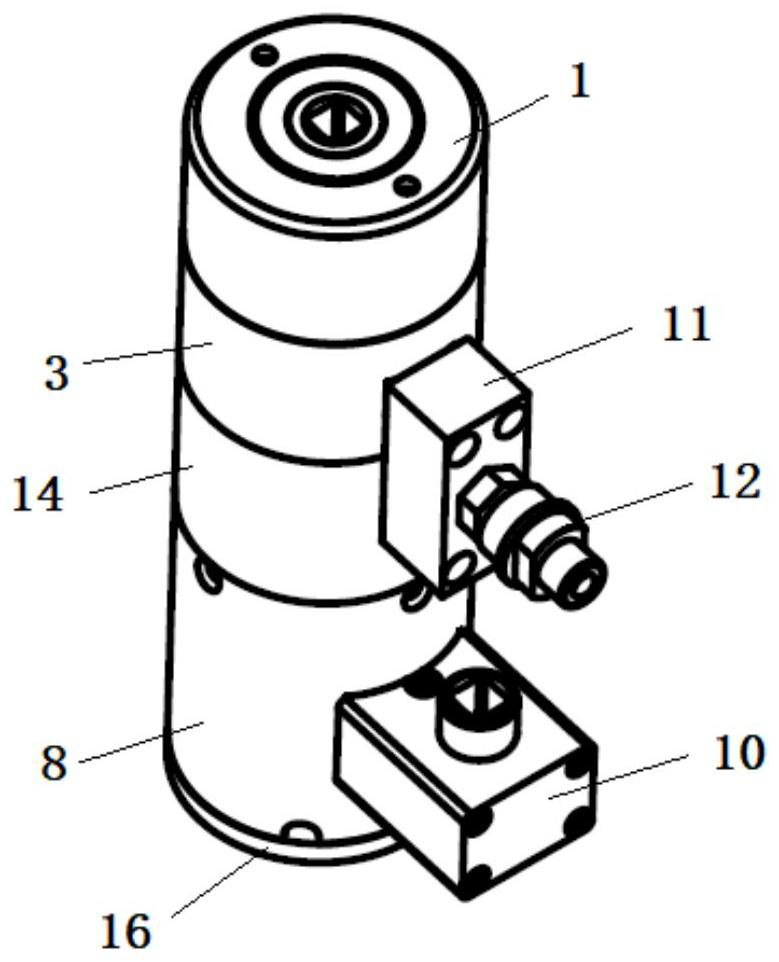

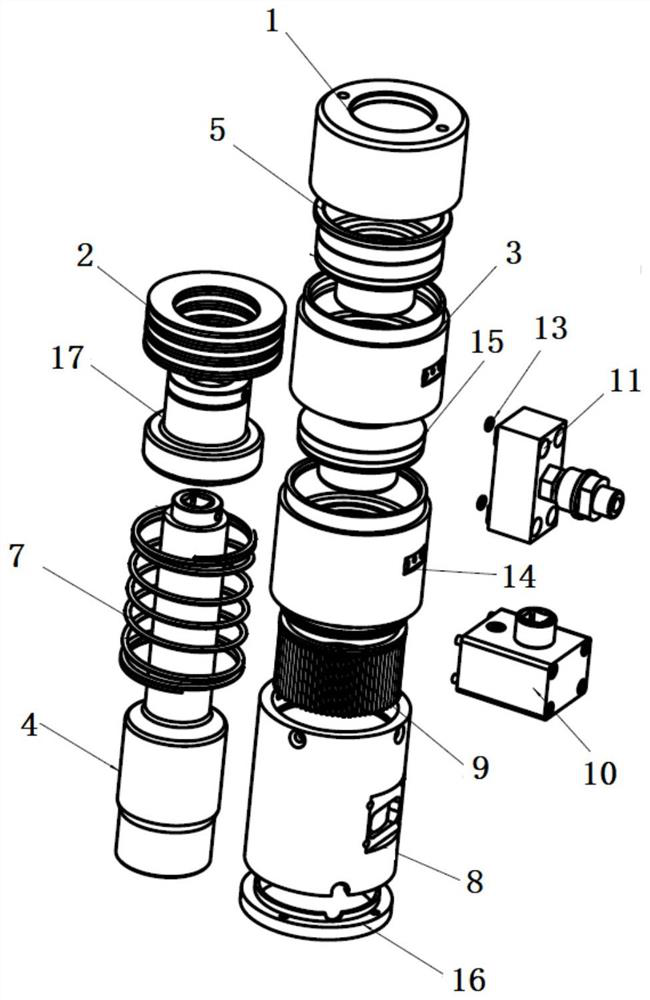

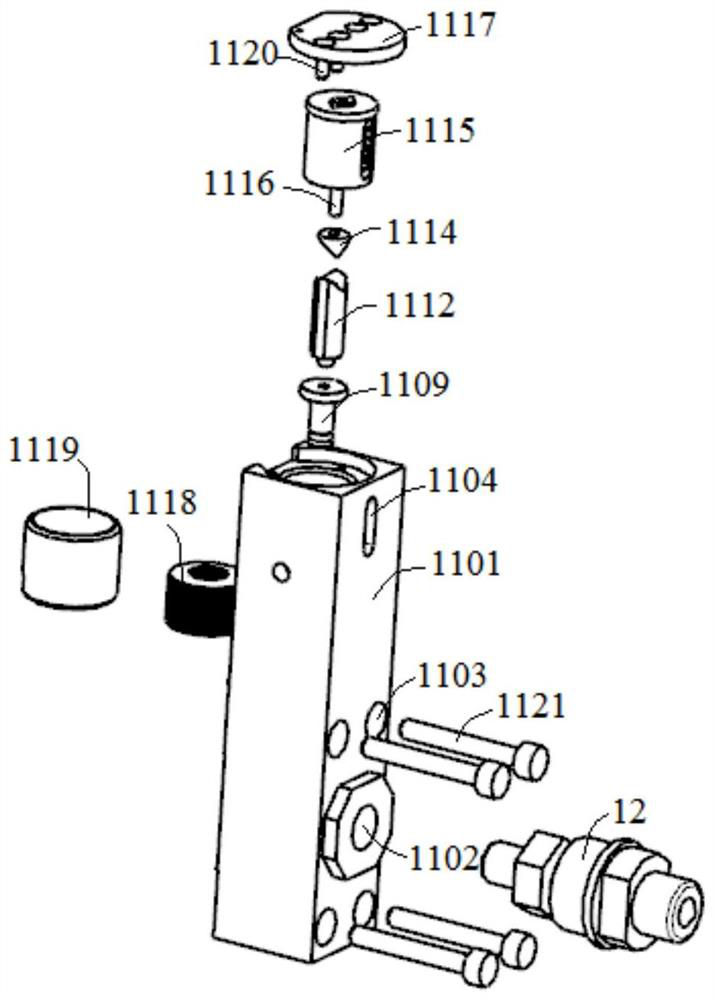

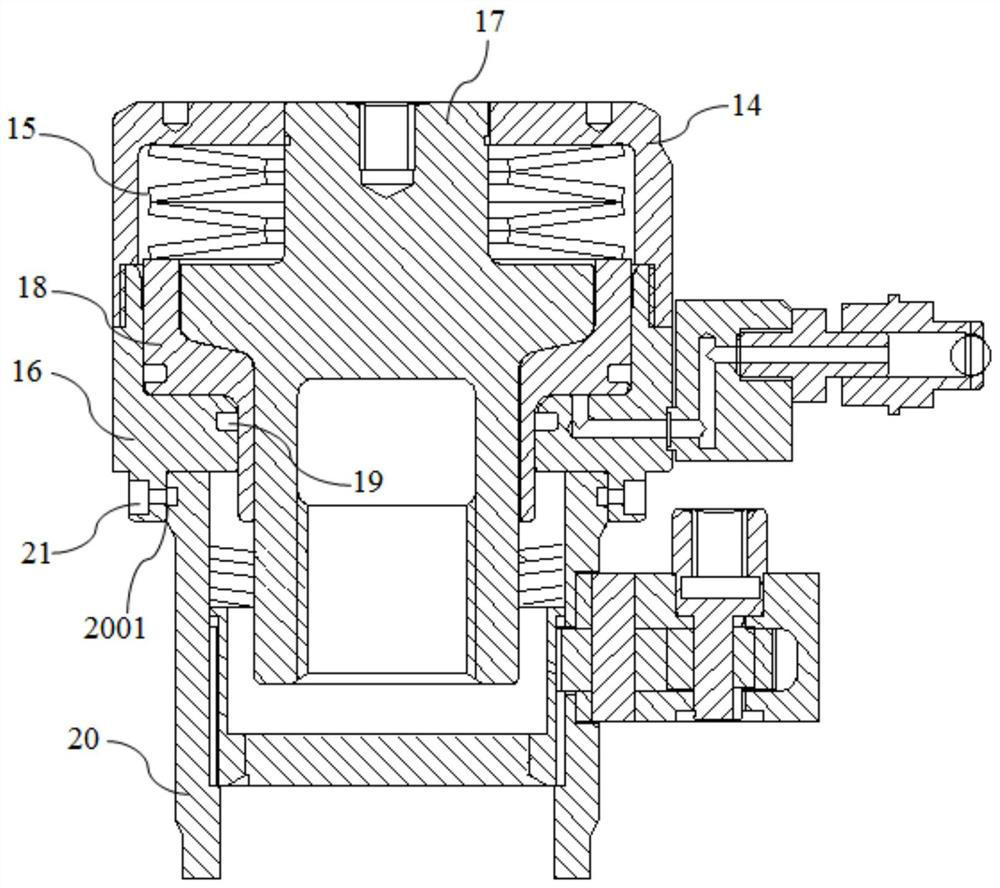

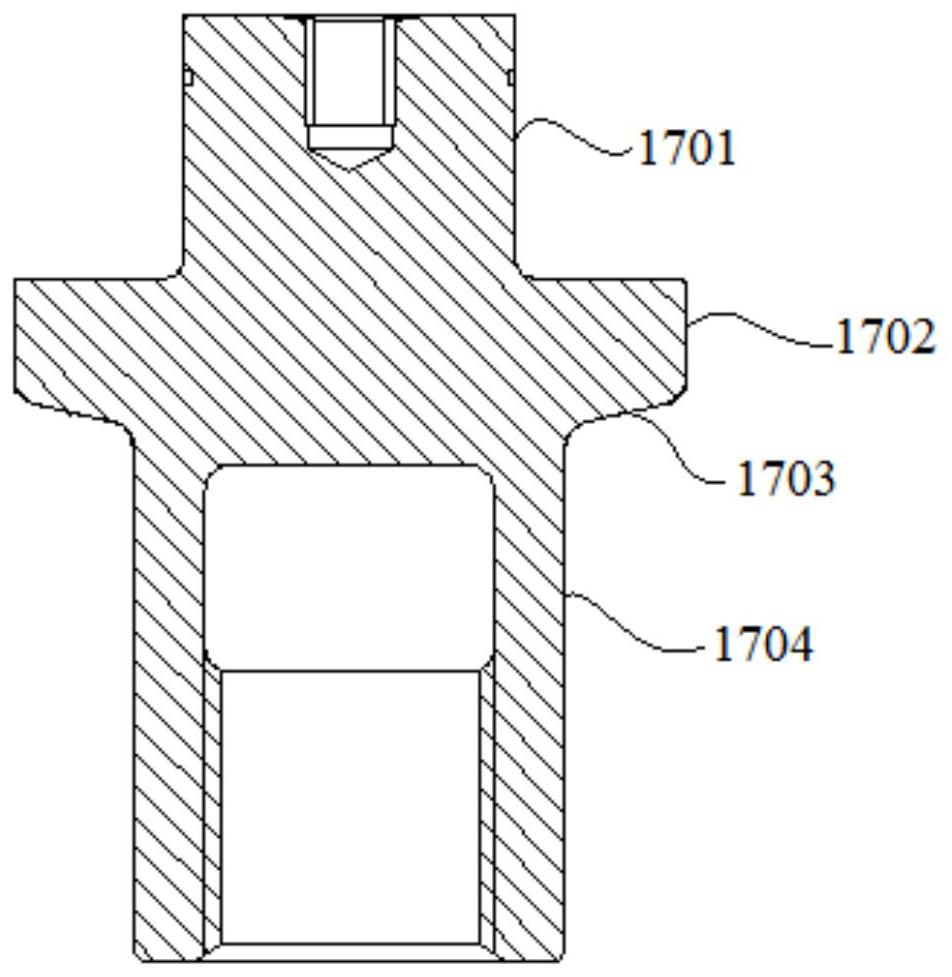

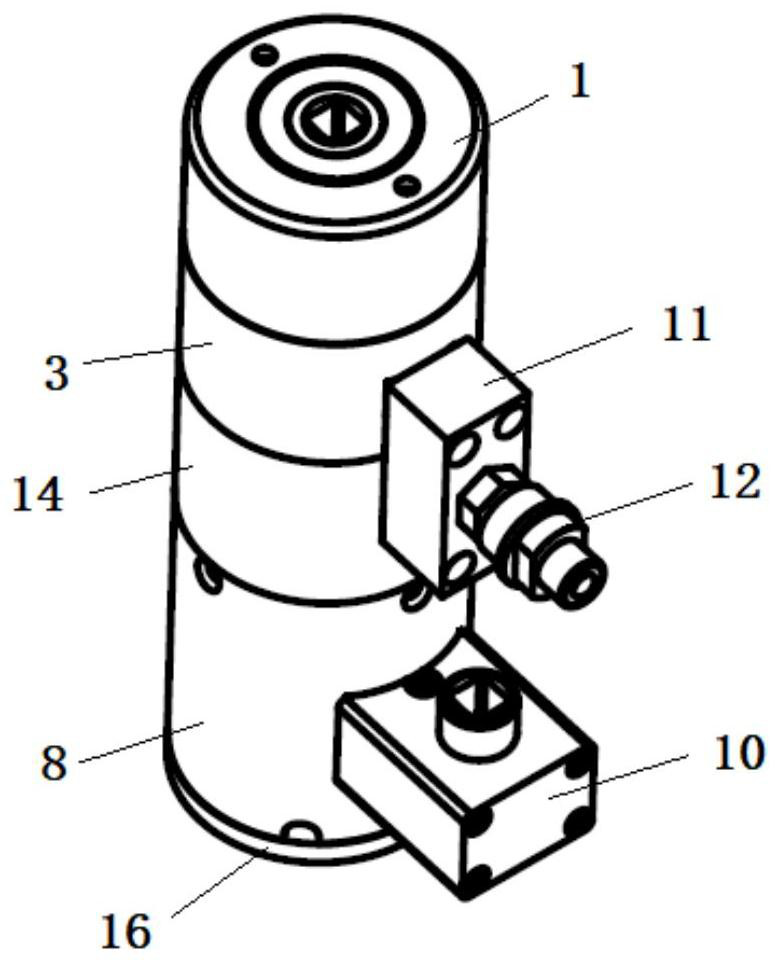

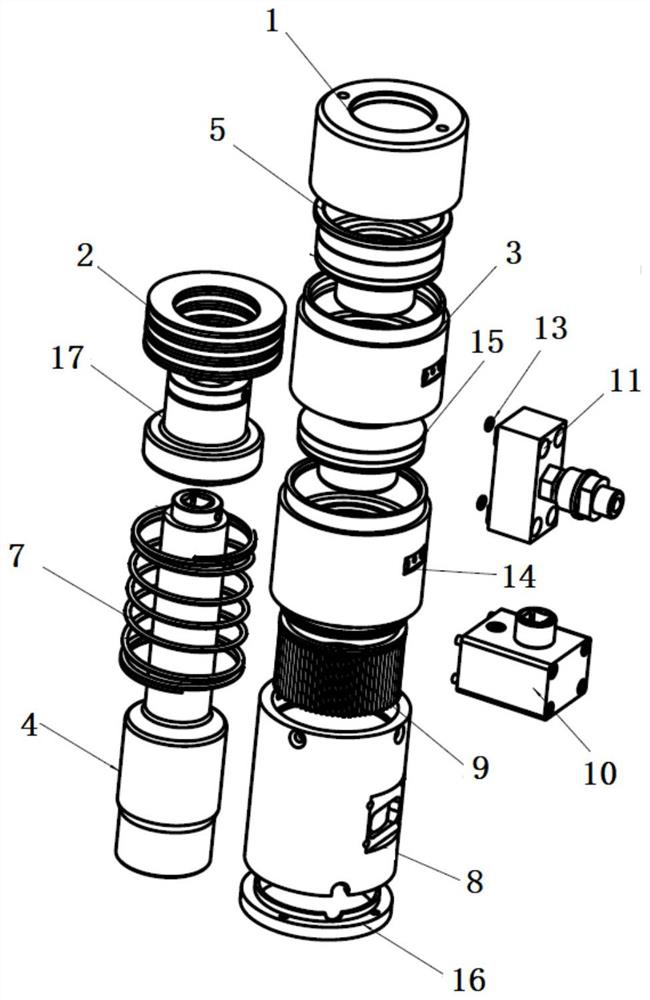

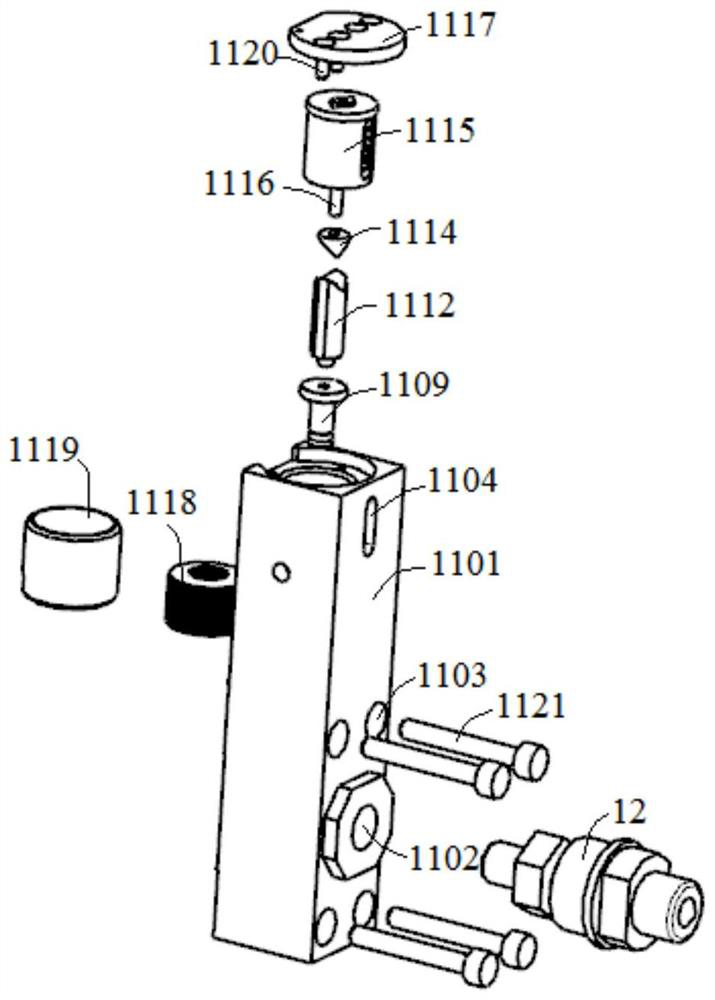

A spring self-resetting two-stage hydraulic tensioner with counting function

ActiveCN111922690BEffectively monitor performance statusEasy maintenanceCounting mechanisms/objectsMetal working apparatusDrive shaftControl engineering

The invention discloses a spring self-resetting two-stage hydraulic tensioner with the function of counting times, and belongs to the technical field of stretching equipment. It includes a stretcher main body and a counting device installed on the side wall of the stretcher main body. The counting device includes an oil distribution block and a digital counter. The oil distribution block is a hollow structure, and the digital counter is installed vertically on the Above the inside of the oil block; a rotating head is fixedly installed on the driving shaft of the digital counter, and a pushing mechanism that cooperates with its rotation is provided under the rotating head. The pushing mechanism is supported and installed in the oil distribution block and can be driven by hydraulic pressure. Moving up and down, the outside of the pushing mechanism is also sleeved with a second disc spring. Adopting the technical solution of the present invention can effectively