Screening, impurity removing and feeding equipment

A kind of equipment and consistent technology, applied in the field of screening, impurity removal and feeding equipment, can solve the problems of troublesome work, blocked holes, low efficiency, etc., and achieve the effect of avoiding the use of labor, avoiding extrusion and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

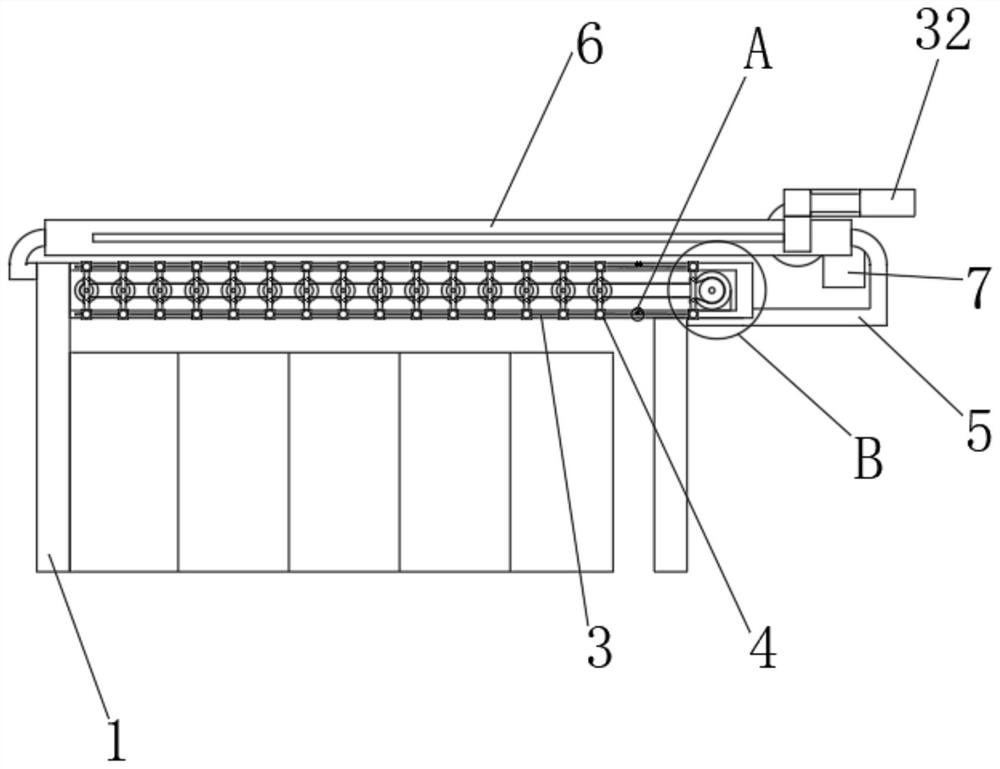

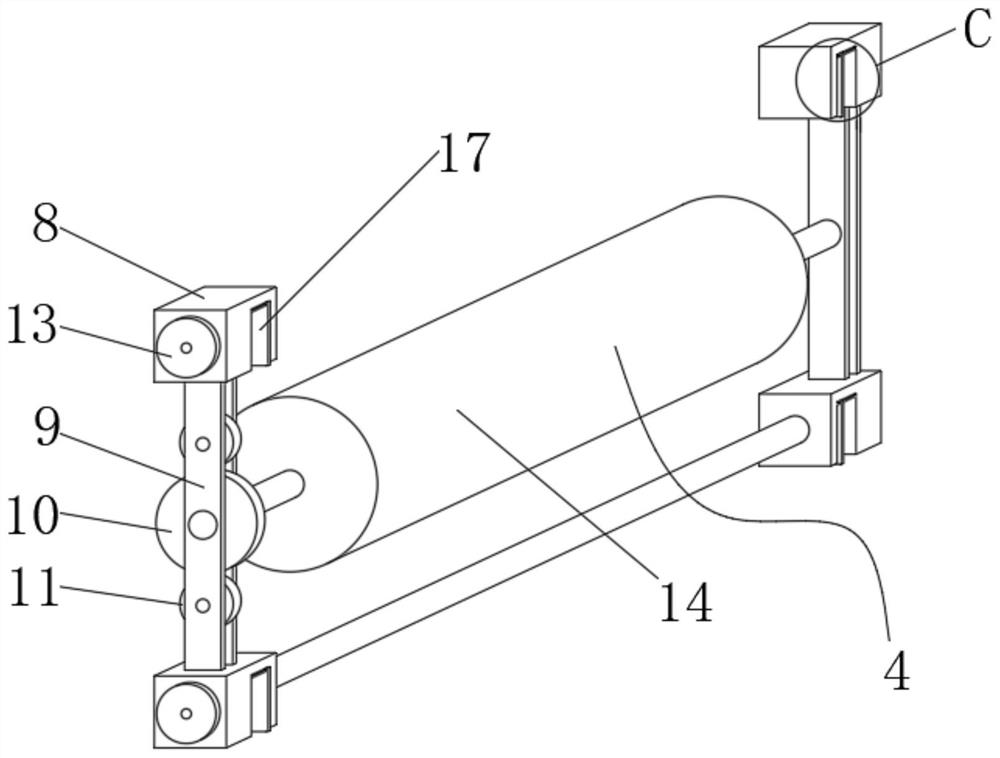

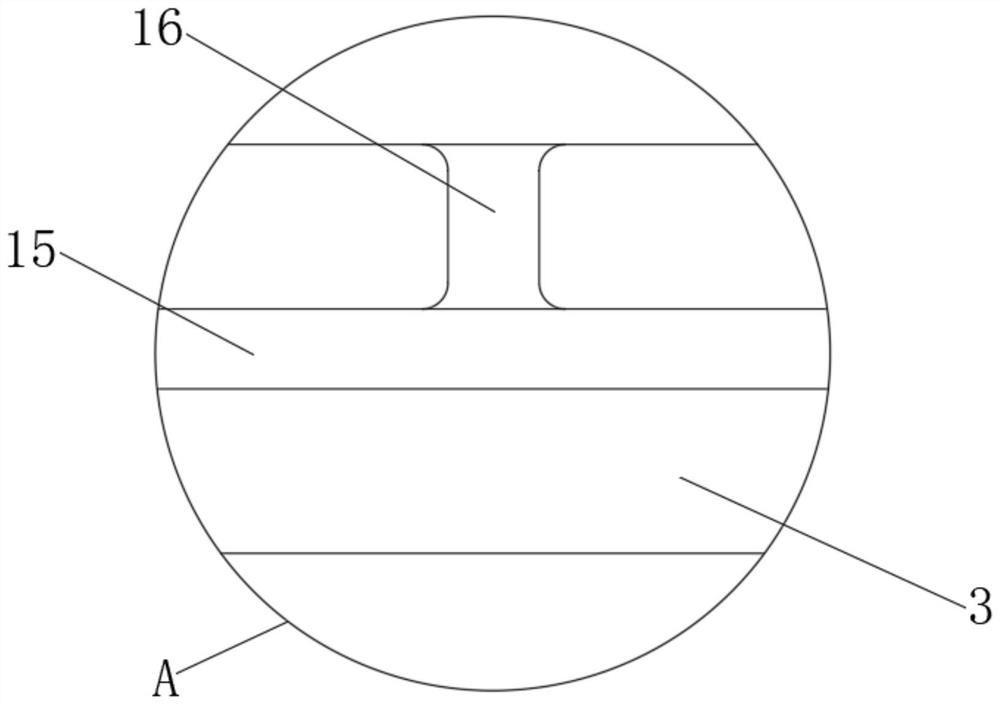

[0034] see Figure 1-8 Shown: a kind of equipment for screening and removing impurities, including a bracket 1, an instrument rack 2 is installed on one side of the bracket 1, a pair of supporting clamping frames 3 are respectively installed at both ends of the instrument rack 2, and one end of the supporting clamping frame 3 It is fixedly connected to the other side of the bracket 1, and the other end of the support clamping frame 3 is fixedly connected to the instrument frame 2. Several clamping mechanisms 4 are installed on the support clamping frame 3, and the middle part of each clamping mechanism 4 Both conveying rollers 14 are installed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com