Novel polaroid laminating equipment

A bonding equipment and polarizer technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as low and cumbersome bonding efficiency and affect the bonding efficiency of polarizers, so as to improve bonding efficiency and ensure accuracy , The effect of protecting cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

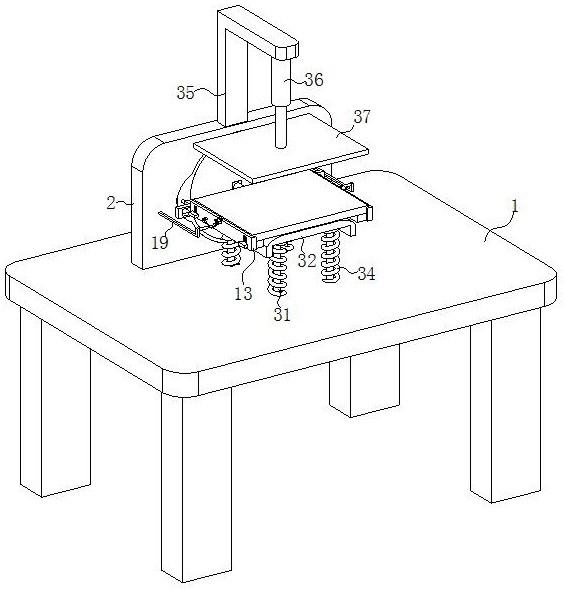

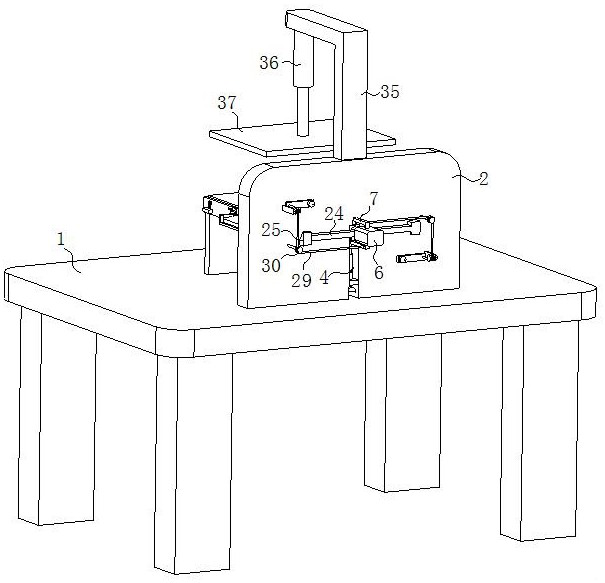

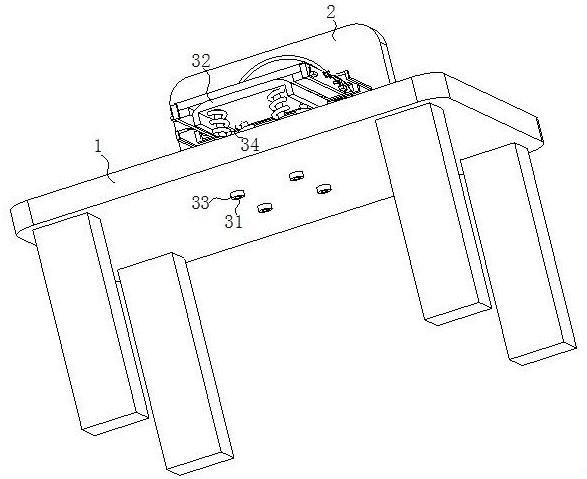

[0027] see Figure 1-9 , the present invention provides a technical solution: a new type of polarizer bonding equipment, including a processing table 1, the top of the processing table 1 is fixedly connected with a first fixing plate 2, and the top of the first fixing plate 2 is connected with a The pressing mechanism of the polarizer, the middle part of the first fixed plate 2 runs through the first rotating rod 3 connected to it in rotation, the first fixed plate 2 is provided with a first chute 4 inside, and the first chute 4 is slidably connected with a first The slider 5, the first rotating rod 3 runs through the first sliding block 5 and is rotationally connected with it, the rear end of the first rotating rod 3 is fixedly connected to the servo motor 6, and the servo motor 6 is connected to the first sliding block 5 through two L-shaped connecting blocks 7 Fixedly connected, the front end of the first rotating rod 3 is fixedly connected with the first rotating plate 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com