solve the above-mentioned problems, facilitate the monitoring of the performance status of the product, prevent human misoperation from causing inaccurate counting, effectively avoid the occurrence of safety accidents during operation, and at the same time use more stable, further improving wind power equipment. installation efficiency.

Owner:马鞍山市罗泰特机械制造有限公司

A Countable Hydraulic Bolt Tensioner

ActiveCN111922691BEffectively monitor performance statusMonitor performance statusCounting mechanisms/objectsMetal working apparatusDrive shaftEngineering

The invention discloses a countable hydraulic bolt tensioner, which belongs to the technical field of tensioning equipment. It includes a stretcher main body and a counting device, the counting device is installed on the side wall of the stretcher main body, the counting device includes a connecting block and a digital counter, the connecting block is a hollow structure, and the digital counter is vertical Installed above the inside of the connecting block; the drive shaft of the digital counter is fixed with a rotating head, and a pushing mechanism is provided under the rotating head to cooperate with its rotation. The pushing mechanism is supported and installed in the connecting block and can be driven by hydraulic pressure. The up and down motion is used to push the rotating head to rotate, and a disc spring is sheathed on the outside of the pushing mechanism. Adopting the technical solution of the invention can effectively monitor the performance state of the product, prevent human misoperation from causing inaccurate counting, effectively avoid the occurrence of safety accidents during operation, and facilitate the maintenance of the tensioner.

Owner:马鞍山市罗泰特机械制造有限公司

Printing presses with auxiliary paper loading

ActiveCN110329809BRealize automatic paper loading functionHigh degree of automationArticle separationProcess engineeringPrinting press

The invention relates to a printing machine with an auxiliary paper loading device. The printing machine comprises a printing machine shell, a paper loading groove and an automatic paper loading mechanism, wherein the automatic paper loading mechanism comprises a paper storage assembly, a paper ordering and transportation assembly and a paper pushing assembly, the paper storage assembly is positioned on one side of the printing machine shell, the paper ordering and transportation assembly is positioned between the paper storage assembly and the printing machine shell, the paper pushing assembly is fixed to the position, close to the paper loading groove, of the printing machine shell, and paper which is stored by the paper storage assembly is carried and ordered through the paper orderingand transportation assembly and then is conveyed into the paper loading groove. When the paper loading groove of the printing machine is short of paper, the paper can be fed into the paper loading groove through the automatic paper loading mechanism, manual operation is not needed, the automation degree is high, and the labor intensity is reduced.

Owner:山东蓝海文化科技有限公司

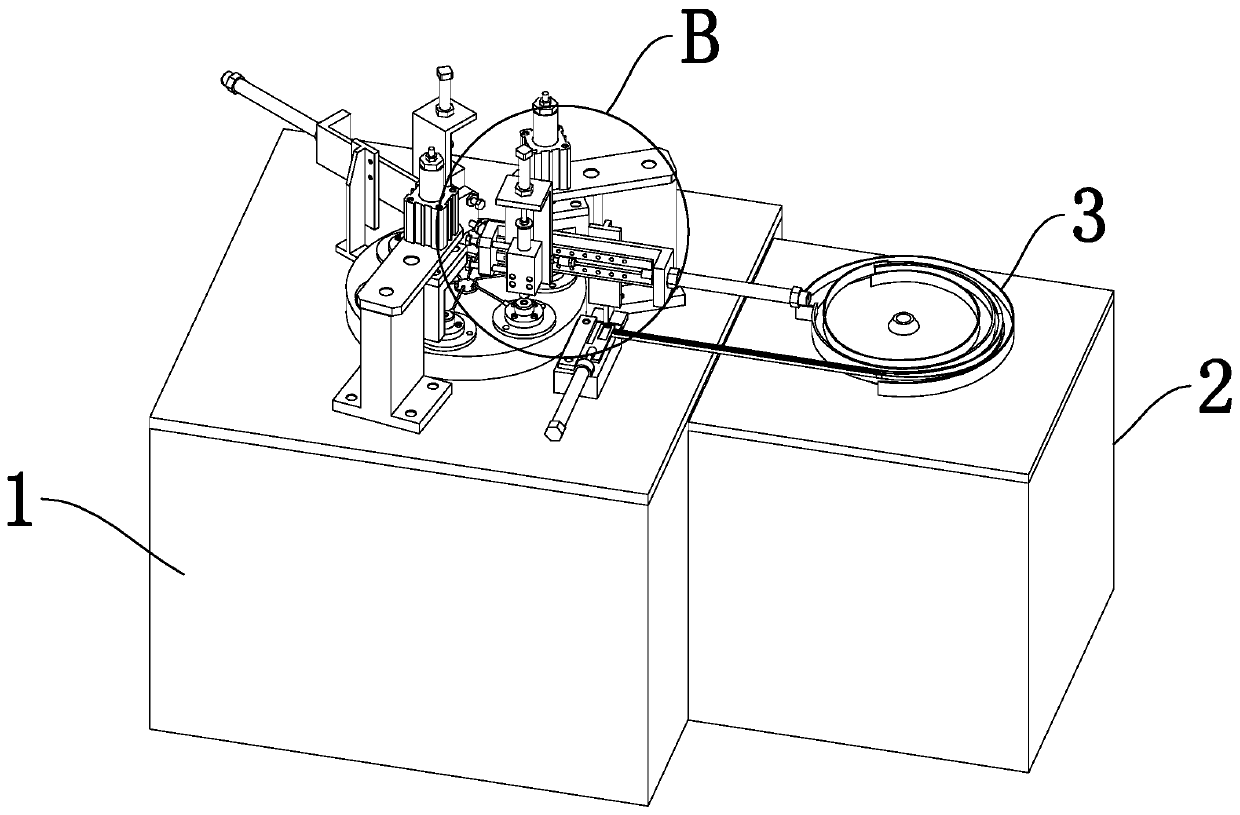

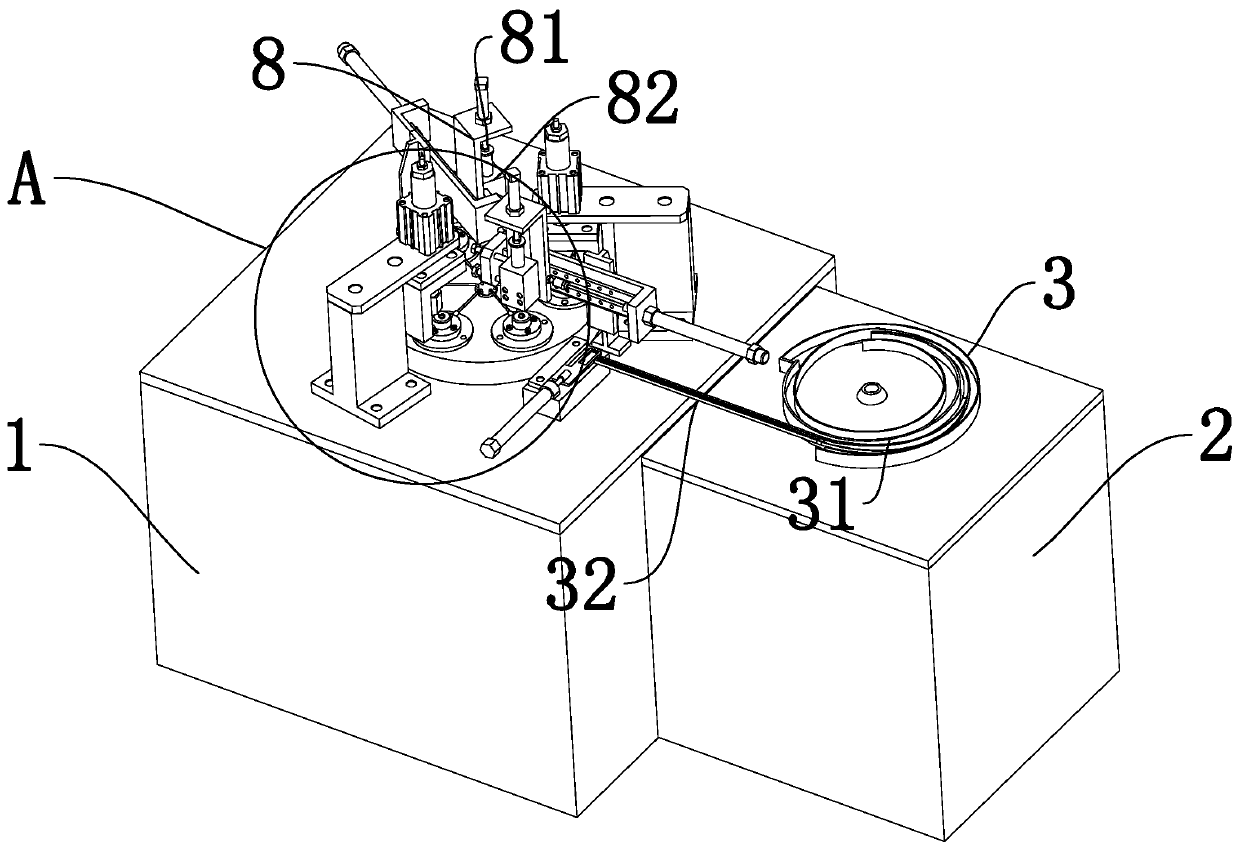

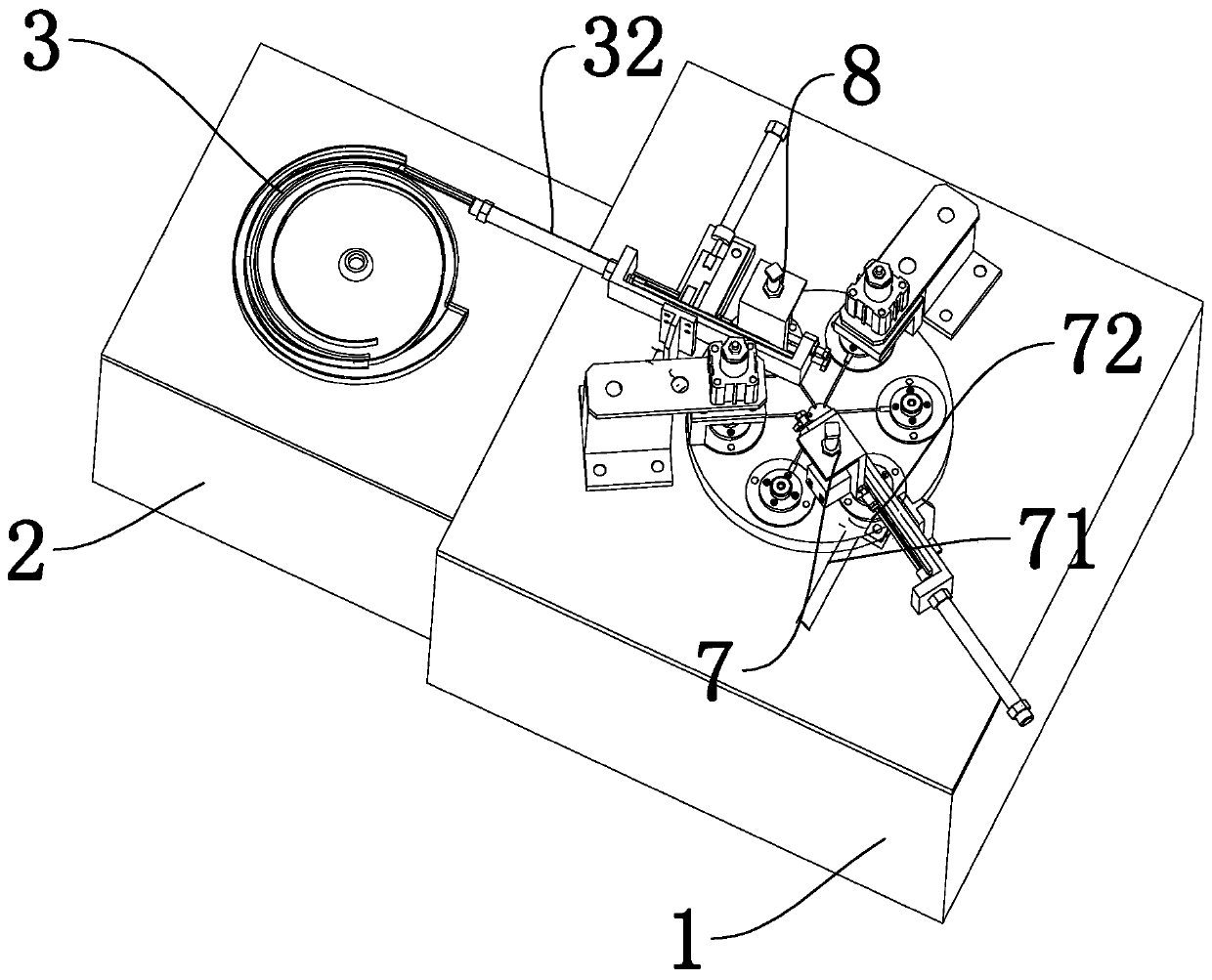

Full-automatic shaft pressing machine

PendingCN110539521APlay the role of automatic feedingAvoid manualPressesEngineeringMechanical engineering

The invention discloses a full-automatic shaft pressing machine. The full-automatic shaft pressing machine comprises a pressing device and a feeding device, wherein the feeding device is fixedly connected with one side of the pressing device; a pressing mechanism is arranged at the upper portion of the pressing device; a rotating device is arranged at the upper portion of the feeding device; the upper end face of the rotating device is spirally connected with a rail; one side of the rail is fixedly connected with a feeding pipe; the pressing mechanism comprises a rotating plate which is fixedly connected with the upper end face of the pressing device; one side, close to the feeding device, of the outer side of the rotating plate is provided with a charging device; the rotating device is connected with the charging device through a charging pipe; the feeding device, the rotating device and the pressing mechanism are arranged in an integration manner so as to realize an automatic feedingfunction in a feeding process; manual operation is prevented; the work efficiency is improved; and mechanical chucking is prevented in the feeding process by arranging a first push shaft between thefeeding device and the rotating device.

Owner:广东华远电子科技有限公司

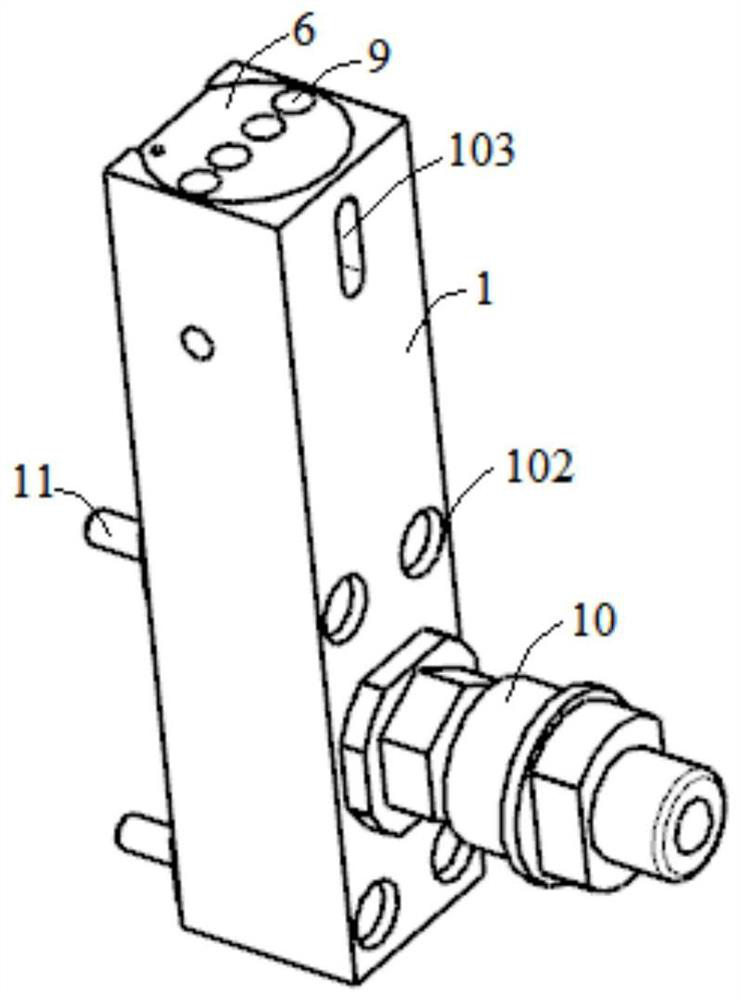

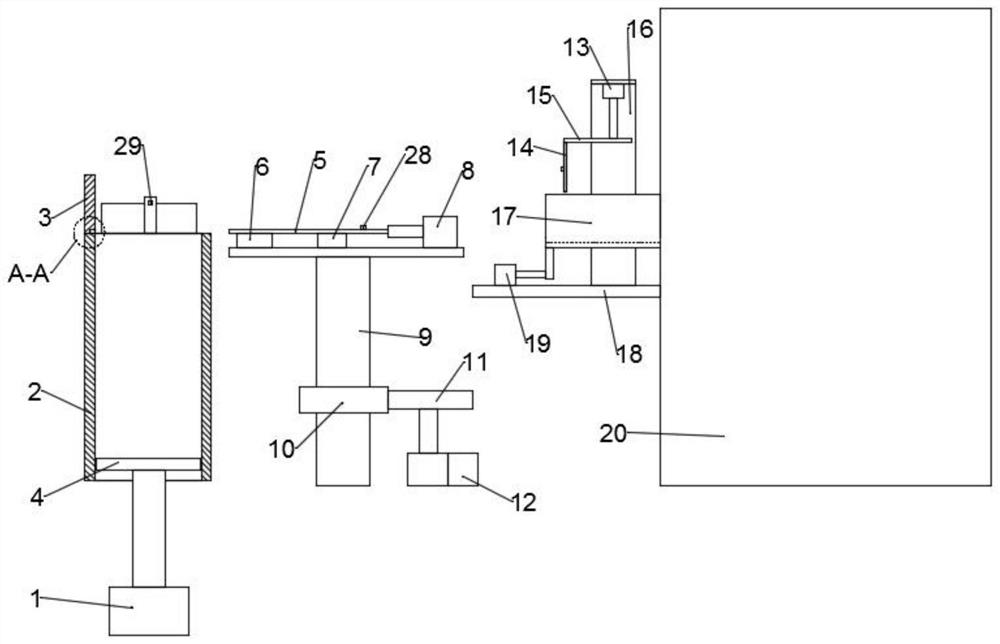

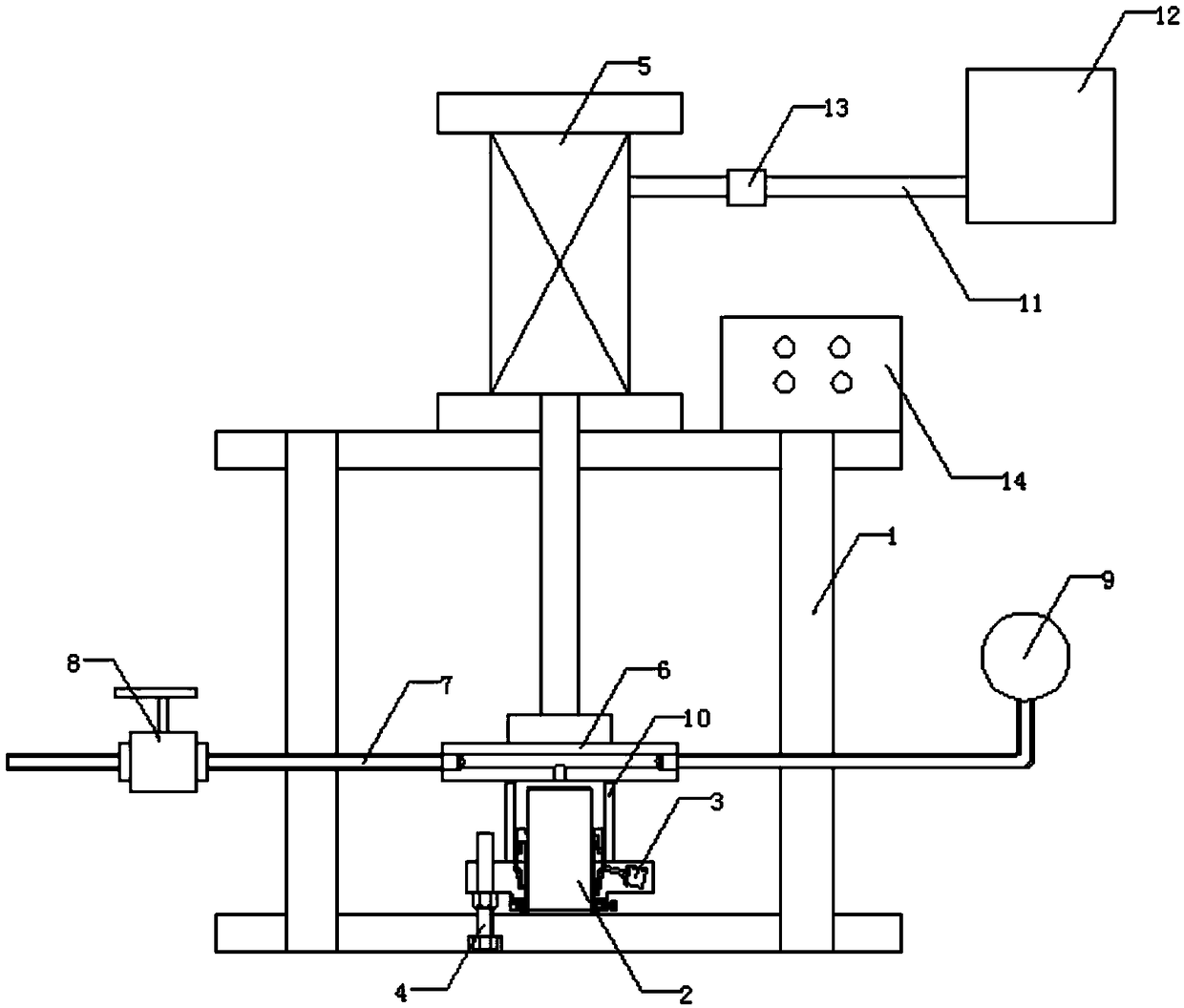

Static pressure testing device for integrated packaging mechanical seal

PendingCN109115426AAvoid manualStable pressure outputMeasurement of fluid loss/gain rateHydraulic cylinderInlet valve

The invention discloses a static pressure testing device for an integrated packaging mechanical seal, which comprises a rack, and is characterized in that the bottom end of the rack is fixedly provided with an integrated packaging mechanical seal, the top end of the rack is fixedly provided with an oil cylinder, a piston rod of the oil cylinder is fixedly connected with the top end of a ventilating disc through a flange, the middle part of the ventilating disc is fixedly provided with an air inlet pipe, one end of the air inlet pipe is fixedly provided with an air inlet valve, the other end ofthe air inlet pipe is fixedly provided with a pressure meter, the middle part of the air inlet pipe is provided with an air outlet, and the bottom end of the ventilating disc is fixedly provided witha cavity. According to the static pressure testing device for the integrated packaging mechanical seal, the ventilating disc, the cavity and the integrated packaging mechanical seal are compressed through extending the piston rod of the oil cylinder so as to quickly form a sealed cavity, the air pressured is charged for testing, the pressure of the hydraulic oil cylinder is provided by a hydraulic station, and the pressure output is stable, so that manual bolt locking is avoided, and the pressure testing efficiency if improved so as to meet the requirement of batch production of the integrated packaging mechanical seal.

Owner:昆山福步工业设备有限公司

A Mathematical Modeling Teaching and Learning System

ActiveCN108614771BAvoid congestionImprove test efficiencyData processing applicationsSoftware testing/debuggingTest efficiencyAlgorithm

The invention discloses a mathematical modeling teaching and learning system, which relates to the field of mathematics teaching. The mathematical modeling teaching and learning system includes: a plurality of student terminals, a scheduling server, a model solving server, a model evaluation server and a model use case server; a model solving server , compile the mathematical model code, and call the test case data from the model case server according to the test case number, test the compiled mathematical model code according to the test case data, and send the test result and test case number to A model evaluation server; the model evaluation server retrieves the reference result corresponding to the test case number from the model case server according to the test case number, compares the reference result with the test result, and calculates an error. Through the invention, the verification of the model and the statistical error can be automated, which improves the test efficiency of the model and facilitates the improvement of the teaching efficiency of teachers.

Owner:ANYANG NORMAL UNIV

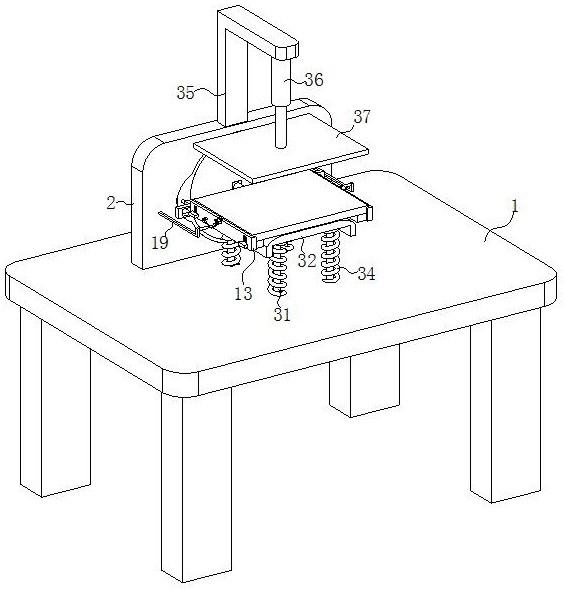

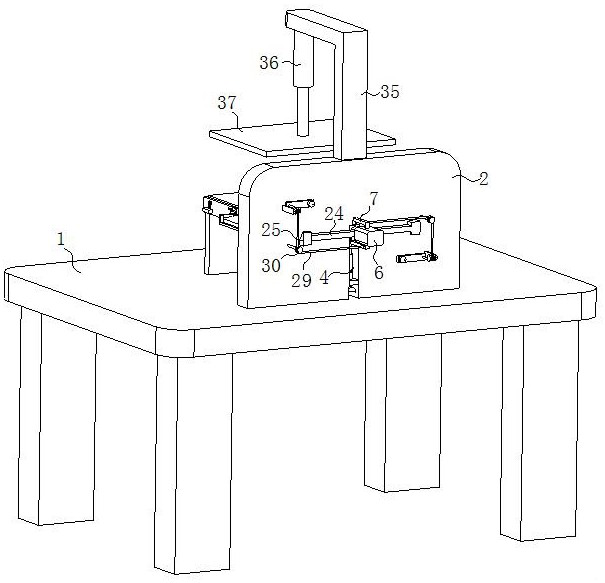

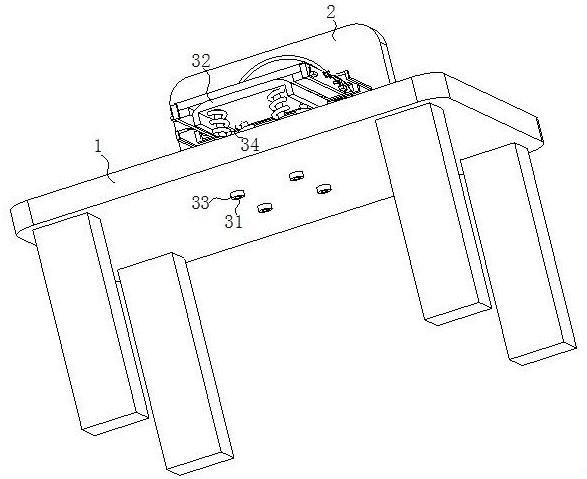

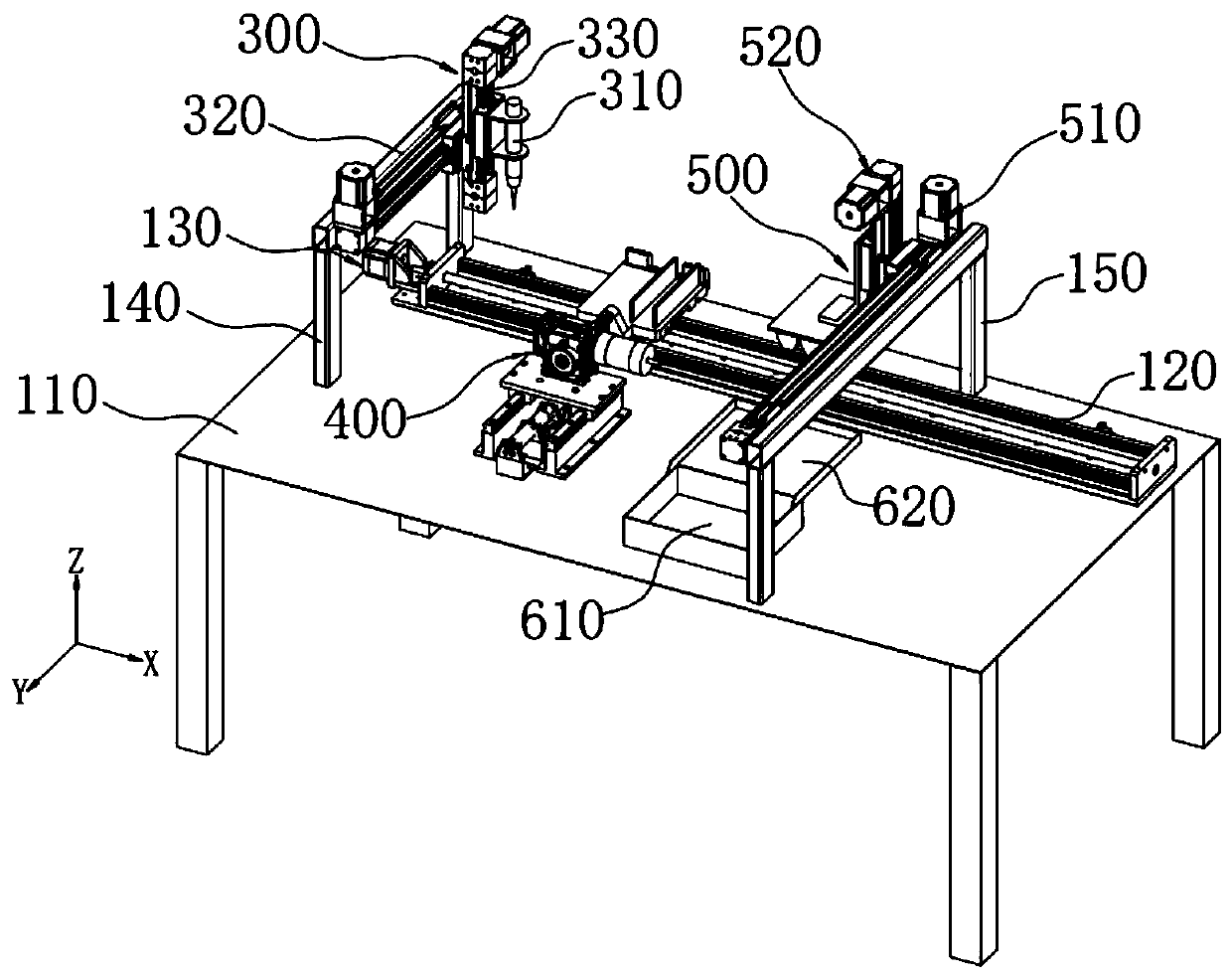

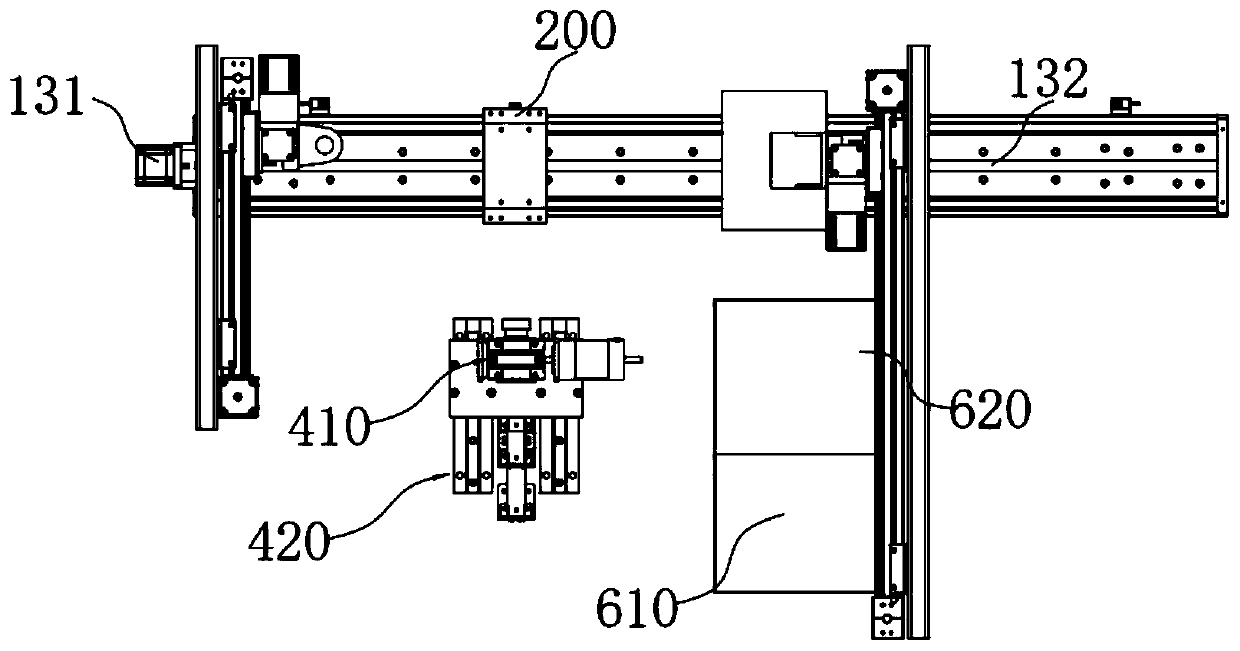

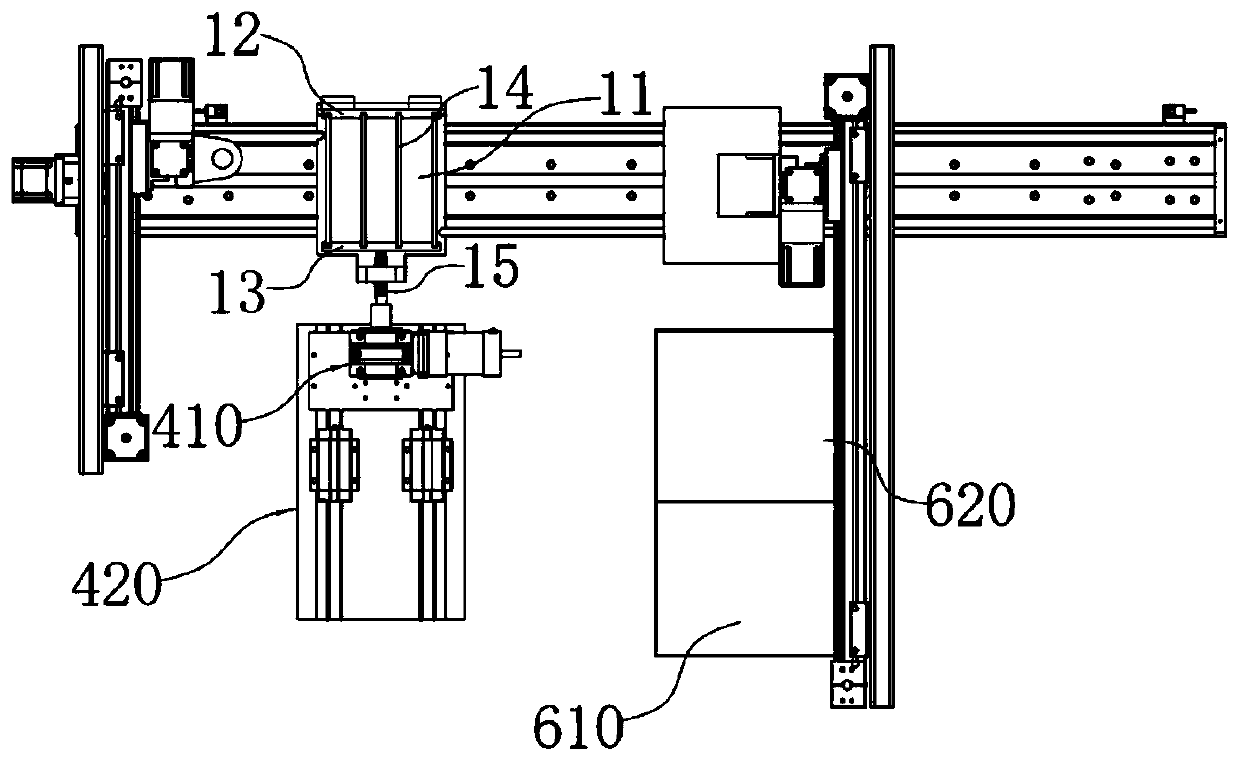

Test mold assembly device

PendingCN111215897AImplement automatic assemblyReduce work intensityLiquid surface applicatorsSpraying apparatusProcess engineeringIndustrial engineering

The invention provides a test mold assembly device, and relates to the technical field of assembly machines. The test mold assembly device comprises a work table, an assembly table, an oil injection module and a jacking mechanism, wherein the assembly table is mounted on the work table, and a test mold part is fed to the assembly table through a feeding mechanism; the oil injection module comprises an injection gun used for spraying sealing oil and a first moving module which drives the injection gun to move and can enable a gun opening of the injection gun to face a test mold base on the assembly table, and the first moving module is mounted on the work table. The jacking mechanism comprises a revolving drive assembly and a first driving mechanism which drives the revolving drive assemblyto do linear motion. The technical problems in the prior art are solved that a test mold is assembled totally depending on manual work, the working intensity of operators is high, and the efficiencyis low.

Owner:NANJING SINOTEST ROBOTICS CO LTD

Screening, impurity removing and feeding equipment

ActiveCN113499973AAvoid manualAvoid squeezing and cloggingSievingScreeningStructural engineeringClassical mechanics

The invention relates to screening, impurity removing and feeding equipment which comprises four supporting and clamping frames. A plurality of clamping mechanisms are installed on the two pair of supporting and clamping frames, a conveying roller is installed in the middle of each clamping mechanism, a driving mechanism is arranged above the supporting and clamping frames, and a cleaning and drying mechanism is installed in the middle of the driving mechanism; the driving mechanism enables the cleaning and drying mechanism to reciprocate, the cleaning and drying mechanism cleans the peripheries of the conveying rollers, any spherical objects are screened and subjected to impurity removing by adjusting the distance between the clamping mechanisms, manual work is avoided, and time and labor are saved; objects to be screened are screened with the diameter as the standard, and the objects fall into corresponding and different boxes in a sorting frame, so that impurity removing and sorting are completed, and extrusion and blockage are avoided; and after cleaning is completed, a drying machine is started to dry the conveying rollers, and therefore the cleanliness of the surfaces of the conveying rollers is kept.

Owner:合肥金果缘视觉科技有限公司

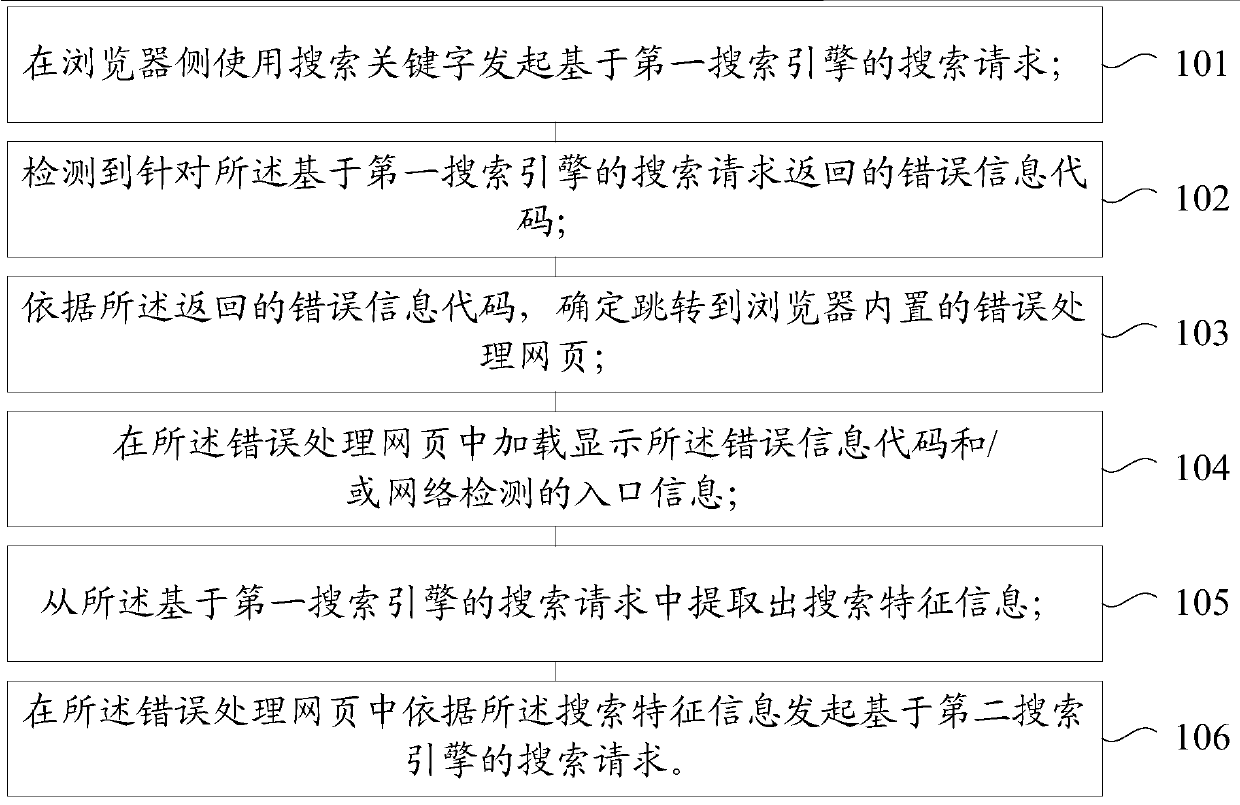

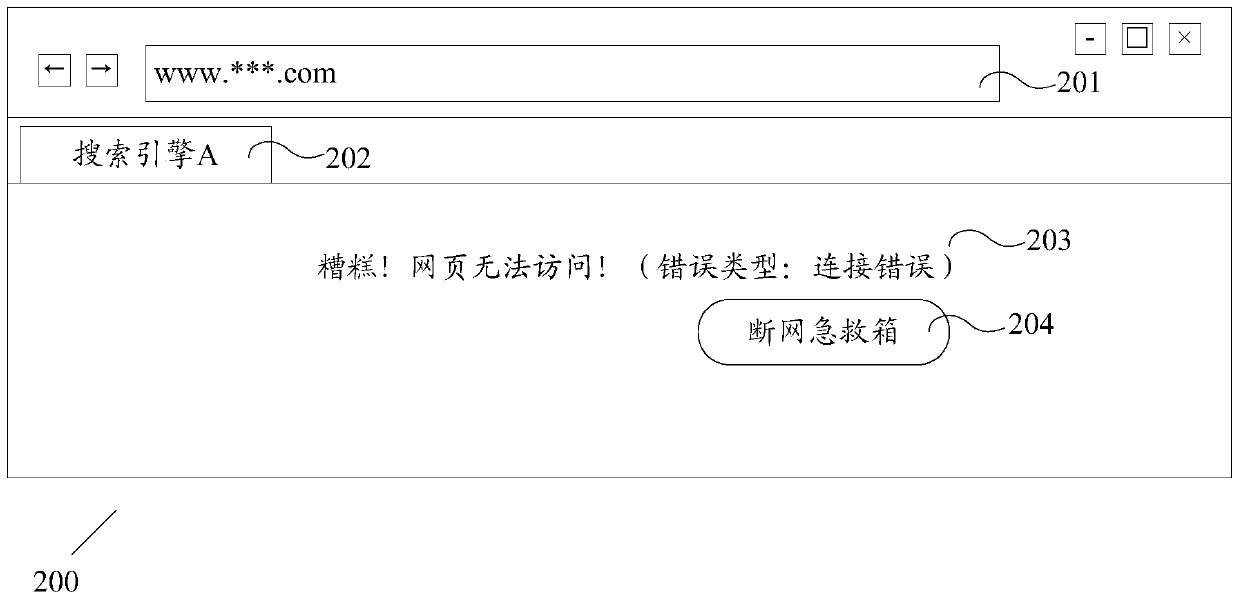

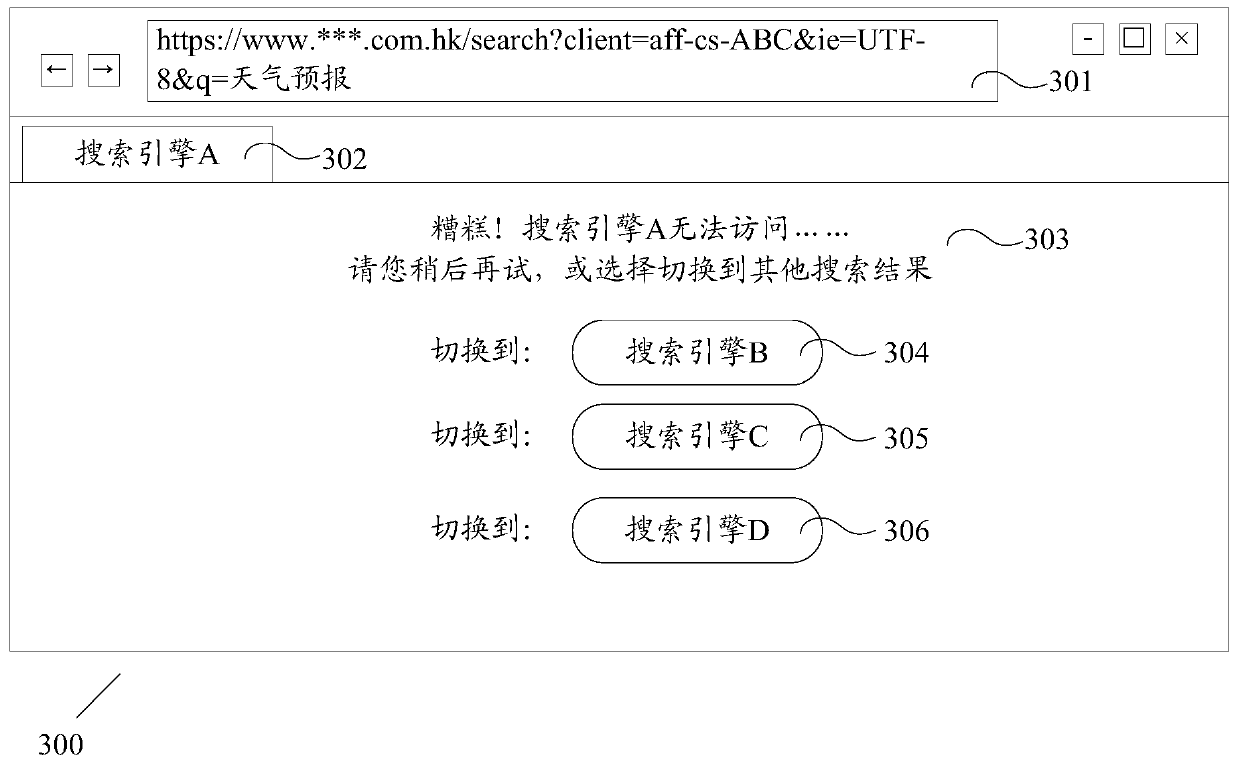

A method and device for searching in a browser

ActiveCN104021154BImprove experienceReduce the number of responsesWeb data indexingSpecial data processing applicationsError processingData mining

The embodiment of the invention provides a method and device for searching a browser. The method comprises the following steps of issuing a search request based on a first search engine through a search keyword on the browser side; detecting error information codes returned according to the search request based on the first search engine; determining to skip to an error handling webpage built in the browser according to the returned error information codes; loading and displaying the error information codes and / or access information of network detection in the error handling webpage; extracting search characteristic information from the search request based on the first search engine, wherein the search characteristic information comprises the search keyword; issuing a search request based on a second search engine according to the search characteristic information in the error handling webpage. According to the method and device for searching the browser, system resource waste of the browser and the search engines is reduced, bandwidth occupancy is reduced, search efficiency is greatly improved, and user experience is promoted.

Owner:BEIJING QIHOO TECH CO LTD

A kind of animal husbandry feed basin cleaning equipment

InactiveCN109047236BImprove water absorptionEasy to useHollow article cleaningAnimal scienceGear drive

Owner:南京幸庄科技创新产业园管理有限公司

Spring self-resetting two-stage hydraulic stretcher with counting function

ActiveCN111922690AEffectively monitor performance statusEasy maintenanceCounting mechanisms/objectsMetal working apparatusDrive shaftControl engineering

The invention discloses a spring self-resetting two-stage hydraulic stretcher with a counting function, and belongs to the technical field of stretching equipment. The spring self-resetting two-stagehydraulic stretcher comprises a stretcher body and a counting device arranged on the side wall of the stretcher body, wherein the counting device comprises an oil separation block and a digital counter; the oil separation block is of a hollow structure, and the digital counter is vertically arranged above the interior of the oil separation block; a rotating head is fixedly arranged on a driving shaft of the digital counter; a pushing mechanism rotatably matched with the rotating head is arranged below the rotating head; the pushing mechanism is supported and arranged in the oil separation block and can move up and down through oil pressure driving; and a second disc spring further sleeves the pushing mechanism. Through the adoption of the technical scheme, the problem can be effectively solved, the performance state of a product can be conveniently monitored, the inaccurate counting due to manual error operation is prevented, the occurrence of safety accidents in the operation is effectively avoided, meanwhile, the use is more stable, and the installation efficiency of wind power equipment is further improved.

Owner:马鞍山市罗泰特机械制造有限公司

Device for automatically packaging cartons

PendingCN112607125AAvoid packagingReduce labor costsWrapper twisting/gatheringElectric machineryEngineering

The invention discloses a device for automatically packaging cartons. The device comprises a carton body and a connecting box, a buckling mechanism is arranged at the bottom of the carton body, and a packaging mechanism is arranged at the bottom of the connecting box; and the buckling mechanism comprises a motor, the motor is fixedly arranged in the carton body, the motor is fixedly connected with a first reciprocating screw rod through an output shaft, a connecting rod is fixedly arranged on one side of the first reciprocating screw rod, a second reciprocating screw rod is fixedly arranged on one side of the connecting rod, and one side of the second reciprocating screw rod is connected with one side wall of an inner cavity of the carton body through a bearing. Through mutual cooperation of the buckling mechanism and the packaging mechanism, the carton body can be packaged, manual packaging of the carton body is avoided, the labor cost is reduced, meanwhile, the labor cost of workers is low, the packaging efficiency of the carton body is improved, and more convenience in using is brought to a user.

Owner:贵州新邦羽包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com